Firehawk M7XT User manual

FireHawk®M7XT

Air Mask

NFPA 1981: 2013 Edition

NFPA 1982: 2013 Edition (Integrated PASS Version Only)

CBRN Agent Approved Air Mask

OPERATION AND INSTRUCTIONS

This device complies with Part 15 of the FCC Rules. Operation is subject to the following conditions:

(1) This device may not cause harmful interference and (2) this device must accept any interference that may cause undesired

operation.

MSA 2211 (L) Rev. 8 © MSA 2017, 2022

This manual must be carefully read and followed by all persons who have or will have the responsibility for using or servicing

this air mask. This air mask will perform as designed only if used and serviced according to the instructions; otherwise it could

fail to perform as designed, and persons who rely on the air mask could sustain serious personal injury or death.

This Self-Contained Breathing Apparatus (SCBA) is certified by the National Institute of Occupational Safety and Health (NIOSH).

See supplement P/N 10145467 for NIOSH approval information.

Changes and modifications not expressly approved by the manufacturer could void the user’s authority to operate the equipment.

Use in conjunction with personal protective ensembles that provide appropriate levels of protection against dermal hazards.

Some CBRN agents may not present immediate effects from exposure, but can result in delayed impairment, illness, or death.

Direct contact with CBRN agents requires proper handling of the SCBA after each use and between multiple entries during the same use.

Decontamination and disposal procedures must be followed. If contaminated with liquid chemical warfare agents,

dispose of the SCBA after contamination.

The respirator should not be used beyond 6 hours after initial exposure to chemical warfare agents to avoid possibility of agent perme-

ation.

FAILURE TO FOLLOW THE ABOVE ITEMS IN ADDITION TO ALL ESTABLISHED CBRN PROTECTIVE MEASURES CAN RESULT IN SERIOUS PER-

SONAL INJURY OR DEATH.

The warranties made by MSA with respect to the product are voided if the product is not installed, used and serviced in

accordance with the instructions in this manual. Please protect yourself and your employees by following the instructions.

Please read and observe the WARNIN S and CAUTIONS inside. For any additional information relative to use or repair, write or call 1-

877-MSA-FIRE (672-3473) during regular working hours.

"!

WARN NG

"!

DANGER

Prnt. Spec. 10000005389(A) Mat. 10128861

CR: 800000052505 Doc. 10128861

2

NTRODUCT ON

N OSH APPROVAL NFORMAT ON

CAUT ONS AND L M TAT ONS

I- Contains Electrical parts that may cause an ignition in flam-

mable or explosive atmospheres.

J- Failure to properly use and maintain this product could result

in injury or death.

M- All approved respirators shall be selected, fitted, used and

maintained in accordance with MSHA, OSHA and other

applicable regulations.

N- Never substitute, modify, add or omit parts. Use only exact

replacement parts in the configuration as specified by the

manufacturer.

O- Refer to Users Instructions, and/or maintenance manuals for

information on use and maintenance of these

respirators.

S- Special or critical User’s Instructions and/or specific use limi-

tations apply. Refer to user instructions before

donning.

CAUT ONS AND L M TAT ONS OF USE FOR CBRN SCBA

Q- Use in conjunction with personal protective ensembles that

provide levels of protection against dermal hazards.

R- Some CBRN agents may not present immediate effects from

exposure, but can result in delayed impairment, illness, or

death.

T- Direct contact with CBRN agents requires proper handling of

the SCBA after each use and between multiple entries during

the same use. Decontamination and disposal procedures

must be followed. If contaminated with liquid chemical war-

fare agents, dispose of the SCBA after decontamination.

U- The respirator should not be used beyond 6 hours after initial

exposure to chemical warfare agents to avoid possibility of

agent permeation.

CAUT ONS AND L M TAT ONS OF EMERGENCY BREATH NG

SUPPORT SYSTEMS (EBSS)

• Activation or engagement of EBSS in either the donor or

receiver mode changes the SCBA use to Escape-Only,

approved service time for either the donor, or the receiver

is no longer applicable.

• EBSS may not be engaged or activated in donor mode

after the donor End-of-Service-Time-Indicator (EOSTI) has

activated.

• Users must be fully trained in the operation of EBSS in

accordance with a training program conforming to the

requirements of NFPA Standards 1404, Fire Service

Respiratory Protection Training and 1500, Fire Department

Occupational Safety and Health Program.

• Simultaneous connection of more than two users, one

donor and one receiver, is not permitted.

• SCBAs operated in EBSS mode are approved for escape

only.

• Entry approval only restored after re-charge, either host or

donor.

• Connection not to be established after donor/host EOSTI

activation.

• Limited to one donor/receiver (host/parasite) pair.

• Not suitable for connection in CBRN environment.

S - SPEC AL OR CR T CAL USER’S NSTRUCT ONS

Approved for use at temperatures above -25°F. Approved only

when the compressed-air container is fully charged with air

meeting the requirements of the Compressed as Association

Specification -7 for quality verification level (grade) D air or

equivalent specifications. In fire service applications, MSA recom-

mends breathing air quality in accordance with NFPA 1989,

Standard on Breathing Air Quality for Emergency Services

Respiratory Protection. The cylinder shall meet applicable DOT

specifications.

MSA2211 (L) Rev. 8 - 10128861

TABLE OF CONTENTS

NIOSH Approval Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Special or Critical Users Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Inspection and Functional Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Quick-Fill and URC Coupling Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Donning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Using the Air Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cold Weather Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

URC Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Removing the Air Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cleaning and Disinfecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Flow Test and Overhaul Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Quick-Fill®System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

ExtendAire®II System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Telemetry Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

NTRODUCT ON

Do not alter this air mask. Altering will void the Intrinsic-Safety rat-

ing and may affect the Intrinsic-Safety of the device. Misuse or

abuse of the FireHawk M7 HUD or I-HUD, FireHawk M7XT Control

Module, or FireHawk M7XT Power Module, or using this equip-

ment in a manner or situation not intended by the manufacturer,

may result in damage to the FireHawk M7 HUD or

I-HUD, FireHawk M7XT Control Module, or FireHawk M7XT Power

Module, resulting in personal injury or death to user or persons

dependent on the user. Always inspect the FireHawk M7 HUD or I-

HUD for damage before use. If damage is found,

immediately remove the device from service. The FireHawk M7

HUD or I-HUD, FireHawk M7XT Control Module, and FireHawk

M7XT Power Module are approved intrinsically-safe and conform

to UL/ANSI 913 for use in Class I, Div. I, roups C and D hazardous

locations, temperature rating T1.

Use the air mask with adequate skin protection when worn in

gases and vapors that poison by skin absorption (for example:

hydrocyanic-acid gas). In making renewals or repairs, parts identical

with those furnished by the manufacturer under the pertinent

approval shall be maintained.

Approval for use against CBRN chemical warfare agents is main-

tained only when using approved components and

following instructions listed on the NIOSH approval matrix (P/N

10145467).

Do not mark the air mask, i.e., with stamps, labels, paint, or other

method. Use of such markings may interfere with apparatus use

or may constitute a flammability hazard.

For more information on the air mask use and performance stan-

dards, please consult the following publications:

NFPA Standard 1500, Fire Department Occupational Safety and

Health Programs (Chapter 5); and NFPA 1981 standards, on

Open-Circuit Self-Contained Breathing Apparatus (SCBA) for

Emergency Service. National Fire Protection Association,

Batterymarch Park, Quincy, MA 22269.

ANSI Standard Z88.5, Practices for Respiratory Protection for the

Fire Service; and, ANSI Standard Z88.2, Practices for Respiratory

Protection. American National Standards Institute, 1430

Broadway, New York, NY 10018.

OSHA Safety and Health Standards (29 CFR 1910) (see specifically

Part 1910. 134), available from the Superintendent of Documents,

U. S. overnment Printing Office, Washington, DC 20402.

Compressed as Association, Inc., 1725 Jefferson Davis Hwy.,

Suite 1004, Arlington, VA 22202.

NOTE: The FireHawk M7 HUD or I-HUD, FireHawk M7XT Control

Module, and FireHawk M7XT Power Module, were

tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful inter-

ference in a residential installation. This equipment generates,

uses, and can radiate radio frequency and, if not installed in

accordance with instructions, may cause harmful interference to

radio communications. However, there is no guarantee that inter-

ference will not occur in a particular installation. If this equipment

does cause interference to radio or television reception, which

can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or

more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the

receiver.

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

The FireHawk M7 HUD or -HUD, FireHawk M7XT Control

Module, and FireHawk M7XT Power Module contain electri-

cal parts which have not been evaluated as an ignition

source in flammable or explosive atmospheres by

MSHA/N OSH.

1. Read and follow all N OSH and other approval

limitations.

2. DO NOT use the carrier and harness assembly as a verti-

cal raising or lowering device.

3. DO NOT use the air mask as an underwater device.

4. This system must be supplied with respirable [Quality

Verification Level (Grade) D, see ANS /CGA G-7.1-1989]

or higher quality air; and a dew point not to exceed -

65°F (24ppm v/v) [Compressed Gas Association

Specification G-7.1 for Quality Verification Level (Grade)

D Gaseous Air]. n fire service applications, MSA recom-

mends breathing air quality in accordance with NFPA

1989.

5. This device may not seal properly with your face if you

have a beard, gross sideburns or similar physical charac-

teristics (see NFPA-1500 and ANS Z88.2). An improper

facial seal may allow contaminants to leak into the face-

piece, reducing or eliminating respiratory protection. Do

not use this device if such conditions exist. The face-to-

facepiece seal must be tested before each use. Never

remove the facepiece except in a safe, non-hazardous,

non-toxic atmosphere.

6. Return to a safe atmosphere immediately if

discoloration, crazing, blistering, cracking, or other

deterioration of the facepiece lens material is observed.

7. Users must wear suitable protective clothing and

precautions must be taken so that the air mask is not

exposed to atmospheres that may be harmful to it.

8. Take into account the following factors which may affect

the duration or the service time.

a. the degree of physical activity of the user;

b. the physical condition of the user;

c. the degree that the user’s breathing rate is increased

by excitement, fear, or other emotional factors;

d. the degree of training or experience which the user

has had with this or similar equipment;

e. whether or not the cylinder is fully charged;

3MSA2211 (L) Rev. 8 - 10128861

"!

WARN NG

"!

CAUT ON

NTRODUCT ON

f. the presence in the compressed air of carbon dioxide

concentrations greater than the .04% level normally

found in atmospheric air;

g. the atmospheric pressure; if used in a pressurized tun-

nel or caisson at 2 atmospheres (15 psi gauge) the

duration will be one-half as long as when used at 1

atmosphere; at 3 atmospheres the duration will be

one-third as long; the service time of the air mask is

based on 1 atmosphere of pressure.

h. the condition of the air mask.

9. Prior to storage of the air mask at temperatures below

0˚F, verify that the FireHawk M7XT Power Module and

FireHawk M7 HUD or -HUD are equipped with full

charge batteries. Verify that the FireHawk M7XT Control

Module displays a full charge battery status icon. Verify

that the FireHawk M7 HUD or -HUD do not display low

battery status indicators.

Misuse can result in serious injury or death.

CBRN AGENT APPROVAL LABEL

The MSA CBRN Agent approved air mask has this approval label

attached to the carrier and harness.

MPORTANT NOT CE FOR RESP RATOR USERS AND RESP RA-

TORY PROTECT ON PROGRAM ADM N STRATORS

1. An adequate respiratory protection program must include

knowledge of hazards, hazard assessment, selection of prop-

er respiratory protective equipment, instruction and training

in the use of equipment, inspection and maintenance of

equipment, and medical surveillance. [See OSHA regulations,

Title 29 CFR, Part 1910.134 (c).]

2. This SCBA and PASS may be used only after proper instruc-

tion and training in its use as specified in NFPA-1500 and

OSHA regulations Title 29 CFR, Part 1910.134.

3. Quantitative fit testing should be conducted to determine

proper facepiece size prior to using the respirator. A Fit Test

Kit (MSA P/N 10044576) is available for conducting quantita-

tive fit tests with the Ultra Elite®XT Facepieces. The facepiece

donning instructions must be carefully followed when using

the respirator and when conducting fit tests.

4. The CBRN Firehawk Second Stage Regulator must be flow

tested every year and overhauled on a periodic basis. An

overhaul kit (MSA P/N 10048942) is available.

CONTACT NFORMAT ON

In the event of a product concern, contact your local MSA autho-

rized repair center or distributor, who will provide the necessary

information to MSA for issue resolution. To report any serious

concerns, or to speak with a certification organization, use the

following contact information:

Manufacturer

MSA Customer Service

Phone: 1-877-MSA-FIRE

Certifying Agencies

National Institute of Occupational Safety and Health (NIOSH)

Phone: 800-CDC-4636

Safety Equipment Institute (SEI)

Phone: 703-442-5732

4

MSA2211 (L) Rev. 8 - 10128861

See instructions for required component

part numbers, accessories, and

additional cautions and limitations of use.

CBRN Agent Approved

DESCR PT ON

FireHawk M7XT Air Masks from MSA are pressure-demand, self-

contained breathing apparatus (SCBA) certified by the National

Institute for Occupational Safety and Health (NIOSH) for use in

atmospheres immediately dangerous to life or health:

``Immediately dangerous to life or health’’ means conditions that

pose an immediate threat to life or health or conditions that

pose an immediate threat of severe exposure to contaminants,

such as radioactive materials, which are likely to have adverse

cumulative or delayed effects on health [Title 42 CFR, Part 84.2,

(Q)].

This air mask complies with the National Fire Protection

Association (NFPA) Standard 1981 for Open-Circuit Self-

Contained Breathing Apparatus (SCBA) for Emergency Services,

and Standard 1982 for Personal Alert Safety Systems (PASS).

This air mask has been designated by NIOSH as being CBRN

(chemical, biological, radiological, and nuclear) Agent Approved.

It complies with the special tests under NIOSH 42 CFR 84.63(c);

Chemical Agent Permeation and Penetration Resistance Against

Distilled Sulfur Mustard (HD) and Sarin ( B) and the Laboratory

Respirator Protection Level (LRPL) tests.

The FireHawk M7XT Air Mask consists of the following

components.

• PR14™ First Stage Regulator

• Firehawk Second Stage Regulator

• Cylinder and Valve Assembly

• Audi-Larm™ Audible Alarm with URC Assembly

• FireHawk M7 Carrier and Harness Assembly

• Ultra Elite XT Facepiece

• FireHawk M7 HUD or I-HUD

• FireHawk M7XT Control Module

• FireHawk M7XT Power Module

Optional FireHawk M7XT Air Mask Components

• Ultra Elite XT Communications System

• FireHawk M7XT Telemetry Module

• MSA Accountability System

• Rescue Belt II

• ExtendAire II (EBSS)

F REHAWK M7XT A R MASK COMPONENTS

PR14 F RST STAGE REGULATOR

The PR14 First Stage Regulator reduces the pressure from the

cylinder and valve assembly to an intermediate pressure, which is

in turn further reduced by the Firehawk Second Stage Regulator

to a pressure that is respirable by the user.

The regulator incorporates a large, easily replaceable, sintered fil-

ter to capture particulates that may be in the air stream.

F REHAWK SECOND STAGE REGULATOR

The Firehawk Regulator is a pressure-demand regulator, which

maintains a positive pressure in the facepiece while the air mask

is in use.

The Firehawk Regulator attaches to the facepiece via a slide-to-

connect or a push-to-connect feature.

There are also two types of Firehawk Regulator intermediate

pressure hose connections, threaded and quick-connect.

CYL NDER AND VALVE ASSEMBLY

*as approved by NIOSH

The cylinder valve includes a metal valve body, threaded connec-

tion for filling and attachment of the Audi-Larm Alarm, hand-

wheel, safety disc (burst disc), and pressure gauge.

The pressure gauge continuously shows the air pressure in the

cylinder.

The handwheel is used to open and close the cylinder valve.

AUD -LARM ALARM W TH URC ASSEMBLY

The Audi-Larm Alarm rings when there is approximately 33% of

the air mask’s rated service time remaining and when the cylin-

der valve is first opened, providing an audible indication that the

alarm is working properly.

A high pressure hose delivers air at cylinder pressure from the

Audi-Larm Alarm to the PR14 First Stage Regulator.

NOTE: The remaining service time calculations are based on a 40

LPM (liters per minute) NIOSH breathing rate.

All FireHawk M7XT Air Masks are equipped with an Audi-Larm

Alarm that includes a URC Assembly (Universal Rescue

Connection). The URC Assembly is a male Quick-Fill inlet for use

by Rapid Intervention Crews for emergency filling of the SCBA or

DESCR PT ON

5MSA2211 (L) Rev. 8 - 10128861

Capacity

Cubic Ft.

Pressure

psig

Rated Service* Time

minutes

45 4500 30

88 4500 60

45 2216 30

66 4500 45

Cylinder Remaining Service

Time (approx)

End of Service

Time ndicator

Pressure (approx)

30 min. 2216 psi 10 minutes 785 psi

30 min. 4500 psi 10 minutes 1600 psi

45 min. 4500 psi 15 minutes 1600 psi

60 min. 4500 psi 20 minutes 1600 psi

DESCR PT ON

during transfill operations. Also included with the URC Assembly

is a pressure relief valve for protection of the cylinder burst disc.

F REHAWK M7 CARR ER AND HARNESS ASSEMBLY

DO NOT use this carrier and harness assembly as a vertical

raising or lowering device. Misuse can result in serious

personal injury or death.

The carrier consists of a backplate, a cylinder band with latch to

hold the cylinder, and a harness, consisting of shoulder pads, chest

strap (optional), adjustable pull straps, waist belt, waist belt mount-

ed regulator retainer, swiveling lumbar pad (optional), and Rescue

Belt II (optional).

ULTRA EL TE XT FACEP ECE

The facepiece is available in three sizes (small, medium, and

large).

The facepiece lens is constructed of high temperature resistant

materials and super-hardcoated to meet the requirements of

NFPA 1981.

The facepiece has a low-resistance, pressure-demand

exhalation valve.

An inhalation check valve in the inlet housing keeps moisture

and contaminants out of the Firehawk Regulator.

The facepiece has a speaking diaphragm for clear communica-

tion.

F REHAWK M7 HUD OR -HUD

The FireHawk M7 HUD, located on the Ultra Elite XT Facepiece

enables a user to see incremental cylinder pressure, PASS pre-

alarms, battery status, and telemetry information (optional) while

wearing the air mask.

The FireHawk M7 I-HUD performs the same functions as the

FireHawk M7 HUD, and it is located inside the Ultra Elite XT

Facepiece.

F REHAWK M7XT CONTROL MODULE

The FireHawk M7XT Control Module is the user’s interface with

the air mask.

The FireHawk M7XT Control Module is equipped with an

analog gauge as well as an LCD to provide the user vital informa-

tion: numeric and iconic cylinder pressure, battery status,

thermal alarm (optional), and time remaining.

If the air mask is equipped with the optional FireHawk M7XT

Telemetry Module, the radio link status and evacuation alarms

are displayed.

The integrated PASS motion sensor is housed within the

FireHawk M7XT Control Module.

F REHAWK M7XT POWER MODULE

The FireHawk M7XT Power Module on the lower portion of the

backplate houses the batteries, serves as the cylinder stop, emits

audible PASS alarms, and has buddy lights.

The FireHawk M7XT Power Module is linked to the FireHawk

M7XT Control Module via the power cable.

OPT ONAL F REHAWK M7XT A R MASK COMPONENTS

Ultra Elite XT Communications System

The Ultra Elite XT Communication System is an electronic speech

projection system available with either an amplifier or an amplifi-

er with radio interface connection. The Ultra Elite XT

Communication System is connected to the Ultra Elite XT

Facepiece using the ClearCommand Communication System

Bracket.

F REHAWK M7XT TELEMETRY MODULE

The FireHawk M7XT Telemetry Module provides the firefighter

with two-way communication with Incident Command. The fire-

fighter’s vital statistics such as cylinder pressure, service time

remaining, PASS alarm, low battery alarm, and thermal alarm are

transmitted back to Incident Command via the MSA

Accountability System Base Station. Also, the firefighter can be

notified of an emergency evacuation alert remotely by Incident

Command. The radio transmitter is located inside of the FireHawk

M7XT Power Module.

RESCUE BELT

The MSA Rescue Belt II is a personal escape system integrated

into a FireHawk M7 Carrier and Harness Assembly. The system is

designed to provide the user a means of escape from an

elevated position. Use of the Rescue Belt II must be in

accordance with the user’s fire department procedures. Refer to

care and use instructions (P/N 10115063).

6

MSA2211 (L) Rev. 8 - 10128861

"!

WARN NG

V SUAL NSPECT ON AND FUNCT ONAL TESTS

NSPECT ON

Conduct the Following: Before Use, After Each Use, and Monthly

Thoroughly inspect this air mask upon receipt and before use.

This air mask is to be used only by trained and qualified

personnel. Read and understand these instructions before

attempting to use this equipment.

Inspect the entire air mask after it is cleaned and disinfected.

NFPA-1500, as well as ANSI Standards Z88.2 and Z88.5, describe

three levels of inspection procedures which are to be performed.

Refer to these documents, or to an inspection

program prepared by a health professional in establishing an

inspection program.

•f the air mask exhibits any of the conditions listed in the

Component nspection section or if the air mask does

not function properly as described in the Functional

Tests section, the air mask must be removed from

service.

•DO NOT inspect the air mask before cleaning if there is

danger of contacting hazardous contaminants. Clean

and disinfect first, then inspect.

•Never substitute, modify, add, or omit parts. Use only

exact replacement parts in the configuration as specified

by the manufacturer.

Misuse can result in serious personal injury or death.

COMPONENT NSPECT ON

1. Facepiece

a. Inspect the facepiece for rubber deterioration, dirt, cracks,

tears, holes, or tackiness.

b. Inspect the head harness straps for tears, loss of

elasticity, or missing buckles or straps.

c. Inspect the lens for cracks, scratches, and a tight seal with

the facepiece rubber.

d. Ensure the exhalation valve is clean and operates easily.

The valve must move off the seat and return when

released.

e. Inspect the facepiece inlet for damage. Ensure the

spider gasket and valve disc are present.

f. Inspect the facepiece rubber around the FireHawk M7

HUD or I-HUD and/or Ultra Elite XT Communication

System bracket (optional) for holes or tears.

2. FireHawk M7 HUD or I-HUD

a. Inspect the FireHawk M7 HUD or I-HUD for cracks or other

signs of damage which could allow contaminants to enter

the housing.

b. Reassemble the FireHawk M7 HUD to the bracket on

the Ultra Elite XT Facepiece or reinstall the FireHawk M7 I-

HUD in the Ultra Elite XT Facepiece.

3. Ultra Elite XT Communication System

a. Remove the amplifier housing from the facepiece and

inspect the housing for cracks or other signs of damage.

b. Reassemble the amplifier housing on the facepiece.

c. Depress the on/off button on the unit and then release it.

d. Look through the facepiece lens. The red LED should be

illuminated at the top of the amplifier unit.

e Scrape a fingernail lightly across the voicemitter micro-

phone grille of the voicemitter microphone assembly.

f. Listen for this sound reproduced in the amplifier speaker.

g. Depress and release the on/off button again to turn the

unit OFF. The LED on the amplifier unit should be OFF.

4. Firehawk Second Stage Regulator

a. If the FireHawk M7XT Air Mask is equipped with a quick-

connect second stage intermediate pressure hose, inspect

the rubber washer for deterioration, dirt, cracks, tears, or

tackiness.

b. Inspect the intermediate pressure hose between the

Firehawk Second Stage Regulator and the PR14 First Stage

Regulator. Look for cuts or severe abrasions. If damage is

present, replace the hose.

5. PR14 First Stage Regulator

a. Inspect the regulator mounting bracket (attached to the

backplate) for cracks, weakened areas, or signs of heat or

chemical related damage.

b. Inspect the regulator mounting bracket screws to ensure

they are secure.

c. Inspect the regulator mounting bracket to ensure that it

holds the regulator securely.

d. Inspect the pressure relief valve. Ensure that the relief

holes are clear and free of debris or other contaminants.

Ensure that the pressure relief valve is properly secured.

e. Inspect the hose connections. Ensure that the hoses are

properly secured.

6. Audi-Larm Alarm

a. Unthread the Audi-Larm Alarm coupling nut from the

cylinder valve. Inspect the coupling nut for thread dam-

age.

b. Ensure there is an o-ring present and not damaged.

Replace the o-ring if it is damaged.

c. Ensure that the bell is tight. If the bell is loose or can

rotate, remove the SCBA from service.

d. Inspect the relief valve for damage. Ensure the relief valve

label is not damaged and that the relief valve ports are not

showing. If damaged, remove the air mask from service

and replace the relief valve.

e. Reattach Audi-Larm Alarm to the cylinder valve.

f. Ensure that the Audi-Larm coupling nut is hand-tight (no

tools).

7. High Pressure Hose

a. Inspect the high pressure hose between the Audi-Larm

Alarm and the PR14 First Stage Regulator. Look for cuts or

severe abrasions. If damage is present, replace the hose.

8. Cylinder and Valve Assembly

a. Air mask cylinders should be recharged as soon as possi-

ble after use. Cylinders should not be stored partially

charged for two reasons:

7MSA2211 (L) Rev. 8 - 10128861

"!

WARN NG

V SUAL NSPECT ON AND FUNCT ONAL TESTS

• If used without recharge, the available service time of

the air mask is reduced.

• The cylinder burst disc vents excess pressure if a

full cylinder is over exposed to fire or heat. If the

cylinder is not full, it may be damaged before the

burst disc vents.

b. If the cylinder is less than FULL (within 10% of rated ser-

vice pressure), recharge it before storage. Cylinder air must

be at least C A Quality Verification Level ( rade) D res-

pirable air. In fire service applications, MSA recommends

breathing air quality in accordance with NFPA 1989.

c. Inspect the cylinder valve for signs of damage. The valve

may be opened slightly to ensure it operates properly. Be

sure to fully close the valve.

d. Inspect the cylinder body for cracks, dents, weakened areas,

corrosive agents causing the fibers to break or peel, or signs

of heat-related damage. If the cylinder is damaged return it

to an MSA Service Center.

e. Check the hydrostatic test date on the cylinder approval

sticker located on the cylinder shell. Fiberglass composite

cylinders must be tested every three years. Carbon-

wrapped and aluminum cylinders must be tested every

five years. Aluminum cylinder life is indefinite if proper

inspection and hydro test procedures are followed and

they indicate that the cylinder may remain in service.

f. Ensure the needle and gauge face on the cylinder valve

gauge are clearly visible and that the gauge stem is not

bent.

It is also essential that the required inspections and tests be per-

formed on all air mask cylinders in accordance with Department

of Transportation (DOT) regulations. DOT regulations require that

composite cylinders be retired from service after the fifteenth

year. This does not include cylinder valve assemblies that may be

reused. Aluminum cylinder service life is indefinite if proper

inspection and hydrostatic test procedures are followed and they

indicate that the cylinder may remain in service. Contact an MSA

distributor or sales associate for more information regarding this

policy.

NOTE: ANSI Z88.5 recommends checking cylinder pressure

weekly. For maximum safety the cylinders should be stored full or

empty (pressure above ambient but less than 100 psi).

9. FireHawk M7 Carrier and Harness

a. Operate the latch wing on the cylinder band to ensure

that it opens and closes properly and that it holds the

cylinder securely. If the cylinder band and latch is locked,

the latch wing should not turn.

b. Inspect the back plate for cracks, weakened areas, or signs

of damage due to heat or chemical related damage.

c. Inspect all harness components for cuts, tears,

abrasions, or signs of damage due to heat or chemical

related damage.

10. Rescue Belt II

a. Refer to care and use instructions (P/N 10115063).

11. FireHawk M7XT Control Module (integrated PASS version)

a. Inspect the gauge hose and power cable for any visible

signs of damage.

b. Inspect for external cracks in the housing and ensure the

rubber cover is not damaged.

c. Ensure the buttons are not damaged or missing.

d. Ensure the gauge hose and power cable are securely

attached to the FireHawk M7XT Control Module.

e. Check both lens covers for dirt or moisture. If present refer

to the Cleaning and Disinfecting section, (item 3e).

12. FireHawk M7XT Power Module

a. Inspect the FireHawk M7XT Power Module housing for

external cracks and ensure that the FireHawk M7XT Power

Module, battery tube, and cylinder stop are securely

attached to the backplate.

b. Inspect the piezo emitters on both sides of the FireHawk

M7XT Power Module. Ensure that the emitter covers are

not obstructed by dirt or debris.

c. Ensure that the power cable is securely attached to the

FireHawk M7XT Power Module. The fitting on the power

cable should not be able to be unthreaded by hand.

13. Record Keeping

a. Following inspection, the date and initials of the

designated inspector should be recorded on an

inspection tag. A more detailed record of the operations

performed can be noted on an inspection and

maintenance log, available from MSA. When the

inspection data has been recorded, the air mask is ready

for use.

All repair and replacement of subassemblies must be carried

out by an MSA certified repair technician. Failure to follow

this warning will void NFPA and N OSH certifications and

can result in serious personal injury or death.

FUNCT ONAL TESTS

Conduct the Following: Before Use, After Each Use, and Monthly

1. Check that the Firehawk Regulator and facepiece can hold a

negative pressure.

a. Close the cylinder valve and purge any air from the system

using the bypass knob on the Firehawk Regulator.

b. Hold the facepiece against the face to create an effective

seal.

c. Attach the Firehawk Regulator to the facepiece and inhale

until the facepiece begins to collapse against the face.

Hold breath for approximately 10 seconds. Negative pres-

sure should be maintained and the facepiece should

remain collapsed against the face for the entire 10 sec-

onds.

d. Do not use the air mask if negative pressure cannot be

maintained in the facepiece. Return the Firehawk

Regulator and facepiece to a certified repairperson.

2. Check Firehawk Regulator operation.

NOTE: Firehawk Regulator functional checks must be conducted

with a full cylinder. Check the pressure gauge on the cylinder

valve to verify that the cylinder is full.

a. Push the release buttons on the side of the regulator.

8

MSA2211 (L) Rev. 8 - 10128861

"!

WARN NG

V SUAL NSPECT ON AND FUNCT ONAL TESTS

b. Ensure that the regulator bypass knob is fully closed

(clockwise).

c. Observe the LED display of the FireHawk M7 HUD or

I-HUD. Ensure that the cylinder valve is completely

opened.

d. Open the Firehawk Regulator bypass knob (counter-clock-

wise). Ensure that air flows from the regulator. Close the

bypass knob (clockwise).

e. Attach the regulator to the facepiece. Ensure proper regu-

lator attachment by pulling on the regulator.

f. Don the facepiece or hold the facepiece against the face

to create an effective seal.

g. Inhale sharply to start air flow. Breathe normally. Ensure

proper regulator response. The regulator should not make

any unusual sounds including whistling, chattering, or

popping.

h. Remove the facepiece from the face. Ensure that air flows

freely. Push the regulator release buttons. Ensure that air

flow stops.

i. If the regulator fails to meet any of the above checks,

remove the air mask from service. Return the regulator to

a certified repairperson.

3. FireHawk M7 HUD or I-HUD, FireHawk M7XT Control Module,

FireHawk M7XT Power Module, and Audi-Larm Alarm.

a. Verify proper function of the FireHawk M7 HUD or I-HUD,

FireHawk M7XT Control Module, FireHawk M7XT Power

Module, and Audi-Larm Alarm by observing the FireHawk

M7XT Control Module gauge and display when the alarms

ring and tone. Perform this test with a minimum cylinder

pressure of 1200 psi for 2216 psi air masks and 2000 psi for

4500 psi air masks.

b. Pressurize the system by opening the cylinder valve. Listen

for the FireHawk M7XT Power Module to sound and for

the Audi-Larm Alarm to ring briefly.

c. Observe the LED display of the FireHawk M7 HUD or I-

HUD. The LEDs must illuminate and correspond to the sys-

tem pressure.

d. Ensure that the alarm button on the FireHawk M7XT

Control Module and the buddy lights on the FireHawk

M7XT Power Module are slowly flashing green.

e. Allow the FireHawk M7XT Control Module to remain

motionless for approximately 20 seconds. Listen for the

FireHawk M7XT Power Module to sound the low/high/low

repeated tones of the PASS pre-alarm. Verify that the

alarm button on the FireHawk M7XT Control Module and

the buddy lights of the FireHawk M7XT Power Module are

slowly flashing red. Also verify that the orange LED is dis-

played in the FireHawk M7 HUD or I-HUD. Ensure that the

FireHawk M7XT Control Module remains motionless until

the full PASS alarm activates. Listen for the FireHawk M7XT

Power Module to sound the loud PASS alarm. Look for the

alarm button on the FireHawk M7XT Control Module and

the buddy lights on the FireHawk M7XT Power Module to

rapidly flash red.

f. Reset the PASS alarm by pressing the reset button (yellow)

on the side of the FireHawk M7XT Control Module two

times within approximately one second.

g. To check the manual activation of the PASS alarm, press

and hold the alarm button on the front of the FireHawk

M7XT Control Module for approximately three seconds.

Listen for the PASS alarm to be emitted from the FireHawk

M7XT Power Module.

h. Reset the PASS alarm. Press the reset button (yellow) on

the FireHawk M7XT Control Module two times within

approximately one second.

i. Allow the FireHawk M7XT Control Module to remain

motionless until the PASS pre-alarm sounds. Shake the

FireHawk M7XT Control Module to reset the alarm.

j. Disconnect the Firehawk Regulator from the facepiece.

k. Close the cylinder valve fully.

l. Slowly crack the bypass valve on the Firehawk Regulator

to bleed off pressure until the FireHawk M7XT Control

Module pressure reading drops below the following

values:

o 785 psi - approximately (2216 psi system)

o 1600 psi - approximately (4500 psi system)

A flashing red LED must display in the FireHawk M7 HUD or I-

HUD at the appropriate pressure listed above. The Audi-Larm

Alarm will ring and the alarm button on the FireHawk M7XT

Control Module and buddy lights on the FireHawk M7XT Power

Module will flash red at this time.

m. The alarms should continue until the air pressure is 250

psi or less. If the Audi-Larm Alarm, FireHawk M7XT Control

Module, FireHawk M7XT Power Module, or FireHawk M7

HUD or I-HUD does not function properly, the air mask

must be removed from service.

n. When the system pressure falls below 250 psi, turn the

FireHawk M7XT Control Module off (sleep mode) by press-

ing the reset button (yellow) two times within approxi-

mately one second.

4. Open the bypass valve slowly to release any remaining

pressure in the system. Close the bypass valve.

9MSA2211 (L) Rev. 8 - 10128861

QU CK-F LL AND URC COUPL NG NSPECT ON

DO NOT disconnect the Audi-Larm Alarm coupling nut when

pressure is shown on analog pressure gauge. Release all

pressure from the air mask by opening the Firehawk

Regulator bypass valve. Removing the coupling nut with the

air mask is pressurized can result in serious personal injury,

death, or damage to equipment.

QU CK-F LL AND URC COUPL NG NSPECT ON

Inspect the URC and Quick-Fill coupling for tightness of the cou-

pling halves and tightness of the coupling to the air mask.

Perform both inspections simultaneously.

1. Close the cylinder valve and relieve system pressure. (See

D SCONNECT NG THE F REHAWK PUSH-TO-CONNECT

REGULATOR or D SCONNECT NG THE SL DE-TO-CON-

NECT F REHAWK REGULATOR for instructions).

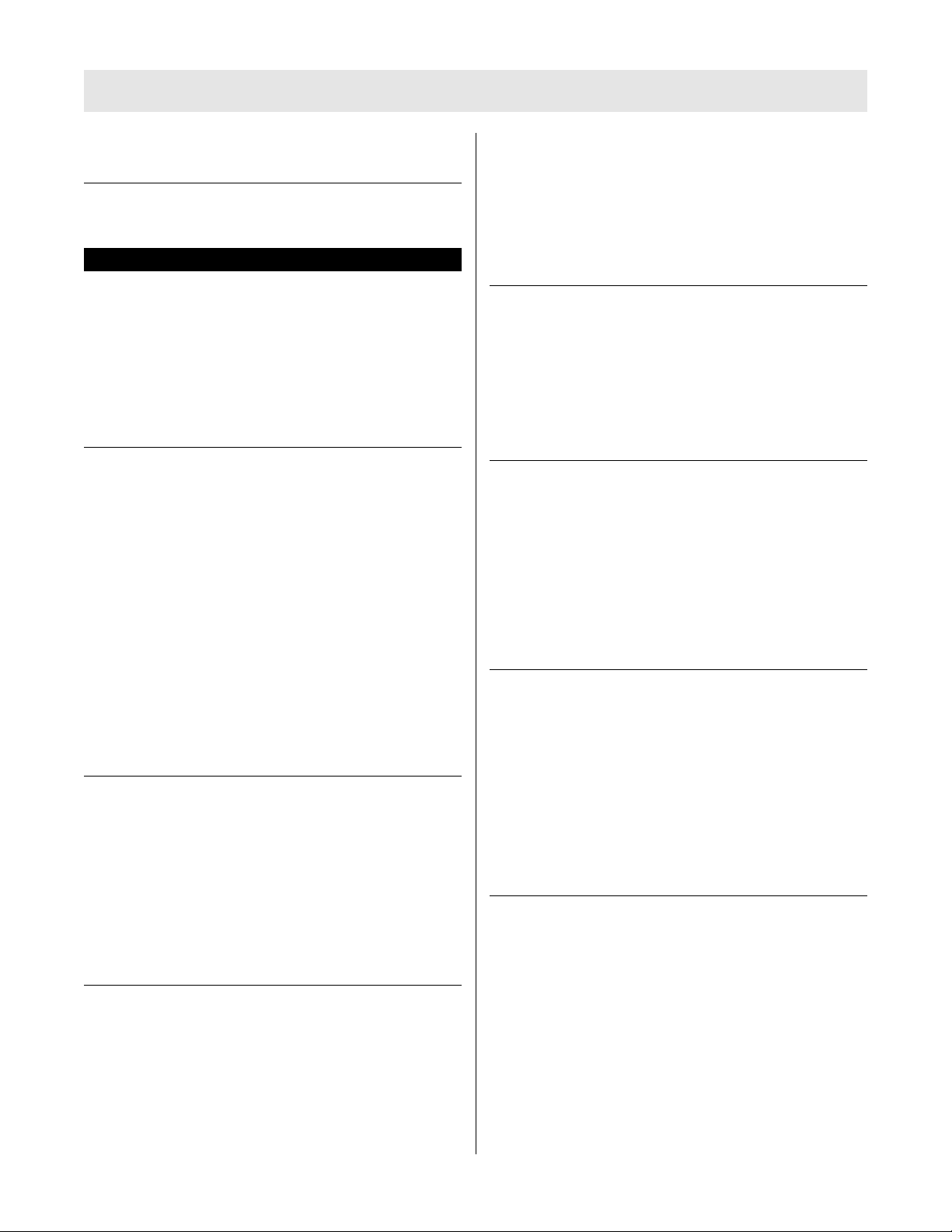

2. Use a fine-tip ink marker

and a ruler or straight

edge to draw a line on

the male coupling. Make

sure the line extends

across the joint and cou-

pling hex flats onto the

Audi-Larm or Quick-Fill

manifold body.

3. Put the dust cover on the coupling.

4. rasp the dust cover by hand and, using maximum effort,

attempt to loosen the coupling at the joint by turning the

dust cover counterclockwise. Do not use tools.

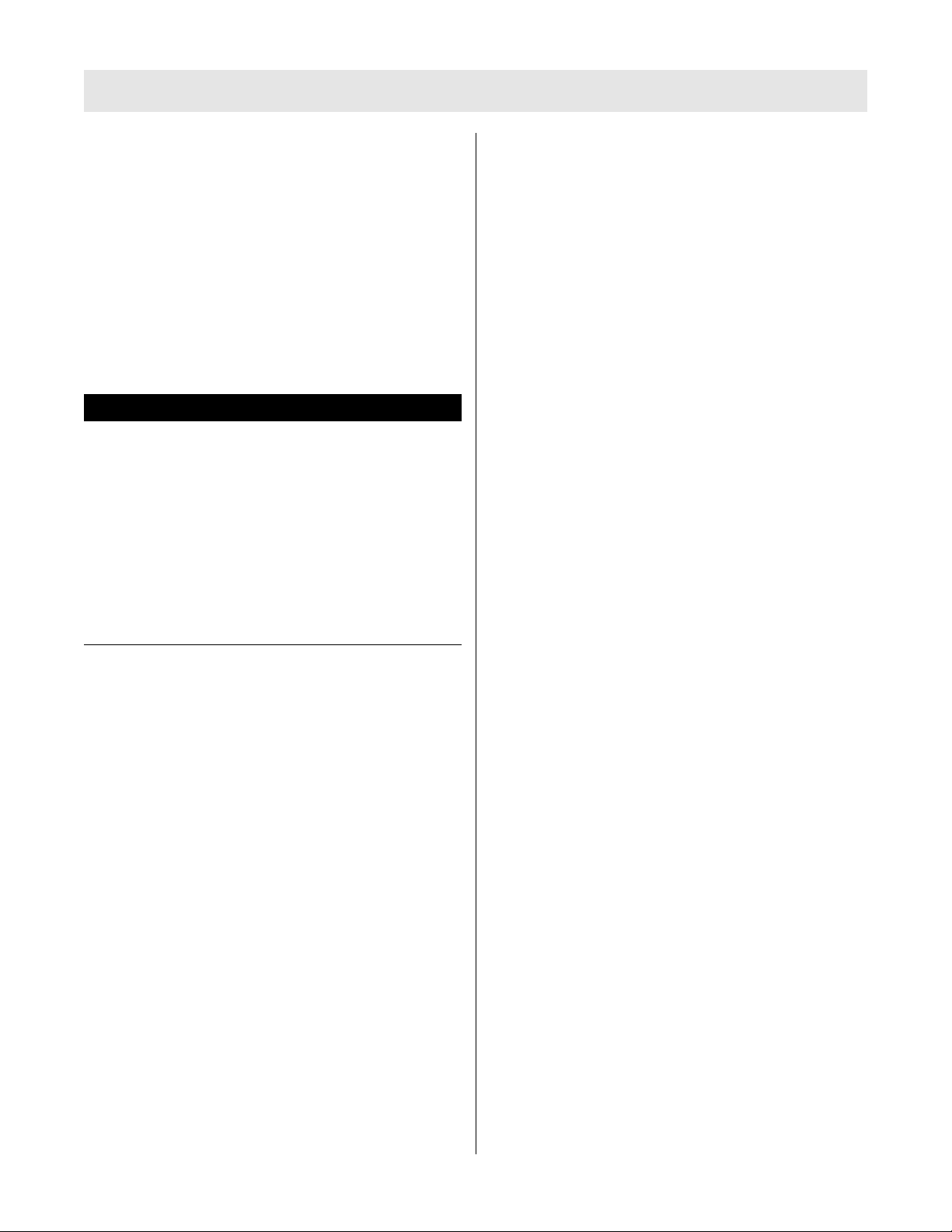

5. If the line does not line up

across the joint...

...or across the joint where

the coupling attaches to

the air mask, remove the

air mask from service until

a replacement coupling is

installed. If the line does

line up, the coupling is

sufficiently tight and the

air mask may be returned

to service.

10

MSA2211 (L) Rev. 8 - 10128861

"!

WARN NG

DONN NG

DONN NG THE A R MASK

1. Remove the facepiece from the case.

DO NOT use a cover lens in a high-temperature environ-

ment, such as firefighting. High temperatures may distort

the cover lens. Or, moisture trapped between a cover lens

and the facepiece lens may condense and distort vision.

Always remove the cover lens before donning the facepiece.

Misuse can result in serious injury or death.

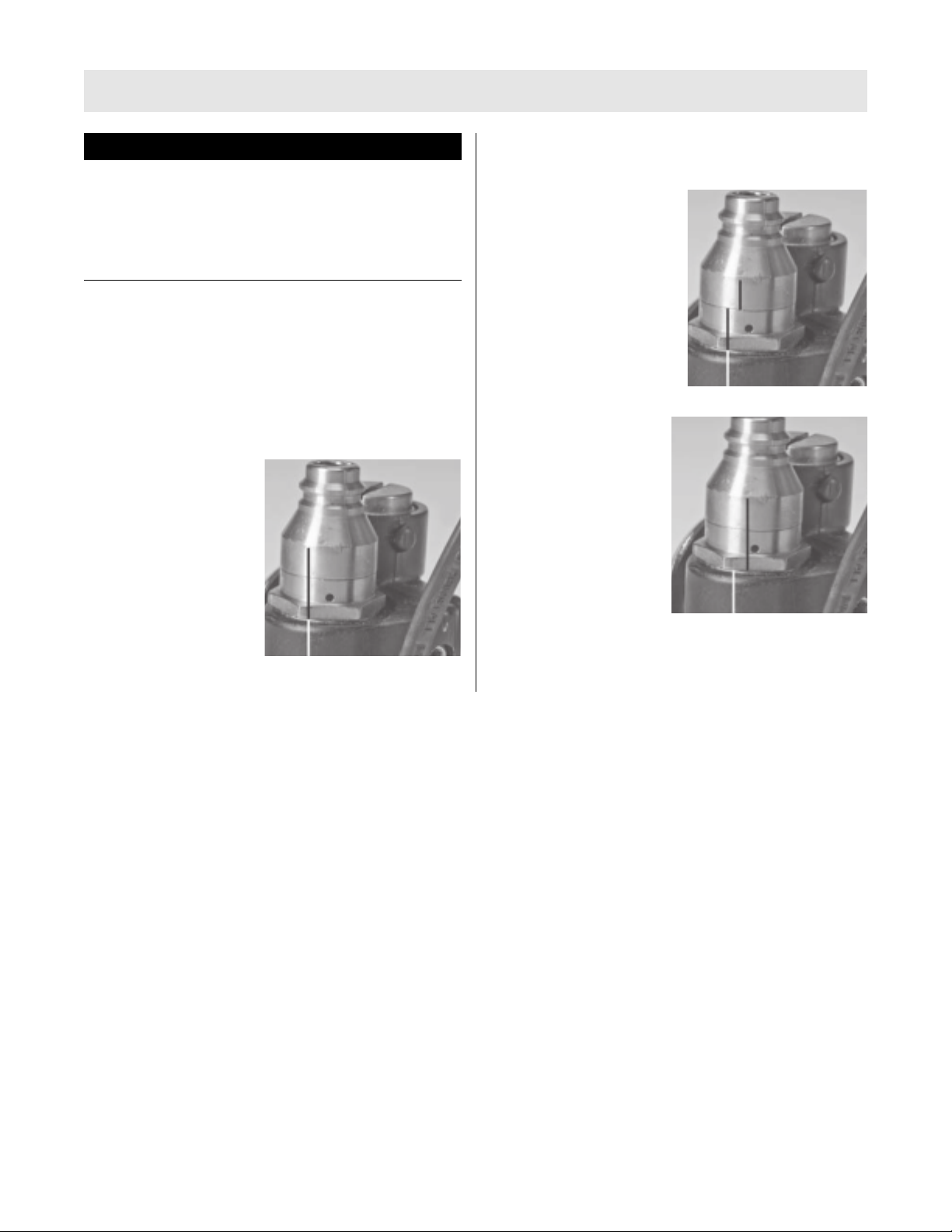

2. Ensure the the Audi-Larm

coupling nut is hand-tight

(no tools).

3. Ensure that the cylinder is fully pressurized.

4. Reach the right arm inside the right shoulder straps and

grasp the FireHawk M7XT Control Module. Slide the left arm

through the left shoulder straps.

5. Bend forward slightly; resting the carrier on the back.

6. Attach the chest strap buckle (optional).

7. Fasten the waist belt and pull it tight for a snug fit. Most of

the air mask weight should be carried on the hips.

8. Stand up straight. Pull the shoulder strap pull tabs out to

tighten the shoulder straps. Additional adjustments to the

waist belt may be needed.

9. The shoulder straps and waist strap ends must be tucked in

and lay flat across the body.

BEFORE US NG THE A R MASK

1. rasp the Firehawk Regulator and push the side buttons.

2. Ensure that the red bypass

knob is fully closed (clock-

wise).

3. Reach behind and fully

open the cylinder valve.

4. As the system pressure rises from 50 to 250 psi, both visible

and audible alerts activate automatically, indicating that the

air mask is functioning properly. Such alerts include a brief

ring from the Audi-Larm Alarm, a chirp from the FireHawk

M7XT Power Module, and a pressure display on the FireHawk

M7 HUD or I-HUD LEDs.

5. No air should flow from

the Firehawk Regulator. If

it does, repeat steps 1 and

2.

6. Ensure the FireHawk M7 HUD or I-HUD and FireHawk M7XT

pressure indicators show a full cylinder.

11 MSA2211 (L) Rev. 8 - 10128861

"!

CAUT ON

"!

WARN NG

"!

WARN NG

"!

WARN NG

Listen for any hiss or pop sounds from the Audi-Larm Alarm,

if heard, do not use the air mask. Return it to an MSA trained

or certified repairperson. Misuse can result in serious injury

or death.

DO NOT use the air mask if the Audi-Larm Alarm fails to ring,

the FireHawk M7XT Power Module fails to sound, or the

FireHawk M7 HUD or -HUD fails to light, The air mask must

be checked and corrected for proper operation by an MSA

trained or certified repairperson before using. Misuse can

result in serious injury or death.

DO NOT use the air mask if the cylinder gauge and FireHawk

M7 pressure readings are not within 5% (110/2216 psi and

225/4500 psi) of full cylinder pressure. Send the unit to an

MSA certified repair person.

DONN NG

7. Check the Firehawk

Regulator’s bypass

operation. rasp the red

knob and turn it counter-

clockwise. Listen for air-

flow and then turn it to

the off position.

8. Fully close the cylinder valve.

9. Listen for air leaks and watch the pressure indicators on the

FireHawk M7XT Control Module or NightFighter HUD

Transmitter for 10 seconds.

DO NOT use the air mask if the pressure drops more than

100 psi in ten seconds, The air mask must be repaired; other

wise, reduced available service time may result.

10. Crack the Firehawk Regulator bypass valve slowly to bleed off

pressure until the FireHawk M7 HUD or I-HUD and FireHawk

M7 pressure indicators drop below:

o 785 psi-approximately (2216 psi system)

o 1600 psi-approximately (4500 psi system)

At these pressures the FireHawk M7 HUD or I-HUD should display

a flashing red LED, the Audi-Larm Alarm should ring continuous-

ly, and the alarm button on the FireHawk M7XT Control Module

and the buddy lights on the FireHawk M7XT Power Module

should be flashing red.

11. When the system pressure falls below 250 psi, turn the

FireHawk M7XT Control Module off by depressing the reset

button (yellow) two times within approximately one

second.

DO NOT use the air mask if the Audi-Larm Alarm fails to ring

or fails to continuously ring down to pressures of 250 psi, or

if the FireHawk M7XT Control Module or FireHawk M7 HUD

or -HUD fails to light properly. The air mask must be

checked and corrected for proper operation by an MSA

trained or certified repair-person before using. Misuse can

result in serious injury or death.

NOTE: The FireHawk M7 HUD or I-HUD will automatically turn

itself OFF approximately 60 seconds after the air mask has been

depressurized. A red LED will flash until the device turns off.

DONN NG THE FACEP ECE

NOTE: A nosecup is always required for use with this air mask.

A nosecup must be installed in the facepiece. Misuse can

result in serious injury or death.

NOTE: Before donning, ensure that the Firehawk Regulator seal-

ing ring is seated properly in its groove on the outlet of the regu-

lator and that it is not torn, gouged, or nicked.

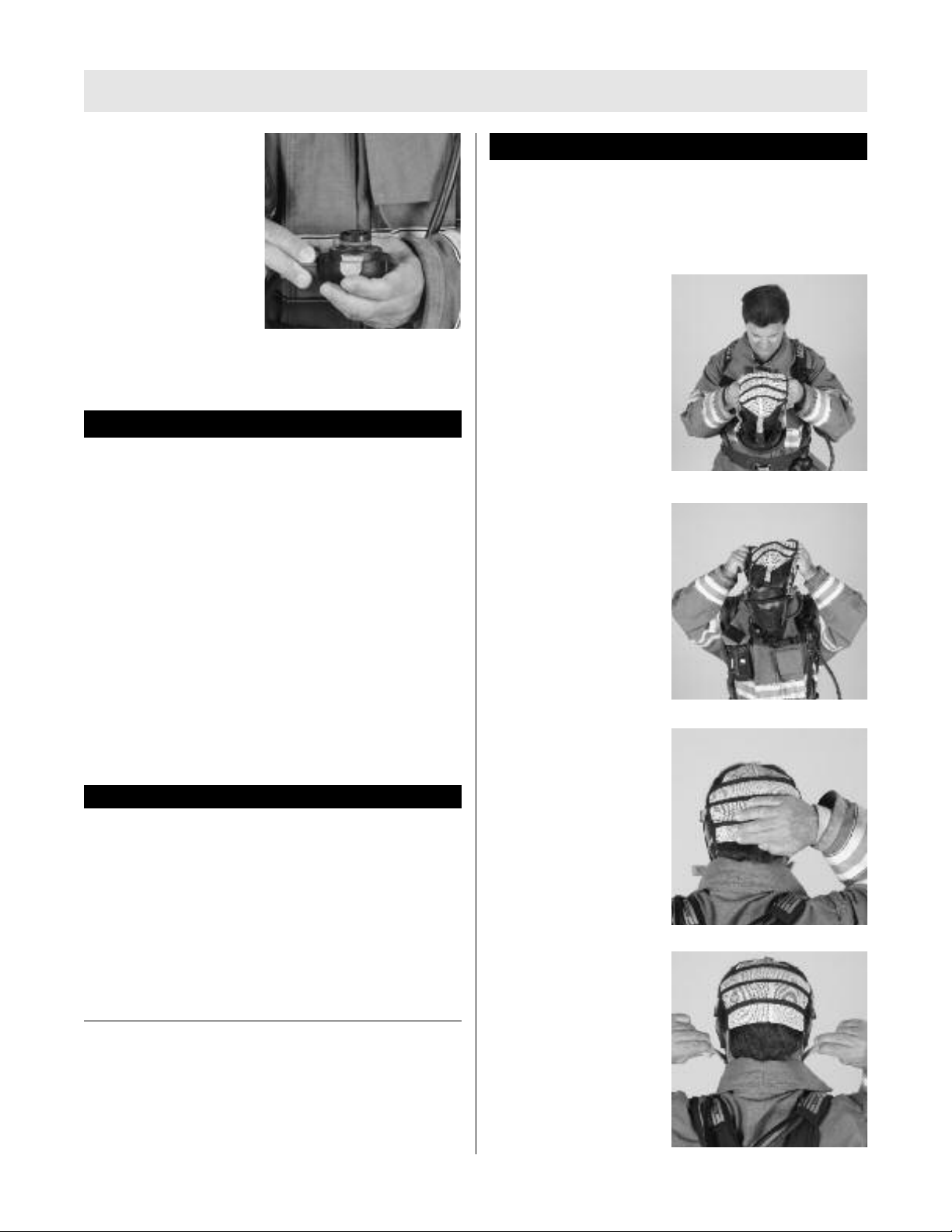

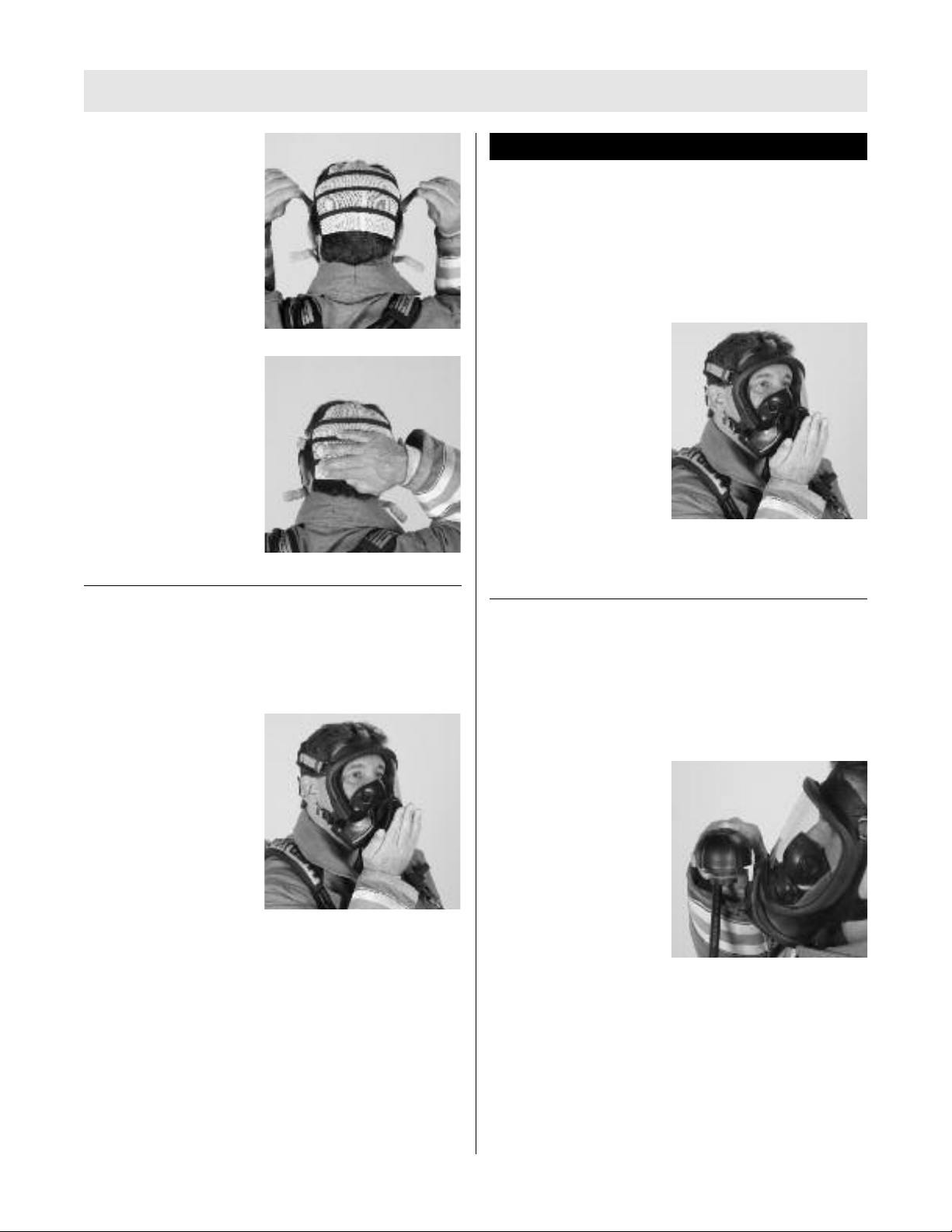

1. Loosen all the harness

straps. rip the bottom

straps.

2. Insert chin into the lower

part of facepiece, then

pull the harness back over

the head.

3. Pull the back of harness

downward until centered

at the back of the head.

4. Tighten the two lower

straps first by pulling

them straight back, not

out. Tighten the facepiece

until the mask is snug

against the face.

12

MSA2211 (L) Rev. 8 - 10128861

"!

CAUT ON

"!

WARN NG

"!

WARN NG

DONN NG

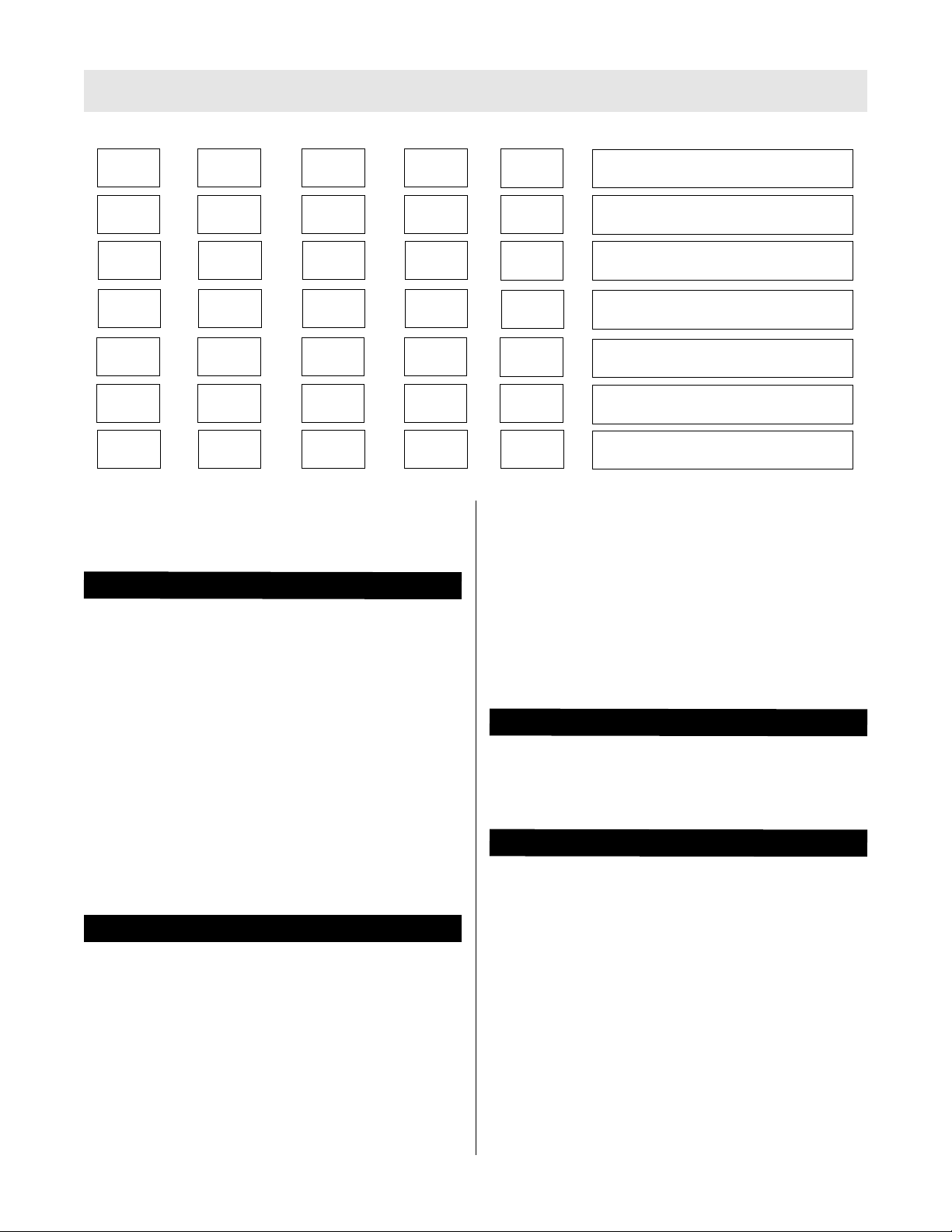

5. Tighten the two side tem-

ple straps in the same

manner as described in

step 4. Ensure that the

facepiece tabs are not

tucked under the face

seal.

6. Ensure the back of the

harness is centered on the

back of the head and that

the facepiece seal pro-

vides uniform pressure on

the face at all points.

Readjust the straps if

needed.

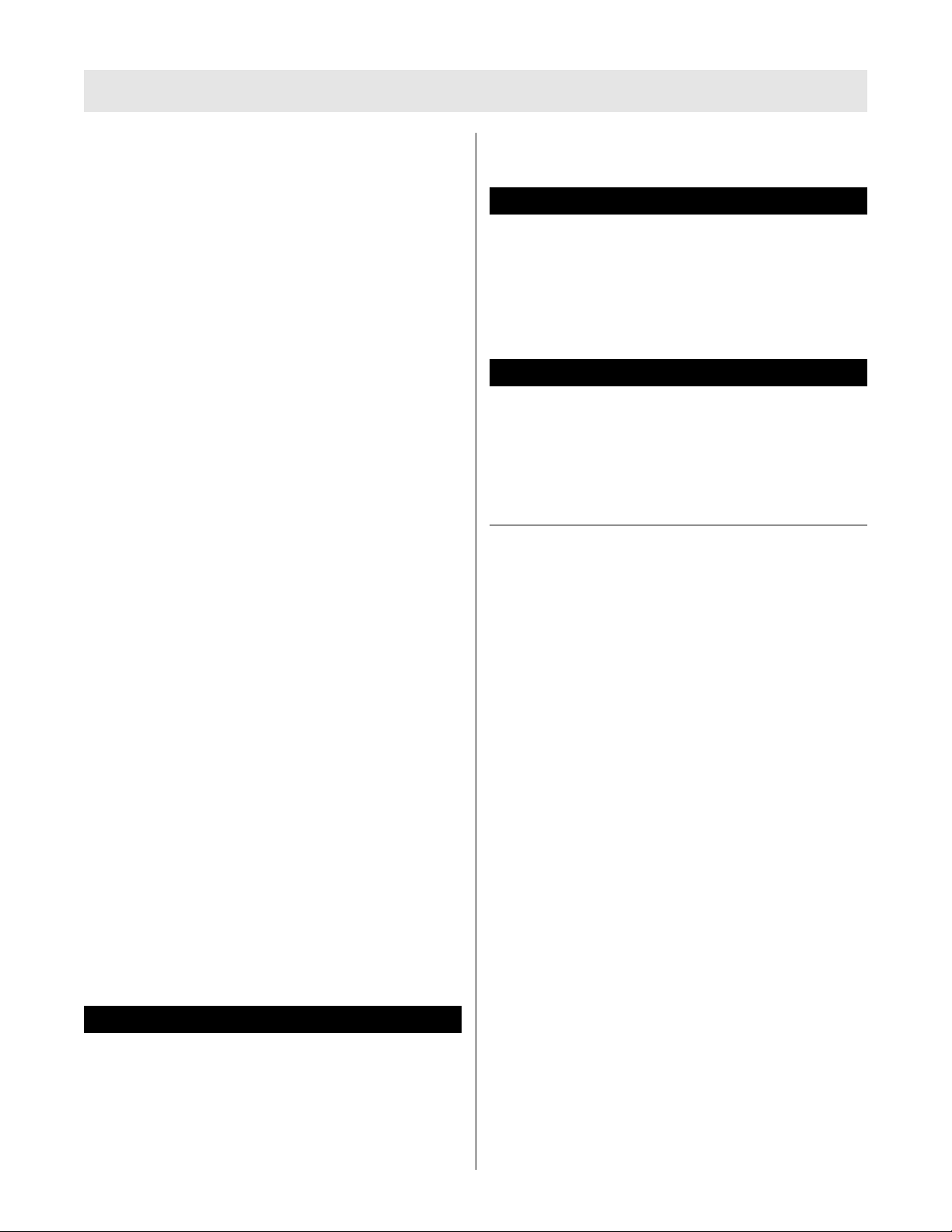

FACEP ECE F T CHECK

NOTE: Check the inhalation valve by inhaling. If the facepiece

does not provide sufficient flow of air, do not use facepiece. The

facepiece must be repaired or replaced.

1. Check facepiece fit,

a. Hold the palm of the

hand over the face-

piece inlet adapter.

b. Take a deep breath and

hold it for at least 10

seconds. The facepiece

should collapse and

stay collapsed against

the face. If it does not,

readjust the facepiece

and test again. f this

does not correct the leak, do not use the facepiece.

2. Test the exhalation valve.

a. Take a deep breath and hold it.

b. Block the facepiece inlet adapter with the palm of the

hand and exhale. If the exhalation valve is stuck, a heavy

rush of air around the facepiece may be noticed. A sharp

exhalation of air may be needed to open the valve. If this

does not release the valve, do not use the facepiece.

This device may not seal properly to the face if a beard,

gross sideburns or similar physical characteristics (see NFPA-

1500 and ANS Z88.2) exist. An improper facial seal may

allow contaminants to leak into the facepiece, reducing or

eliminating respiratory protection. Do not use this device if

such conditions exist. The face-to-facepiece seal must be

tested before each use. Never remove the facepiece except

in a safe, non hazardous non-toxic atmosphere. Misuse can

result in serious injury or death.

3. Open the cylinder valve

fully. Push in on the side

buttons of the Firehawk

Regulator to stop air flow.

4. Listen for any hissing or popping sounds from the Audi-Larm

Alarm. If heard, return the air mask to an MSA trained or certi-

fied repairperson.

NSTALL NG THE SL DE-TO-CONNECT F REHAWK

REGULATOR ON THE FACEP ECE

NOTE: The slide-to-connect regulator has a side button with a

two pronged fork protruding from it. If this “fork” is not present

refer to the nstalling the Push-To-Connect Firehawk

Regulator section of this manual.

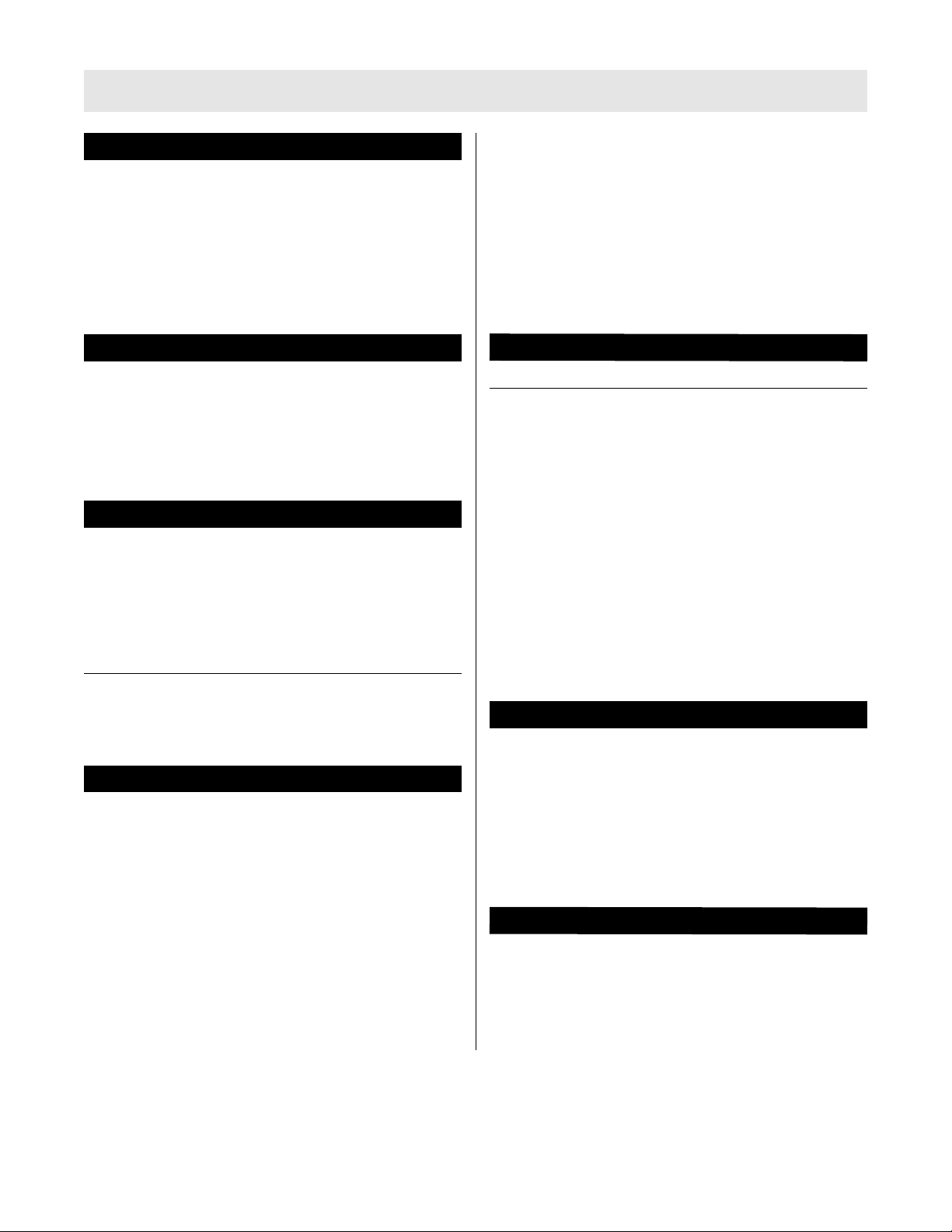

1. rasp and orient the regu-

lator so that red bypass

knob is pointing to the

right and slide button is

on top.

13 MSA2211 (L) Rev. 8 - 10128861

"!

WARN NG

DONN NG

2. Slide the regulator on to

the rail of the facepiece

cover. Slide the regulator

down the rail until the

regulator stops.

3. Insert the regulator into

the facepiece inlet by

pushing inward.

4. Ensure proper engagement by pulling on the regulator to

verify that the regulator is securely attached to facepiece.

DO NOT use the air mask unless the Firehawk Regulator is

connected properly. A regulator that is not installed correct-

ly can separate from the facepiece unexpectedly. Return the

air mask to an MSA trained or certified repairperson to cor-

rect the condition. Misuse can result in serious injury or

death.

5. Inhale sharply to start the airflow.

a. Check the bypass again by turning the red knob counter-

clockwise until increased airflow is felt. Close the bypass.

There must be a continuous flow of air when the bypass

knob is opened. f not, do not use the air mask. The air mask

must be checked and the condition corrected by an MSA

trained or certified repairperson before it can be used.

Misuse can result in serious injury or death.

NOTE: If the air mask passes all tests, it is ready for use. These

tests must be performed every time before entering a hazardous

atmosphere. If the air mask fails to meet any of the tests, the con-

dition(s) must be corrected before using the air mask.

NSTALL NG THE PUSH-TO-CONNECT F REHAWK

REGULATOR

NOTE: There are two versions (slide-to-connect and push-to-con-

nect) of the Firehawk Regulator available for the FireHawk M7XT

Air Mask. A slide-to-connect Firehawk Regulator can be identified

by examining the side buttons. The slide-to-connect has a side

button with a two pronged fork protruding from it. If this “fork” is

present, refer to Installing the Slide-To-Connect Firehawk

Regulator section.

1. rasp the Firehawk Regulator and insert the regulator into

the facepiece by pushing inward. Check proper engagement

by pulling on the regulator to ensure that the regulator is

securely attached to facepiece.

DO NOT use the air mask unless the regulator is connected

properly. A regulator that is not installed correctly can sepa-

rate from the facepiece unexpectedly. Return the air mask to

an MSA trained or certified repairperson to correct the condi

tion. Misuse can result in serious injury or death.

2. Inhale sharply to start the airflow.

3. Check the bypass again by turning the red knob counter-

clockwise until increased air flow is felt. Close the bypass.

There must be a continuous flow of air when the bypass

knob is opened. f not, do not use the air mask. The air mask

must be checked and the condition corrected by an MSA

trained or certified repairperson before it can be used.

Misuse can result in serious injury or death.

NOTE: If the air mask passes all tests, it is ready for use. These

tests must be performed every time before entering a hazardous

atmosphere. If the air mask fails to meet any of the tests, the con-

dition(s) must be corrected before using the air mask.

14

MSA2211 (L) Rev. 8 - 10128861

"!

WARN NG

"!

WARN NG

"!

WARN NG

"!

WARN NG

US NG THE A R MASK

PRECAUT ONS DUR NG USE

NOTE: If the breathing apparatus or any component fails, mal-

functions, or becomes damaged, contact MSA at 1-877-672-3473

(FIRE) or email customer service at [email protected]. SCBA

products may be considered hazardous material. In addition, U.S.

Department of Transportation exceptions and approvals may

apply to SCBA products. Please contact customer service at 1-

877-672-3473 (FIRE), or visit www.MSAnet.com/prism, for more

information.

Periodically check the pressure indicated on the FireHawk M7XT

chest mounted pressure indicator.

• Air flow in the air mask is reduced: Immediately open the

Firehawk Regulator bypass. Immediately return to fresh air.

• Air mask free-flows: Immediately return to fresh air.

• Audi-Larm Alarm Rings: Immediately return to fresh air.

• FireHawk M7 HUD or I-HUD low pressure indicator lights and

flashes red: Immediately return to fresh air.

• FireHawk M7XT Control Module alarm button flashes red:

Immediately return to fresh air.

Periodically check the pressure indicated on the FireHawk M7

HUD or I-HUD and FireHawk M7XT chest-mounted pressure indi-

cator during use. The FireHawk M7XT Control Module continually

displays the cylinder pressure while the FireHawk M7 HUD or I-

HUD indicates when each successive alert cylinder pressure level

(see Chart 1 for FireHawk M7 HUD or Chart 2 for I-HUD) of the

total cylinder pressure has been reached for 20 seconds. When

the needle on the FireHawk M7XT chest-mounted pressure indi-

cator reaches the red zone on the gauge face the Audi-Larm

Alarm will begin ringing, the FireHawk M7 HUD or I-HUD will dis-

play a flashing red LED, and the alarm button on the FireHawk

M7XT Control Module and buddy lights on the FireHawk M7XT

Power Module will flash red. When the Audi-Larm Alarm starts

ringing or when the pressure reaches approximately 33% of the

rated service pressure, return to fresh air.

The FireHawk M7 HUD or I-HUD, FireHawk M7XT Control Module,

and Audi-Larm Alarm indicate when cylinder pressure drops

below these approximate values:

o 785 psi-approximately (2216 psi system)

o 1600 psi-approximately (4500 psi system)

When the FireHawk M7 HUD or I-HUD, FireHawk M7XT Control

Module, or Audi-Larm Alarm indicates 33% cylinder pressure,

immediately return to fresh air.

NOTE: Air mask available service time is greatly reduced when

the Firehawk Regulator bypass is used.

Leave the contaminated area immediately if:

• Breathing becomes difficult

• Dizziness or other distress occurs

• You taste or smell the contaminant

• You experience nose or throat irritation

• SCBA not functioning according to the

instructions or training

Misuse can result in serious injury or death.

NOTE: See NIOSH Approval Label, Inserted in the Users

Instructions for complete list of CAUTIONS and LIMITATIONS for

the respirator.

Misuse or abuse of the FireHawk M7 HUD or -HUD, the

FireHawk M7XT Control Module, FireHawk M7XT Power

Module, or the equipment to which they are attached, or

using this equipment in a manner or situation not intended

by the manufacturer, may result in damage to the equip-

ment or may result in personal injury or death to user or

persons dependent on the user or damage to the

equipment.

• Always inspect the FireHawk M7 HUD or -HUD,

FireHawk M7XT Control Module, and FireHawk M7XT

Power Module for damage before use. f damage is

found, immediately remove the device from service.

• DO NOT alter these components. Altering will void the

ntrinsic-Safety rating and may affect the ntrinsic-Safety

of the device.

F REHAWK M7 HUD OR -HUD

FireHawk M7 HUD or -HUD Functionality

1. The FireHawk M7 HUD or I-HUD allows the user to see the

cylinder pressure while the air mask is in use. The FireHawk

M7XT Control Module wirelessly communicates with the M7

HUD or I-HUD. Both the FireHawk M7 HUD and I-HUD dis-

play the cylinder pressure in one quarter cylinder increments,

by an LED pattern.

• As each quarter cylinder pressure has been reached, down

to 50%, a unique LED pattern will be displayed for approx-

imately 20 second before extinguishing. The display can

be refreshed by pressing and holding the mode button

(green) on the FireHawk M7XT Control Module for approx-

imately three seconds.

• Just before 33% of the rated service pressure has been

reached, a single flashing red LED will be displayed and

will continue to flash until the unit is turned off or the

cylinder has been refilled.

• The FireHawk M7 HUD or I-HUD must be within approxi-

mately 18 inches of the FireHawk M7XT Control Module to

properly receive the signal being transmitted.

2. Both the FireHawk M7 HUD and I-HUD have a buddy light

that flashes red when the air mask has reached 33% of the

rated service pressure. This buddy light is not visible to the

user while the air mask is in use.

3. When the user of the air mask remains motionless for

approximately 20 seconds, the PASS pre-alarm will begin to

sound. During this pre-alarm, the FireHawk M7 HUD or I-HUD

will display an orange LED, and this LED will extinguish when

full PASS alarm has been reached or the pre-alarm has been

reset.

15 MSA2211 (L) Rev. 8 - 10128861

"!

WARN NG

"!

WARN NG

"!

WARN NG

US NG THE A R MASK

4. When an evacuation command has been sent to the user (if

the optional FireHawk M7XT Telemetry Module is in use), the

FireHawk M7 HUD or I-HUD will display an alternating red

and orange LED until the evacuation has been confirmed.

5. The FireHawk M7 HUD or I-HUD has a photo sensor that

automatically adjusts the brightness of the LEDs based on

the intensity of the ambient light measured outside of the

facepiece.

6. The FireHawk M7 HUD or I-HUD indicates a low battery con-

dition in either the HUD or FireHawk M7XT Power Module by

a flashing yellow LED. A user can confirm the power module

low battery indicator by viewing the low battery indicator on

the control module display. If this condition exists, return to

fresh air, and replace the batteries immediately. See

Replacing Batteries in the FireHawk M7 HUD or I-HUD.

Refer to Chart 1 for a full description of all FireHawk M7 HUD LED

patterns.

Refer to Chart 2 for a full description of all FireHawk M7 I-HUD

LED patterns.

16

MSA2211 (L) Rev. 8 - 10128861

Chart 1: FireHawk M7 HUD LED Patterns for FireHawk M7XT Air Masks

Y Y

R

RO

O

Y

100% to 76%

Full Cylinder, 4 reen LED

20 Sec. Steadily ON

75% to 51%

3/4 Full Cylinder, 3 reen LED

20 Sec. Steadily ON

50% to 34%

1/2 Full Cylinder, 2 Yellow LED

30 Sec. Flashing ON/OFF

33% to 0%

1/4 Full Cylinder, 1 Red LED

Flashing Continuously

Yellow LED, Low Battery HUD

and/or HUD Transmitter

Flashing Continuously

Orange LED for PASS Pre-Alarm

(integrated PASS)

Red / Orange LEDs alternating for

Evacuation Signal

(telemetry)

US NG THE A R MASK

17 MSA2211 (L) Rev. 8 - 10128861

REPLAC NG THE BATTER ES

Replacing the Batteries in the FireHawk M7 HUD

Replace the batteries in the FireHawk M7 HUD or -HUD

when the low battery LED flashes. Use only recommended

battery types. Change the batteries in a non-hazardous area

only. Misuse can result in serious personal injury or death.

1. Unthread the battery cap (counter-clockwise) on the

FireHawk M7 HUD battery tube.

2. Remove the battery cartridge from the FireHawk M7 HUD.

3. Remove the batteries and discard.

4. Ensure that moisture or debris is not present in the battery

compartment.

5. Inspect the battery cartridge for signs of damage such as cor-

rosion on the battery terminals or cracks in the cartridge. If

the battery cartridge is damaged, replace the cartridge

immediately.

6. Insert three AAA alkaline batteries in the appropriate loca-

tions on the cartridge. Follow the notations on the cartridge

to ensure proper battery orientation.

Use only Rayovac 824 LR03, Rayovac Ultrapro LR03,

Energizer E92, Energizer ndustrial EN92, Duracell MN2400,

or Duracell Procell PC2400 alkaline batteries in the FireHawk

M7 HUD. Use of other batteries, or a combination of batter-

ies from different manufacturers, will affect the performance

of unit and void the ntrinsic Safety Approval.

7. Insert the battery cartridge into the battery tube on the

FireHawk M7 HUD.

8. Before installing the battery cap, verify that the o-ring is in

place and free of damage and debris. If the o-ring is missing or

damaged, replace o-ring. Failure to do so may allow moisture

or contaminants into the battery tube and cause the device to

not function properly.

9. Thread the battery cap on to the battery tube of the

FireHawk M7 HUD (clockwise). Hand-tighten cap until snug.

Do not over-tighten battery cap.

10. As the battery cap makes contact with the battery cartridge,

verify that the FireHawk M7 HUD display turns on and goes

through its start up sequence before turning off. The yellow

LED should not be flashing.

Replacing the Battery in the FireHawk M7 -HUD

Replace the batteries in the FireHawk M7 HUD or -HUD

when the low battery LED flashes. Use only recommended

battery types. Change the batteries in a non-hazardous area

only. Misuse can result in serious personal injury or death.

DO NOT attempt to remove the -HUD by pulling on one

side or the other as this may cause damage to the device.

Use only even force on both sides of the device. Misuse can

result in serious personal injury or death.

1. Unthread the battery cap (counter-clockwise).

2. Remove the battery and discard.

3. Ensure that moisture or debris is not present in the battery

compartment.

4. Inspect the battery cap for signs of damage such as corro-

sion on the battery terminal or cracks in the cap. Replace the

battery cap if it is damaged.

5. Insert a replacement battery.

Chart 2: FireHawk -HUD LED Patterns for FireHawk M7XT Air Masks

"!

WARN NG

"!

WARN NG

"!

WARN NG

"!

WARN NG

Y

R

Y

O

R O

76% to 100%

Full Cylinder, 3 reen Right Side LED

75% to 51%

3/4 Full Cylinder, 2 reen Right Side LED

34% to 50%

1/2 Full Cylinder, 2 Yellow Right Side LED

Flashing Continuously

33% to 0%

1/4 Full Cylinder, 1 Red Right Side LED

Flashing Continuously

Low Battery

Left Side Yellow LED

Flashing Continuously

PASS Pre-Alarm

Orange Left Side LED

Evacuate

Red and Orange Left Side LED

Flashing Alternating

Y

US NG THE A R MASK

Use only Duracell Ultra M3, Panasonic Photopower CR2 or

Energizer CR2 Photo lithium batteries in the FireHawk M7

-HUD. Use of other batteries will affect the performance of

the unit and void the ntrinsic Safety Approval. Misuse can

result in serious personal injury or death.

6. Before installing the battery cap, verify that the o-ring is in

place and free of damage and debris. If the o-ring is missing

or damaged, replace the o-ring.

Failure to repla e a missing or damaged o-ring may allow

moisture or ontaminants into the housing and ause the

devi e to not fun tion properly.

7. Thread the battery cap into the housing and tighten until the

index mark on the battery cap aligns with the index mark on

the housing. Do not over-tighten the battery cap.

DO NOT over-tighten the battery cap. Over-tightening the

battery cap can result in a cracked housing and a com-

promised water seal. Misuse can result in serious personal

injury or death.

8. Verify that the FireHawk M7 I-HUD display turns on and goes

through its start-up sequence before turning off.

BATTERY D SPOSAL/RECYCL NG

Dispose of or recycle batteries in accordance with all applicable

federal, state, and local regulations.

DO NOT dispose of the batteries in fire. They may explode.

Misuse can result in serious personal injury or death.

ASSEMBLY OF THE F REHAWK M7 HUD ON THE FACEP ECE

NOTE: Assemble the FireHawk M7 HUD to the facepiece bracket

before donning the air mask.

With the facepiece lying on its side:

1. Align the metal tab on the FireHawk M7 HUD with the metal

plate on the front edge of the bracket.

2. Rotate the FireHawk M7 HUD so that the tab falls into the

slot behind the thumbscrew.

3. Thread the thumbscrew into the tab to finger-tight.

ASSEMBLY OF THE F REHAWK M7 -HUD N THE FACEP ECE

1. Install the I-HUD by pushing forward on the center nose-

bridge.

NOTE: The locking mechanism (top arm of the retaining clip) will

wrap around the IHUD’s nose-bridge from the backside.

2. Push forward on the arm of the clip to ensure there is little to

no space between the bend of the locking arm and the

nose-bridge of the I-HUD.

NOTE: To remove the I-HUD, pull the locking arm away from

the nose bridge of the I-HUD. Pull the arm back and away on

an angle. The locking arm is constructed of spring steel , allow-

ing the arm to spring back into the proper position for the

next I-HUD insertion.

DO NOT attempt to remove the -HUD by pulling on one

side or the other as this may cause damage to the device.

Use only even force on both sides of the device. Misuse can

result in serious personal injury or death.

FUNCT ONAL TESTS

NOTE: Refer to the Visual Inspection and Functional Test

section of this manual.

Always test the FireHawk M7 HUD or -HUD and the entire

air mask to be sure that the system operates properly before

entering any hazardous atmosphere. DO NOT use this

device unless it passes all inspection and functional tests.

Misuse can result in serious personal injury or death.

18

MSA2211 (L) Rev. 8 - 10128861

"!

WARN NG

"!

WARN NG

"!

WARN NG

"!

WARN NG

"!

WARN NG

"

WARN NG

"!

CAUT ON

DO NOT use a screwdriver to tighten the thumbscrew.

US NG THE A R MASK

19 MSA2211 (L) Rev. 8 - 10128861

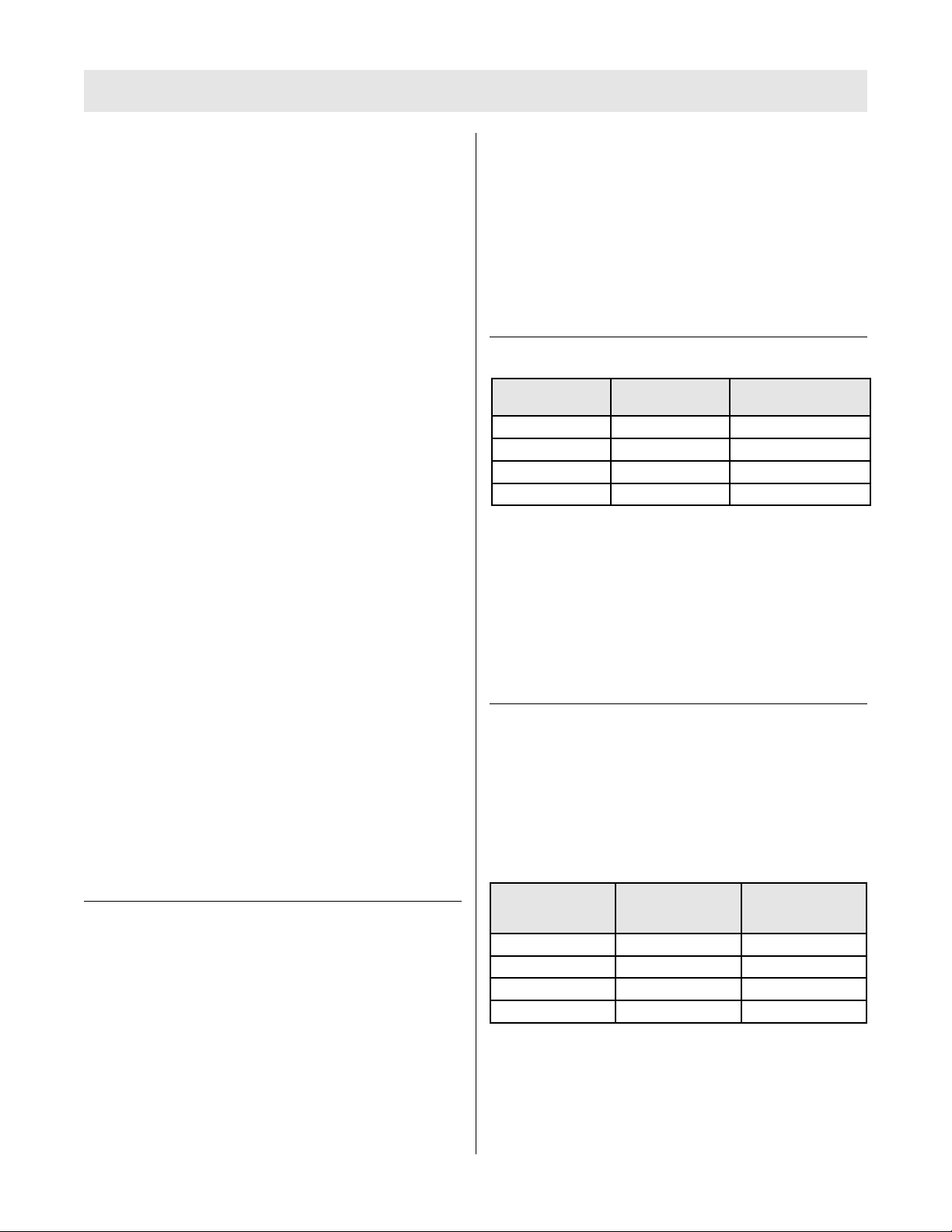

*Action only available when the FireHawk M7XT Telemetry Module is used.

**Action available only if SCBA with integrated PASS is configured with Thermal Alarm option.

Chart 3: Audible / Visual ndicators Firehawk M7XT Power Module and Control Module

ACT ON AUD BLE ND CATOR,

POWER MODULE

V S BLE ND CATOR,

CONTROL MODULE

automatic activation with

the system pressurized

single upsweep with ending

lower tone green / red LED flash front panel

the manual activation

alert sequence of 1 down

sweep, 4 upsweeps (medium

speed), 8 upsweeps (high

speed), and repeated until

deactivated.

green / red LED flash front panel - red light

flashing

sensing mode (with or without

pressure) none green LED flashes

pre-alarm

with or

without

pressure

2 low speed low / high / low tones

red LED flashes

4 medium speed low / high / low

tones

4 stages of 7 rapidly alternating

low / high tones

full alarm (with or without

pressure)

alert sequence of 1 down

sweep, 4 upsweeps (medium

speed), 8 upsweeps (high

speed), and repeated until

deactivated.

red LED flashes

Deactivation of full alarm

( 2 reset button presses) single short (high) tone beep

red LED flashes

green LED flashes

deactivation of pre-alarm

(with shake or move unit) none green LED flashes

redundant alarm (cylinder

pressure is below 33% of rated

service pressure)

none red LED flashes

low battery 1 beep every 5 seconds empty battery icon on display

thermal alarm activation** (see

thermal alarm activation curve) 1 beep every 3 seconds** flashing thermometer icon on display**

radio link

with

base

station*

none radio link indicator icon in upper left corner

of display*

none radio link indicator icon disappears*

evacuation signal received*

continuous medium speed

upsweep alerts until

acknowledged*

flashing “running man” icon appears on

display*

first 4 seconds

(approx)

link is

established

out of range

second 4 seconds

(approx)

last 4 seconds

(approx)

US NG THE A R MASK

FUNCT ONAL TESTS

NOTE: Refer to the Visual Inspection and Functional Test section

of this manual.

Always test the FireHawk M7 HUD or I-HUD and the entire air

mask to be sure that the system operates properly before enter-

ing any hazardous atmosphere. DO NOT use this device unless it

passes all inspection and functional tests. Failure to follow this

warning can result in serious personal injury or death.

F REHAWK M7XT CONTROL MODULE FUNCT ONAL TY

• The FireHawk M7XT Control Module is assembled to the

gauge line hose and is connected to the FireHawk M7XT

Power Module by the power cable. The FireHawk M7XT

Control Module serves as the user interface with the air mask

and it also serves as the wireless transmitter for the FireHawk

M7 HUD or I-HUD.

• The FireHawk M7XT Control Module has three control but-

tons.

o The RESET/OFF button (yellow) on the side of the FireHawk

M7XT Control Module resets the PASS device from the full

alarm mode. It also shuts the unit off after the cylinder valve

has been closed and all pressure is bled from the system.

When the optional FireHawk M7XT Telemetry Module is

used, the Reset button allows the user to confirm an evacua-

tion command.

o The center lighted ALARM button (green/red) activates the

full PASS alarm with or without air pressure.

o The top MODE button (green) will refresh the display in

the FireHawk M7 HUD or I-HUD, activate the backlight on

the display of the FireHawk M7XT Control Module, set the

FireHawk M7 HUD or I-HUD to continuous display mode,

and toggle the FireHawk M7XT Control Module digital dis-

play mode between pressure remaining and calculated

service time remaining. When the FireHawk M7XT Control

Module is OFF, the mode button (green) can be used to

scan an ID Tag into the unit (when optional FireHawk

M7XT Telemetry Module is used).

• The FireHawk M7XT Control Module turns on automatically

when the user opens the air mask cylinder valve. As the sys-

tem pressure reaches approximately 250 psi, both visible and

audible alarms activate automatically, indicating that the unit

is functional (audible alarms are emitted from the FireHawk

M7XT Power Module located on the backplate). The unit

remains in monitor mode until the user closes the cylinder

valve, purges the system pressure, and presses the reset but-

ton (yellow) on the side of the FireHawk M7XT Control

Module two times within approximately one second.

• While the air mask is in use, if the user is motionless for