Fireye MicroM Series User manual

1

£

FIREYE

MicroM

FLAME SAFEGUARD CONTROLS

MEC320TS, MEP696, MEUV4

WARNING: Selection of this control for a particular application should be made by a com-

petentprofessional,licensedbyastateorothergovernment.Inappropriateapplicationofthis

product could result in an unsafe condition hazardous to life and property.

DESCRIPTION

The Fireye MicroM Series Flame Safeguard Control is a compact, microprocessor based,

modular burner management system designed to provide automatic ignition and continuous

flame monitoring for commercial sizes of heating and process equipment firing any type of

fuel. The advantages of the MicroM are zero dependence on discrete components previ-

ously used for timing functions thereby extending the stability of the system and reducing

the effects of time and temperature.

A complete MicroM system consists of the relay module, MEC320TS, programmer mod-

ule, MEP696, amplifier module, MEUV4, subbase, 61-3060 or 61-5042 and UV scanner,

UV1A3 or UV1A6. An optional alphanumeric display (ED510) is available that provides

complete English language description of the current operating status as well as diagnostic

history.

To maximize safety the MEP696 provides early spark termination followed by a pilot prov-

ing period. This prevents the unwanted detection of spark generated by a maladjusted pilot

and spark assembly. The air flow switch connected between terminals 7 and 6 must be

closed within 10 seconds after the start of a cycle. Below is a detailed list of the MEP696

operating parameters.

Functions provided on the MEC320TS chassis and MEP696 programmer:

1. Fixed 30 second pre-purge period

2. Ignition terminal 4 shuts off 10 seconds into the Pilot Trial for Ignition

3. 5 second Pilot Proving period

4. Pilot terminal 3 shuts off 5 seconds into the Main Trial for Ignition

5. Post Purge has selectable 0 or 60 seconds duration

6. Release to modulate contacts 1 second after AUTO

7. Lockout occurs if air flow, terminal 6, is not proven 10 seconds into purge

8. Modbus communications allowing for hookup to plc system

9. Dip-switch selectable communication baud rate, 4800, 9600 or 19200 baud

10. Dip-switch selectable pilot trial for ignition timing, 5 or 10 seconds

11. Smart LEDs that provide on board diagnostic lockout information

12. Amplifier test jacks provide uniform 0-10 vdc for flame signal strength

MC-3200

JUNE 6, 2006

APPROVED

2

£

SPECIFICATIONS

Supply: 120 VAC (min. 102, max. 132) 50/60 Hz.

Power Consumption: 12 VA (Operating)

Shipping Weight (Approx): 3 lbs (1.4 kg)

Table 1: AMBIENT TEMPERATURE LIMITS

Table 2: LOAD RATINGS

Table 3: COMPOSITION OF EACH COMBINATION

MAXIMUM MINIMUM

Control 140qF60qC- 40qF- 40qC

Scanner UV1A, UV2,

UV8A, 45UV3

200qF93qC- 40qF- 40qC

45UV5-1007, 45UV5-1009 200qF93qC- 40qF- 40qC

Photocell 45CM1 165qF74qC- 40qF- 40qC

Flame Rod

(Tip 2460 F)

1500qF816qC- 40qF- 40qC

48PT2 125qF52qC-40qF -40qC

CSIA5 140qF60qC-40qF -40qC

COMBINATION NUMBER PILOT FUEL TERMINAL 3 IGNITION TERMINAL 4 MAIN VALVE TERMINAL 5

1 C NO LOAD E

2 B NO LOAD E

3NO LOAD NO LOAD E

4 E A E

5NO LOAD A E

6 D A E

7 D A D

8NO LOAD A D

ABCDE

4.5A Ignition 50 VA Pilot Duty

plus 4.5A ignition

180 VA Ignition

plus motor values

with: 600VA

inrush., 360 VA

open, 250 VA hold

2A Pilot Duty 65 VA Pilot Duty

plus Motor valves

with: 3850 VA

in rush., 700 VA

open, 250 VA hold

3

£

DIMENSIONS

APPROVALS

Underwriters Laboratories Inc.

Listed Guide MCCZ - File MP1537

Listed Guide MCCZ7, Canada - File MP1537

Underwriters Laboratories Inc.

Recognized Components Guide MCCZ2

Recognized Components Guide, Canada MCZZ8 - File MP1537

Factory Mutual System (FM) Approved

2”

(50.8)

1/2”-14 STRAIGHT

FEMALE PIPE THREAD

1” DIA

(25.4)

UV1A UV SCANNER

36” FLEXIBLE CABLE (UV-1A-3)

72” FLEXIBLE CABLE (UV-1A-6)

2 3/8”

(60.3) 1 3/16”

(30)

1/2”

(12.7)

”L”

1/2”-14 NPT

13/16” HEX

(20.6)

15/16” HEX

(23.8)

”L” LENGTH AS SPECIFIED: 12”, 18”, 24” (304.8, 457.2, 609.6)

69ND1 FLAME ROD

5 3/16”

5 3/16”

MOUNTING BASE

5 5/16”

4”

4” 1/2”’

1/2”

3/16” DIA. MOUNTING

HOLES (4)

KNOCKOUTS (12)

FOR 1/2”

CONDUIT

P0

S1

7

S2

8

3

2/N

5

A

4

1

6

3/16” MOUNTING

HOLES

(4)

CAUTION: Published load ratings assume that no control be required to handle

inrush current more often than once in 15 seconds. The use of control switches,

solenoids, relays, etc. which chatter will lead to premature failure. It is important to

run through a test operation (with fuel shut off) following the tripping of a circuit

breaker, a blown fuse, or any instance of chattering of any external current con-

In order for the MicroM to gather and retain statistical and historic data such as

burner hours, burner cycles, system hours and average flame signal, it is necessary

that Terminal 1 be powered at all times. Removing power from Terminal 1 at the

end of the firing cycle causes all data gathered during the previous 16 hours or

lockout occurrence will be lost. For conversions or upgrades from older TFM or

M-Series II controls that use MART1 amplifiers, it is that Terminal 1 be directly

4

£

ORDERING INFORMATION

INSTALLATION OF CONTROL, SCANNERS AND FLAME DETECTORS

Wiring Base

Mount the wiring base on the burner or on a panel. The location should be free from exces-

sive vibration and within the specified ambient temperature rating. The base may be

mounted in any angular position.

All wiring should comply with applicable electrical codes, regulations and local ordi-

nances. Use moisture resistant wire suitable for at least 90 degrees C. Good electrical wir-

ing practice should be followed to ensure an adequate ground system. Refer to Fireye

Service Note SN-100 separately and General Grounding Rules later in this document for

grounding methods.

A good ground system should be provided to minimize the effects of AC quality problems.

A properly designed ground system meeting all the safety requirements will ensure that any

AC voltage quality problems, such as spikes, surges and impulses have a low impedance

path to ground. A low impedance path to ground is required to ensure that large currents

involved with any surge voltages will follow the desired path in preference to alternative

paths, where extensive damage may occur to equipment.

Refer to bulletin MP-5601 for a detailed description of the MEP696 programmer.

Refer to bulletin MC-5000 for additional information about the MicroM product line.

MicroM Chassis Types (Common for all controls, includes dust cover):

MEC320TS 120 VAC input with MED8 daughter board

MEP696 Programer module, fixed 30 second pre-purge, lockout on flame fail, lockout on air flow

opening 10 seconds after start of cycle, selectable baud rate, PTFI, post purge, recycle/

non-recycle air flow interlock, proof of air interlock open at start

MEUV4 UV Amplifier, 3 sec. FFRT, uses UV1A, UV2, UV8A, UV90 and 45UV3-1050 scanners

MED8 Plug in daughter board

UV1A3 Scanner, UV: 1/2” NPT connector, 3 ft. flex conduit

UV1A6 Scanner, UV: 1/2” NPT connector, 6 ft. flex conduit

61-3060 Closed wiring base, surface mounting

61-5042 Open wiring base, cabinet mounting

WARNING: Controls require safety limits utilizing isolated mechanical contacts.

Electronic limit switches may cause erratic operation and should be avoided.

5

£

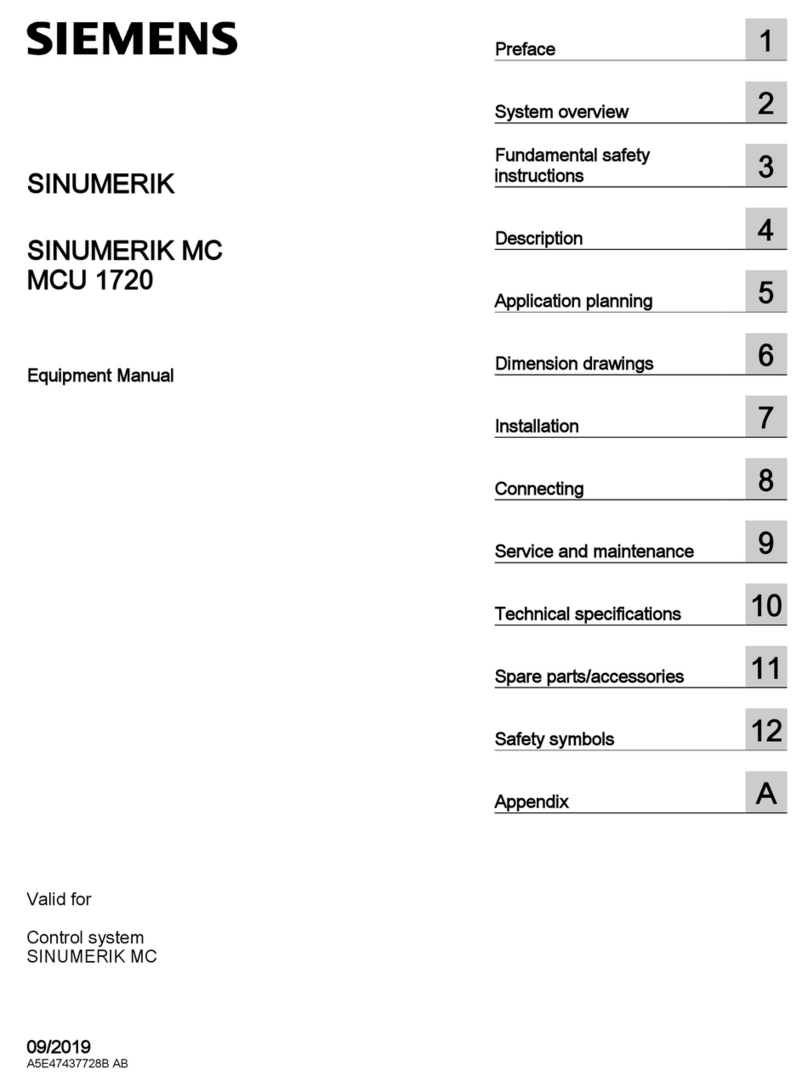

FIGURE 1. WIRING ARRANGEMENT FOR PILOT IGNITED BURNERS USING MEP696 PROGRAMMER

INSTALLING THE PROGRAMMER AND AMPLIFIER MODULES

WARNING: Remove power from the control before proceeding.

FIGURE 2. .

Remove the dust cover from the chassis. Insert the amplifier module into the slot in the cor-

ner of the chassis and gently push the module into position. Insert the programmer module

into the slot at the right side of the chassis and gently push the module into position.

WARNING: Turn off the power when installing or removing the control.

PV MV

S1

7

35

4

1

A

S2

PILOT VALVE

BLOWER MOTORALARM

8

120VAC

50/60Hz

T

P

FLAME AMPLIFIER

SPARK

KI KF

IGNITION

H

N2

FLAME

SCANNER

OR

CONTACTOR

MAIN FUEL VALVE

OPERATING

CONTROL

KA KB

AIR FLOW

INTERLOCK

FLAME

ROD

ONLY

KL

(WATCHDOG)

F1

6

KP

MODULATE CONTACTS

LOCATED ON

DAUGHTER BOARD

PROGRAMMER

AMPLIFIER

6

£

Replaceable Fuse

The chassis modules are designed with a field replaceable fuse. The fuse is located on the

printed circuit board below the transformer. In the event the fuse becomes OPEN, the Oper-

ating Control, PTFI, and Flame LED’s will light. Terminals 3 (pilot) and 4 (ignition) KF

will not be energized and the control will lock out and indicate Lockout, Check Blown

Fuse. The fuse can blow as a result of an overload condition on Terminals 3, 4, or 5. To

replace the fuse, remove power from the system and using a small screwdriver or similar

tool, install a Fireye replacement fuse (P/N 23-197) or equivalent 10 amp fuse (e.g. Wick-

man # 19373-071-K).

WARNING: Disconnect power before servicing.

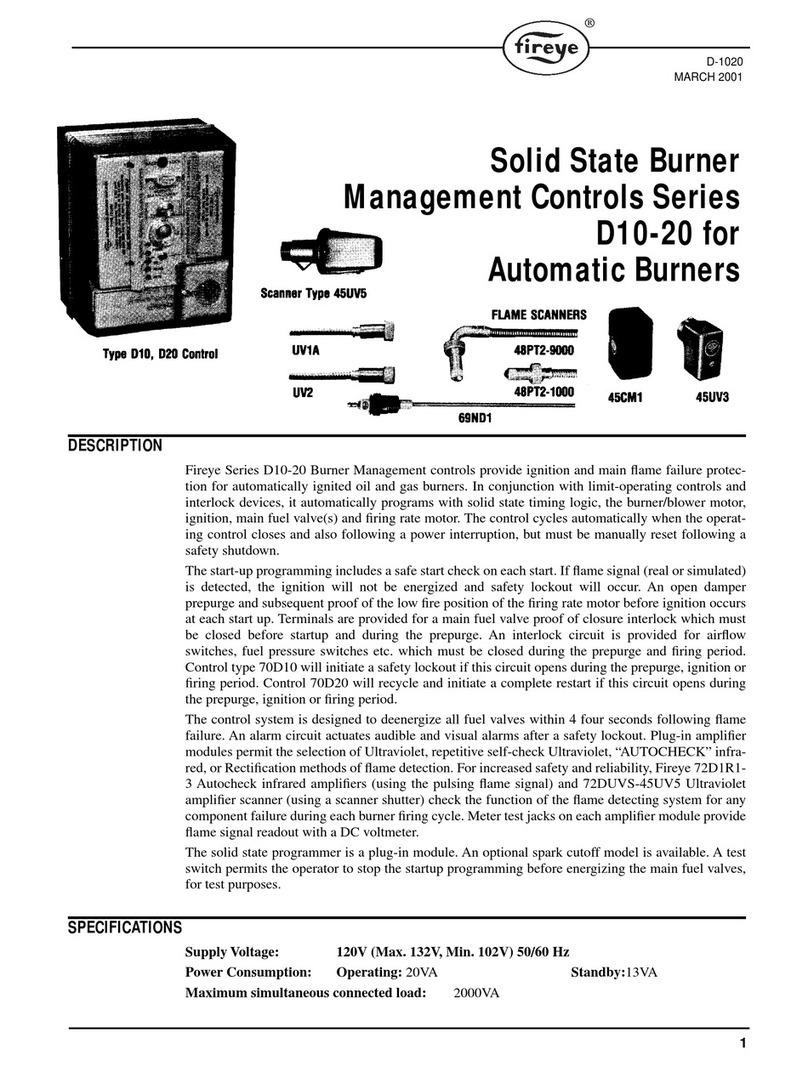

FIGURE 3.

MEP696 Programmer Dip Switch Configuration

Note: C refers to switch closed position, closed position is when the switch is toward the printed cir-

cuit board. O refers to switch open position or when the switch is moved away from the printed cir-

cuit board. Indicating arrow on top of programmer cover points toward closed position.

Except for baud rate selection, once the switches are set, they become permanently stored

after 8 hours of continuous operation or they can be manually set through the use of the

SWITCH FUNCTION

654321

C C 4800 BAUD

RATE

SELECTION

C O 9600

O C 19200

O O 19200

C DISABLED POST

PURGEO60 SECONDS

C5PTFI

TIMEO10

C DISABLE PROVE AIR

FLOW OPEN

AT START

OENABLE

C RECYCLE

O NON-RECYCLE

Replaceable

Fuse Location

7

£

optional ED510 display. Refer to the section using the optional ED510 display for detailed

information.

The ED510 display operates at 4800 baud only. To use the ED510 display, power must be

removed and dip switches 1 & 2 must be set in the CLOSED position.

Dipswitch Definitions

Baud Rate: On every application of power, the communication baud rate is determined by

switches 1 & 2. The available selections are 4800, 9600 ad 19200 baud. Note the ED510

requires the baud rate to be set at 4800, switches 1 & 2 closed.

Post Purge: If enabled, Terminal #8 (blower motor or contactor) will remain energized for

60 seconds after terminal #7 or Terminal #6 is detected as open.

PTFI Time: The length of time that Terminal #3 and Terminal #4 will be energized after the

pre-purge period to detect pilot flame.

Prove Air Flow Open: After power is detected on Terminal #7 (limit control) and before

energizing Terminal #8 (blower motor or contactor) no power must be detected on Terminal

#6 (running interlock switch). If power is detected on Terminal #6, the MicroM will hold

for 60 seconds after which safety lockout will occur. On recycle operation, if this is enabled,

Terminal #8 will be de-energized to allow Terminal #6 to open.

Recycle: Applies to air flow interlock opening during the Run condition. If the air flow

interlock (Terminal #6) opens, the control will de-energize Terminals #3, #4 and #5, and if

Recycle is selected a new prepurge period will begin. Lockout and alarm will occur imme-

diately after air flow interlock opening if Non-Recycle is selected.

LED INDICATOR LIGHTS

The MEP696 Programmer Module has 5 LED lights to indicate the operating status of the

control and also to display the coded sequence under locked out conditions. The function of

the lights under a normal operating condition is:

Operating Control: This LED is energized whenever the burner control switch and all

other various limit switches are closed and power is applied to Terminal #7.

Interlock or Air Flow: This LED is illuminated whenever power is detected on Terminal

#6, indicating the air flow switch or other running interlock is closed. If the operating con-

trol is closed and the running interlock switch remains open, this LED will flash at a 1 sec-

ond rate. Lockout will occur if the switch remains open for 10 seconds into the start of the

cycle.

PTFI: This LED is illuminated only during the pilot trial for ignition period and the stabili-

zation period.

Flame: This LED is on whenever a flame signal is detected, and the control is not in a

locked out state.

LED

INDICATORS SWITCHES

(shown in closed or OFF position)

DIP

8

£

Alarm: This LED flashes when an alarm condition is detected and is also used as an

address indicator (see communication).

During an alarm condition, the Alarm LED is made to flash at approximately a 1 second

rate. The remaining four LEDs are illuminated as a coded sequence identifying the reason

for the lockout. For instance, for a LOCKOUT - FLAME FAIL- PTFI, the INTERLOCK,

PTFI and FLAME LED’s will all be lit steady, with the Alarm LED flashing. This remains

true if power is removed and then restored while in a locked out condition.

While in the Idle or Off state, the LEDs are made to flash sequentially every minute to show

the operational status of the control. The LEDs can be tested by pressing and releasing the

Reset push button, while in the Idle or Off state

LOCKOUT CODES

❍ = NOT LIGHTED

● = LIGHTED

✱ = FLASHING

All LED’s Flashing indicates defective programmer.

All MicroM chassis are shipped with a convenient peel off label that can be applied to any

surface (inside cover) for future reference.

MSGN DESCRIPTION OP CTRL AIRFLOW

INTLCK

TFI FLAME ALARM

DEC HEX

6 6 Lockout Line Frequency Noise Detected ●❍❍●✱

7 7 Lockout Flame Fail - TFI ❍● ●●✱

15 0F Lockout Fault Unknown ●●●●✱

16 10 Lockout Amplifier High Count Fail ❍❍❍❍✱

19 13 Lockout Flame Fail - MTFI ❍❍ ●●✱

20 14 Lockout False Flame - STANDBY ❍●❍❍✱

21 15 Lockout Intrlck Open ●●●❍✱

22 16 Lockout Intrlck Closed ❍● ●❍✱

24 18 Lockout Chassis Opto ●●❍●✱

37 25 Lockout Flame Fail - AUTO ❍●❍●✱

39 27 Lockout Fuel Valve State Change ❍❍❍●✱

54 36 Lockout Check Chassis ❍❍❍●✱

55 37 Lockout Check Programmer ❍❍ ●❍✱

56 38 Lockout Check Amplifier ●❍

❍❍✱

58 3A Lockout Amplifier Auto Check Fail ●❍●❍✱

59 3B Lockout Check BLOWN FUSE ●❍●●✱

76 4C Lockout Check Scanner ●●❍❍✱

N/A N/A System Error ✱✱✱✱●

9

£

DIAGNOSTIC MESSAGES - TROUBLESHOOTING GUIDE

PLUG-IN DAUGHTER BOARD

Description

A plug-in board is pre-installed in the MEC320TS chassis to provide local reset, remote alpha-

numeric display, serial communications and normally closed relay contacts.

FIGURE 4. PLUG -IN BOARD LOCATION AND INSTALLATION

POSSIBLE CAUSE SOLUTION

Check Programmer Voltage on Terminal 5 at improper time. Inspect wiring to main fuel valve

Welded watchdog relay Replace chassis

Internal diagnostic failure Replace programmer

Check Chassis Voltage on Terminal 3 or 4 at improper time. Inspect wiring to pilot valve and igniter.

Welded watchdog relay Replace chassis

Chassis Opto Opto-Coupler(s) short circuited Replace chassis

Amplifier High Count Fail Amplifier signal level high Replace Amplifier module

Amplifier Auto Check Fail Flame signal too high Use orifice in sight pipe

Internal Amplifier diagnostic fault Replace Amplifier module

Check Scanner Defective shutter Inspect scanner wiring, replace scanner

UV tube false firing Replace UV tube or scanner

Check Blown Fuse No power detected on terminal 3 Inspect defective pilot valve or igniter

Defective fuse Replace fuse

Line Frequency Noise Detected Spikes detected on AC mains Check for SCR motors or DC drives

Inspect ground system

Fuel Value State Change Terminal 5 (main fuel) detected on during TFI Check external wiring or replace chassis

Check Amplifier Amplifier not passing diagnostic tests Replace Amplifier module

System Error Noise transient Check high energy ignition noise location. Be

sure it is not arcing to chassis or wrapped with

scanner wiring.

STANDOFF

PLUG-IN BOARD

RELEASE

DIRECTION

SERIAL COMMUNICATIONS

REMOTE DISPLAY

RJ45 JACK

RELAY CONTACTS

(RS485)

B

A

MED8

10

£

SEQUENCE TIMING

Table 4: MEP696 Timing Sequence

COMMUNICATIONS

The protocol to be used is Modbus RTU. This is implemented by the master (PC, PLC, etc.) issuing a

poll to the slave (MicroM) and the slave responding with the appropriate message.

A typical format of a poll request is as follows:

DST refers to the logical address of the slave set but using reset pushbutton or ED510.

FNC is the function being requested. FNC 03 is a read request.

ADR is the message number or register number of the data being requested. In Modbus, register

addresses begin at 40001 but is interpreted as address 00.

DAT is the number of words being requested. A word is an integer consisting of 2 bytes.

The normal response from a slave is as follows:

DBC is the data byte count being returned. It must be two times the DAT number from the poll

request.

DATA is the data returned and is always a series of 2 byte integers. If 4 words were requested then

DBC would be 8 and there would be 8 data bytes or 4 data words containing the requested data.

The format of the data is 4800, N, 8, 1 meaning 4800 baud, no parity, and 1 stop bit.

DST FNC ADR

HI

ADR

LO

DAT

HI

DAT

LO

CRC

LO

CRC

HI

DST FNC DBC DATA….

Hi/Lo

CRC

LO

CRC

HI

11

£

Below is a table of currently available messages provided by the MicroM programmers, followed by

a description where necessary.

Messages 00, 05, 08, 10, 15, 21 and 26 are unique in that a limited number of successive registers

can be combined with these requests. For example, a request to message 00 can contain up to 6 data

words. The response to this would contain STATUS, MSGN, GSTAT, TIMER, FLAME and

LOGSTAT. If the requested data word count (DAT) were to be 2 then the response would contain

STATUS and MSGN only. Message 15, last 6 lockouts, can return data ranging from 1 to 6, with 1

referring to the most recent lockout.

Message 26 returns the current operating status as well as stored burner hours and burner cycles as a

snapshot of the entire MicroM system. When all 9 words are requested, the data returned consists of

STATUS, MSGN, FLAME, INPUTS, OUTPUTS, BNRMINS, and BNRCYCS.

MESSAGE

ADDRESS

WORDS

REQUESTED

RESPONSE VALUE

00 1-6 STATUS 83 (053H) = RUN;

202 (0CAH) = LOCKOUT

01 1 MSGN Current message being displayed (see Table 3)

02 1 GSTAT Defines Timer Type

03 1 TIMER Time, Flame, Address

04 1 FLAME Flame Signal

05 1-3 LOGSTAT Current logic module, PURGE, PTFI, AUTO

06 1 INPUTS Input limits state

07 1 OUTPUTS Output relays state

08 2, 4 or 8 SYSMINS System on minutes

10 2 or 4 BNRMINS Burner on minutes

12 2 CYCLES Completed Burner Cycles

14 1 LOCKOUT COUNT Stored Lockout Count

15 1-6 LOCKOUT HISTORY Last 6 Lockouts, first word is most current lock-

out

21 1-2 DEVTYP Programmer device type, 5=EP, 6=EPD,

7=MicroM

22 1 AMPTYP Amplifier Type;

MECD=080H;

MEUV=090H;

MEIR=0A0H;

MERT=0B0H;

MEUVS=0C0H

23 1 PROGTYP Programmer Type

24 2 FLAME SIGNAL

AVERAGES

PTFI and Auto Flame Signal Averages

26 1-9 Combined Status See Description Below

35 6 Most Recent Lockout Data

Returns complete lockout description of stored

lockout history. Includes lockout message,

lockout module, @ burner hours, and @ burner

cycles

41 6 2nd Most Recent Lockout

Data

47 6 3rd Most Recent Lockout

Data

53 6 4th Most Recent Lockout

Data

59 6 5th Most Recent Lockout

Data

65 6 6th Most Recent Lockout

Data

12

£

The MSGN being transmitted is a numerical value and must be interpreted by the communicating

device, which actually is an advantage since this can be made to be whatever message text the end

user wants. In other words, it allows for programming custom messages without actually changing

the message in the programmer.

The MicroM stores its burner on time (Terminal 5 powered) and system on time (L1 powered) in

minutes. Internally, the programmer converts this to hours for display purposes, however the result is

rounded down. The information being supplied by Modbus will be the actual time in minutes and it

is up to the communicating device to do the conversion. Since the maximum value stored in the

MicroM is 9,999,999 minutes, the maximum value in hex therefore, is 98967FH and comprises of

two data words. The maximum cycle count is 999,999 decimal or 0F423FH, still two data words. As

an example, the System on Minutes data is transmitted from the MicroM to the interface as high

word / low word as shown below:

Note: Data from address 9 cannot be accessed directly.

All values are represented in a HEX or base 16 format.

GSTAT determines the type of value TIMER represents. TIMER can be a running timer such as is

used in purge, a flame signal or meaningless. Only the lower nibble of GSTAT has any value. If this

value is 0 then the TIMER value has no meaning. The value in TIMER is a background minute timer

in the MicroM and should be ignored. If GSTAT is between 4 and 7, the TIMER represents the cur-

rent value flame signal. If GSTAT is a 1, 2, or 3 then TIMER represents a running timer value.

The baud rate of the MicroM is fixed at 4800 bits per second. The format of the data is 8 data bits, no

parity and 1 stop bit. Due to the RS485 format, the communication format is considered half-duplex.

That is, only one user is permitted on the communication lines at a time.

The information contained in INPUTS and OUTPUTS represents the status of the interlocks and

relays respectively. For the INPUTS, a 1 in the interlock position defines the interlock as being on or

energize where the 1 in any bit position in the OUTPUT register signifies the relay as being ener-

gized.

Reset, Scrl and Mode represent the keypad located on the ED510 display. A ‘0’ in any of these posi-

tions indicates the switch is depressed. A ‘1’ in the opto-coupler position indicates the opto-coupler

is on or interlock closed.

A ‘1’ in any terminal position indicates the relay is energized. Term 4 indicates the state of K1 relay,

located in the MEP500 series programmers.

It is suggested that repeated polling interval not be less than 200 mSec per request. Requesting

data such as burner minutes, system minutes and burner cycles be kept at a minimum due to

the amount of processing time required to gather that data.

MESSAGE ADDRESS 8 MESSAGE ADDRESS 9

HIGH WORD LOW WORD

HIGH BYTE LOW BYTE HIGH BYTE LOW BYTE

098H 96H 7FH

INPUTS

Term 5 Term 3 Term 6 Term 7

Reset Scrl Mode RF Pilot Intrlck OpCntrl Ref

OUTPUTS

Term 8 Term A Term 3 Term 5 Term 4

N/A N/A N/A Blower Alarm Pilot Main Fuel MTFI

13

£

Table 1: Logic Dispatch

LOGIC DISPATCHER

VALUE MicroM

HEX DEC

45H 69 MPOSTIDLE

46H 70 MPREPURGE1

47H 71 MPURGE

48H 72 MTFI

49H 73 MSTABLE

4AH 74 MTFMF

4BH 75 MAUTO

4CH 76 MSHTDWN1

4DH 77 MSHTDWN2

4EH 78 MIDLE

14

£

Addressing Modes

For communication in a multi-burner or multi-control environment, each MicroM must have a

unique address. The range of address allowed within the MicroM is 0 to 31 allowing for a possible

32 units to be connected in a single multi-drop node. As shipped the default address is 0. The address

of the MicroM may be set using two methods. Using the ED510 display, it is necessary is SCRL to

the PROGRAM SETUP menu and enter that submenu with the MODE key. SCRL down until the

display indicates UNIT ADDRESS with the actual address of the MicroM being displayed on the top

line of the display. Pressing and releasing the RESET key will cause the address to increment. The

Table 2: Message Description

DEC HEX MicroM Message

1 1 L1-7 OPEN

2 2 FALSE FLAME

3 3 STARTING BURNER

44

5 5 INTRLCK OPEN

6 6 LOCKOUT LINE FREQUENCY NOISE DETECTED

7 7 LOCKOUT FLAME FAIL - PTFI

8 8 UNIT ADDRESS

99 MTFI

10 0AH IGNITION TIMING

11 0BH

12 0CH FLAME SIGNAL

13 0DH CYCLE COMPLETE

14 0EH OFF

16 10H LOCKOUT AMPLIFIER HIGH COUNT FAIL

19 13H LOCKOUT FLAME FAIL – MTFI

20 14H LOCKOUT FALSE FLAME – STANDBY

21 15H LOCKOUT INTRLCK OPEN

22 16H LOCKOUT INTRLCK CLOSED

23 17H INTRLCK CLOSED (PROVING AIR FLOW OPEN AT START)

24 18H LOCKOUT OPTO FAILURE

30 1EH FALSE FLAME

37 25H LOCKOUT FLAME FAIL - AUTO

39 27H FUEL VALVE STATE CHANGE

40 28H AIR FLOW CLOSED

49 31H LOCKOUT FLAME FAIL - PTFI

54 36H LOCKOUT CHECK CHASSIS

55 37H LOCKOUT CHECK PROGRAMMER

56 38H LOCKOUT CHECK AMPLIFIER

58 3AH LOCKOUT AMPLIFIER AUTO CHECK FAIL

59 3BH LOCKOUT CHECK BLOWN FUSE

76 4CH LOCKOUT CHECK SCANNER

15

£

address after 31 is 0. The second method is to use the local reset located on the plug-in board. It is

first necessary to open the operating control (L1-7) to have the MicroM in the IDLE or STANDBY

position. Depressing the reset switch for greater than 10 seconds will cause the address of the

MicroM to be displayed in a binary format on the LEDs located on the programmer board. Because

the default is address 0, and since address 0 would mean no LEDs would be lit; the ALARM LED is

made to flash when the address is 0. The OP CTRL LED is the least significant bit while the

ALARM relay is the most significant bit. To increment the address counter, depress and release the

RESET push button and observe the LED pattern. If the RESET switch is untouched for 30 seconds

the current address displayed will be stored to memory and the MicroM will automatically exit the

address mode.

TEST JACK VOLTAGE

For all amplifiers, the MicroM provides a uniform 0-10 volt signal to represent the flame signal

strength. A signal reading greater than 4 volts is considered sufficient to provide reliable operation.

This same signal is also available in a numerical format on the ED510 display. The chart below cor-

relates the test jack voltage to the numerical value. The signal clamps at 10 volts at a numerical value

greater than 42 and the numerical value clamps at 80.

0

1

2

3

4

5

6

7

8

9

10

616202428323640 60 80

AMPLIFIER TEST JACK VOLTAGE VS. ED510 DISPLAY BOARD

TEST JACK VOLTAGE

16

£

NOTICE When Fireye products are combined with equipment manufactured by others and/or inte-

grated into systems designed or manufactured by others, the Fireye warranty, as stated in its

General Terms and Conditions of Sale, pertains only to the Fireye products and not to any

other equipment or to the combined system or its overall performance.

WARRANTIES FIREYE guarantees for one year from the date of installation or 18 months from date of

manufacture of its products to replace, or, at its option, to repair any product or part thereof

(except lamps, electronic tubes and photocells) which is found defective in material or

workmanship or which otherwise fails to conform to the description of the product on the

face of its sales order. THE FOREGOING IS IN LIEU OF ALL OTHER WARRANTIES

AND FIREYE MAKES NO WARRANTY OF MERCHANTABILITY OR ANY OTHER

WARRANTY, EXPRESS OR IMPLIED. Except as specifically stated in these general terms

and conditions of sale, remedies with respect to any product or part number manufactured

or sold by Fireye shall be limited exclusively to the right to replacement or repair as above

provided. In no event shall Fireye be liable for consequential or special damages of any

nature that may arise in connection with such product or part.

FIREYE MC-3200

3 Manchester Road JUNE 6, 2006

Derry, New Hampshire 03038 USA

www.Fireye.com

£

Other manuals for MicroM Series

2

This manual suits for next models

3

Table of contents

Other Fireye Controllers manuals

Fireye

Fireye NEXUS NX6100 series User manual

Fireye

Fireye BurnerPRO BP110 User manual

Fireye

Fireye PPC5000 User manual

Fireye

Fireye FX Series User manual

Fireye

Fireye PPC4000 SERIES User manual

Fireye

Fireye SureFire II User manual

Fireye

Fireye PPC6000 Series Manual

Fireye

Fireye D10 Series User manual

Fireye

Fireye SB Series User manual

Fireye

Fireye PPC6000 Series Operating instructions