- 6 -

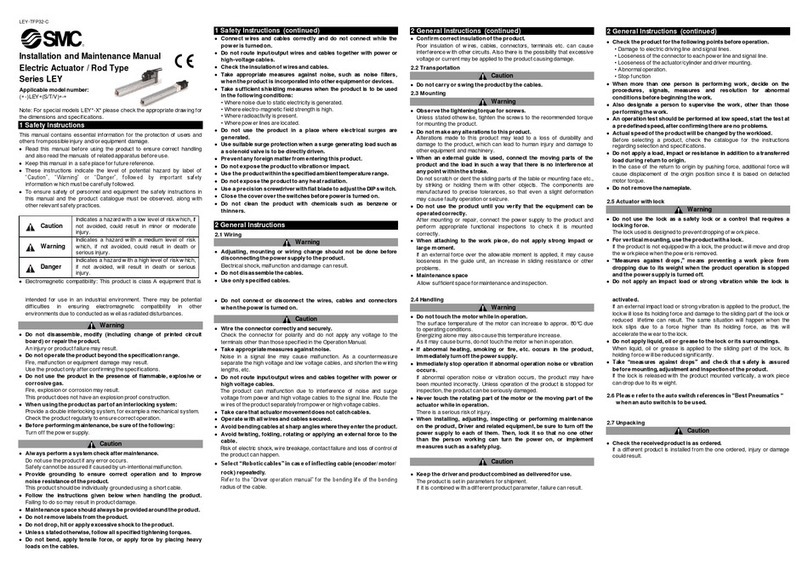

Caution

(1) Connection and disconnection of tube from

one-touch fitting

①Insertion of tube

1) Cut the tube perpendicularly, being careful not

to damage the external surface. Use SMC's

tube cuter TK-1, 2 or 3 for cutting. Do not cut

the tube with pliers, nippers, scissors, etc.

This may flatten the tube and connection to the

fitting may fail, causing disconnection of the

tube and air leakage.

2) The outside diameter of polyurethane tubing

swells when internal pressure is applied, so it

may not be possible to re-insert used tubing into

One-touch fittings. Confirm the outside diameter

of the tubing. If the accuracy of the outside

diameter is +0.07mm or more for φ2, and

+0.15mm or more for other sizes, insert into the

one-touch fitting again without cutting it. When

tubing is re-inserted into a One-touch fitting,

confirm that the tubing is able to go through the

release button smoothly.

3) Hold the tube and push it in slowly, inserting it

securely all the way into the fitting.

4) After inserting the tubing, pull on it gently to

confirm that it will not come out. If it is not

installed securely all the way into the fitting,

problems such as leakage or disconnection of

the tube can occur.

②Removal of the tube

1) Press the release button firmly. Push the collar

evenly around its circumference.

2) Hold down the release button while pulling out

the tube. If the release button is not held down

fully, it will be more difficult to pull out the tube.

3) If the removed tubing is to be used again, cut

off the section of the tubing which has been

gripped. Re-using the gripped portion of the

tube can cause problems such as air leakage or

difficulty in removing the tube.

(2) Connection of the metal rod accessories

Do not use tube, resin plug, reducer, etc. after

connecting a fitting with a metal rod (KC series,

etc.) to a One-touch fitting. This can cause

the tube to disconnect.

(3) When mounting the tube, resin plug or metal

rod, do not press the release button.

Do not press the release button unnecessarily

before mounting tubing, resin plugs and metal

rods. This can cause the tube to disconnect.

Caution

(4) When using tubing from a manufacturer

other than SMC, be careful of the tolerance of

the tubing O.D. and tubing material.

1) Nylon tubing Within ±0.1 mm

2) Soft nylon tubing Within ±0.1 mm

3) Polyurethane tubing Within +0.15 mm,

Within -0.2 mm

Do not use tubing which does not satisfy the

specified tubing O.D. accuracy, or tubing with an

I.D., material, hardness, or surface roughness that

differs from SMC's tubing. Please consult SMC if

anything is unclear. It may cause difficulty in

connecting the tubing, leakage, disconnection of

the tubing, or fitting damage.

(5)Tubing O.D.φ2

Tubing other than that from SMC cannot be used

because it may result in the inability to connect the

tube, air leakage after connecting the tube, or

disconnection of the tube.

(1) When connecting piping to the

One-touch fitting, use a pipe length

with sufficient margin, in

accordance with the piping

conditions shown in Figure 1.

Also, when using a tying band, etc.,

to bind the piping together, make

sure that external force does not

come to bear on the fitting.

(See Fig.2)