Fireye FLAME-MONITOR E110 User manual

1

®

DESCRIPTION

The Fireye®E110 FLAME-MONITOR™ System is a microprocessor based burner management

control system designed to provide the proper burner sequencing, ignition and flame monitoring pro-

tection on automatically ignited oil, gas, and combination fuel burners. In conjunction with limit and

operating controls, it programs the burner/blower motor, ignition and fuel valves to provide for

proper and safe burner operation. The control also provides current operating status and lockout

information in the event of a safety shutdown. The manner in which this information is displayed is

dependent on the type of programmer (EP or EPD) and display module (ED510 or ED500).*Refer

to Flame-Monitor PROGRAMMER SELECTION later in this document for the various combina-

tions of programmer and display modules.

The E110 consists of the EB700 chassis, dust cover, and shortened mounting screw (P/N 48-1836).

The display module (ED510), if required, must be ordered separately. Interchangeable programmer

and flame amplifier modules allow for complete versatility in selection of control function, timing,

and flame scanning means. Functions such as pre-purge, recycling interlocks, high fire proving inter-

lock, and trial for ignition timing of the pilot and main flame are determined by the programmer

module. The E110 Flame-Monitor can be used with ultra-violet, auto-check infrared, flame rod, or

self-check ultraviolet flame scanners by choosing the proper amplifier module.

The eighteen (18) terminal wiring base allows for many functional circuits including motors, valves,

and ignition transformers as well as multiple interlocks such as high purge, low purge, fuel valve and

running interlock circuits. The E110 uses the same wiring base as the Fireye E100 Flame-Monitor

control, D Series and C Series Controls and is directly interchangeable with most models without

rewiring.

Additional functions of the Flame-Monitor system include:

•A non-volatile memory which allows the control to remember its history and present position

even when power is interrupted.

•A constant flame signal read-out via display module or 0-10 VDC output (EPD

programmers only).

•Read-out of main fuel operational hours and complete cycles via display module.

•Modbus communications via RS485 multi-drop link.

•Dipswitches located on the EP programmer to allow selectable purge time.

•A run/check switch which allows the operator to stop the program sequence in any of three dif-

ferent positions (Purge, PTFI, or Auto).

•Remote Display Capability.

•Annunciate 16 additional interlocks using E300 Expansion Module.

* The ED500 display was the predecessor of the ED510 display and uses an older design. It does not have the latest features

of the ED510 display module.

E110 FIREYE

FLAME-MONITOR™

BURNER MANAGEMENT CONTROL

FOR USE WITH THE

MICROPROCESSOR-BASED

EP AND EPD STYLE

PROGRAMMER MODULES

E-1101

MARCH 28, 2013

APPROVED

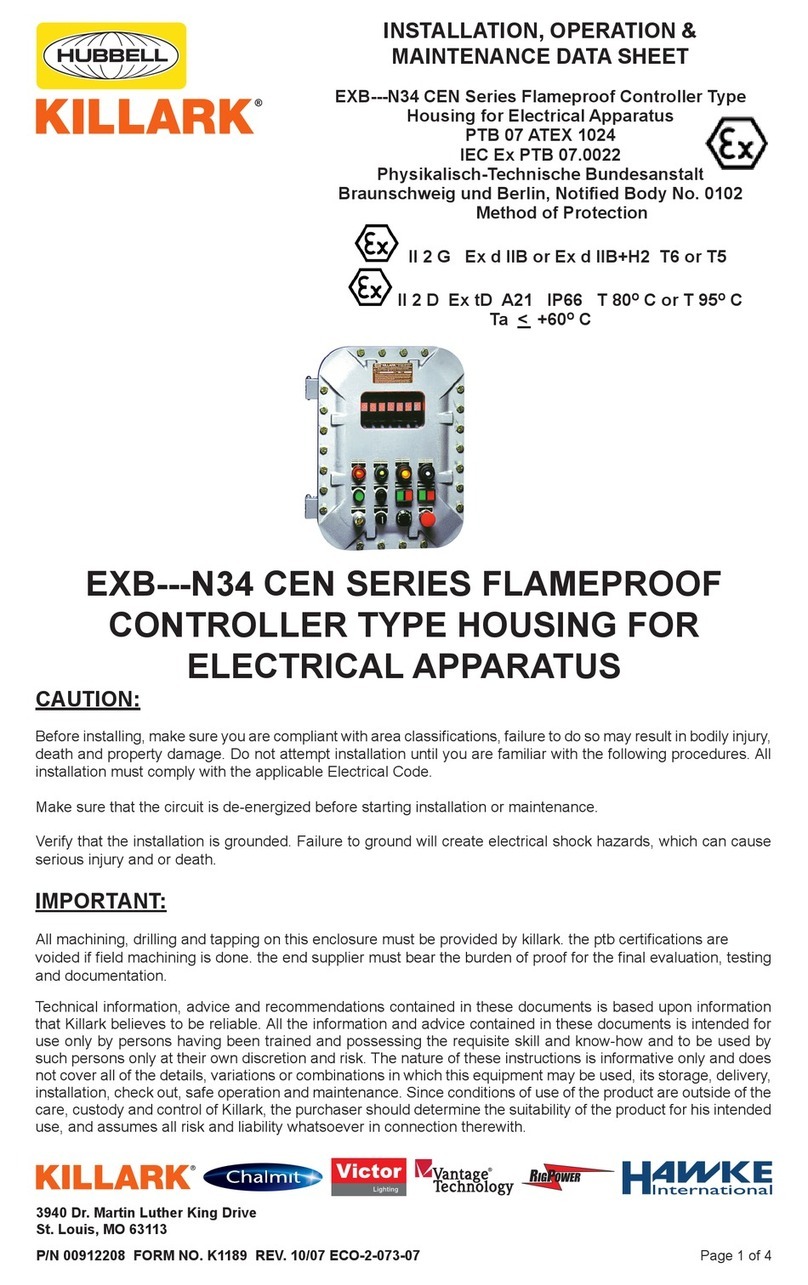

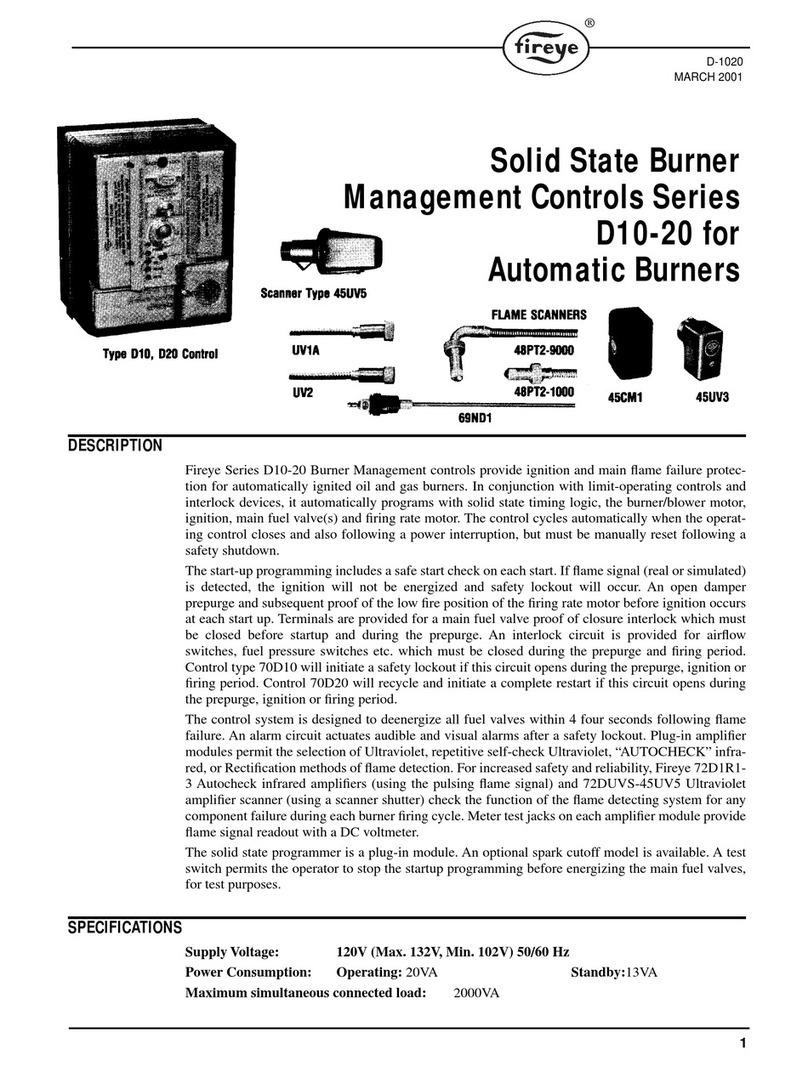

E110 with ED510 Display Module

2

®

FLAME-MONITOR SPECIFICATIONS

Supply Voltage:

E110: 120 VAC (+10%, -15%) 50/60 Hz

E120: 220 VAC (+10%, -15%) 50/60 Hz

Power Consumption: 25 VA

Shipping Weight: (E110 Approx.) 5 lbs. (2.3kg)

OPERATING TEMPERATURE LIMITS

LOAD RATINGS

Maximum Simultaneous Connected Load: 2000 VA

CONTROL MAXIMUM MINIMUM

E110, E120, EB700, EB701 140°F 60°C - 40°F - 40°C

EP, EPD Programmers 140°F 60°C - 40°F - 40°C

All Amplifiers 140°F 60°C - 40°F - 40°C

ED510 Display 140°F 60°C 32°F 0°C

Scanner UV1A, UV2, UV8A,

45UV3, UV90

200°F 93°C - 40°F - 40°C

45UV5-1007, 45UV5-1009 200°F 93°C - 40°F - 40°C

Flame Rod

(Tip 2460 F)

1500°F 816°C - 40°F - 40°C

48PT2 140°F 60°C - 40°F - 40°C

Humidity: 85% R.H. (Non-condensing)

TERMINAL TYPICAL LOAD A. Maximum Rating @120V-50/60Hz B. Alternate Rating @120-50/60Hz

5, 6 Individually or

Combined

Pilot Valve(s) and Igni-

tion Transformer(s)

50VA Pilot Duty (Solenoid Valves)

plus 500VA (Transformer)

125VA Pilot Duty Solenoid Valves plus

250VA (Transformer)

7 Main Fuel Valve(s) 250VA Pilot Duty (Solenoid Valve) 1250 VA Opening 500 VA Holding

(Motorized Valve) plus 65 VA Pilot Duty

(Solenoid Valve)

M Burner/Blower Motor 9.8 F.L.A. * 58.8 L.R.A. 240 VA Pilot Duty (Motor Starter Coil)

10-11-12-X Modulator 125 VA Pilot Duty

AAlarm 50 VA Pilot Duty

Terminal ratings may be selected from either column A or B: (select the rating from the column for each terminal which best applies to

the connected load on that terminal).

* F.L.A. = full load amps L.R.A. = locked rotor amps

CAUTION: While programmers are mechanically interchangeable in that they mate with

a common wiring base, you should select the correct model for your application. Inappro-

priate application of a control could result in an unsafe condition hazardous to life and

property. Selection of a control for a particular application should be made by a competent

professional, such as a boiler/burner service technician licensed by a state or other govern-

ment agency.

3

®

ELECTRICAL RATINGS

VA ratings (not specified as pilot duty) permit the connection of transformers and similar devices

whose inrush current is approximately the same as their running current.

VA Pilot Duty ratings permit the connection of relays, solenoid valves, lamps, etc. whose total oper-

ating load does not exceed the published rating and whose total inrush current does not exceed 10

times the rating.

Running and locked rotor ratings are intended for motors. VA and VA Pilot Duty loads may be

added to a motor load provided the total load does not exceed the published rating.

WARNING: This equipment is a Class B digital apparatus which complies with the Radio

Interference Regulations, CRC c.1374.

CAUTION: Published load ratings assume that no contact be required to handle inrush cur-

rent more often than once in 15 seconds. The use of control switches, solenoid, relays, etc.

which chatter will lead to premature failure. It is important to run through a test operation

(with fuel shut off) following the tripping of a circuit breaker, a blown fuse, or any known

instance of chattering of any external current consuming devices.

APPROVALS

Underwriters Laboratories Inc.:

MCCZ File MP 1537

Controls, Primary Safety - Listed

MCCZ2 File MP1537

Controls, Primary Safety - Component

MCCZ7 File MP1537

Controls, Primary Safety Certified for Canada

MCCZ8 file MP1537

Controls, Primary Safety Certified for Canada - Component

Acceptable by: Industrial Risk Insurers (I.R.I.)

Factory Mutual Approved

Note: E120 is FM approved only.

WARNING: This equipment generates and can radiate radio frequency energy, and if not

installed and used in accordance with the instruction manual may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A comput-

ing device pursuant to Subpart J of part 15 of FCC Rules, which are designed to provide rea-

sonable protection against such interference when operated in a commercial environment.

Operation of this equipment in a residential area is likely to cause interference in which case

the user, at his own expense, will be required to take whatever measures which may be

required to correct the interference.

4

®

APPLICABLE BULLETINS

All bulletins are available in .pdf format at www.fireye.com.

FLAME AMPLIFIER SELECTION

SCANNER SELECTION

E120, Flame-Monitor Chassis, 220 VAC Operation, FM approved E-1201

Programmers, Non-Recycle Operation EP-1601, EPD-1601

Programmers, Recycle Operation EP-2601, EPD-2601

Programmers, Non-Modulating EP-3801, EPD-3801

Amplifiers EAMP1

Display, ED510 ED-5101

Expansion Module E-3001

FIREYE P/N DESCRIPTION USE WITH SCANNER

EUV1 Standard UV Amplifier UV1A, UV8A 45UV3, UV2

E1R1 Autocheck Infrared Amplifier 48PT2

E1R2 Autocheck Infrared Amplifier (For special applications -

high sensitivity—consult factory)

48PT2

E1R3 Autocheck Infrared Amplifier. (Without oil fog rejection

spray circuitry.)

48PT2

ERT1 Rectification Amplifier 69ND1

EUVS4 Self-Check UV Amplifier 45UV5-1007/1008/1009

FIREYE P/N DESCRIPTION USE WITH

SCANNER

BULLETIN

48PT2-1003

48PT2-9003

48PT2-1007

48PT2-9007

4-263-1

Infrared 1/2" straight mount 96" TC-ER

Infrared 1/2" 90angle mount 96" TC-ER

Infrared 1/2" straight mount 48" TC-ER

Infrared 1/2" 90angle mount 48" TC-ER

Replacement photo detector

E1R1, E1R2,

or E1R3

SC-103

UV1A3

UV1A6

UV8A

UV2

UV2A6

45UV3-1050

UV90-3

UV90-6

UV90-9

UV 1/2" straight 36" TC-ER cable

UV 1/2" straight 72" TC-ER cable

UV 1/2" 90head 72" unshielded leads

UV 3/8" straight 36" TC-ER cable

UV 3/8" straight 72" TC-ER cable

UV 3/4" cast aluminum housing 8' cable

UV 90° lateral view with 36” flex conduit

UV 90° lateral view with 72” flex conduit

UV 90° lateral view with 108” flex conduit

EUV1 SC-102

69ND1-1000K4

69ND1-1000K6

69ND1-1000K8

Flame rod 12", 1/2" N.P.T. mount

Flame rod 18", 1/2" N.P.T. mount

Flame rod 24", 1/2" N.P.T. mount

ERT1 SC-103

45UV5-1007

45UV5-1008

45UV5-1009

4-314-1

Self-check UV 1" British thread mounts, 230V

Self-check UV 1" British thread mounts, 120V

Self-check UV 1" N.P.T. threads, 120V

Replacement UV tube

EUVS4 SC-101

5

®

FIREYE®FLAME-MONITOR™ Selection Guide

1. SELECT CHASSIS

E110 FLAME-MONITOR, 120 VAC operation

E120 FLAME-MONITOR, 220 VAC operation

2. SELECT PROGRAMMER

EP Programmers provide selectable operation (e.g. extended purge time)

EPD programmers have integral LED indicator display.

3. SELECT DISPLAY

Required for EP Programmers, Optional for EPD programmers

ED510 2 line x 16 character LCD display.

4. SELECT AMPLIFIER

Requires appropriate flame scanner.

5. SELECT WIRING BASE

60-1386-2 Surface mount

60-1466-2 Panel mount

6. SELECT ACCESSORIES

(on following page).

NON-RECYCLE OPERATION RECYCLE OPERATION DESCRIPTION NON-MODULATION DESCRIPTION

EP160 EPD160 EP260 EPD260 10 and 15 sec. TFI EP380, EP387, EPD380 30 sec. purge

EP161 EPD161 EPD261 Extended MTFI EP381 EPD381 15 sec. purge

EP165

EP166

Pilot stabilization

Pilot stabilization

EP382 EPD382 1 sec. purge

EP170 EPD170 EP270 EPD270 Early spark termination EP390 EP390 90 sec. purge

NOTE: The EP programmers listed above are available in both Spanish and French languages.

Consult factory or your local Fireye distributor for ordering information.

DESCRIPTION USE WITH SCANNER

EUV1 Standard ultra-violet amplifier UV1A, UV2, UV8A, 45UV3,

UV90

EUVS4 Self-check ultra-violet amplifier 45UV5-1007, 1008, 1009

E1R1 Autocheck infra-red amplifier 48PT2

E1R2 Autocheck infrared amplifier (with high sensitivity circuitry) 48PT2

E1R3 Autocheck infrared amplifier (without oil fog rejection circuitry) 48PT2

ERT1 Flame rectification amplifier 69ND1

6

®

FIREYE P/N DESCRIPTION BULLETIN

ED510 Display Module (2 line x 16 characters LCD Display) ED-5101

129-145-1, -2, -3 Remote Display Mounting Kit (for ED510) with 4', 8' or 2' cable respectively E-8002

E350-3, -6 Expansion Module cables in 3' and 6' lengths E-3001

ED150-3, -6, -15, -25 Remote Reset cables in 3', 6', 15' and 25' lengths E-8001

ED600 Multi-port Cable Adapter E-8001

ED610 Multi-port Adapter (for ED510 and RS485 communications) E-8002

E500-3 Communication Interface (up to 6 Flame-Monitor controls) E-5001

EC485 RS232 to RS485 converter for direct connect EC-4851

ED512-2, -4, -8 Communications interface cables in 2', 4' and 8' lengths E-8002

ED580-2, -4, -8 Remote display cables in 2', 4' and 8' lengths E-8002

IT1000 Wireless communication monitor system for up to 10 Flame-Monitor Controls INT-1000

7

®

FLAME-MONITOR Ordering Information

E110 Flame-Monitor (One required) ED510 Display Module

Required with EP Programmers

Optional with EPD Programmers

Amplifier Module (One Required) Wiring Base (One Required)

E1R1

E1R2

E1R3

EUV1

EUVS4

ERT1

60-1386-2

60-1466-2

Programmer Module (One Required)

EP Programmer

EP160

EPD Programmeror

EP161

EP165

EP166

EP170

EP260

EP265

EP270

EP380

EP381

EP382

EPD160

EPD161

EPD170

EPD260

EPD261

EPD270

EPD380

EPD381

EPD382

EPD390

E110 consists of:

EB700 Chassis

EC600 Dust Cover

Mounting Screw (48-1836)

Surface Mount

(shown)

Cabinet Mount

EP programmers must have an Eng. code of 28 or

later (e.g. 9414-28). EPD Programmers must have

an Eng. code of 02 or later.

EP387

EPD167

EP390

8

®

FLAME SCANNERS

CAUTION: The UV1, UV2, UV8A, UV90 and 45UV3 ultra-violet flame scanners and associ-

ated amplifier modules are non-self checking UV systems and should be applied only to burn-

ers that cycle often (e.g.: a minimum of once per 12 hours) in order for the safety checking

circuit to be exercised. If component checking is required during burner operation for con-

stantly fired burners, utilize the self-checking ultra-violet flame scanners (45UV5) with asso-

ciated amplifier module (EUVS4), or the infrared flame scanner (48PT2) with associated

Auto Check amplifier (E1R1, E1R2, E1R3).

FLAME-MONITOR PROGRAMMER SELECTION

All programmers for the Flame-Monitor Series are designated with the prefix "EP" or “EPD.” The

functional operation, flame failure response time, purge timings, firing rate motor circuit, trial for

ignition timings, recycling function and display messages are determined by the programmer.

Following is a chart of the most common programmers. Refer to the appropriate product bulletin for

a detailed description of the operation of each programmer.

Take note of the programming sequence chart for each programming module for the proper explana-

tion of pre-purge timings.

WARNING: THE INAPPROPRIATE SELECTION OR APPLICATION OF A PROGRAM-

MER MODULE COULD RESULT IN AN UNSAFE CONDITION HAZARDOUS TO LIFE

AND PROPERTY. The various programmer modules (EP(D)160, EP(D)260 and EP(D)380)

are interchangeable because they plug into a common chassis. Changing the dipswitches

modifies the operation of each programmer module. Care should be taken to insure the

proper dipswitch settings. Refer to the appropriate programmer bulletin for dipswitch set-

tings. Selection of the programmer module and setting the dipswitches for a particular appli-

cation should be made by a competent professional, such as a Boiler/Burner technician

licensed by a state or government agency, engineering personnel of the burner, boiler or fur-

nace manufacturer (OEM) or in the performance of duties based on the information from the

OEM.

UV90

45UV5

UV8A

45UV3-1050

UV1A

69ND1

48PT2-9000

9

®

PROGRAMMER AND DISPLAY MODULE COMPATIBILITY

All programmers for the Flame-Monitor Series are designated with the prefix “EP” or “EPD.” The

ED510 is a 2 line by 16 character LCD display with keypad to provide both current and historical

information pertaining to the operation of the control. Refer to Bulletin ED-5101 for a complete

description of the features and capabilities of the ED510 display module. The ED500 is an eight

character LED display, was the predecessor to the ED510 and does not have the latest features of the

ED510 display module. EP style programmers with an Engineering code of 28 or later (e.g. 9414-28)

are compatible with both the ED510 and ED500 display module. EP style programmers with an

Engineering code before 28 are only compatible with the ED500 display. The EPD style program-

mers (with an Engineering code 02 or later) are compatible with the ED510 display module as well.

Note: The EPD style programmers do not require a display module to function.

FIREYE

PART

NUMBER

Pre-purge

program-

ming

(Seconds)

Proven

High Fire

Purge

Interlock

(D/8 Ckt)

Proven

Low Fire

Start

Interlock

(M/D Ckt)

Intermittent

Ignition/

Pilot

Interrupted

Ignition/

Pilot

Early Spark

Termination

Pilot

Trial-for-Ignition

Main

Trial-for-Ignition

Running

Interlock

(3/P CKT)

Firing Rate

Motor

Circuit

EPD/EP2PROGRAMMERS

EPD160

EP160

EPD1678

301

Supervised

Yes Yes No Yes No 10

10

10

15

Non Recycle Yes

EPD161

EP161

30 1

Supervised

Yes Yes No Yes No 10

10

10

30

Non Recycle Yes

EP165 7 301

Supervised

Yes Yes No Yes No 10

10

—

10 6Non Recycle Yes

EP1667301

Supervised

Yes Yes No Yes No 10

10

—

15 6Non Recycle Yes

EPD170

EP170

30 1

Supervised

Yes Yes No Yes Yes 5

10

—

10

Non Recycle Yes

EPD260

EP260

30 1No Yes No Yes No 10

10

10

15

Recycle Yes

EPD261 30 1No Yes No Yes No 10

10

10

30

Recycle Yes

EPD270

EP270

30 1No Yes No Yes Yes 5

10

—

10

Recycle Yes

EPD380

EP380

EP3878

30 No Yes Yes3Yes Yes 410

10

10

Intermittent 3

Recycle 5None

EPD381

EP381

15 No Yes Yes3Yes Yes 4 10

10

10

Intermittent 3

Recycle 5 None

EPD382

EP382

0 No Yes Yes3Yes Yes 4 10

10

10

Intermittent 3

Recycle 5 None

EPD390

EP390

90 No Yes Yes3Yes Yes 4 10

10

10

Intermittent 3

Recycle 5None

All programmers have a maximum 4 second Flame Failure Response Time (FFRT) with the exception of the EP165 and EP166 (2 sec. FFRT).

All EPD Programmers and EP Programmers have selectable 3-P Proven Open to Start feature via dipswitch.

1These programmers add a 30 second waiting period to the prepurge while the firing rate motor is driven to the low fire position.

2 Purge timings can be extended via dipswitches of EP style programmers.

3Selectable intermittent or interrupted (15 sec. MTFI) operation of terminal 6 via dipswitch (EP models only).

4These programmers can use terminal “X” for spark termination. This requires jumpering terminals 5 and 10 on the wiring base. PTFI timing is 5 seconds on terminal “X.”

5Selectable Recycle or Non-Recycle Operation via dipswitch.

6During MTFI terminal 6 is energized for 5 seconds (pilot stabilization) before energizing terminal 7 for 10 seconds for EP165 and 15 seconds for EP166 only.

7EP165 will lockout on power interruption.

8The EPD167 and EP387 wait indefinitely for the low fire start switch (M-D) to close.

Term 5

Term 6

Term 5

Term 6

10

®

For a complete system, choose one of each of the following:

- Chassis - Flame Detector

- Programmer Module - Wiring Base

- Amplifier Module

WARNING: Installer must be trained and qualified. Follow the burner manufacturers in-

structions, if supplied. Otherwise, proceed as follows:

INSTALLATION OF CONTROL

Wiring Base

Mount the wiring base on the burner or on a panel. The location should be free from excessive vibra-

tion and within the specified ambient temperature rating. The base may be mounted in any angular

position.

All wiring should comply with applicable electrical codes, regulations and local ordinances. Use

moisture resistant wire suitable for at least 90 degrees C. Good electrical wiring practice should be

followed to ensure an adequate ground system. Refer to Fireye Service Note 100 separately and Gen-

eral Grounding Rules, later in this document, for recommended grounding methods

A good ground system should be provided to minimize the effects of AC quality problems. A prop-

erly designed ground system meeting all the safety requirements will ensure that any AC voltage

quality problems, such as spikes, surges and impulses have a low impedance path to ground. A low

impedance path to ground is required to ensure that large currents involved with any surge voltages

will follow the desired path in preferences to alternative paths, where extensive damage may occur to

equipment.

Refer to suggested Wiring Diagram on page 32.

WARNING: Controls require safety limits utilizing isolated mechanical contacts. Electronic

limit switches may cause erratic operation and should be avoided.

BEFORE INSTALLING THE CONTROL

CAUTION: Ensure that electric power is turned off. Refer to SN-100 for recommended

grounding techniques.

Be aware that power to some interlocks (operating controls, air flow switches, modulating cir-

cuits, etc.) may be derived from sources other than what is controlling the Flame-Monitor.

If either a ground or a short circuit is detected, it must be eliminated before the control is plugged

into the wiring base and power turned on.

Test the electrical field wiring for short circuits and grounds. The recommended method requires the

use of an ohmmeter set on its lowest resistance scale.

Note: When using ultra-violet or infrared scanning, be sure to remove any jumpers on the wiring

base which ground the S2 terminal.

1. Touch the meter probes together and calibrate accurately to ensure a reliable test.

2. Disconnect the neutral wire (L2) from the control system at the power source. Clip one meter

test lead to the grounded green terminal on the lower right side of the wiring base and with the

other probe touch each other terminal. At no time should the meters show continuity or read 0

ohms.

11

®

3. Reconnect the neutral wire (L2) at the power source. Remove the test probe from the grounded

terminal and reconnect it to Terminal L2 in the wiring base. With the other probe, touch each

other terminal. It is normal to obtain a resistance reading on the meter at some terminals during

this test as there are resistive loads (coils, transformers, lamps, etc.) connected whose normal

DC resistance may be less than 5 ohms. However, at no time should the test meter read zero

ohms.

CAUTION: Restore power for the following test.

4. With Flame-Monitor removed, measure voltage from L2 to all other terminals. Reading should

be zero on all terminals except Ll.

INSTALLING THE CONTROL

CAUTION: Electric power must be turned off during installation.

1. Check the electrical tabs on the bottom of the chassis—if they are bent out of position, reposi-

tion them with your fingers so that they are in line as shown here.

2. Select the appropriate programmer and amplifier modules for your application. Remove the dust

cover from the chassis. Insert the amplifier module into the slot marked Flame Amplifier Mod-

ule and gently push the module into position. Insert the programmer module into the slot

marked Programmer Module and gently push the module into position. Attach the display to the

program module and plug ED580-1 into RJ45 connections.

3. Slide the slots at the bottom of the assembled control over the tabs on the wiring base. Push the

control into position. Insert a screwdriver through the hole in the top of the control and tighten

the retaining screw.

4. Electric power may now be turned on.

OPERATION

The programmer module determines the functional operation of the E110 control (e.g. purge timing,

trial for ignition timings, recycle or non-recycle operation, etc.). For purposes of illustration, we will

be looking at the EP160/EPD160 Programmer functions and messages associated with the ED510

display module in this bulletin. Because the messages change depending upon which EP style

programmer is being used, it is necessary to check the bulletin covering the specific program-

mer for exact details. Refer to the suggestions shown in this bulletin before proceeding to power the

Fireye E110 Flame-Monitor system. Items such as scanner installation, short circuit tests and safety

information should be reviewed.

12

®

CAUTION: On initial power-up and on restarts following a power failure, the control will

perform self-test diagnostics for 15 seconds.

Start-Up (Normal Cycle)

Note: For direct spark ignited oil burners, substitute the words Main-Oil Valve for Pilot Valve.

1. Constant 120 VAC should be available to the Ll-L2 terminals only on the wiring base.

2. The operating control circuits (Ll-13) will close, signaling the burner to start its firing sequence.

3. If the fuel valve end switch (13-3) is closed, the burner/blower motor (terminal M) circuit is

energized. The running interlock (limit) circuit (3-P) will close (e.g. all limits, interlocks, etc. are

proven).

4. The firing rate motor (Modulator Motor) is driven toward the high purge open damper position

(10-X circuit made).

5. When the firing rate motor reaches its open damper position, the Hi Purge switch closes (D-8)

and the prepurge interval of 30*seconds is initiated. The ED510 will display:

PURGE 0:05

HIGH FIRE PURGE

If the D-8 circuit does not close, the program will hold in this position for ten minutes waiting for it

to close. If it does not, the control will lockout.

6. When the prepurge is completed, the firing rate motor is driven toward the low purge damper

position (10-12 ckt. made). The ED510 will display:

PURGE 0:35

LOW FIRE PURGE

7. Following the minimum 30 second delay (to permit the firing rate motor to get to the low fire

position), the control will wait for the low fire switch (M-D) to close. When it closes, the trial for

ignition sequence will start. If after ten minutes, the M-D circuit is not closed, the control will

lockout. The EPD167 will wait indefinitely for the M-D circuit to close.

* Prepurge timing is selectable via dipswitches.

TYPE EP(D)160

NON-RECYCLE RUNNING INTERLOCKS (3/P) PURGE TIME - 30 SEC.*

FLAME FAILURE RESPONSE TIME 4 SEC.

PROGRAMMING SEQUENCE

L1/13

ON

LFS

CLOSED

(MD)

FIRING

PERIOD L1/13

OFF

MTFI

10 SEC

PTFI

10 SEC

MTFI

15 SEC

PURGE

30 SEC

M

T

E

R

M

I

N

A

L

S

5

6

7

POST PURGE

15 SEC

MIN

30 SEC

HIGH (10-X) LOW (10-12) AUTO (10-11) LOW (10-12)

(MODULATOR MOTOR CIRCUIT)

HFS

CLOSED

(D8)

DIPSWITCH SETTINGS

123456

INACTIVE Down Down Down Down

Refer to appropriate programmer

bulletin for a complete description

of the dipswitch functions.

13

®

8. The trial for ignition period begins with Terminal 5 and 6 being energized simultaneously. This

is known as PTFI (Pilot Trial for Ignition). The ED510 will display:

PTFI 0:02

IGNITION TIMING

This period is ten seconds in duration. If no flame is detected after ten seconds, the control will de-

energize Terminals 5 and 6 and lockout. When flame is detected during this 10 second period, the

ED510 will display

PTFI 20

FLAME SIGNAL

9. With flame proven at the end of PTFI, the main flame trial for ignition (MTFI) period begins.

Terminal 7 is energized. The ED510 will display:

MTFI 35

FLAME SIGNAL

Terminal 5 is de-energized 10 seconds later and Terminal 6 is de-energized after another 5 seconds.

10. The firing rate motor is now sent to the auto position (10-11 ckt made) and is under the com-

mand of the proportional controller. The ED510 will display:

AUTO 40

FLAME SIGNAL

NOTE: Trial-for-Ignition timings depend on the programmer selected. The timing chart on page 9

points out the differences in the EP(D)160, EP161, EP165, and EP(D)170.

Normal Shutdown

1. When the operating control circuit (L1-13) opens, the main fuel valve is de-energized. The fir-

ing rate motor is driven to the low purge position (10-12 ckt made).

2. Following a 15 second post purge, the burner/blower motor is de-energized.

3. The burner is now off and the ED510 will display

STANDBY

L1-13 OPEN

Burner history can be displayed by using ED510 keypad. See bulletin ED-5101.

BACKLIT DISPLAY

The ED510 display has a two (2) line by sixteen (16) character backlit LCD display. The backlit

function is energized when power is applied to the FLAME MONITOR.

Contrast Control: The contrast for the LCD display is factory set. If the contrast must be adjusted

for any reason (e.g.: remote mounting), a potentiometer is provided on the back of the ED510 dis-

play board. Refer to bulletin ED-5101 for detailed information.

FLAME SIGNAL

0-9

10

20-80 NORMAL

MINIMUM ACCEPTABLE

NOT ACCEPTABLE

14

®

LOCKOUTS

When a safety shutdown occurs, the control will display a message indicating LOCKOUT and the

reason for the lockout. The alarm circuit (Terminal “A”) will be energized. The non-volatile memory

will remember the status of the control even if a power failure occurs. By momentarily depressing the

reset button on the display, the control can be reset. The button must be held down for one second and

then released. Very little force is required to do this. Do not press hard.

Safety Shutdown

1. If the running interlock circuit does not close, the control will lockout and the blower motor will

be de-energized. If the interlock circuit opens during a start-up or firing period, all fuel valves

will be de-energized and the control will lockout.

2. If the proven high fire circuit (D-8) has not closed after a ten (10) minute “Hold” period at the

start of prepurge, the control will lockout.

3. If the low fire start circuit (M-D) has not closed after a ten (10) minute “Hold” period at the end

of prepurge, the control will lockout.

4. If dipswitch 6 is in the “Up” position (3-P prove open to start-enabled), and the 3-P circuit is

closed at the start of the operating cycle, the control will hold for one (1) minute waiting for the

3-P circuit to open. If, after one (1) minute, the 3-P circuit does not open, the control will lock-

out.

5. If pilot flame is not detected during the 10 second trial for ignition period, the pilot valve and

ignition transformer will be de-energized and the control will lockout on safety.

6. If main flame is not detected at the end of the main flame trial for ignition period, all fuel valves

will be de-energized and the control will lockout on safety.

7. If the main flame fails during a firing cycle, all fuel valves will be de-energized within 4 seconds

maximum, after loss of flame signal and the control will lockout on safety.

8. The EP165 and EP166 programmers will lockout on a power interruption.

9. If flame is detected when the operating control (L1-13) is open, the control will wait sixty (60)

seconds and then lockout if flame is still present. If the operating control closes and flame is

detected during purge, the blower motor (term M) remains energized and the purge sequence is

put on hold. If the flame signal goes away within sixty (60) seconds, the control will proceed

with a normal start-up. If flame signal is still present after sixty (60) seconds, the control will

lockout.

NOTE: Manual Reset is required following any safety shutdown.

NOTE: Depressing and releasing the reset button during a cycle will cause the control to shut the

burner down and recycle.

DESCRIPTION OF FUNCTIONS OF OPERATING CONTROLS

1. Operating Controls: Generally pressure or temperature activated, the operating control closes,

causing the burner start-up sequence to begin. When the operating control opens, the burner

shuts off. The operating control is connected in the L1-13 circuit on the wiring base.

2. Limit Switches: These are generally pressure, water level or temperature activated

a. Recycle —when it is desired to stop the burner when the limit switch opens and restart it

when the limit switch reclosed, they are connected between Terminals L1 and 13.

b. Non-Recycle —when it is necessary to stop the burner when the limit switch opens and

prevent it from starting until both the limit switch recloses and the manual reset is activated,

they are connected between terminals 3 and P.*

* Refer to programmer selection on page 9 to determine which programmers offer non-recycle operation of the running inter-

lock circuit (ckt. 3-P).

15

®

3. Fuel Valve End Switch Interlock: This is generally an integral switch mounted on the main

fuel valve and activated by the valve stem. It is connected between Terminal 3 & 13. The fuel

valve end switch interlock prevents a burner start-up if the valve stem is not in the “valve

closed” position.

4. Purge Interlock: Generally a firing rate motor linkage position switch or a differential air-pres-

sure switch, that proves a maximum purge air flow rate. It is connected between Terminals D

and 8. The purge interlock proves that the purge air flow rate is at maximum during the purge.

5. Running Interlocks: These generally are air flow switches, high and low fuel pressure

switches, oil temperature switches, atomizing media pressure switches, and excess smoke den-

sity controls. These interlocks prove proper conditions for normal operation of the burner. They

are wired in series and connected between Terminals 3 and P.

6. Low Fire Start Interlock: Generally a firing rate motor linkage position switch or a damper

position switch, will prove both the linkage and dampers are in their proper positions to begin

burner light off. This switch is connected between Terminals M and D.

IMPORTANT INFORMATION — PLEASE READ CAREFULLY

DETECTING AIR FLOW SWITCH (3-P) CLOSED AFTER START

In code 39 programmers and above, the method used to detect the air flow switch closed at the

beginning of a cycle has been changed to avoid any nuisance lockouts. Currently, after the operating

control closes, the programmer waits 10 seconds for the air flow switch to close and if not closed

will go into lockout. The EP programmers utilize the open damper switch interlock, D-8, to deter-

mine the wait time for the air flow switch to close. If, at the start of a cycle after a blower turns on,

the D-8 interlock is detected as closed, most likely indicating a jumped high fire switch, the pro-

grammer allows 20 seconds for the air flow switch to close. Alternatively, at startup, if the D-8 inter-

lock is open, indicating the firing rate motor is at the low fire position and the damper is closed, the

programmer will not check for the air flow switch closed until 10 seconds after the open damper

switch has closed and the purge period has begun. This means the programmer will send the mod

motor to the high fire position, forcing the high fire damper switch to close, and will then begin its

10 second timer to check for the air flow switch to close.

EP160 - DIP SWITCH 1

When used in conjunction with Nexus PPC5000, dip switch 1 in the UP position provides a 3 second

delay between burner cycles. This time period is used to de-energize the blower motor, terminal M.

This allows sufficient time for the PPC5000 to realize a new cycle is beginning and it can reset its

operating parameters accordingly.

Refer to the specific programming bulletin for additional information regarding dip switch settings.

16

®

EP(D)160 LOGIC FLOW DIAGRAM NORMAL CYCLE

MODULATOR HELD

AT LOW FIRE

MODULATOR SENT

FROM AUTO TO

LOW FIRE

MODULATOR SENT

FROM LOW FIRE

TO AUTO

BLOWER STOPS 15 SEC. AFTER L1-13 OPENS STANDBY

L1-13 OPEN

19

TERMINAL 7 DE-ENERGIZED

18

DEMAND SATISFIED L1-13 OPENS

17

TERMINAL 7 REMAINS POWERED

16

TERMINAL 6 CUT OUT 15 SEC AFTER 7 CUT IN14

TERMINAL 5 CUT OUT 10 SEC. AFTER 7 CUT IN13

MAIN FUEL POWERED ON TERMINAL 7 AT END OF PTFI12

SPARK & PILOT POWERED ON TERMINALS 5 & 610

YES

YES

YES

LOW FIRE PURGE COMPLETED IN 30 SEC.

8

HIGH FIRE PURGE COMPLETED IN 30 SEC.7

YES

NO

NO

NO

NO

NO

YES

YES

YES

NO

OPERATING CONTROL CLOSED L1-13

POWER ON TERMINALS L1 & L21

MODULATOR SENT

TO LOW FIRE

MODULATOR SENT

FROM LOW TO

HIGH FIRE

MODULATOR SENT

FROM HIGH FIRE

TO LOW FIRE

NO LOCKOUT +

LOCKOUT +

HOLD 10 MIN. THEN LOCKOUT +

HOLD 10 MIN. THEN LOCKOUT +

15 IS FLAME PROVED?

IS FLAME PROVEN WITHIN 10 SEC?

IS LOW FIRE INTERLOCK MADE? M-D

ARE LIMITS L1 TO 13 MADE?

3

4

5

6

POST PURGE

CYCLE COMPLETE

AUTO

FLAME SIGNAL

MTFI

FLAME SIGNAL

PTFI

FLAME SIGNAL

PTFI

IGNITION TIMING

PURGE

HIGH FIRE PURGE

LOCKOUT +

LOCKOUT +

0:05

0:05

0:02

19

35

40

STANDBY

L1-13 OPEN

2

IS F.V.E.S. MADE 13-3

IS AIR FLOW SWITCH MADE? 3-P

IS HIGH FIRE INTERLOCK MADE? D-8

PURGE

LOW FIRE PURGE

0:40

+ LOCKOUT AND HOLD MESSAGES ARE EXPLAINED IN THE FOLLOWING PAGES.

9

11

17

®

ED510 MESSAGES

RUN MESSAGES

The operating control of the FLAME-MONITOR (terminals L1-13) is open.

Firing rate motor sent to high fire (term. 10-X made), purge timing displayed

upper right hand corner.

Firing rate motor sent to low fire (term. 10-12 made), purge timing displayed in

upper right hand corner.

PTFI timing started. Pilot not proven yet. PTFI timing displayed in upper right

hand corner.

Pilot flame proven during PTFI. Flame signal strength displayed in upper right

hand corner.

Main flame proven during MTFI. Flame signal strength displayed in upper right

hand corner.

Modulator motor sent to auto position (term 10-11 made). Flame signal strength

displayed in upper right hand corner.

Demand satisfied. L1-13 open. Blower motor de-energized 15 seconds after L1-13

opens.

HOLD MESSAGES

Dipswitch #6 (3-P Proven Open to Start) is set in the Up position (Enabled). At the

start of the cycle, the 3-P circuit was closed. It will hold in this position for 60 sec-

onds and then lockout if the 3-P circuit does not open.

The control has driven the firing rate motor to high purge (term. 10-X made) and is

waiting for the high fire switch (term. D-8) to close. It will hold this position for

ten (10) minutes and then lockout if the D-8 circuit does not close. Applies to

EP(D)160, EP(D)161, EP165, EP166, EPD167 and EP(D)170 programmers.

Dipswitch #6 (3-P Proven Open to Start) is set in the Up position (Enabled). At the

start of a cycle the D-8 circuit was closed. It will hold in this position for 30 sec-

onds and then lockout if the D-8 circuit does not open. Possible solution is to

remove jumper from D-8 circuit or properly set the firing rate motor and switches.

Applies to EP(D)160, EP(D)161, EP165, EP166, EPD167 and EP(D)170 pro-

grammers

Dipswitch #6 (3-P Proven Open to Start) is set in the Up position (Enabled). At the

end of high fire purge and beginning of low fire start, the M-D circuit is closed. It

will hold in this position for 30 seconds and then lockout if the M-D circuit does

not open. The solution is to remove jumper from the M-D circuit or properly set

the firing rate motor and switches. Applies to EP(D)160, EP(D)161, EP165,

EP166, EPD167 and EP(D)170 programmers

STANDBY

L1-13 OPEN

PURGE 0:05

HIGH FIRE PURGE

PURGE 0:35

LOW FIRE PURGE

PTFI 0:02

IGNITION TIMING

PTFI 19

FLAME SIGNAL

MTFI 25

FLAME SIGNAL

AUTO 40

FLAME SIGNAL

POST PURGE 0:05

CYCLE COMPLETE

HOLD STANDBY 0:23

3-P INTLK CLOSED

HOLD PURGE 0:00

D-8 LIMIT OPEN

HOLD PURGE 0:00

D-8 LIMIT CLOSED

HOLD PURGE 0:30

M-D LIMIT CLOSED

18

®

The control has finished purge and the firing rate motor is driving to the low fire

position (term. 10-12 made) waiting for the low fire start switch (term. M-D) to

close. It will hold this position for ten (10) minutes and then lockout if the M-D

circuit does not close, excluding the EPD167.

The running interlock circuit (3/P) has not closed within the first ten (10) seconds

of purge. The control will hold for ten (10) minutes and then lockout. Applies to

recycle programmers only.

Flame has been sensed during the burner off time (term. L1-13 open) or during the

purge period. This message will hold for sixty (60) seconds and then lockout if

flame is still present. Flame signal strength is displayed in the upper right hand

corner.

LOCKOUT MESSAGES

Dipswitch #6 (3-P Proven Open to Start) is set in the Up position (Enabled). At the

start of the cycle, the 3-P circuit was closed, and the control has waited 60 seconds

for the 3-P circuit to open.

The control has held for more than 10 minutes waiting for the high fire switch (D-

8) to close. Applies to EP(D)160, EP(D)161, EP165, EP166, EPD167 and

EP(D)170 programmers.

Dipswitch #6 (3-P proven open to start) is set in the Up position (Enabled). The

D-8 circuit has been closed for 30 seconds at the start of cycle. Applies to

EP(D)160, EP(D)161, EP165, EP166, EPD167 and EP(D)170 programmers

Dipswitch #6 (3-P proven open to start) is set in the Up position (Enabled).The M-

D circuit has been closed for 30 seconds at the end of high purge or at the begin-

ning of low fire start. Applies to EP(D)160, EP(D)161, EP165, EP166, EPD167

and EP(D)170 programmers

The running interlock circuit (3-P) has opened during the purge period or failed to

close within the first 10 seconds of purge on non-recycle programmers or has not

closed within 10 minutes on recycle programmers.

The fuel valve end switch wired between terminals 13 and 3 opened during purge

or at start up.

The control has held for more than 10 minutes waiting for the low fire switch

(M-D) to close. This does not apply to the EPD167 or EP387.

The running interlock circuit (3-P) has opened during the pilot trial for ignition

period. Applies to non-recycle programmers only.

The running interlock circuit (3-P) has opened during the main trial for ignition

period. Applies to non-recycle programmers only.

The running interlock circuit (3-P) has opened during the main burner on period.

Applies to non-recycle programmers only.

HOLD PURGE 0:00

M-D LIMIT OPEN

HOLD PURGE 0:10

3-P INTLK OPEN

HOLD STANDBY 25

FALSE FLAME

LOCKOUT STANDBY

3-P INTLK CLOSED

LOCKOUT PURGE

D-8 LIMIT OPEN

LOCKOUT PURGE

D-8 LIMIT CLOSED

LOCKOUT PURGE

M-D LIMIT CLOSED

LOCKOUT PURGE

3-P INTLK OPEN

LOCKOUT STANDBY

13-3 FUEL VALVE END SWITCH

LOCKOUT PURGE

M-D LIMIT OPEN

LOCKOUT PTFI

3-P INTLK OPEN

LOCKOUT MTFI

3-P INTLK OPEN

LOCKOUT AUTO

3-P INTLK OPEN

19

®

Flame has been sensed during the burner off time (term. L1-13 open) or during the purge

period for sixty (60) seconds.

A flame failure occurred during the pilot trial for ignition period.

A flame failure occurred during the main trial for ignition period.

A flame failure occurred during the main burner on period.

This message appears because of ignition cable noise. Reroute scanner wires away from

high voltage ignition cables. Check for proper spark gap or cracked porcelain. Check for

proper grounding of wiring base and power supply. Replace worn ignition cable and/or

faulty connections.

Excessive current or short circuit detected on terminals 5, 6, or 7 during PTFI, MTFI, or

Auto. The control will lockout upon sensing this condition on two consecutive cycles.

During pilot trial for ignition period, voltage sensed on terminal 7 is different from the pre-

vious cycle. (e.g.: jumper added or removed between term. 7 and 5 or 6).

Electrical noise detected on terminals L1 and L2.

A power interruption to terminals L1 and L2 has caused the control to lockout. Applies to

EP165 and EP166 programmers only.

CHECK MESSAGES

The "Run-Check" switch has been placed in the Check position during purge and will hold

indefinitely. The firing rate motor is being driven to the high purge position.

The "Run-Check" switch has been placed in the Check position after high fire purge and

will hold indefinitely. The firing rate motor is being driven to the low fire position.

The "Run-Check" switch has been placed in the Check position during the pilot trial for

ignition period. Flame signal strength is displayed in the upper right hand position. The

control will lockout on safety only when no flame signal is sensed for a continuous 30 sec-

onds while the control is in the Check position.

The "Run-Check" switch has been placed in the Check position during the main burner on

period. and the firing rate motor is driven to the low fire position. Flame signal strength is

displayed in the upper right hand corner.

LOCKOUT STANDBY

FALSE FLAME

LOCKOUT PTFI

FLAME FAIL

LOCKOUT MTFI

FLAME FAIL

LOCKOUT AUTO

FLAME FAIL

LOCKOUT PTFI

SCANNER NOISE

LOCKOUT PURGE

SHORT CIRCUIT TERM 5,6,7

LOCKOUT PTFI

FUEL VALVE STATE CHANGE

LOCKOUT AUTO

LINE FREQUENCY NOISE DETECTED

LOCKOUT

AC POWER FAIL

CHECK PURGE 0:15

D-8 HI LIMIT

CHECK PURGE 0:45

M-D LOW LIMIT

CHECK PTFI 19

FLAME SIGNAL

CHECK AUTO 25

LOW FIRE SIGNAL

20

®

The “Check-Run” switch has been placed in the Check position with the operating

control circuit (L1-13) open. Every time the Reset button is depressed and held for

one second will increment the Unit Address by one. Refer to programmer bulletin

for additional information on Unit Address.

DIAGNOSTIC MESSAGES

POSSIBLE CAUSE SOLUTION

— High electrical noise — Check for proper ground on power supply.

— Install noise suppressor on power supply.

— Defective field wiring. — Make sure line phase on interlock circuit is

the same as found on L1/L2 power supply to

E110.

— Defective amplifier. — Replace amplifier.

— Defective IR scanner. — Replace IR cell.

— Voltage on terminal 7 at

improper time.

— Defective Chassis.

— Defective Programmer.

— Check wiring to terminal 7.

— Replace Chassis (EB700).

— Replace Programmer.

— Voltage on terminal 5 or 6 at improper

time.

— High Electrical Noise.

— Failed Programmer.

— Worn Chassis.

— Check wiring to terminals 5 and 6.

— Install noise suppressor on power

supply

— Re-route scanner wires away from high

voltage wiring.

— Replace Programmer.

— Replace Chassis.

— Flame signal detected during shutter

close time on 45UV5 scanner.

— Stuck scanner shutter. Replace 45UV5

scanner.

— The E300 Expansion Module has a

defective optocoupler.

— Replace E300 Expansion Module.

— Amplifier has failed diagnostic checks. — Replace amplifier.

— Defective programmer. — Replace programmer.

CHECK STANDBY 00

UNIT ADDRESS

LOCKOUT AUTO

CHECK AMPLIFIER

LOCKOUT PTFI

CHECK CHASSIS

LOCKOUT PURGE

CHECK PROGRAMMER

LOCKOUT AUTO

CHECK SCANNER

LOCKOUT AUTO

CHECK EXPANSION MODULE

LOCKOUT AUTO

AUTO CHECK AMPLIFIER FAIL

FIREYE ED510

SYSTEM ERROR

Table of contents

Other Fireye Controllers manuals

Fireye

Fireye PPC4000 SERIES User manual

Fireye

Fireye PPC6000 Series Operating instructions

Fireye

Fireye MicroM Series User manual

Fireye

Fireye PPC6000 Series Manual

Fireye

Fireye SB Series User manual

Fireye

Fireye BurnerPRO BP110 User manual

Fireye

Fireye FX Series User manual

Fireye

Fireye D10 Series User manual

Fireye

Fireye PPC6000 Series User manual

Fireye

Fireye PPC5000 User manual

Popular Controllers manuals by other brands

Sunlight Supply

Sunlight Supply TITAN CONTROLS KRONUS 2 instruction manual

Sensus

Sensus 461-57S Installation and maintenance instructions

RIB

RIB T2-CRX Simplified instructions

Omron

Omron sysmac EtherCAT NJ101 Series Connection guide

MFJ

MFJ MFJ-1270X instruction manual

Growee

Growee Hydro Master quick start guide