Fireye PPC5000 User manual

1

®

DESCRIPTION The PPC 5000 is an electronic fuel/air ratio controller employing techniques of parallel positioning

for industrial burners firing gaseous and/or liquid fuels.

The basic unit controls four servo motors, positioning them to within 0.1 of an angular degree. Seven

programmable profiles are available where each profile determines the positional relationship

between all servo motors across the firing range of the burner. The unit has the capability to increase

the number of motor drives from four to eight. These servo motors can operate fuel butterfly or

metering valves and air dampers.

Variable speed interfaces are available to control, the burner fan motor speed and water feed pumps.

Controlling the fuel/air ratio by adjustment of fan speed saves electrical energy and reduces noise.

When the motor speed is halved an 80% electrical energy saving can be realized. Up to four variable

speed interfaces can be added to a single PPC 5000.

Oxygen trim control is another valuable option to achieve maximum efficiency and fuel savings. Fir-

eye’s zirconia oxygen probe has earned an international reputation for reliability and longevity. Oxy-

gen trim automatically and continuously compensates for all the variables that affect efficient

combustion. This option will give typical fuel savings of 2% and will ensure safe and efficient com-

bustion when firing fuels with varying calorific value.

Optional simultaneous firing software has been developed by Fireye which employs novel, dynamic

setpoint technology. It ensures that the correct fuel/air ratio is maintained across the firing range

when two fuels are being fired simultaneously and the ratio of one fuel to the other is maintained

correctly. A single 4 to 20mA signal varies the mix of the two fuels being fired. Oxygen trim is

needed for all simultaneous firing applications. Fuels or fuel combinations with differing and/or

varying calorific values can be accommodated. Switching between various fuel combinations

becomes a routine task.

“ComFire” communications software is an option available for the PPC 5000 electronic fuel/air ratio

controller. This powerful package gives connection to a local or remote personal computer via an

RS485 connection. Information such as setpoints, profiles and engineer’s data is displayed in tabular

and graphic form. A dynamic plant mimic shows the status of all burners on the site provided that

they have PPC 5000 controls. Burner utilization curves can be displayed as chart recorder images

and alarms with time and date stamp are also shown. “ComFire” provides non-safety critical ana-

logue and digital control of the burner from the PC. It is possible to select “burner on”, “trim on”,

“release to ignite”, “release to modulate”, “enable boiler sequencing”, lead boiler for sequencing

control and boiler setpoint. Modulation rate, boiler control setpoints and limits can also be varied

from the PC.

Sequencing software for up 10 boilers is also available allowing the operator to select any boiler as

the lead boiler. As the demand increases the burners progressively move to “high fire” leaving the

last two boilers brought “online” to “modulate”.

As the demand decreases boilers progressively move from “high fire to “modulating” and then from

“modulating to “off-line”. Three pass code levels ensure that unauthorized personnel cannot service

the burners nor change commissioning data. The unit has extensive self diagnostics with primary and

secondary level fault analysis.

PPC5000

Fuel / Air Ratio

Controller

PPC-5000

APRIL 18, 2013

2

Table of Contents

This bulletin describes the installation and commissioning of the PPC5000 fuel / air ratio controller. It may be used in conjunction with

the following other bulletins:

— Nexus NEX-1001 bulletin

— ComFire combustion analysis tool user bulletin

— Nexus / PPC5000 boiler sequencing bulletin

Description....................................................................................................................................1

Safety information.........................................................................................................................4

Installation.....................................................................................................................................5

Mounting the display.....................................................................................................................6

Circuit board removal....................................................................................................................7

Option link selection .....................................................................................................................8

Servo-motor Selection...................................................................................................................9

Wiring..........................................................................................................................................10

Operation in run mode.................................................................................................................16

Start-up sequence ........................................................................................................................19

Modulation..................................................................................................................................20

Safety shutdown (burner lockout)...............................................................................................20

The display..................................................................................................................................21

Motor adjustment ........................................................................................................................24

Feedback potentiometer ..............................................................................................................24

Control direction .........................................................................................................................24

Adjusting microswitch positions.................................................................................................24

Locking the servo-motor to the valve shaft.................................................................................25

Operation in commissioning mode .............................................................................................26

Commissioning data....................................................................................................................26

Option set mode ..........................................................................................................................27

Commission ratio mode ..............................................................................................................28

Adjust ratio mode........................................................................................................................29

Finding the software issue & unit configuration.........................................................................31

The oxygen trim option...............................................................................................................32

Oxygen probe description ...........................................................................................................32

Installation of oxygen probe........................................................................................................33

Wiring..........................................................................................................................................35

Interface to auxiliary equipment .................................................................................................37

Calibrating and servicing the oxygen probe................................................................................38

Removing the oxygen probe .......................................................................................................39

SOx, NOx, smoke, CO, AUX1, AUX2, O/P1, O/P2 ..................................................................40

Oxygen trim operation ................................................................................................................40

Commissioning oxygen trim.......................................................................................................40

Flow calculation table .................................................................................................................43

3

®

Troubleshooting.......................................................................................................................... 45

Inverter (variable speed) drives.................................................................................................. 47

System configuration.................................................................................................................. 47

Description of control method.................................................................................................... 48

Setting up the inverter for use with the 5000.............................................................................. 48

Setting up the 5000 for use with a inverter drive........................................................................ 49

Troubleshooting inverter problems............................................................................................. 50

Option parameters....................................................................................................................... 51

Option parameter selection of profiles and drives...................................................................... 72

Derivation of modulation rate..................................................................................................... 73

Faults and fault finding............................................................................................................... 74

Fault listing................................................................................................................................. 75

The engineer’s key...................................................................................................................... 79

Troubleshooting.......................................................................................................................... 84

Technical specification ............................................................................................................... 87

Oxygen probe kit ........................................................................................................................ 89

5000 Commissioning sheet......................................................................................................... 89

Option parameters....................................................................................................................... 90

Distribution board connections................................................................................................... 91

AH221250 (for use with 2 x IDB).............................................................................................. 91

AH221312 (for use with 1 x IDB & 1 x FMI)............................................................................ 92

4

SAFETY INFORMATION

WARNING: The equipment in this manual is capable of causing property damage, severe

injury or death. It is the responsibility of the owner or user to ensure that the equipment

describedhereinisinstalled,operatedandcommissionedincompliancewiththerequirements

of all national and local legislation which may prevail.

When this equipment is mounted on a burner/boiler, due regard must be given to the requirements of

that appliance.

Before attempting to install, commission or operate this equipment, all relevant sections of this

document must be read and fully understood. If in doubt about any requirements consult the

supplier. Installation, commissioning or adjusting of this product MUST be carried out by suit-

ably trained engineers or personnel qualified by training and experience.

The manufacturer of this equipment accepts no liability for any consequences resulting from the

inappropriate, negligent or incorrect installation, commissioning or adjustment of operating parame-

ters of the equipment.

This equipment MUST only be mounted on to burners as detailed in the contracted specification.

The supplier must approve any change in the specification in writing.

Control panels MUST NOT be left uncovered while power is on. If it is essential to do so while rec-

tifying faults, only personnel qualified by training and experience should be involved.

The time any covers are off must be kept to a minimum and warning notices MUST be posted.

Before attempting any work on this equipment, the electrical supplies MUST be isolated.

Safety interlocks MUST NOT be removed or over-ridden. Any faults detected MUST be corrected

before the unit is operated.

CAUTION: Some versions of this equipment contain a lithium battery.

Note: The manufacturer of this equipment has a policy of continual product improvement and

reserves the right to change the specifications of the equipment and the contents of this manual with-

out notice.

WARNING: Explosion of fire hazard can cause property damage, severe injury or death. To

prevent possible hazardous burner operation, verification of safety requirements and inter-

locks must be performed each time a control is installed on a burner.

5

®

INSTALLATION

BEFORE INSTALLING THE PPC5000 CONTROL

Wiring Base

Install the PPC5000 where the relative humidity never reaches the saturation point. The PPC5000

system is designed to operate in a maximum 80% relative humidity continuous, non-condensing

environment. Do not install the PPC5000 system where it can be subjected to vibration in excess of

0.5G continuous maximum vibration. The PPC5000 system is not a weather tight enclosure.

Wiring must comply with all applicable codes, ordinances and regulations.

1. Wiring must comply with NEC Class 1 (Line Voltage) wiring.

2. Limits and interlocks must be rated to simultaneously carry and break current to the ignition

transformer, pilot valve and main fuel valve(s).

3. Recommended wire routing of lead wires:

a. Do not run high voltage ignition transformer wires in the same conduit with any other

wires.

b. Do not route flame detector lead wires in conduit with line voltage circuits. Use separate

conduit where necessary.

4. Maximum wire lengths:

a. The maximum lead wire length is 200 ft. (61 meters) to terminal inputs (Operating limits,

interlocks, valves, etc.).

b. Modbus communications: The maximum cable length of wire is 3200 feet (1000 meters)

for RS-485.

FIGURE 1. Mounting the Control Unit

This section contains basic installation

information concerning the PPC5000 sys-

tem (controller and panel-mounted dis-

play), the servo-motors and the wiring.

The control unit is designed to be fitted

inside the burner control cabinet. The cabi-

net should have a minimum protection

level of NEMA 12 (IP40) for indoor use,

or NEMA 4 (IP54) for outdoor use.

The control unit should be mounted so that

the circuit boards within it are vertical, to

maximize cooling efficiency.

A clearance is required of a least 80mm

above and 20mm below and at the sides of

the controller enclosure.

The operating temperature range of the

equipment is 0 to 60°C.

CAUTION: Ensure that electric power is turned off. Refer to SN-100 for recommended

grounding techniques.

Be aware that power to some interlocks (operating controls, air flow switches, modulating

circuits, etc.) may be derived from sources other than what is controlling the PPC5000.

5.7” (144mm)

2.7” (70mm)

8.1”

(205

mm)

8.7”

(220

mm)

7.6”

(192

mm)

1/8” (M4) CLEAR

ALL DIMENSIONS IN INCHES (MILLIMETERS)

FRONT VIEW

UP

6

FIGURE 2. Mounting the Display

WIRING CONNECTIONS

DISPLAY CONTROLLER PPC5000

1 = 5v PA8

2 = KEY RETURN PA9

3 = DATA PA10

4 = CLOCK PA11

5 = STROBE PB3

6 = GROUND PA15

1 5/8” (40mm)

4 HOLES (M4 CLEAR)

PANEL CUT-OUT

3 7/16” (87mm)

4 1/4” (108mm)

3 26/32” (97mm)

4 1/8” (105mm)

4 27/32” (123mm so.)

PANEL FRONT

The display should be mounted on the

front of the burner cabinet, or similar

accessible location, as close to the con-

troller as is practical.

Refer to factory for cable recommenda-

tions if the display’s cable length needs to

be extended.

It extends for [40mm]/[1.6in] behind the

panel, and [5mm]/0.2in] in front of the

panel.

The maximum allowable panel thickness is

[7mm]/[0.3in].

7

®

Circuit Board Removal

Please refer to the exploded unit drawing below.

5. Disconnect the unit’s power supply.

6. Undo the four screws and remove the grey plastic lid to expose the connectors.

7. Remove all the connectors.

8. Undo the four hexagonal pillars, and lift away the retainer frame.

9. Carefully remove the distribution board.

10. Each of the daughter boards can now be removed as required by pulling on the edge of the PCB

(do not pull the connector strips).

8

Option Link Selection

The unit has a number of option selection links, located on various boards. The function and settings

are marked along side each link. These links must be set to the correct position before power is

applied.

Power Supply Voltage

The 5000 control system must be set for the correct supply voltage.

The supply voltage is selected via a link arrangement on the power supply board. The possible sup-

ply voltages are tabulated below, together with the necessary fuse rating.

In order to set these links and fit the correct supply fuse, the power supply board must be removed

(see Circuit board removal).

Boiler Pressure and Temperature Sensor Type and Supply

If a boiler pressure/temperature sensor or modulation potentiometer is used, the links LK9 and LK10

on the power supply board must be set to suit the type of sensor. For example:

For a 4-20mA loop-power sensor, choose a +20V supply with current (I) input.

For a 0-5V modulation potentiometer, choose a +5V supply with voltage (V) input

Ensure that option parameter 3.2 is set to match this jumper position.

Potentiometer Supply Voltage

The 5000 can either supply +5v or +15v DC to the potentiometers.

If the potentiometer moves over its entire 270º range for 90º of servo-motor travel, select a +5v

supply.

If the potentiometer is a 340º type but only moves over 90º of its range for 90º of servo-motor travel,

select a +15v supply.

For the basic drive board, a single jumper link (LK1) is fitted which determines the supply voltage

for all four feedback potentiometers connected to the board. The position for each supply voltage is

printed on the circuit board adjacent to the jumper.

For the isolated drive board, two jumper links are fitted which determine the supply to each of the

two feedback potentiometers connected to the board. The positions for each supply voltage are

printed on the board next to the link. LK1 selects the supply voltage for feedback potentiometer 1.

In order to set the feedback potentiometer supply jumpers, the boards must be removed from the

enclosure. For details of how to do this, see Circuit board removal.

SUPPLY VOLTAGE (V) LINKS REQUIRED FUSE RATING (mA)

110 LK1 AND LK3 315 ANTI-SURGE

120 LK4 AND LK6 315 ANTI-SURGE

220 LK2 AND PARK 160 ANTI-SURGE

240 LK5 AND PARK 160 ANTI-SURGE

POTENTIOMETER TYPE SUPPLY VOLTAGE

MINIMUM

POTENTIOMETER VALUE

(Ohms)

MAXIMUM

POTENTIOMETER VALUE

(Ohms)

270° with full travel 5V 1K 5K

340° with 90° travel 15V 3K 15K

9

®

RS485 TERM (RS485 serial communications termination resistor)

The position of this link is important only

if the RS485 serial communications are to

be used. The two units at the end of the

communications bus should have this link

set to the IN position. All other units

should have the link set to the OUT posi-

tion. If only two units are on the communications bus, set the links on both units to the IN position.

This link is LK1 on the burner interface board.

SERVO-MOTOR SELECTION

Motor Requirements

Since the servo-motors are not always supplied as part of the 5000 system, a few guidelines are

useful when selecting suitable motors other than those supplied by Fireye.

• All servo-motors must be of the same operating voltage, not exceeding 250V rms / 50V rms

depending on board type.

• All motors must be AC

• The servo-motor current must not exceed 150mA rms / 750mA rms depending on board type.

• If the motor voltage is lower than the mains supply voltage then a suitable power supply (such

as a transformer) must be provided

• The motor supply to the 5000 must be protected with a suitable fuse for the motors being used.

The fuse must not exceed 3A to ensure that damage to the control unit does not occur

• The servo-motor time for 90° movement must not be less than 10 seconds or more than 60 sec-

onds

• All servo-motors must have internal limit switches fitted which are adjusted to prevent exces-

sive rotation

• All servo-motors must be able to drive the load imposed on them

• All servo-motors must have suitable protection for the burner environment (for example, IP65

for applications exposed to the weather).

If in any doubt about a particular servo-motor’s suitability, seek confirmation from your equip-

ment supplier, who have a list of suitable motors.

Potentiometer requirements

All servo-motor potentiometers should be good quality plastic film types, with high resolution.

Depending on the supply voltage, a minimum resistance is allowed for the feedback potentiometers

to prevent excessive current consumption. See section 1 - Potentiometer supply voltage on page 8 for

details.

The potentiometer must be securely fixed to the output shaft of the gearbox in such a way as to give

accurate indication of the shaft position under all conditions and at all times.

IN

OUT

RS485

TERM

IN

OUT

RS485

TERM

IN

OUT

RS485

TERM

PC

10

Wiring

WARNING: Wiring Installation must be carried outby acompetent electrician andis subject

to I.E.E. wiring regulations (BS 7671:1992) and/or local standards.

Hazardous voltages must be isolated before service work is carried out.

The clamping bar on the control unit performs only an earth function and does not provide strain

relief. Secure all cables carried in conduit at both ends using a suitable anchorage method in the cab-

inet.

If the mains power is known to be noisy or suffer from occasional brown-outs or black-outs then a

correctly rated (20w) un-interruptible power supply (UPS) should be used to ensure a clean continu-

ous mains power supply to the 5000 controller. This must be located as close as possible to the unit.

To comply with EMC requirements, wire the control unit using the specified cable sizes and shield

connections. Clamp all signal cable shields to ground using the clamping bar provided on the control

unit. Connect all cable shields to ground at the control unit end only, with the exception of the cables

that connect the display and pressure sensors. Use Belden 8735 or equivalent.

The unit case and PA6 must be connected to Ground.

Using the Cable Clamp

A clamping bar is provided on the control

unit for termination of cable screens

where necessary.

The cable should be prepared by cutting

around the outer sleeve, taking care not to

damage the screen (1).

Pull the sleeving apart to expose 1/3”

(8mm) of the screen (2).

Place the exposed length of screen under

the clamp bar and tighten the screws (3).

8mm

(1)

(2)

(3)

11

®

LIVE and NEUTRAL Supply

The LIVE and NEUTRAL supplies must be con-

nected using multi-strand single core PVC insu-

lated 16/0.2mm wire. The live connection should

be fused with a maximum rating of 3A.

The NEUTRAL connection for PC19 must be

wired to PA4. The NEUTRAL for PC19 must not

come from anywhere else.

Interface to Burner Controller Units

WARNING: Although the 5000 system has an optional software controlled postpurge this

MUST NOT be used to replace the pre-purge as dictated by the chosen burner controller.

Please note whatever burner controller is being used that the PPC 5000 must be wired so

that a safety shutdown will switch off the burner.

Since many different burner controller units can be

used with this system, it is only intended that guid-

ance on interconnection be given in this bulletin.

Specific information for interconnection to

approved "burner controllers" should be obtained

from the manufacturer. Alternatively specific infor-

mation should be obtained by reference to the sup-

plier of this equipment.

These connections must be wired using single con-

ductor TEW, AWM or MTW within the cabinet.

Conductors to be pulled through conduit should be

THHN or TFFN.

Maximum wiring size is 16 AWG.

Fuel, auto/man (H/A), up, down, aux 1 and aux 2 inputs

These inputs must be connected using multi-strand single core PVC insulated 16/0.2mm wire. Note

that these inputs expect high voltage mains signals with the same phase as the mains supply on PA1.

The three fuel selection inputs are used to determine which profile the unit selects. Each profile can

fire any combination of the three different fuels.

LIVE PA 1

NEUTRAL PA3

NEUTRAL PA4

LIVE

NEUTRAL

MAX 3A

NEUTRAL

TO PC19

PC19

PC17

PC16

PC15

PC14

PC13

ON / OFF PC12

HI / LO PC11

PC10

PC9

PC8

PURGE PC7

IGN PC6

COMM PC5

CONTROL TRIAC PC4

CONTROL TRIAC PC3

SAFETY RELAY PC2

SAFETY RELAY PC1

BURNER CONTROL SIGNALS

12

The two auxiliary inputs can be configured via option parameters to provide / override various status

inputs such as fault mute, burner on etc.

If the hand/auto (H/A) input is off, the UP and DN inputs will have no effect, and the unit will mod-

ulate automatically.

If the hand/auto (H/A) input is on, the UP input will cause the modulation rate to increase

if it is energized, and the DN input will cause the modulation rate to decrease if it is

energized.

Motor Up/Down Outputs and Feedback Potentiometer Inputs

The motor up/down out-

puts should be connected

using single conductor

TEW, AWM or MTW

within the cabinet. Conduc-

tors to be pulled through

conduit should be THHN

or TFFN. Maximum wiring

size is 16 AWG. The con-

nections to the motor

should be made via its

switched inputs, so that the

internal micro switches

prevent the motor being

damaged if it is driven to

either end of its travel.

Motor feedback potentiom-

eter cabling must be overall

shielded 3-conductor PVC

insulated Belden 8735 or

similar. Since this cable may be run in conduit with the motor drive wiring, its voltage rating must

exceed the maximum voltage carried by any other cable in the same conduit.

Connect the shield with the use of the clamping bar.

Make all connections at the servo-motor first. Incorrect connection may damage or destroy the

motor potentiometer.

PROFILE 1

INPUT

(PC13)

OFF

PROFILE 2

INPUT

(PC14)

OFF

PROFILE 4

INPUT

(PC17)

OFF

PROFILE

SELECTED

NONE

BURNER OFF

ON OFF OFF 1

OFF ON OFF 2

ON ON OFF 3

OFF OFF ON 4

ON OFF ON 5

OFF ON ON 6

ON ON ON 7

M

LINE/MOTOR

CABLE CLAMP

NEUTRAL/MOTOR

COMMON

SUPPLY

MOTOR COM PE 1

MOTOR UP PE 3/5/8/10

MOTOR DN PE 2/4/7/9

POT SUPPLY PD 4/10/13/18

FEEDBACK PD 3/9/12/17

POT GND PD 2/8/11/16

13

®

Pressure/Temperature Sensor Input

The pressure/temperature cabling

must be overall shielded 3-conduc-

tor Belden 8735 or similar. Since

this cable may be run in conduit

with high voltage wiring, its voltage

rating must exceed the maximum

voltage carried by any other cable

in the same conduit.

The input is suitable for use with 0-5V

or 4-20mA signals (externally or inter-

nally powered), the PXMS-XXX steam

pressure sensor, or a three wire resis-

tance thermometer.

Refer to the option links section for

details on setting the correct voltage

and input type.

Connect the cable shield to the controller with the use of the clamping bar.

Make all connections at the sensor/transmitter first.

SENSOR SUPPLY PA16

SENSOR IN PA17

SENSOR GND PA18

CABLE

CLAMP

Fireye PXMS-XXX

SENSOR

+ -

OR EXT. SELF-

POWERED

4-20mA /0-5V

5/20V

+

-

CABLE

CLAMP

SENSOR GND PA18

SENSE RTD PA19

RTD SUPPLY PA20

3 – WIRE

RESISTANCE

THERMOMETER

14

RS485 / RS232

The RS485 cabling must be overall shielded 3-conductor Belden 8735 or similar. Terminate the

shield at one unit only using the cable clamp provided.

For details on connecting NEXUS integrated burner controllers, PPC5000 fuel/air ratio controllers

and a PC onto the communications bus, refer to bulletin NEX-1501 (ComFire combustion analysis

tool) or NEX-SO (boiler sequencing).

Controlled Shutdown Triac and Safety Shutdown Relay

The controlled shutdown triac should be wired into the ”stat" circuit to switch the burner on/off as

the temperature/pressure reaches the limit condition.

The safety shutdown relay must be wired to ensure that the burner is immediately switched off if the

relay opens, to prevent any hazardous condition occurring. See recommended interface wiring for

details of how this is accomplished via connection to burner controllers.

PURGE and IGN Outputs

The PURGE (PC7) terminal will be connected to the COM (PC5) terminal when the 5000 is at purge

position.

The IGN (PC6) terminal will be connected to the COM (PC5) terminal when the 5000 is at the igni-

tion position.

See Appendix for details of how these terminals should be interfaced to burner controllers.

HI/LO Input

This input is active during start-up only.

When this terminal is connected to mains potential, the 5000 will move to purge position. When this

terminal is not connected to mains potential, the unit will move to ignition position.

See Interface to Burner Control Units section on page 11 for details of how these terminals should be

interfaced to burner controllers.

Alarm Relay

This is provided to add an external siren or

lamp for indication of a unit fault or flue

gas alarm limit. The alarm relay must not

be used to shutdown the burner. This

function is provided by the safety shut-

down relay.

RS485 COMMS

BUS

To PC /

modem (via

converter) or

Nexus /

PPC5000

+

GND

-

CLAMP

Rx

Tx

GND

CLAMP

RS232 to

local PC

or modem

+

GND

-

CLAMP

Rx

Tx

GND

CLAMP

+

GND

-

CLAMP

Rx

Tx

GND

CLAMP

CLOSED IN ALARM PB12

OPEN IN ALARM PB13

COMMON PB14

LIVE SUPPLY

Siren or

Lamp

NEUTRAL

15

®

Digital Outputs

The digital outputs are set-up via

option parameters 16.1, 16.2, & 16.3.

The outputs are intended to drive exter-

nal relays, as shown here for output 2.

Remote Setpoint

The remote setpoint input is available

as a 4-20mA current input. It con-

nects to terminal PQ2, labeled “AUX

MOD I/P”. For details relating to

zero and span adjustment see Option

Parameter section. See option 3.3.

Final Checks

Before applying power, make the following checks:

• The unit is set for the correct line supply voltage.

• All other link positions are correct.

• All fuses within the unit are intact and of the correct value.

• All wiring and connections have been made according to the specifications detailed in this sec-

tion.

• The Feedback Potentiometer is wired correctly. Terminal 6 on the servo-motor MUST be wired

to PD 3/9/12/17 depending on the motor mapping. See option 20.

TO

EXTERNAL

CIRCUITS

USE ONLY MANUFACTURER

APPROVED RELAYS

+12V PB7

DIGITAL OUTPUT 1 PB8

DIGITAL OUTPUT 2 PB9

DIGITAL OUTPUT 3 PB10

+20V PQ1

AUX MOD I/P PQ2

0V PQ6

CABLE

CLAMP

LOOP POWERED

4-20mA SENSOR

+ -

OR EXT. SELF-

POWERED

4-20mA

20V

+

-

16

Operation in Run Mode

Start-up Sequence

When a fuel selection is made, and the ‘burner select’ signal is given, the burner will start up. The

control unit will run through the sequence described below.

No Name Description

0, 1 INITIALIZE The unit has just been powered up. If there are no faults,

the unit will immediately proceed to status 3.

Otherwise, it jumps to status 2.

2 SAFETY SHUTDOWN There is a safety critical fault present which is preventing

the burner from being fired safely.

All drives (motors and inverters) are driven to their close

(P0) positions. The safety shutdown output (PC1-2) and

controlled shutdown output (PC3-4) are both open circuit.

See Faults and fault finding section.

3 BURNER OFF The safety shutdown output (PC1-2) is closed but the

controlled shutdown output (PC3-4) is open, preventing

the burner from firing.

The unit will proceed to status 4 if:

— Burner select input (PC12) is off (EK5 = 0)

— High/low initiate input (PC11) is off (EK4 = 0)

—þMeasured value below low control limit (EK14 = 1)

If the burner select input (PC12) is on for more than 3

seconds, the unit will go to status 2 with F56.

All drives (motors and inverters) are driven to their close

(P0) positions.

4 WAIT FOR PURGE The safety shutdown output (PC1-2), the controlled shut

down

output (PC3-4) and the ignition prove output are all closed.

The unit will proceed to status 5 if:

— A valid profile is selected using PC13, 14 and/or 17

— Burner select input (PC12) is on (EK5 = 1)

— High/low initiate input (PC11) is on (EK4 = 0)

— All drives (motors and inverters) are driven to their close

(P0) positions.

5 PROVE CLOSE The safety shutdown output (PC1-2), the controlled shut

down

(P0) POSITIONS output (PC3-4) and the ignition prove output are all closed.

All selected motors are driven fully down, and 4mA is output

to the inverters.

The unit will proceed to status 6 if:

— All drives have stopped moving and match their close

(P0) positions to within ±5° (or ±55 for inverters).

— Burner select input (PC12) is on (EK5 = 1)

— High/low initiate input (PC11) is on (EK4 = 1)

— The inverter stop time (option parameter 22.4) has expired

If the burner select (PC12) or high/low initiate (PC11) inputs

are turned off or the profile selection (PC13, 14 and/or 17) is

changed, the unit returns to status 3.

17

®

If any of the measured drive positions do not match P0,

the unit will change to status 2 with a drive positioning fault.

6 PROVE PURGE The safety shutdown output (PC1-2) and the controlled

(P1) POSITIONS shutdown output (PC3-4) are both closed.

All selected motors are driven fully up, and 20mA is

output to the inverters.

The unit will proceed to status 7 if:

— All drives have stopped moving and match their purge

(P1) positions to within ±5° (or ±55 for inverters).

— Burner select input (PC12) is on (EK5 = 1)

— High/low initiate input (PC11) is on (EK4 = 1)

If the burner select (PC12) or high/low initiate (PC11) inputs

are turned off or the profile selection (PC13, 14 and/or 17) is

changed, the unit returns to status 3 (or status 13 if a post

purge has been selected using option parameter 09.1).

If any of the measured drive positions do not match P1, the

unit will change to status 2 with a drive positioning fault.

7PRE-PURGE The safety shutdown output (PC1-2), the controlled

(CLOSING FUEL shutdown output (PC3-4) and the purge prove output (PC5-7)

DRIVES) are all closed.

All selected air and option drives are driven to their purge

(P1) positions.

All selected fuel drives are driven to their close (P0)

positions.

The unit will proceed to status 8 when all fuel drives have

stopped moving.

The high/low initiate input (PC11) is ignored.

If the burner select input (PC12) is turned off or the profile

selection (PC13, 14 and/or 17) is changed, the unit returns to

status 3 (or status 13 if a post purge has been selected using

option parameter 09.1).

If the measured air or option drive positions do not match P1,

the unit will change to status 2 with a drive positioning fault.

8PRE-PURGE The safety shutdown output (PC1-2), the controlled

shutdown output (PC3-4) and the purge prove output (PC5-7)

are all closed.

All selected air and option drives are driven to their purge

(P1) positions.

All selected fuel drives are driven to their close (P0)

positions.

The unit will proceed to status 9 when the high/low initiate

input (PC11) is turned off.

If the burner select input (PC12) is turned off or the profile

selection (PC13, 14 and/or 17) is changed, the unit returns to

status 3 (or status 13 if a post purge has been selected using

option parameter 09.1).

If the measured air or option drive positions do not match P1,

the unit will change to status 2 with a drive positioning fault.

9 MOVING TO THE The safety shutdown output (PC1-2) and the controlled

IGNITION shutdown output (PC3-4) are both closed.

18

POSITION All selected drives (motors and inverters) are driven to their

ignition (P2) positions.

The unit will proceed to status 10 if:

— The drives have stopped moving.

— If selected, a ‘release to ignite’ signal is received via serial

comms or an auxiliary input (see option parameters 15.1 and

15.2)

If the burner select input (PC12) is turned off, the profile

selection (PC13, 14 and/or 17) is changed or the high/low

initiate input (PC11) is on, the unit returns to status 3

(or status 13 if a post purge has been selected using option

parameter 09.1).

10 IGNITION The safety shutdown output (PC1-2), the controlled shutdown

output (PC3-4) and the ignition prove output (PC5-6) are

all closed.

All selected drives (motors and inverters) are driven to their

ignition (P2) positions.

The unit will proceed to status 11 when the ignition time has

expired (see option parameter 08.1)

If the burner select input (PC12) is turned off, the profile

selection (PC13, 14 and/or 17) is changed or the high/low

initiate input (PC11) is on, the unit returns to status 3

(or status 13 if a post purge has been selected using option

parameter 09.1).

If the measured drive positions do not match P2, the unit will

change to status 2 with a drive positioning fault.

11 MOVING TO THE The safety shutdown output (PC1-2) and the controlled

LOW FIRE shutdown output (PC3-4) are both closed.

POSITION All selected drives (motors and inverters) are driven to their

low fire (P3) positions.

The unit will proceed to status 12 if:

— The drives have stopped moving.

— The low fire hold time has expired (see option parameter

8.2)

— If selected, a ‘release to modulate’ signal is received via

serial comms or an auxiliary input (see option parameters

15.1 and 15.2)

If the burner select input (PC12) is turned off or the profile

selection (PC13, 14 and/or 17) is changed the unit returns to

status 3 (or status 13 if a post purge has been selected using

option parameter 09.1).

The high/low initiate input (PC11) is ignored.

If the drive positions are outside the ignition and low fire

positions, the unit will change to status 2 with a drive

positioning fault.

12 MODULATION The unit modulates all selected drives in ratio to the required

modulation rate. Trim will be applied after the transport

delay has expired (if selected). The modulation may be

limited by the oxygen trim function (see EK77 & EK78).

If the burner select input (PC12) is turned off, the profile

selection (PC13, 14 and/or 17) is changed or the measured

19

®

value exceeds the high control limit, the unit returns to status

3 (or status 13 if a post purge has been selected using option

parameter 09.1).

The high/low initiate input (PC11) is ignored.

If any selected drive deviates from its profile setpoint, the

unit will change to status 2 with a drive positioning fault.

13 MOVING TO POST The safety shutdown output (PC1-2) is closed but the

PURGE controlled shutdown output (PC3-4) is open, preventing

the burner from firing.

All selected air and option drives are driven to their purge

(P1) positions.

All fuel drives are driven to their close (P0) positions.

The unit will proceed to status 14 when the air and option

drives have stopped moving.

The burner select input (PC12), fuel select inputs (PC13, 14

and 17) and the high/low initiate input (PC11) are ignored.

14 POST PURGE The safety shutdown output (PC1-2) and the controlled

shutdown output (PC3-4) are both closed.

All selected air and option drives are driven to their purge

(P1) positions.

All fuel drives are driven to their close (P0) positions.

The unit will return to status 3 when the post purge time has

expired (see option parameter 09.1).

The burner select input (PC12), fuel select inputs (PC13, 14

and 17) and the high/low initiate input (PC11) are ignored.

If the measured air or option drive positions do not match P1,

the unit will change to status 2 with a drive positioning fault.

Startup sequence

Safety shutdown O/P (PC1-2)

Controlled shutdown O/P (PC 3-4)

Ignition prove output (PC 5-6)

Purge prove output (PC 5-7)

HI / LO initiateinput (PC 11)

Burner on input (PC 12)

Fuel drive(s)

A

ir and option drive(s)

- Energized\active - Don't care

0/1 2 3 4 5 6 7 8 9 10 11 12 13 14

Fuel select inputs (PC13, 14, 17)

20

Modulation

During stage 12 (modulation), the unit will position the fuel and air motors as programmed for the

profile selected.

In auto modulation mode, the system will modulate as necessary to either track the input or maintain

the pressure/temperature of the boiler at the entered setpoint (See Option parameters section). If

boiler sequencing is enabled and active, the unit will start, stop and modulate according to instruc-

tions issued from the unit controlling the lead boiler.

In manual modulation mode, the system will either modulate in response to the keyboard up/down

keys or the external up/down signals.

Safety Shutdown (Burner Lockout)

A safety shutdown will occur under the following conditions:

• In stages 5, 6, 7, 8, 10, 11, 12, or 14, if a drive is not in the correct position.

• During stage 6, a drive speed has been measured to be outside the allowable range.

• During modulation (stage 12), an oxygen trim limit has been reached, and this has been config-

ured to shut the burner down (see option parameter 39.0).

• In any stage, if an internal or external fault not previously mentioned occurs which may affect

the safe operation of the burner.

The display is a 2 line 20 character per line dot matrix vacuum fluorescent unit allowing the use of

plain text messages for most display parameters. The display must be fitted to allow commissioning

of the system but once commissioning has been completed, the display may be removed, providing

either the control unit lamps and external switches and/or lamps are fitted for fault indication and

reset.

Table of contents

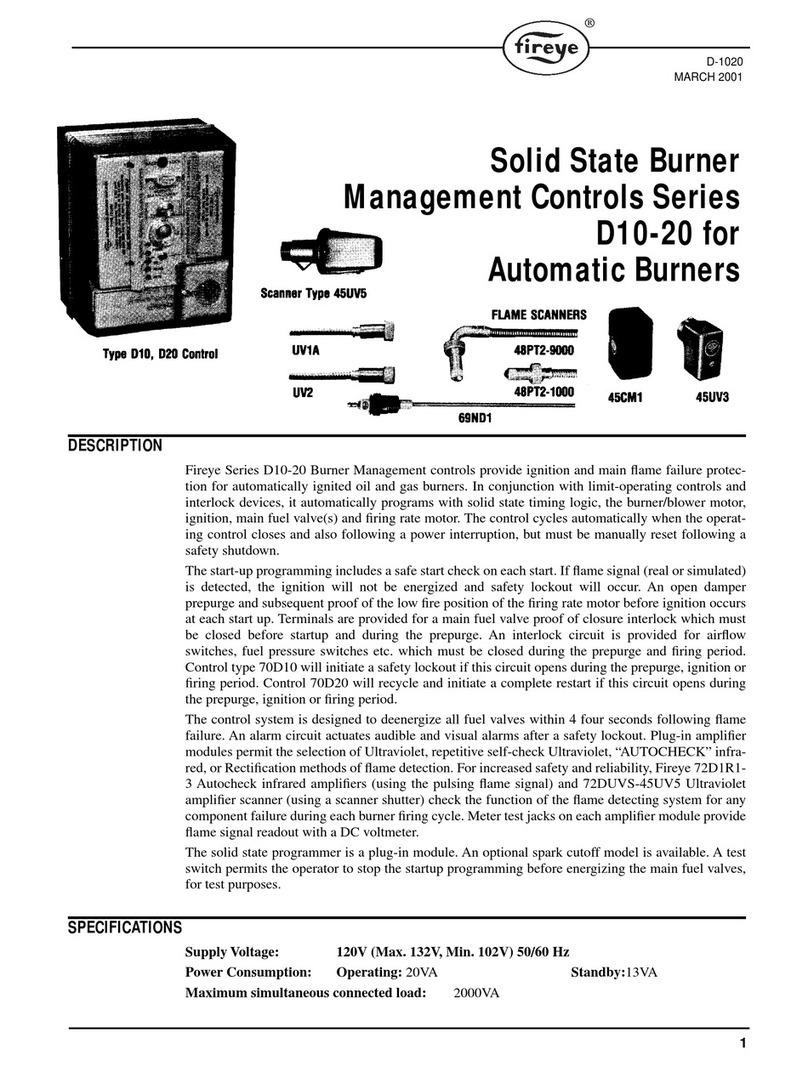

Other Fireye Controllers manuals

Fireye

Fireye BurnerPRO BP110 User manual

Fireye

Fireye PPC6000 Series Operating instructions

Fireye

Fireye NEXUS NX6100 series User manual

Fireye

Fireye BurnerPRO BP110 User manual

Fireye

Fireye D10 Series User manual

Fireye

Fireye PPC6000 Series User manual

Fireye

Fireye FLAME-MONITOR E110 User manual

Fireye

Fireye MicroM Series User manual

Fireye

Fireye PPC6000 Series Manual

Fireye

Fireye PPC4000 SERIES User manual