IM 05P08D81-11EN page 1/4

Contents

1. Safety Precautions

2. ModelandSuxCodes

3. How to Install

4. HardwareSpecications

5. HowtoConnectWires

6. TerminalWiringDiagrams

7. Setup Procedure

8. Operations

9. Troubleshooting

Introduction

ThankyouforpurchasingtheUT32A-D/MDLController.(TheUT32A-Dwithoption

/MDLhasnodisplay.)

Thisoperationguidedescribestheinstalling,wirings,setupow,andtroubleshooting

oftheUT32A-D/MDL.Theguideshouldbeprovidedtotheenduserofthisproduct.

Besuretoreadthisoperationguidebeforeusingtheproduct in ordertoensure

correctoperation.Fordetailsofeachfunction,refertotheelectronicmanual.Before

usingtheproduct,refertothetableofModelandSuxCodestomakesurethatthe

deliveredproduct isconsistentwiththemodelandsuxcodes youordered.Also

makesurethatthefollowingitemsareincludedinthepackage.

•DigitalIndicatingController(themodelyouordered)..............................x1

•UnitLabel(L4502VZ) ..............................................................................x1

•TagLabel(L4502VE) ..............................................................................x1

(Onlywhenordered.)

•OperationGuide(thisdocument) ............................................................x2(A3size)

(InstallationandWiring,InitialSettings,Operations,andParameters)

l

TargetReaders

Thisguideisintendedforthefollowingpersonnel;

• Engineersresponsibleforinstallation,wiring,andmaintenanceoftheequipment.

• Personnelresponsiblefornormaldailyoperationoftheequipment.

1. Safety Precautions

Thefollowingsymbolisusedontheinstrument.Itindicatesthepossibilityofinjury

totheuseror damage to the instrument, and signies that the user must refer to the

operationguide or user’smanualforspecialinstructions.Thesamesymbol is usedin

theoperationguideanduser’smanualonpagesthattheuserneedstoreferto,together

withtheterm“WARNING”or“CAUTION.”

Calls attention to actions or conditions that could cause serious

or fatal injury to the user, and indicates precautions that should be

taken to prevent such occurrences.

Calls attention to actions or conditions that could cause injury to

the user or damage to the instrument or property and indicates pre-

cautions that should be taken to prevent such occurrences.

Theequipmentwhollyprotectedbydoubleinsulationorreinforcedinsulation.

Functionalgroundingterminals

(Donotusethisterminalasaprotectivegroundingterminal).

Note

Identiesimportantinformationrequiredtooperatetheinstrument.

■Warning and Disclaimer

(1) YOKOGAWA makesnowarranties regardingtheproduct exceptthosestatedin

theWARRANTYthatisprovidedseparately.

(2) Theproductisprovidedonan"asis"basis.YOKOGAWAassumesnoliabilityto

anyperson or entityforanylossordamage,director indirect,arisingfromthe

use of the product or from any unpredictable defect of the product.

■ Safety,Protection,andModicationoftheProduct

(1)Inordertoprotectthesystem controlled by this product and theproductitself,

andtoensure safe operation,observethesafetyprecautionsdescribedinthe

operationguide.Useofthe instrument in a manner notprescribedhereinmay

compromise the product's functions and the protection features inherent in the

device.Weassumenoliabilityforsafety,orresponsibilityfortheproduct'squality,

performanceorfunctionalityshouldusersfailtoobservetheseinstructionswhen

operatingtheproduct.

(2)Installationofprotectionand/orsafetycircuitswithrespecttoalightning

protector;protectiveequipmentforthesystemcontrolledbytheproductandthe

productitself;foolprooforfail-safedesignofaprocessorlineusingthesystem

controlledbytheproductortheproductitself;and/orthedesignandinstallation

ofotherprotectiveandsafetycircuitsaretobeappropriatelyimplementedasthe

customer deems necessary.

(3) Be sureto usethe spareparts approvedby YOKOGAWA whenreplacing parts

or consumables.

(4) This productis notdesigned ormanufactured to beused incritical applications

thatdirectly affectorthreatenhuman lives.Suchapplicationsincludenuclear

powerequipment,devices usingradioactivity,railwayfacilities, aviation

equipment,air navigationfacilities,aviationfacilities,andmedicalequipment.

Ifsoused, it is the user’sresponsibility to include in the system additional

equipmentanddevicesthatensurepersonnelsafety.

(5) Modicationoftheproductisstrictlyprohibited.

(6)

Thisproductisintendedtobehandledbyskilled/trainedpersonnelforelectricdevices.

(7)ThisproductisULRecognizedComponent.InordertocomplywithULstandards,

end-productsarenecessarytobedesignedbythosewhohaveknowledgeofthe

requirements.

l

Power Supply

Ensure that the instrument’s supply voltage matches the voltage

of the power supply before turning ON the power.

lDo Not Use in an Explosive Atmosphere

Do not operate the instrument in locations with combustible

or explosive gases or steam. Operation in such environments

constitutes an extreme safety hazard. Use of the instrument in

environments with high concentrations of corrosive gas (H2S,

SOX, etc.) for extended periods of time may cause a failure.

lDo Not Remove Internal Unit

The internal unit should not be removed by anyone other than

YOKOGAWA's service personnel. There are dangerous high voltage

parts inside. Additionally, do not replace the fuse by yourself.

lDamage to the Protective Construction

Operation of the instrument in a manner not specified in the

operation guide may damage its protective construction.

This instrument is an EMC class A product. In a domestic environ-

ment this product may cause radio interference in which case the

user needs to take adequate measures.

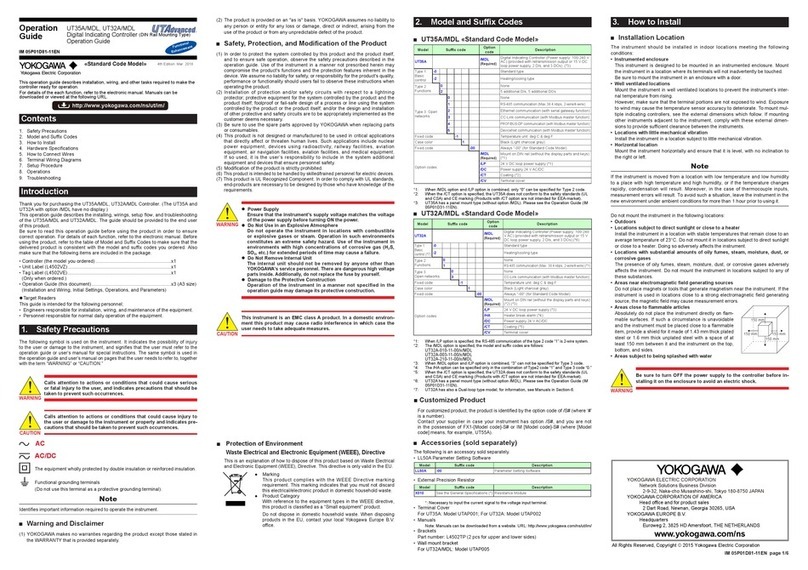

2. ModelandSuxCodes

■UT32A-D/MDL «Standard Code Model»

Model Suxcode Option

code Description

UT32A /MDL

(Required)

DigitalIndicatingController(Powersupply:100-240

VAC)(providedwith3DIs,and3DOs)(*2)

Type1:

Basic

control

-D Dual-looptype

Type2:

Functions 1

RS-485communication(Max.38.4kbps,2-wire/4-wire)

Type3:

Open networks 0None

Fixedcode -1

Temperatureunit:degC°F

Casecolor 1Black(Lightcharcoalgray)

Fixedcode -00 Always"-00"(forStandardCodeModel)

Option codes

/MDL

(Required)

MountonDINrail(withoutthedisplaypartsandkeys)

/DC Powersupply24VAC/DC

/CT Coating(*1)

/CV Terminalcover

*1: Whenthe/CToptionisspecified,theUT32Adoesnotconformtothesafetystandards(UL

andCSA)andCEmarking(Productswith/CToptionarenotintendedforEEA-market).

*2: UT32A-Dhasapanelmounttype(withoutoption/MDL).PleaseseetheOperationGuide

(IM05P08D31-11EN).

*ForinformationonotherModeltypes,seeManualsinSection-9.

■CustomizedProduct

Forcustomizedproduct,theproductisidentiedbytheoptioncodeof/S#(where‘#’

isanumber).

Contactyoursupplierincaseyourinstrumenthasoption/S#,andyouarenot

inthepossession of FX1-[Model code]-S# orIM[Modelcode]-S#(where[Model

code]means,forexample,UT55A).

■Accessories (sold separately)

Thefollowingisanaccessorysoldseparately.

• LL50AParameterSettingSoftware

Model Suxcode Description

LL50A -00 ParameterSettingSoftware

• ExternalPrecisionResistor

Model Suxcode Description

X010 SeetheGeneralSpecications(*) ResistanceModule

*:Necessarytoinputthecurrentsignaltothevoltageinputterminal.

• TerminalCover

ForUT32A:ModelUTAP002

• Manuals

Note:Manualscanbedownloadedfromawebsite.URL:http://www.yokogawa.com/ns/ut/im/

• Brackets

Partnumber:L4502TP(2pcsforupperandlowersides)

• Wallmountbracket

ForUT32A-D/MDL:ModelUTAP005

• Areasclosetoammablearticles

Absolutelydonot place the instrumentdirectlyonam-

mablesurfaces.Ifsuch a circumstance is unavoidable

andtheinstrumentmustbeplacedclosetoaammable

item,provideashieldforitmadeof1.43mmthickplated

steel or 1.6 mm thick unplated steel with a space of at

least150mmbetweenitandtheinstrumentonthetop,

bottom,andsides.

• Areas subject to being splashed with water

Be sure to turn OFF the power supply to the controller before in-

stalling it on the enclosure to avoid an electric shock.

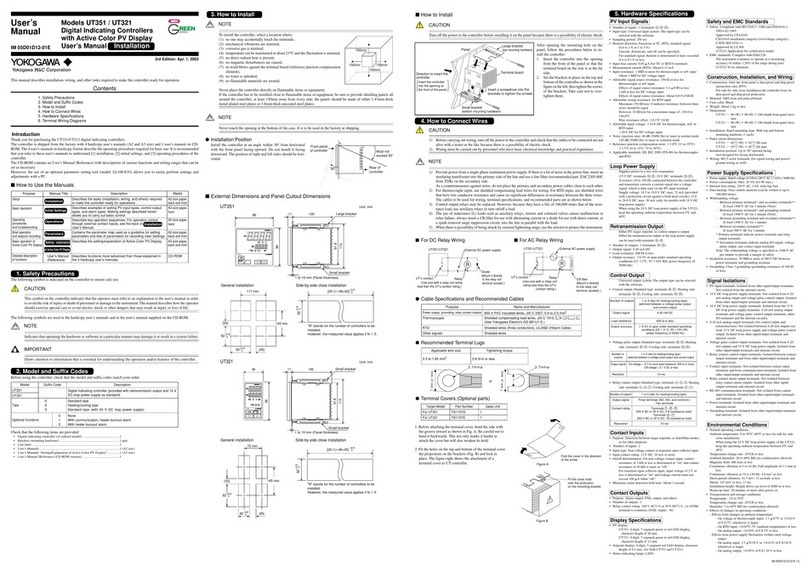

■Mounting on a DIN Rail

InserttheDIN rail into thetopareaofDINrailgroove(atonelocation)ontherear

panel,andsecureinplacewiththebottomslidelock.

DIN rail

DIN rail

Slide lock

Push

Make sure that foreign materials do not enter the inside of the in-

strument through the case’s slit holes.

■Removing from the DIN Rail

Insertaat-bladescrewdriver(guideline:100mmshaftlength,6mmbladewidth,0.8

mmbladethickness)intothebottomslidelockholeandpulldowntoreleasetheslide

lock.Whenslidelockisunlocked,theinstrumentcanberemovedfromtheDINrail.

Slide lock

Pull

Push up

DIN rail

150 mm150 mm

150 mm

150 mm

Operation

Guide

IM 05P08D81-11EN

UT32A-D/MDL

Digital Indicating Controller

(Dual-loop, DIN Rail Mounting Type)

Operation Guide

This operation guide describes installation, wiring, and other tasks required to make the

controller ready for operation.

4th Edition : Mar. 2018

«Standard Code Model»

For details of the each function, refer to the electronic manual. Manuals can be

downloaded or viewed at the following URL.

Functional

Enhancement

http://www.yokogawa.com/ns/ut/im/

www.yokogawa.com/ns

YOKOGAWA ELECTRIC CORPORATION

Network Solutions Business Division

2-9-32, Naka-cho Musashino-shi, Tokyo 180-8750 JAPAN

YOKOGAWA CORPORATION OF AMERICA

Head office and for product sales

2 Dart Road, Newnan, Georgia 30265, USA

YOKOGAWA EUROPE B.V.

Headquarters

Euroweg 2, 3825 HD Amersfoort, THE NETHERLANDS

All Rights Reserved, Copyright © 2015 Yokogawa Electric Corporation

■Protection of Environment

Waste Electrical and Electronic Equipment (WEEE), Directive

ThisisanexplanationofhowtodisposeofthisproductbasedonWasteElectrical

andElectronicEquipment(WEEE),Directive.ThisdirectiveisonlyvalidintheEU.

● Marking

ThisproductcomplieswiththeWEEEDirectivemarking

requirement.Thismarkingindicatesthatyoumustnotdiscard

thiselectrical/electronicproductindomestichouseholdwaste.

● ProductCategory

WithreferencetotheequipmenttypesintheWEEEdirective,

thisproductisclassiedasa“Smallequipment”product.

Donotdisposeindomestichouseholdwaste.Whendisposing

productsintheEU,contactyourlocalYokogawaEuropeB.V.oce.

3. How to Install

■Installation Location

Theinstrumentshould be installed in indoor locationsmeetingthefollowing

conditions:

• Instrumented enclosure

Thisinstrumentis designed to bemountedinaninstrumentedenclosure.Mount

theinstrumentinalocationwhereitsterminalswillnotinadvertentlybetouched.

Be sure to mount the instrument in an enclosure with a door.

• Well ventilated locations

Mounttheinstrumentinwellventilatedlocationstopreventtheinstrument’sinter-

naltemperaturefromrising.

However,makesurethattheterminalportionsarenotexposedtowind.Exposure

to wind may cause the temperature sensor accuracy to deteriorate. To mount mul-

tipleindicatingcontrollers,see the external dimensions which follow.Ifmounting

otherinstrumentsadjacenttotheinstrument,complywiththeseexternaldimen-

sionstoprovidesucientclearancebetweentheinstruments.

• Locations with little mechanical vibration

Installtheinstrumentinalocationsubjecttolittlemechanicalvibration.

• Horizontal location

Mounttheinstrumenthorizontallyandensurethatitislevel,withnoinclinationto

therightorleft.

Note

Ifthe instrumentismovedfromalocationwithlow temperatureandlowhumidity

toaplace with hightemperatureandhighhumidity,orifthetemperaturechanges

rapidly,condensation willresult.Moreover,inthecaseof thermocoupleinputs,

measurementerrorswillresult.Toavoidsuchasituation,leavetheinstrumentinthe

newenvironmentunderambientconditionsformorethan1hourpriortousingit.

Donotmounttheinstrumentinthefollowinglocations:

• Outdoors

• Locations subject to direct sunlight or close to a heater

Install the instrument in a location with stable temperatures that remain close to an

averagetemperatureof23°C.Donotmountitinlocationssubjecttodirectsunlight

orclosetoaheater.Doingsoadverselyaectstheinstrument.

• Locations with substantial amounts of oily fumes, steam, moisture, dust, or

corrosive gases

Thepresenceofoilyfumes,steam,moisture,dust,orcorrosivegasesadversely

aectstheinstrument.Donotmounttheinstrumentinlocationssubjecttoanyof

these substances.

• Areasnearelectromagneticeldgeneratingsources

Donotplacemagnetsortoolsthatgeneratemagnetismneartheinstrument.Ifthe

instrumentis usedinlocationsclosetoastrongelectromagneticeld generating

source,themagneticeldmaycausemeasurementerrors.