FIRETRACE FTILPINTHTBI User manual

Operating Manual:

Firetrace®Indirect Low

Pressure Integrated High

Throughput Bi-Directional

Fire Suppression System for

Engine Compartment

Please read this manual thoroughly before carrying out the

installation of this system

Firetrace®systems shall only be installed by trained engineers

FIRETRACE

AUTOMATIC FIRE SUPPRESSION SYSTEMS

LTD

®

Page | 1

CONTENTS

Section Description PAGE

1 Introduction________________________________________________ 2

Safety Precautions___________________________________________ 2

2 System overview____________________________________________ 3-4

ABC Dry Chemical Extinguishing Agent___________________________ 4

3 System Design and Limitations_________________________________ 5

Storage and Operating Temperatures________________________ 5

System Operating Pressure________________________________ 5

Nozzle and Discharge Pipe Requirements_____________________ 6

Discharge Piping and Fitting Specifications____________________ 6

Firetrace Detection/Actuating/Discharge Tubing_______________ 6

4 Firetrace Installation Instructions________________________________ 7

Cylinder/Valve and Bracket Assemblies_______________________ 7

Discharge Piping and Nozzles_______________________________ 8

Discharge Line Tees and Angles_____________________________ 8

Firetrace Detection/Actuation/Discharge Tubing_______________ 9-10

Connecting the Firetrace® Tubing onto Fittings________________ 11

Commissioning Instructions________________________________ 12

5 Service and Maintenance Instructions_____________________________ 13

Service and Maintenance for ABC Dry Chemical Systems__________13

Annual Servicing for FTILPINTHBIV Systems____________________ 13

6 System Component List________________________________________ 14

Detection Line Parts List___________________________________ 15

Discharge Line Parts List___________________________________ 16

Page | 2

1 - Introduction

This manual is written for the fire protection professional that designs, installs and maintains Firetrace Ltd Indirect

Low Pressure Integrated High-Throughput Bi-Directional system, this system must be designed, installed,

inspected, tested, maintained, and recharged by a competent and trained engineer.

Safety Precautions

The following safety precautions must always be followed

•Read and understand this Manual and the other documents referenced herein.

•The valve discharge ports must be sealed with the plugs provided at all times and only removed when the

system is connected into the discharge pipeline.

•PPE suitable to the local environment shall be worn when installing a Firetrace® System. Wear safety

glasses when working with pressurised cylinders and charging equipment.

•Make sure the Integrated Ball Valve (accessed by removing the top gauge of the cylinder valve) is in the

closed (horizontal) position, the safety caps have been installed, and the detection tubing has been

removed from the cylinder valve, before removing the cylinder from the installation and before

performing any servicing, leak tests or system changing.

•Follow all the safety procedures included on the cylinder labels and within this manual.

•Never assume that a cylinder is empty. Treat all cylinders as if they are fully charged.

Any questions concerning the information contained within this manual shall be addressed to:

Firetrace® Ltd

Unit 22-24 Knightsdale Road

Ipswich

Suffolk

IP1 4JJ

Telephone: 01473 744090

Fax: 01473 744901

Page | 3

2 - System Overview

The Firetrace Indirect Low Pressure Integrated High Throughput Bi-Directional (FTILPINTHTBI) Fire Suppression System

is designed for local applications within engine areas using ABC Dry Powder. In addition to the main engine

compartment the system can also be extended to cover adjacent battery / hydraulic compartments

Other Firetrace systems are available for the bespoke protection of remote electrical voids.

The System uses linear heat detection tubing that can detect a fire, or a temperature above that of normal operation.

The tubing offers detection along its entire length ensuring fast and accurate activation throughout the risk areas. In

addition to the discharge nozzles the Firetrace system also uses patented “bi-directional” technology. This means that

a percentage of the extinguishant is deployed directly from the activation burst hole ensuring that it immediately

tackles the source of ignition. This unique function provides the ability to protect small or concealed areas without

the need for additional diffusers.

Using high quality ABC Dry powder, the system is compatible with all potential fire classes including, diesel, electrical,

Hybrid, Hydrogen and CNG.

The Firetrace system is designed to cover all principal risk areas within the engine compartment and the nozzle

placement ensures that extinguishant is deployed over all identified hazards. The additional benefit of deployment

from the tubing burst means that all areas are covered even if they were not initially identified as a primary risk.

The Firetrace system operates pneumatically and does not require energy from the vehicle nor operator to operate.

Each installed system is equipped with detection tubing, discharge piping, and nozzles. The pre-designed concept

minimizes the amount of engineering involved in the application design. When the discharge piping and nozzles are

installed within the limitations stated in this Manual, no hydraulic calculations are required to determine pressure

drop, agent flow, or discharge time.

The hazard being protected can be any size, shape, or volume provided that the hazard being protected is within the

limitations described in this Manual. When installed, each extinguisher is a self-contained unit, meaning that it is

equipped with its own automatic (non-electric) detection system. This system, when actuated, automatically releases

the suppression agent into the hazard area.

These extinguisher units can be combined to protect a larger size hazard, and can be simultaneously actuated or a

delayed discharge can be incorporated.

Upon actuation, an optional pressure switch can be used to indicate discharge, shutdown ventilation, close all

openings, shut-off electrical power, etc. as may be required.

Dry powder is stored in a steel cylinder pressurized with nitrogen to 12bar at 21°C (174psig at 68°F). Each cylinder is

equipped with a straight dip tube and must only be mounted in a vertical (upright) position.

Each cylinder is equipped with a plated brass valve, a pressure gauge to monitor cylinder pressure, an integrated

quarter turn ball valve with pressure gauge to monitor Firetrace® tubing pressure with an optional status indicator

module (SIMI). The integrated ball valve must be kept in closed position at all times when the cylinder is not in service.

The system utilizes Firetrace flexible tubing that is attached to the top of the cylinder valve. This tubing is pressurised

with nitrogen to maintain the cylinder valve in the closed position. This tubing acts as a continuous linear thermal

detector that ruptures to create a diffuser upon direct flame impingement or at high temperatures associated with

fire conditions. Once the detection tubing is ruptured, the cylinder valve automatically opens, allowing the dry powder

to flow through the discharge piping and through the Firetrace tubing, distributing the extinguishing agent through

the nozzles into the protected area.

Page | 4

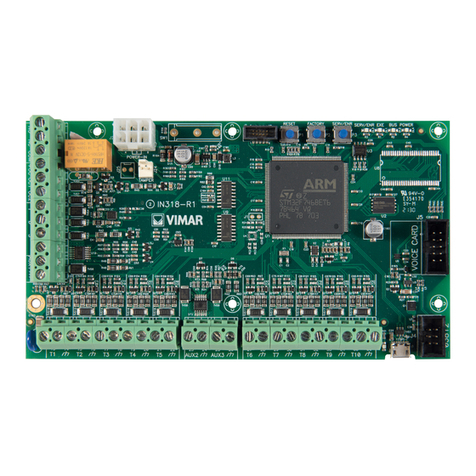

Firetrace® FTILPINTHTBI Systems consist of the following major components:

1. Cylinder/Valve Assembly

2. Cylinder Mounting Bracket

3. Firetrace detection/actuating/discharge tubing and fittings

4. Discharge Nozzles

5. Pressure Switch (Optional)

6. Discharge piping and Fittings

For a more comprehensive list of technical illustrations and part numbers, please see section 6.

ABC Dry Powder Extinguishing Agent

ABC dry powder has been treated to be water repellent and capable of being fluidized and free flowing so that it can

be discharged through hoses and piping under the influence of an expellant gas. When discharged, dry powder will

drift through the air and settle on surrounding surfaces.

Following a discharge, the exposed areas must be cleaned off within 24 hours. Dry powder can be cleaned up by one

of the following methods; wiping, vacuuming, blowing off with an airline or pressure washing the exposed areas. In

some cases, the powder can be scraped off a surface if that surface was hot at the time of discharge.

For hazard information, decomposition information, and physical properties of ABC Powder please refer to the

Material Safety Data sheet included with this manual.

Agent Discharges via

Separate Nozzles

A Percentage of Agent

Discharges via Detection Tubing

Figure 1: System Overview Diagram

Page | 5

3 - System Design and Limitations

The FTILPINTHTBI Fire Suppression System design limitations were established and tested by Firetrace Ltd. The units

are certified by SP Technical Institute of Sweden.

These units were subjected to numerous performance tests to verify their suitability and to establish design limitations

for:

7. Hazard Volume

8. Operating Temperature Range

9. Nozzle Placement

10. Nozzle Quantity

11. Maximum Length/Size of Piping and Number of Fittings

Firetrace systems are pre-designed to minimise the amount on engineering required when evaluating a design for

specific application. As long the discharge piping, nozzles and Firetrace tubing is installed within the limits prescribed

in this manual then no further calculations are required for pressure drop, flow rates, or discharge time. When any

additional limitations to hazard volume, area coverage, maximum height, design concentration, agent quantity,

detector arrangement, etc., are also met, the system installation can be understood to comply with the design

requirements. Therefore, no discharge tests or concentration measurements should be required.

Storage and Operating Temperatures

Firetrace® cylinders are designed to be stored and operated at the ambient temperature range of

-20°C and +60°C (-4°F and +140°F)

System Operating Pressure

The normal operating pressure for Firetrace® Systems is 12bar at 20°C (174psig at 68°F).

All Firetrace® systems are designed for an operating temperature range of -20°C to +60°C. Table 1 shows the cylinder

gauge pressure-temperature relationship based on a charging pressure of 12bar at 20°C.

Cylinder Pressure

°C

°F

bar

psig

-20

-4

10.2

148.2

-10

14

10.6

154.7

0

32

11.1

161.1

10

50

11.5

167.5

20

68

12

174

30

86

12.4

180.4

40

104

12.9

186.9

50

122

13.3

193.3

60

140

13.8

199.8

Table 1: Cylinder Pressure-Temperature Relationship

Page | 6

Nozzle and Discharge Pipe Requirements

Specially designed High Throughput Powder Diffusers are used with the FTILPINTHTBI System, this type of nozzle

decreases discharge time and increases the spread of dry powder. The baseline engine compartment must be

designed using at least 3 nozzles to suit hazard configuration of a 4m3 engine compartment.

A standard nozzle layout would include nozzles being installed at the top of the engine compartment roof facing

downwards in a pendant position. One nozzle shall be located above the exhaust manifold in the region where oil is

most likely to spill. Another nozzle shall be in the region of prominent hazards.

Each cylinder valve is equipped with 3 discharge ports (DP). All three discharge ports are to be used onto the engine

compartment.

Discharge Piping Specifications

FTILPINTHTBI Systems shall use flexible discharge hoses for the ABC Dry Chemical distribution system. The following

tubing shall be used;

Hose

Fittings

Nominal

Braid

Dia(mm)

Nominal

Hose

O.D.(mm)

Max. Working

Pressure

Min Burst

Pressure

Min. Bend

Radius

Weight

Kg/m

Bar

PSI

Bar

PSI

mm

IN”

3/8”

15.3

17.4

180

2610

720

10440

130

5.118

0.337

Liner: Synthetic oil resistant rubber

Reinforcement: One high tensile steel wire braid

Cover: Anti-Abrasive synthetic rubber, resistant to oils, fuels and atmospheric conditions

Working Temp: -40°C to 135°C (-40°F to 275°F)

Intermittent Temp: 40°C to 140°C (-40°F to 284°F)

Firetrace Detection/Actuating/Discharge Tubing

For the FTILPINTHTBI System, the Firetrace® tubing is used as a combination for heat detection, system activation

and system discharge.

The detection/actuation/discharge tubing is heat sensitive and in a fire situation is designed to rupture at any point

along the tube upon direct flame impingement or at high temperatures associated with fire conditions. The Firetrace®

detection tubing will burst when subjected to temperatures above 120°C (248°F) and form a diffuser where a

percentage of the Dry powder will be deployed.

The maximum length of Firetrace® detection tubing that can be used for FTILPINTHTBI Systems is 20m.

Page | 7

4 - Firetrace Installation Instructions

This section provides installation instructions covering components and limitations described in Section 2 and Section

3 of this manual.

All components shall be installed to facilitate proper inspection, testing, recharging, and any other required service or

maintenance as may be necessary. Equipment must not be subjected to severe weather conditions or mechanical,

chemical, or other damage which could render the equipment inoperative. The equipment must be installed in

accordance with instructions in this Manual.

Cylinder/Valve and Bracket Assemblies

Cylinders shall be located as close as possible to the protected enclosure. In some cases, the cylinder can be mounted

inside the protected enclosure. The assemblies shall be located in a readily accessible location to allow for ease of

inspection, service, and maintenance. The cylinders shall be located in an environment protected from the weather

and where the temperature range is between -20°C and +60°C (-4°F and +140°F).

The cylinder and bracket shall be mounted in the vertical plane and in no circumstance, must the cylinder be

positioned at an angle of more than 45° from vertical. The cylinder valve must be facing up and oriented so that the

pressure gauge is facing out and away from the mounting wall to facilitate visual inspection.

Mount the cylinder where it will not be subjected to accidental damage or movement. Suitable protection must be

installed where necessary to prevent damage or movement.

1. Securely mount the cylinder bracket to structural support using 4 or more mounting holes.

2. Position the cylinder in the bracket with the cylinder pressure gauge facing out. Secure the cylinder in

place using the bracket latch.

45°

It is recommended wherever possible that

Firetrace cylinders be mounted vertically.

Where vertical positioning is not possible the

system can be mounted within 45° of vertical.

Firetrace Dry Powder Systems are not suitable for horizontal mounting

Page | 8

Discharge Piping and Nozzles

1. It is advised that a risk assessment is be carried out to determine appropriate discharge pipework and

nozzle positioning.

2. Locate the nozzle(s) placement once a risk assessment has been carried out, ensuring design is within

limitations and guidelines described in section 3.

3. Determine the routing of the discharge piping and verify that the pipe length from each discharge port

does not exceed limitations and guidelines described in section 3.

4. Remove the safety fittings from the valve discharge ports as required. Secure the male 3/8 BSP fittings

into each discharge port.

5. Install the discharge piping and fittings between the cylinder and nozzle(s). Secure pipework with the

appropriate fittings as required.

For a more comprehensive list of Discharge Pipe Fittings, refer to section 6

Discharge Line Tees and Angles

Changes in direction of flow cause separation of expellant gas and dry chemical. To provide proper distribution of dry

chemical when using a tee fitting special attention must be given to the method in which an approach is made after a

change in direction. A single tee fitting shall be used per discharge piping.

Page | 9

Firetrace® Detection/Actuation/Discharge Tubing

The Firetrace® Automatic Detection tubing is the key part of the system and acts not only as the detector, actuator

but also as the delivery method for a percentage of the ABC Powder.

The correct installation of the tubing is important to achieve optimum performance from the system. The tubing must

be mechanically protected outside the identified risk area and shall remain accessible to allow future servicing.

The tubing will activate at approximately 120°C and care must be taken to avoid attaching the tubing where

temperatures above this are achieved during normal operation. It is recommended that the tube is a minimum of

150mm away from exceptionally hot surfaces or fitted with additional protection to avoid false activation.

The tubing shall be placed as close as possible to high risk areas as long as they do not reach ambient temperature

higher than 120°C (248°F). For example, a minimum distance from a turbo charger shall be 150mm (6 inches) to

avoid premature tubing activation. See diagram below for a Firetrace detection tubing installation example.

CAUTIO

•The Firetrace® detection tubing needs to be adequately fixed to retain its position.

•The tubing is a soft polymer and is susceptible to wear / chaffing when repeatedly rubbed against a hard or

sharp surface.

•The tubing shall be protected using nylon Kopex at all fixing points and where it passes through holes.

•The Firetrace® tubing acts as the detector, actuator and provides delivery for a percentage of the

extinguishant. It is imperative that the tubing is not kinked or crushed and the above minimum bending

radius must be adhered to.

•If the tubing is kinked or damaged in anyway then the Firetrace® tubing in that section must be replaced.

Figure 5: Minimum and Optimum Bend Radius

Minimum Bend Radius

80mm

Optimum Bend Radius

150mm

Page | 10

•It is important that the detection tubing is exposed within the risk area. Kopex or other conduit sleeves shall

be kept to a minimum length (approx. 15mm (0.6”) either side of fixings) or where the tubing comes into

contact with other surfaces.

•Always leave a small loop of tubing to the cylinder. Whilst this shall also be secured it must be releasable to

allow future servicing of the cylinder.

•It is important that fixings are not concealed as access is required during future servicing. When systems are

installed during construction of the vehicle care should be taken not to fix the tubing anywhere that will not

be accessible following installation of the engine & body parts.

The following models show both “Tyrap” and “P clip” methods of fixing all of which are acceptable:

8mm Firetrace Tubing shall be supported at maximum intervals of 200mm

When the tubing is installed with a group of other cables/pipes it must be positioned on the underside of the loom

and must never be located within the centre of the loom

Page | 11

Connecting the Firetrace® Tubing to fittings

All compression fittings must be secured in the following manner.

a) Cut the tube end ensuring the cut is clean and free from burrs. Check that no debris or swarf has been left

in the tube.

b) Place the nut over the end of the tube with its threaded section towards the end you wish to create the

flare on.

c) Push the tube firmly over the flaring tool ensuring the end of the tube bottoms. Be careful not to kink the

tube during this process.

d) The nut shall be tightened finger tight and then using an appropriate spanner tightened firmly using only

your hands, over tightening can crush the flare.

e) Slacken off the assembly and inspect the end to ensure flare has formed correctly, this flare can now be

used to connect the tube to the system

Method used to create Flare

1. Tubing must be cut square.

The use of a Tube Cutter (Part Number: FT0127) is recommended to achieve an accurate cut

2. Insert tubing through the spring nut/nut.

3. Offer the tubing to the flaring tool, so that the end of the tube stops against the face of the flaring tool,

tighten the nut hand tight.

4. Whilst holding the flaring tool handle, use an appropriate size spanner (14mm spanner for 8mm tube)

tighten the nut spanner tight, the recommended torque is 5.7nm.

5. Undo the nut and inspect the end to ensure the flare has formed correctly. The tubing is now ready to be

connected to the system.

Visual representation of ideal flare.

For a more comprehensive list of Firetrace® Tube Fittings, refer to section 6

Page | 12

Commissioning Instructions.

Locate cylinder and firmly secure with the bracket provided as specified in section 4.

Install detection tubing, discharge pipework and any accessories according to the procedure in section 4.

Remove black transportation cap from the top of the cylinder. Connect the Firetrace® detection tubing to the

top of the cylinder valve, tighten spring nut/nut using the appropriate sized spanner then secure the Firetrace®

detection tube with appropriate methods of fastening.

Remove the gauge from the top section of the cylinder

valve, this reveals the integrated ballvalve which will

be in the off position (horizontal position).

A regulator and calibrated pressure gauge shall be

used to pressurise the detection tubing with dry

nitrogen through the filling adapter (FT0172),

pressurise to 12bar (174psi)

It is recommended to have a portable dry nitrogen

cylinder or Firetrace Nitrogen Fill Kit (FSCK) for on-site

use.

Remove the filling adapter and thread the pressure gauge & o-ring into its place to verify that

the tubing is pressurised to at least 12bar (174psi)

(pressure may have to be adjusted for temperatures higher or lower than 20°C (68°F)).

Using tape, mark the location of the needle on the pressure gauge (High Green) and leave

system for a minimum of ten minutes per metre of Trace detection tube.

In the event of a leak go back to section 4 and check the installation of all fittings and

accessories

If the ball valve is opened abruptly, activation of the cylinder valve may occur, causing the system to discharge.

After confirming that there is no leakage within the detection tubing, remove the gauge from the top section of

the cylinder valve and using the key provided SLOWLY rotate the ball valve counter clockwise to the “ON”

position (vertical position)

The system is now live

An optional Pressure Switch Adapter can be fitted in either gauge adapters otherwise the gauges can be

returned.

Please note that the system will not operate with the isolator valve in the closed position, an optional status

indicator module (FTSIMI) can be used to determine whether the valve is isolated or activated.

Page | 13

Service and Maintenance for ABC Dry Chemical Systems

The Firetrace® systems can operate in a harsh environment and are occasionally subjected to high temperatures and

extreme vibration. It is essential that the systems are regularly serviced to ensure their correct operation.

To comply with British Standard BS 5306 (section three) the following maintenance tasks shall be carried out

periodically.

The British standard recommends that each system is visually inspected every 3 months and then fully serviced at a

maximum interval as specified by the manufacturer.

All ABC Dry Powder systems require discharge testing at maximum 5 year intervals.

The following checks shall be carried out on a 3 month inspection.

•Check the pressure gauge is reading high-green.

•Ensure physical changes of protected areas haven’t affected cylinder suitability.

•Check external surface of the cylinder for evidence of rust or corrosion

•Report any potential problems immediately.

In the event of activation of the system, a replacement should be obtained from Firetrace® Ltd

Firetrace® Ltd recommends a visual inspection of a Firetrace® system at least every three months.

Firetrace Ltd recommends that all powder systems are fully serviced every

6 Months by a competent engineer.

If there’s no visible sign of pressure drop then;

✓Check date of manufacture and record when discharge test is required (5 years from new date on cylinder).

✓Check external condition of cylinder. Replace if there is any sign of damage or wear.

✓Check gauge is facing upwards (if applicable) and that cylinder is installed as upright as possible. Where necessary

reposition cylinder, or highlight any required modifications for return visit.

✓Remove cylinder gauge and ensure correct operation. Clean and lubricate O ring and refit the gauge.

(Due to possible pressure seepage, the gauge must be replaced as soon as possible.)

✓Remove pressure switch (if applicable) and ensure correct operation. Clean and lubricate pressure switch O ring and

refit switch.

(Due to possible pressure seepage, the pressure switch must be replaced as soon as possible.)

✓Remove Cylinder from bracket and agitate powder contents. (Cylinder shall be inverted to achieve this. A noticeable

movement of the contents will be apparent. A rubber mallet can be utilised to achieve this.)

✓Inspect engine compartment and ensure Firetrace® detection tubing is correctly installed and protecting entire risk

area. Check for signs of wear/damage and tighten or replace fixings as necessary.

✓Record details and date of service on cylinder label. Replace cylinder into bracket and ensure it is secured by clamp /

Tyrap.

If there is notable sign of pressure drop then the system must be replaced

Page | 14

System Component List

ITEM NO.

PART NO.

DESCRIPTION

1

FTILPINTHBIV

Indirect Low Pressure High-Throughput

Integrated Bi-Directional Valve

2

FT0438/6-HT

Diptube High-Throughput 426mm White

3

FT0133-P

Steel Cylinder 6kg/Litre with ABC Powder

4

FT0150

6kg Bracket with Stainless Steel Strap

5

FTILPINTHTBI/8

ILP High-Throughput Bi-Directional M18x1 Plug

6

FT1511-8/6-1/8-S

1/8” BSP Fitting for 8mm

7

FT0322/8

Plastic Black Cap for 8mm

8

FTSIMI

Optional Status Indicator Module

1

2

3

4

8

5

6

7

Page | 15

Detection Line Parts List

PART NUMBER

DESCRIPTION

FT1511-8/6-1/8S

Male-Tube/Trace 8mm Trace 1/8” Male – 8mm Special

FT1723-8/6-SS

Anti-Kink Spring Nut 8mm Stainless Steel

FT0269/1/M

Banjo Tee Assembly for Valve Male

FT0118/8

End of Line –12bar 8mm (optional)

FT0253/8

8mm Blank/Stop End

FT0253/8

FT1511-8/6-1/8-S

FT1723-8/6-SS

FT0118/8

FT0269/1/M

Page | 16

Discharge Line Parts List

PART NUMBER

DESCRIPTION

FTILPINTHTBI/8

ILP High-Throughput Bi-Directional M18x1 Plug

FT0284/HT

High-Throughput Diffuser 3/8” BSP

FTILPINTHTBI/11

ILP High-Throughput Bi-Directional Valve M18x1 –3/8” Adapter

FT0260/11

1m 3/8” Flexi Hose 90° Female to Straight Female

FT0260/12

3m 3/8” Flexi Hose 90° Female to Straight Female

FT0260/13

4m 3/8” Flexi Hose 90° Female to Straight Female

FT1210-10

3/8” Tee 10mm 10mm-10mm

FT1210-10

FTILPINTHTBI/8

FTILPINTHTBI/11

FT0284/HT

FT0260/11 - FT0260/12 - FT0260/13

Page | 17

Page | 18

Page | 19

Table of contents

Popular Security System manuals by other brands

ERA

ERA Protect quick start guide

Assistive Technology Services

Assistive Technology Services SERVICE ANIMAL ALERT manual

Gamewell

Gamewell E3 Series manual

Recognition Systems

Recognition Systems HandKey II Installation and operation manual

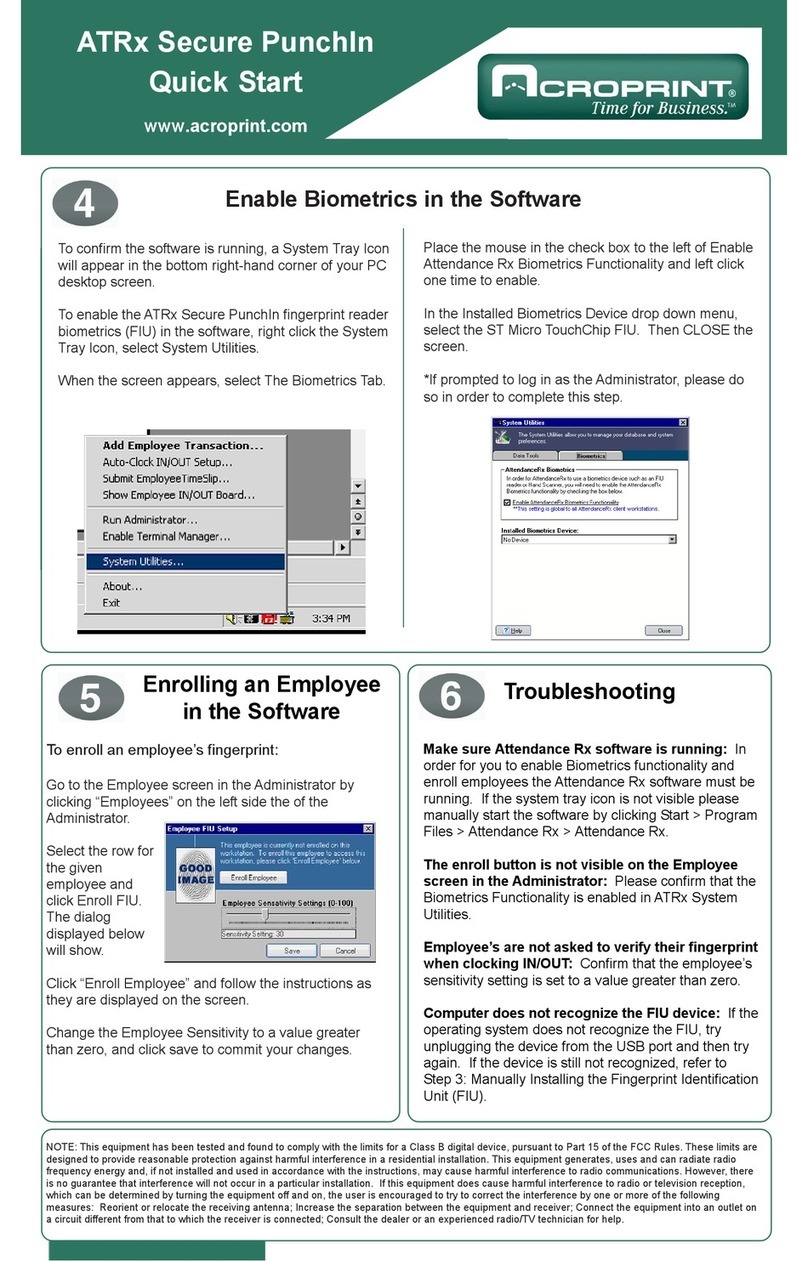

Acroprint

Acroprint ATRx Secure PunchIn quick start guide

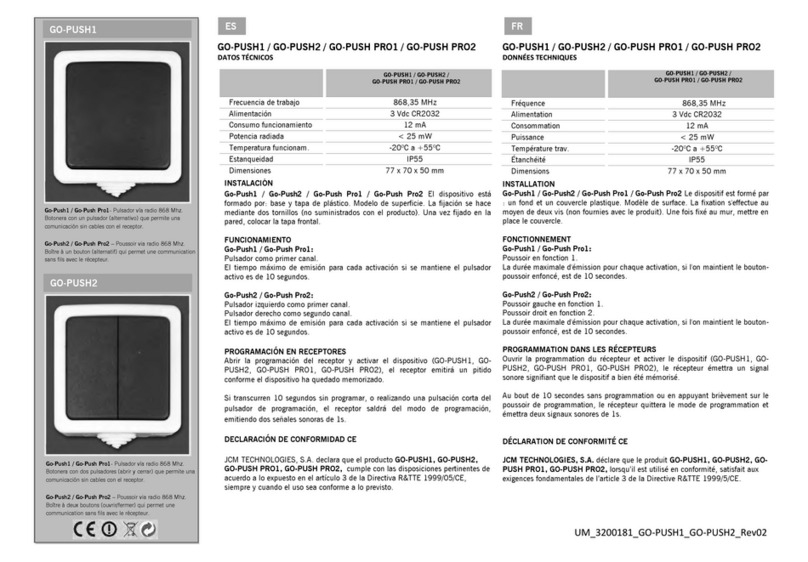

JCM Technologies

JCM Technologies GO-PUSH1 manual