Filtrine QCP Manual

QCP INSTALL]

REV. 03.15.19

Filtrine Mfg. Co. • 15 Kit St. Keene, NH 03431 USA

800-930-3367 • 603-352-5500 • FAX 603-352-0330

WEB www.filtrine.com • EMAIL cool@filtrine.com

FILTRINE IS ISO 9001:2015 CERTIFIED

PRODUCT LINE APPROVED MARK AVAILABLE

MADE IN USA

Please read these instructions completely before installation.

INSTALLATION INSTRUCTIONS

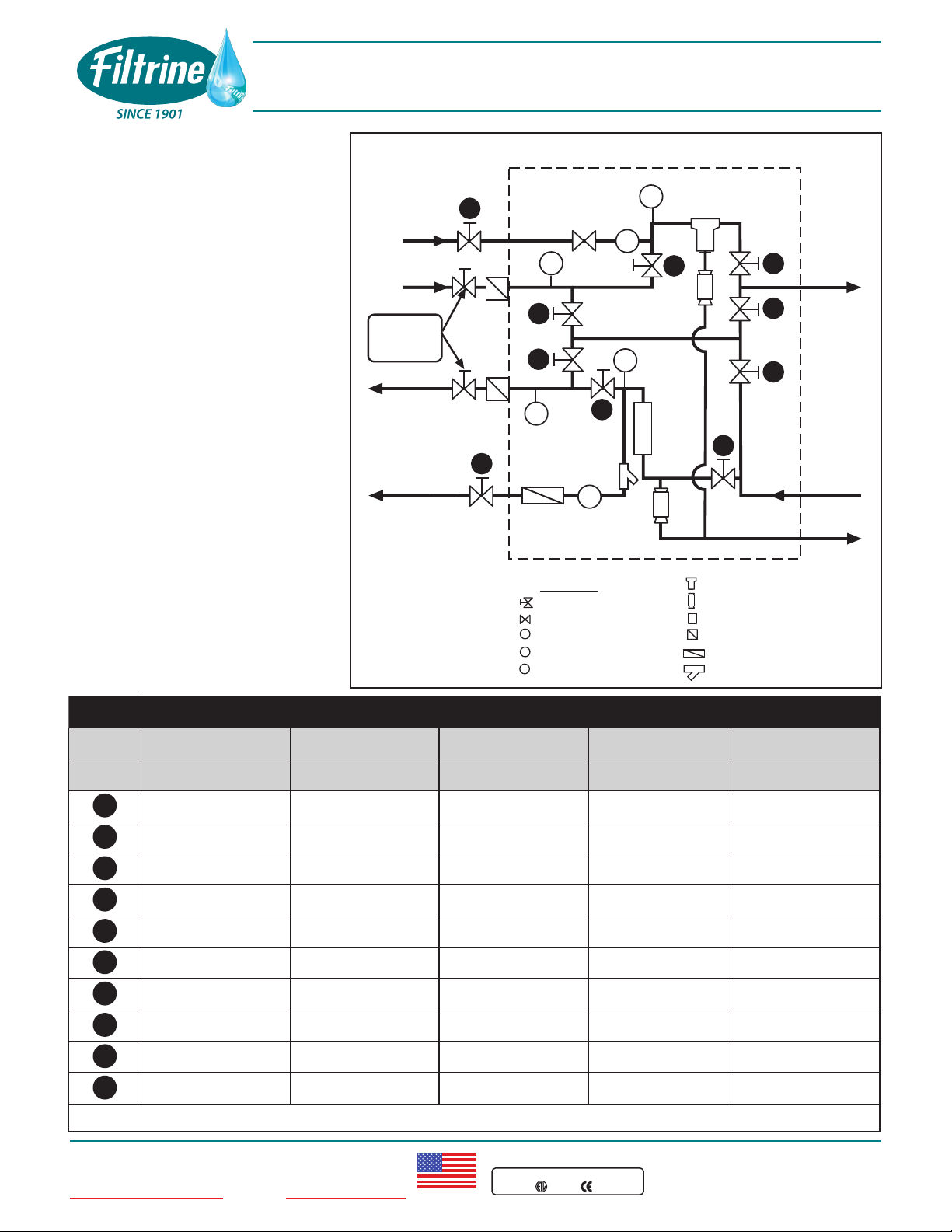

The QCP Quick Connect Panel provides all the diagnostics that

medical equipment manufacturers require.

• Mount the QCP panel in a location where meters can be

read by the medical equipment operators. Consideration

should be given to the routing of chilled liquid line.

• Excessive pipe lengths cause heat gain as well as pressure

reduction. Locate the panel between the chiller and medical

equipment, preferably close to the medical equipment.The

closer the panel is to the medical heat exchanger, the more

useful the temperature readings will be.

• All coolant lines must be insulated to reduce heat gain and

to prevent condensation from forming during high humidity

conditions.

• The piping procedure simply consists of matching QCP

connections to the appropriate points and setting the ball

valves to the desired operation mode. (See Operation

Modes table on page 2.)

• If plumbing line size reduction is being considered, it

must be veried that proper ow and pressure can be

maintained. As a general rule, reducing the pipe size is not

recommended.

• When installation has been completed, put the unit in Full

Bypass Mode. Close the ball valve that feeds the city water

drain while lling the system. If this valve is left open while

the chiller is inoperative and being lled, the uid being

added to the system will run down the drain. Once the chiller

has been started, open this valve.

A list of plumbing/electrical connections to the QCP panel

and where they should be routed:

CITY WATER DRAIN*This connection is piped to a oor

drain or any other suitable water

disposal drain.

TO CHILLER Piped to the RETURN connection

at the chiller.

FROM CHILLER Piped to the chiller DISCHARGE

connection.

CITY WATER SUPPLY*Connect to the municipal water

supply for backup cooling.

FROM EQUIPMENT Piped to the discharge line of the

medical equipment.

SOLENOID COILS*Connect the wires in parallel and

refer to the chiller electrical dia-

gram.

* Optional equipment for QCP-AS

OPERATION

Your QCP will give you years of trouble-free service. Like any

other piece of ne equipment, occasional maintenance may

be required.You will soon discover the exibility designed into

the QCP. In most circumstances, service can be performed on

the unit or chiller without interrupting medical requirements.

There are ve operation modes of the QCP panel summa-

rized below:

1. NORMAL

OPERATION

The standard operating conguration. See

Mode 1 on next page and note location/

settings of valves and ow paths.

2. FULL

BYPASS

This conguration isolates the chiller from

the medical equipment. It can be used when

starting the chiller if the medical equipment

is not yet operational. The chilled water is

simply routed from the chiller discharge

back to the return line. See Mode 2 in chart

on next page and note location/settings of

valves and ow paths.

3. SERVICE

FLOW

METER

In the event the ow meter or other instru-

ments in this path need service, ow can

be routed as shown. See Mode 3 in chart

on next page and note location/settings of

valves and ow paths.

4. SERVICE

FILTER

Filter changes will be required when the

system is initially started and periodically

thereafter. This mode allows uninterrupted

service to the medical equipment while a l-

ter change takes place. See Mode 4 in chart

on next page and note location/settings of

valves and ow paths.

5. CITY

WATER

BACKUP*

This condition will occur if the chiller fails

and actuates solenoids 1 and 2. Notice that

the ow of water is from the city water con-

nection through the medical equipment

and down the drain. IMPORTANT: The city

water pressure must not exceed 80 p.s.i.

The automatic backup will only work if the

system was previously operating in Mode 1

(Normal Mode). See Mode 5 in charton next

page and note location/settings of valves

and ow paths.

* Optional equipment for QCP-AS

Charts on reverse

FILTRINE QCP – QUICK CONNECT PANEL

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

QCP INSTALL]

REV. 03.15.19

Filtrine Mfg. Co. • 15 Kit St. Keene, NH 03431 USA

800-930-3367 • 603-352-5500 • FAX 603-352-0330

WEB www.filtrine.com • EMAIL cool@filtrine.com

FILTRINE IS ISO 9001:2015 CERTIFIED

PRODUCT LINE APPROVED MARK AVAILABLE

MADE IN USA

FILTER MAINTENANCE

The lter is a bag type. Using a 50 micron

bag, the pressure drop is less than 5 p.s.i.

when new.The lter should be changed

if the pressure drop across the unit ex-

ceeds 12 p.s.i. A spare lter should be

kept on hand at all times.

Study the flow path of Mode 4 op-

eration in the chart to the right. This

conguration allows the replacement

of the lter element while delivering

uninterrupted flow to the medical

equipment.This will probably be the rst

routine maintenance performed on the

QCP. Since the system is a closed loop,

the coolant will eventually be cleaned

of all contamination and lter changes

will become rare.

If repeated city water operation is

actuated, lter contamination is likely.

The lter element should be changed

when the pressure drop across the unit

is greater than 12 p.s.i.g.

FILTRINE QCP – QUICK CONNECT PANEL

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

QCP OPERATION MODES: O=OPEN / C=CLOSED

NORMAL FULL BY-PASS SERVICE FLOW METER SERVICE FILTER CITY WATER BACK-UP

*

VALVE 1 2 3 4 5

AO O O C O

BO O O C O

CC C C O C

DC O C O C

EC C O C C

FO O C O O

GC O O C C

HO O C O O

IO C O C O

JO C O O O

*Optional equipment for QCP-AS

T

P

S

M

F

T

P

S

F

S

P

BALL VALVE

BACKFLOW PREV.

SOLENOID

PRESSURE GAUGE

TEMP. GAUGE

CITY

WATER

IN (OPT.)

A

I

B

CD

E

F

G

H

J

QCP PLUMBING SCHEMATIC

T

M

FILTER

1/2" DRAIN VALVE

FLOW METER

CHECK VALV E

IN-LINE CK VALVE

Y- STRAINER

LEGEND

TO

CHILLER

FROM

CHILLER

Provided by

installing

contractor

CITY WATER

DRAIN (OPT)

FROM

EQUIP

TO

DRAIN

TO

EQUIP

This manual suits for next models

1