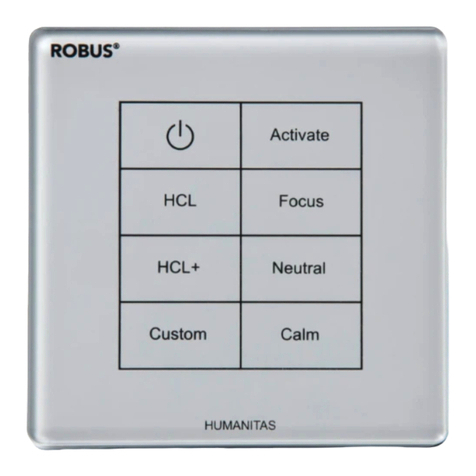

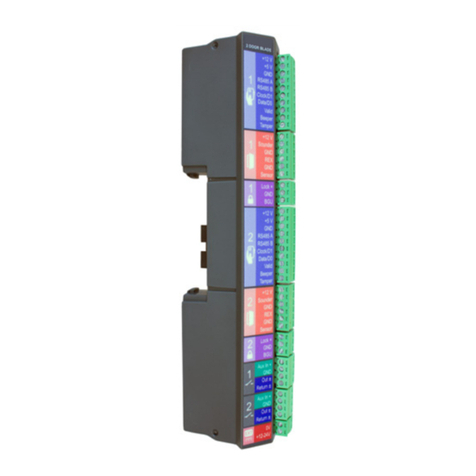

Keypad Programming Procedure

A. Apply power to the controller and turn ON the door mounted disconnect. If the con-

troller is in OFF mode, the display screen will alternate between showing “OFF” and the

incoming pressure along with a red ON/OFF LED on the upper right-hand corner of the

keypad. (If “0000” is shown, then the controller does not see any incoming pressure.)

If the controller is in automatic mode, the ON/OFF LED on the upper right-hand corner

of the keypad will be green and a constant pressure reading shown on the display

screen.

B. Press and hold the Enter Pushbutton for about five seconds (the 3 LED’s to the right of

the display should be flashing). This accesses the programmable settings. First shown

will be “Cu.Ou”. Press the Enter Pushbutton again and a number will be shown. This is

the Stop Pressure point. Use the up or down (+ or -) buttons to select the desired Stop

Pressure point. The longer a button is kept pressed, the faster the displayed number

will change. Once completed, press Enter again. “Cu.Ou” will be shown.

C. Press the right arrow pushbutton once. Now, “Cu.In” will be shown. Press the Enter

Pushbutton and a number will be shown. This is the Start Pressure point. Use the up or

down (+ or -) buttons to select the desired Start Pressure point. The longer a button

is kept pressed, the faster the displayed number will change. Once completed, press

Enter again. “Cu.In” will be shown.

D. Press the right arrow pushbutton once. Now, “Unit” will be shown. The default setting

for the unit of pressure measurement is PSI. If another unit of measurement is desired

(available choices listed above), press the Enter button. Then, use the up or down (+

or -) buttons to select the desired unit of pressure measurement and then press the

Enter button. “Unit” will be shown.

E. Press the right arrow pushbutton once. Now, “t.OFF” will be shown. As described above,

this is the Stop Delay timer. Default setting is 0 seconds. If a Stop Delay is desired,

press the Enter button. Then, use the up or down (+ or -) buttons to select the desired

number of seconds and press the Enter button. “t.OFF” will be shown.

F. Press the right arrow pushbutton once. Now, “t.On” will be shown. As described above,

this is the Start Delay timer. Default setting is 0 seconds. If a Start Delay is desired,

press the Enter button. Then, use the up or down (+ or -) buttons to select the desired

number of seconds and press the Enter button. “t.On” will be shown.

G. Press the right arrow pushbutton once. Now, “Cu.Ou” will be shown and programming

is complete then press and hold the ON/OFF Pushbutton for about two seconds. The

ON/OFF LED on the upper right-hand corner of the keypad should be green and a con-

stant pressure reading should be shown on the display screen.

H. The controller is now ready for automatic operation.

7