Firetrol FTA570F-AG003E Manual

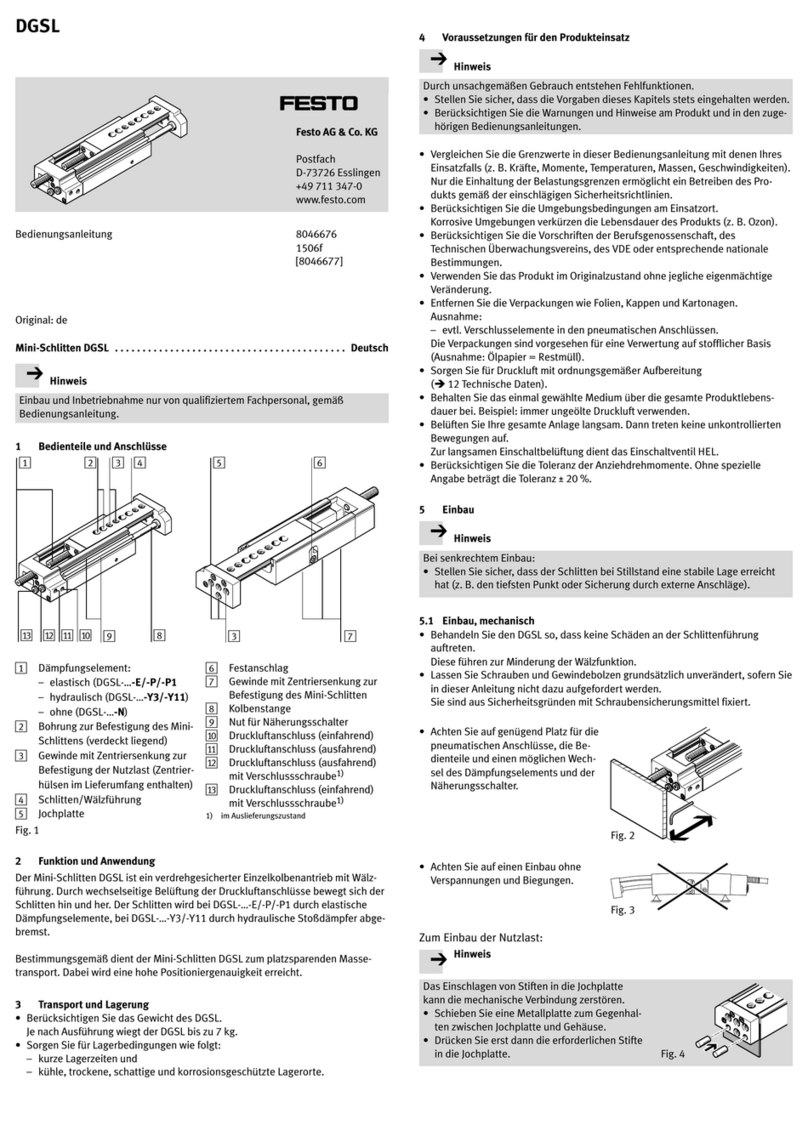

INSTALLATION AND MAINTENANCE MANUAL

FOR JOCKEY PUMP CONTROLLERS

V2023.07 NS570-01(A) 2

V2023.07 3

TABLE OF CONTENTS

Important Safety Information 4

Introduction 6

JockeyPumpCatalogNumber 6

TechnicalData 6

Storage 7

Installation 8

Seismic 8

Environment 8

Electromagneticcompatibility(EMC) 8

Handling 8

Mounting 8

Toolsandmaterialsrequired: 8

Procedure 9

MakingSystemPressureConnections 9

MakingElectricalConnections 9

ImportantPrecautions 9

Procedure 10

Operator Interface 11

Howtoconfigurethecontroller 12

MethodsofStarting/Stopping 12

Automaticmode 12

Manualmode 12

Offmode 12

Bumpforrotation 12

Commissioning 13

Maintenance 14

Patents 15

V2023.07 4

IMPORTANT SAFETY INFORMATION

DANGER

RISK OF

ELECTROCUTION

PERSONAL INJURY OR DEATH COULD OCCUR.

ENSURE ALL POWER IS DISCONNECTED BEFORE INSTALLING

OR SERVICING THIS EQUIPMENT.

DANGER

Do not attempt to install or perform maintenance on

equipment while it is energized! Death, personal injury

or substantial property damage may result from con-

tact with energized equipment. Always verify that no

voltage is present before proceeding and always fol-

low generally accepted safety procedures. Controller

disconnect switch must be in the “off” position in

order to open the enclosure door. Firetrol cannot be

liable for any misapplication or incorrect installation

of its products.

V2023.07 5

Warning:

This product can expose you to chemicals including

DINP, which is known to the State of California to

cause cancer, and DIDP which is known to the State of

California to cause birth defects or other reproductive

harm.

Warning:

This product can expose you to chemicals including

lead and lead compounds, which are know to the State

of California to cause cancer and birth defects or

other reproductive harm.

Formoreinformationgoto:www.P65Warnings.ca.gov

V2023.07 6

INTRODUCTION

FiretrolJockeyPumpControllersareintendedforusewithfirepumpsystems.Theyareusedfor

pressuremaintenanceinfirepumpinstallationstopreventunnecessarycyclingofthemainfire

pump.

TheyarelistedbyUnderwriters’Laboratories,Inc.,inaccordancewithUL508A,Standardfor

IndustrialControllers.Theyarebuilttomeetorexceedtherequirementsoftheapprovingauthor-

itiesaswellasNEMAandthelatesteditionNFPA70NationalElectricalCode.

TheyalsocomplywiththerequirementsoftheElectromagneticCompatibility(EMC)Directive

2014/30/EU,theLowVoltageDirective(LVD)2014/35/EU,theElectromagneticCompatibility

Regulations(2016No.1091)andTheElectricalEquipment(Safety)Regulations(2016No.1101).

Theseinstructionsareintendedtoassistintheunderstandingoftheinstallationandoperationof

thesecontrollers.Readtheinstructionsthoroughlypriortoconnectingoroperatingthecontroller.

Ifthereareanyunansweredquestions,pleasecontactthelocalFiretrolrepresentativeorthefact-

oryservicedepartment.

Jockey Pump Catalog Number

Model No. Example: FTA570F-AG003E

ModelPrefix:FTA570F

(A)TimerOption:Withprogrammabletimer

(G)MotorCurrentProtection:Manualmotorprotector

(E)Voltage:220-240V1-Phase50/60Hz

(003)HPRating:3HP

Technical Data

Rating Value

RatedOperationalCurrentIe AccordingtotheMotor(HP/kW)

RatedInsulationVoltageUi 690,600(IEC)

RatedOperationalVoltageUe 110/120,220/240,380/415,440/480,

575/600,690

RatedImpulseWithstandVoltageUimp 6000V

RatedOperationalFrequency 50/60Hz

Environmentaltemperature 4°Cto40°C(Optional-5°Cto55°C)

Altitude ≤2000m

Relativehumidity 5%to80%

Pollutiondegree 3

ShortCircuitCurrentRatingIcc(SCCR)(A) Accordingtothecontrollerratinglabel

RatedPeakWithstandCurrentIpk AccordingtoIEC61439-1:2020Table7

V2023.07 7

Storage

Ifthecontrollerisnotinstalledandenergizedimmediately,Firetrolrecommendfollowingthe

instructionsfromthechapter3oftheNEMAICS15standard.

V2023.07 8

INSTALLATION

Seismic

JockeyPumpcontrollersareoptionallyseismicapprovedandhasbeentestedinaccordancewith

theICC-ESAC156,IBC2015&CBC2013standards.Properinstallation,anchoringandmount-

ingisrequiredtovalidatethiscompliancereport.Refertothismanualanddrawingstodetermine

theseismicmountingrequirementsandlocationofthecenterofgravity(youmayneedtocontact

factory).Theequipmentmanufacturerisnotresponsibleforthespecificationandperformanceof

anchoragesystems.Thestructuralengineerofrecordontheprojectshallberesponsiblefor

anchoragedetails.Theequipmentinstallationcontractorshallberesponsibleforensuringthe

requirementsspecifiedbythestructuralengineerofrecordaresatisfied.Ifdetailedseismicinstall-

ationcalculationsarerequired,pleasecontactthemanufacturerfortheperformanceofthiswork.

Environment

JockeyPumpcontrollersareintendedtobeinstalledinlocationswhereambienttemperaturesare

within4°Cand40°Candtherelativehumidityiscontrolledbetween5%and80%.Optionally,the

controllercanhaveanextendedtemperatureofupto55°Candaslowas-5°C,providedthatthe

controllerandthepressurewaterpipesareheatedtopreventwaterfreezinganddamagingthe

electronicandthepipingsystem.

Theyareintendedforpollutiondegree3andshallbeinstalledatanaltitudeofnomorethan2000

meters.Forabnormalinstallationenvironment,consultfactory.

Electromagnetic compatibility (EMC)

JockeyPumpcontrollershavebeentestedforthemoststringentconditionsforemissions(Envir-

onmentB)andimmunity(EnvironmentA),hencecontrollerscanbeinstalledineitherenvir-

onment.Allcontrollersvariantssharethesameelectronicsandcomplytothosecriteriawithout

requiringadditionalmeasures.

Handling

TheweightofeachJockeyPumpcontrollerisindicatedonthepackinglabel.Lightweightcon-

trollersdonotrequirespecialhandlinginstructions,whileheavycontrollersareequippedwithlift-

ingmeansandshouldbehandledfollowingtheguidelinesspecifiedinFiretrol'sdocument"Large

EnclosureSafeHandlingRequirements_PN12162021".

Mounting

Consult the appropriate job plans to determine the controller mounting location.

Tools and materials required:

1. Assortmentofcommonhandtoolsofthetypeusedtoserviceelectromechanicalequip-

ment.

2. Drillfordrillingwallanchorholes.

3. Hole(conduit)punch.

V2023.07 9

4. Handlevel.

5. Tapemeasure.

6. Fouranchorswithboltsandwashers,perenclosure.

Procedure

Refer to the controller dimension drawing for necessary mounting dimensions.

Thecontrolleriswallmountedbyusingatleastfour(4)wallanchors,2anchorsforthetopmount-

ingbracketsand2anchorsforthebottommountingbrackets.Thebracketsaredimensionallyon

thesamecenterlineforeaseinmounting.Thereshouldbeaclearanceofatleast6inchesaround

thecontrollertoallowproperaircirculationaroundtheequipment.

1. Usingeitherthedimensionprintorbymeasuringthedistancebetweenthecenterlinesof

thelowerbracketslots,transcribethisdimensionontothewall.Note:Thebottomedgeof

theenclosureshouldbeaminimumof12”(305mm.)fromthefloorincasefloodingofthe

pumproomoccurs.

2. Drillandputanchorsintothewallforthelowermountingbrackets.

3. Markonthewall,thelocationoftheholesintheuppermountingbrackets.

4. Drillandputanchorsintowallfortheuppermountingbrackets.

5. Installboltsandwashersinloweranchors.

6. Alignholesinuppermountingbracketsandinstallboltsandwashersinanchors.

7. Shimanchorsasnecessarytoensurerearofenclosureisverticallevelandenclosureisnot

stressed.

8. Tightenallanchorbolts.

9. Checktobesureenclosuredooropenandclosesfreelyandthatenclosureislevel.

Making System Pressure Connections

Thecontrollerrequiresone(1)“SystemPressure”connectionfromthesystempipingtothe

enclosure.Theconnectionfitting,1/2”NPTmaleport,isprovidedonthebottom,externalsideof

theenclosureforthispurpose.RefertoNFPA20(orPublicationGF100-30)forcorrectfieldpiping

procedureofthesensinglinebetweenthepumpingsystemandthecontroller.

Making Electrical Connections

Important Precautions

Alicensedelectricianmustsupervisetheelectricalconnections.Thedimensiondrawingsshow

theareasuitableforincomingpowerandmotorconnections.Nootherlocationshallbeused.Only

watertighthubfittingsshallbeusedwhenenteringthecabinettopreservetheNEMAorIPrating

ofthecabinet.

The installer is responsible for adequate protection of the Jockey Pump controller

components against metallic debris or drilling chips. Failure to do so may cause

injuries to personnel, damage the controller and subsequently void warranty.

V2023.07 10

Priortomakinganyfieldconnections

1. Opendoorofenclosureandinspectinternalcomponentsandwiringforanysignsoffrayed

orloosewiresorothervisibledamage.

2. Verifythatthecontrollerinformationiswhatisrequiredontheproject:

1. Firetrolcatalognumber

2. Motorelectricalnameplateinformationmatchescontrollerratingforvoltage,fre-

quency,FLAandHP.

3. Project'selectricalcontractormustsupplyallnecessarywiringforfieldconnectionsin

accordancewiththeNationalElectricalCode,localelectricalcodeandanyotherauthority

havingjurisdiction.

4. Refertotheappropriatefieldconnectiondrawingforwiringinformation.

Procedure

Allfieldconnections,remotealarmfunctionsandACwiringarebroughtintotheenclosurethrough

thetoporbottomconduitentrancesasindicatedonthedimensionaldrawing.

Donotplaceconduitentrancesonthesidesoftheenclosure.

1. Usingahole(conduit)punch,createaholeintheenclosureforthesizeconduitbeingused.

2. Installnecessaryconduit.

3. Pullallwiresnecessaryforfieldconnections,remotealarmfunctions,ACpowerandall

otheroptionalfeatures.Bringenoughwireinsidetheenclosuretomakeupconnectionsto

theappropriateline,loadandcontrolterminalblockpoints.Besuretoconsulttheappro-

priatefieldconnectiondiagramincludedwiththemanual.Forproperwiresizing,refertothe

NationalElectricalCode,NFPA70.

4. Makeallfieldconnectionstotheremotealarmfunctionsandanyotheroptionalfeatures.

5. Connectmotortocontrollerloadterminals.

6. FindnameplateonJockeyPumpmotorandmakenoteofitsfullloadamprating.Veritythe

overloadwithinthecontrollerissetforthatnumberofamps.

7. VerifyAClinevoltage,phaseandfrequencywiththecontrollerdataplateontheenclosure

doorpriortoconnecting.

8. ConnectACpower.

9. Checktoseethatallconnectionsarebothcorrectlywired(inaccordancewiththefieldcon-

nectiondiagram)andtight.

10. Closetheenclosuredoor.

V2023.07 11

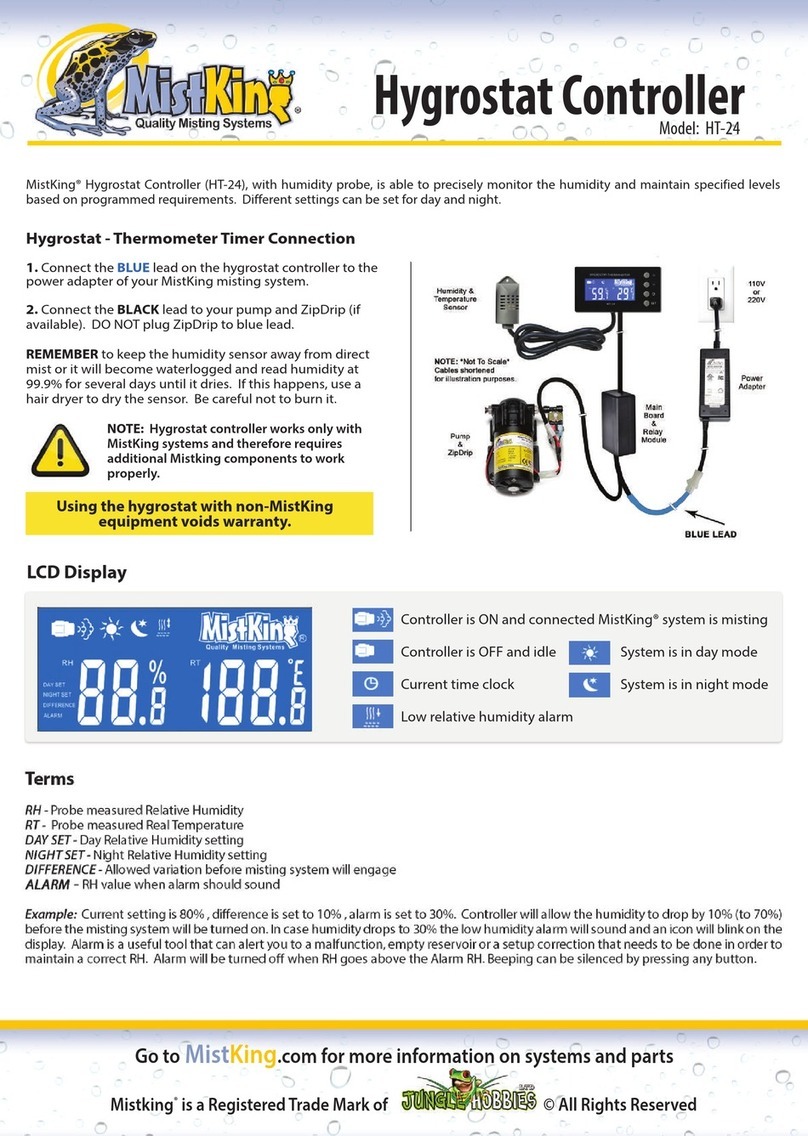

OPERATOR INTERFACE

1. LCDscreen

2. Hand-Off-Autoselector

3. Menunavigationbuttons.

1. Down/decreasevalue

2. Enterconfiguration/enter

3. Up/increasevalue

4. Left

5. Right

4. Integratedalarmbuzzer

5. Exitmenubutton

6. Silencebuzzerbutton

V2023.07 12

How to configure the controller

Toentertheconfiguration,presstheenterconfigurationbutton.Usetheupanddownbuttonsto

selectthevaluetoedit,thenpressenter.Usetheincreaseordecreasevaluebuttontoeditthe

value.Holdingthosebuttonswillchangethevaluewithanincreasedspeed.Oncesatisfiedwith

thevalue,presstheenterbutton.

Editeditemsarenotdirectlyappliedtothecontrollerandaremarkedonthescreenwithan

asterisc.Oncesatisfiedwithyournewvalues,exitthemenubyselectingthefirstmenulineand

pressingenter,or,alternativelypresstheexitmenubutton.Aconfirmationpopupwillappearask-

ingyoutoapplythenewvaluestothecontroller,select"yes"thenpressenter.Youmayaltern-

ativelydiscardallchangesmadebyselecting"no".

Methods of Starting/Stopping

Automatic mode

Whenthemodeselectorisinautomatic,thecontrollerwillstartautomaticallyonlowpressure

detectionbythepressuresensor(belowthecut-inthreshold).

Themotorisautomaticallystoppedaftertherestorationofthepressure(abovethecut-out

threshold),afteraprogrammablerunperiodtimer.

Manual mode

Whenthemodeselectorisinmanual,thecontrollerwillrunthemotorcontinuously.

Off mode

Whenthemodeselectorisinoff,themotorcannotbestartedandwillbestoppedifitwaspre-

viouslyrunning.

Bump for rotation

Successivelyapplyingmanualmodeandoffmodetothecontrollercanbeusedtobumpforthe

motorandcheckrotation.Iftherotationisincorrect,turnOFFpowerwiththedoormounteddis-

connect.Swapanytwoexistingmotorleadwiresthatareonthemotorcontactorinthecontroller

V2023.07 13

COMMISSIONING

1. Verify,andadjustifnecessary,themotoroverloadsetting.

2. Forthree-phasemotors,verifythemotorrotationbybumpingthemotor.Incaseofincorrect

rotation,power off the controllerandswaptwowiresatthecontactorloadside.

3. Entertheconfigurationmenuandinputtheappropriatevaluesfor

1. Pressureunitifrequired,intheAdvancedsubmenu;

2. Cut-out1;

3. Cut-in;

4. Timeron;

5. Timeroff.

4. Exittheconfigurationmenuandsavechanges.

5. Placethehand-off-autoselectorinauto.

1Cut-outisrequiredtobeatleast10PSImorethancut-invalueandshouldbeeditedfirst.

V2023.07 14

MAINTENANCE

Firetrolcontrollersarecoveredbyalimitedwarrantyandbackedbya10-yearsservicelifeoruntil

supplylast,providedthatproperinstallation,commissioning,useandmaintenanceofthecon-

trollerismadeasperthisdocumentandanymaintenancestandardapplicable.

Propercontrollerperformancemustbeassertedatleastonceamonthbyexecutingthefollowing:

1. Withthesystembeingatnominalpressure,ensurethatthepressurereadingiswithintol-

erances

2. Performamanualstartsequenceandverifythat

1. Thereisnonuisancetripping

2. Themotorstartsproperlyandisabletoacceleratewithintheexpectedtime

3. Themotorrotatesintheappropriatedirection

3. Performanautomaticstartsequenceandverifythat

1. Themotorstartswhenthepressurefallsbelowcut-in

2. Thepumpisabletorisethepressureabovethecut-out

3. Themotorstopswhenthepressureisabovecut-out,forautomaticstopsystems,or

byperformingamanualstopotherwise

Inadditiontotheabove,thefollowingpreventativemaintenancemustbeperformedatleastonce

year:

1. Turnoffthecontroller

2. Doavisualinspectionoftheexteriorofthecontroller

3. Opentheenclosureanddoavisualinspectionoftheinteriorofthecontroller

4. Makesurethatthereisnodustaccumulationinsidethecontroller

5. Inspectthetightnessofeachdeadcable

6. Putthecontrollerbackinservice

V2023.07 15

PATENTS

Country Title Grant NO

CA Mechanicalactivatorforcontactor 2741881

US Mechanicalactivatorforcontactor US8399788B2

CA Mechanicalactivatorforelectricalcontactor 165512

CA Mechanicalactivatorforelectricalcontactor 165514

US Mechanicalactivatorforelectricalcontactor D803794

US Mechanicalactivatorforelectricalcontactor Patentpending

EP Mechanicalactivatorforelectricalcontactor 002955393-0001/2

AE Mechanicalactivatorforelectricalcontactor Patentpending

AE Mechanicalactivatorforelectricalcontactor Patentpending

CA Firepumpdigitaloperator 163254

US Firepumpdigitaloperatorinterface D770313

AE Firepumpdigitaloperatorinterface Patentpending

EP Firepumpdigitaloperatorinterface 002937250-0001

CA Systemandmethodfordetectingfailureinapressure

sensorofafirepumpsystem

Patentpending

US Systemandmethodfordetectingfailureinapressure

sensorofafirepumpsystem

Patentpending

V2023.07 16

Contact Technical Support Sales

3362ApexPeakway

Apex,NC27502USA

+1-919-460-5200

Table of contents

Other Firetrol Controllers manuals

Firetrol

Firetrol FTA3100S Product manual

Firetrol

Firetrol FTA2000 Series Product manual

Firetrol

Firetrol Emerson Mark IIXG User manual

Firetrol

Firetrol Jockey XG FTA550 Installation instructions

Firetrol

Firetrol FTA740 Series Product manual

Firetrol

Firetrol FTA1100 Series Product manual

Firetrol

Firetrol FTA560F User manual