Fireye PPC6000 Series Manual

OPERATOR’S

GUIDE

FOR

PPC6000

SERIES

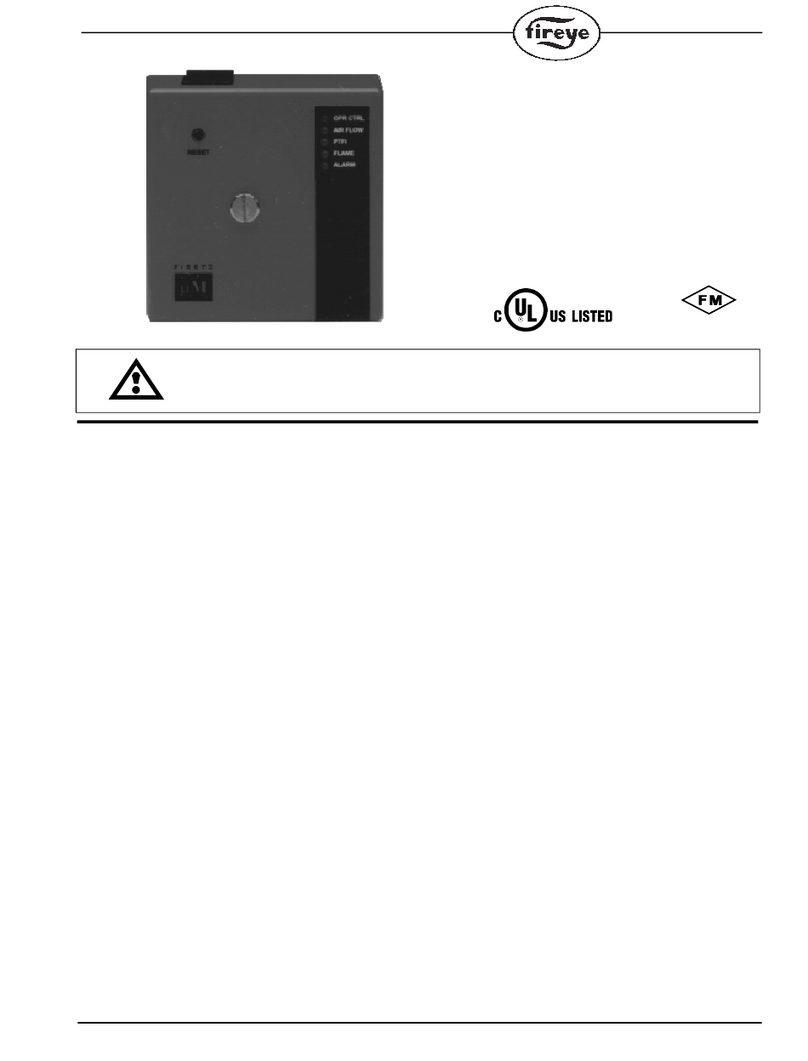

DESCRIPTION:

This document supplies the owner/operator with sufficient information to make

appropriate changes to operating parameters associated with normal boiler plant

needs. Items such as system setpoint adjustments e.g. temperature, pressure, PID

adjustments and alarm corrective action and adjustments.

The following items are covered in this manual:

1 Introduction _____________________________________________________2

2 General _________________________________________________________2

3 Password _______________________________________________________2

4 Adjusting Cut IN and Cut OUT_____________________________________3

5 Manual Modulation ______________________________________________4

6 Resetting the Control _____________________________________________4

7 Fault and Fault Finding __________________________________________11

8 Fault subsets ___________________________________________________11

9 Fault listing ____________________________________________________12

10 PID Tutorial____________________________________________________18

11 The Startup / Shutdown Stages ____________________________________19

NXOG-6001

MARCH 9, 2007

2

1 Introduction

As an operator there are generally only a few items of interest as far as operating the Nexus PPC6000. They

are:

xSetting the system’s operating pressure or temperature.

xAdjusting the cut in or cut out value.

xManually modulating the boiler.

xResetting the control after a safety shut down.

xFinding the Fault that caused the shut down.

All of the other options and adjustments should be done by the combustion technician, as changes to certain parameters could result in an

unsafe operating mode.

2 General

The Nexus display and keypad allows the operator (or combustion technician) access to all set points and

option parameters for commissioning and operating the Nexus PPC6000. The keys are labeled with their

primary function on the key, their secondary function under the key. E.g.: COM/ENTER.

Several levels of passwords protect the integrity of the control. These passwords are numbers entered by

using the up/down arrow keys after pressing the COM (commissioning) key. To enter the password start by

pressing the COM (commissioning) key. You will have 30 seconds to reach the password value and press the

ENTER (COM) key.

3 Password

The only password an operator should require is the “site Passcode.” This can be set as a number from 0-

999. The factory default number is 154. The site Passcode can be changed if desired, however, this requires

the use of a higher-level Passcode.

Warning: Should the Passcode be changed and forgotten, the PPC6000 will have to be reprogrammed

by using the higher-level Passcode. Until then, no adjustments are possible.

Operating Pressure – PID (set point) 1 or (2)*

* NOTE: ( ) Parentheses indicate set point 2 option parameter. E.g. Day/night.

To set or adjust the boiler’s operating pressure follow steps 1 thru 7:

1. Press the COM key.

2. Use the UP key to raise the value to 154 (or new Site Passcode, if changed).

3. Press the ENTER key. This is the same key as COM.

4. If the display shows the angular positions of the servomotors, press the MODE key to change to

option parameters. Using the up or down key move to OPTION 21.1 (22.1). This is the control

value the Nexus will modulate the burner to maintain.

5. Use the left or right arrow key to move the cursor to the lower portion of the display, then using the

up/down arrow key change the setting.

6. Press the ENTER key to accept the new set point.

7. To exit and return to the normal run mode, press the RUN key followed by the ENTER key.

3

Note: The next time you enter the site password you will return to the last option selected.

4 Adjusting Cut IN and Cut OUT

Follow steps 1 through 3 above.

4. If the display shows the angular positions of the servomotors, press the MODE key to change to

option parameters. Using the up or down key, move to OPTION 21.6 (22.6) for Cut In or 21.7

(22.7) for Cut Out. This is the control value the Nexus will start/stop the burner after reaching the

cut in/out value. This value is a differential value when option parameter 21.5 (22.5) is set at 2.

That is, it is subtracted/added from/to the operating set point. Once set, this value will follow any

change in the set point programmed in option 21.1 (22.1). These values are actual values if 21.5

(22.5) are set to 1. (see table below)

Option parameter

21.5 (22.5) value

Meaning

0No limits. The burner will run until another method is used to switch

it off.

1Absolute limit. The values entered in option parameters 21.6

(22.6) and 21.7 (22.7) are the actual limit values.

2Deviation limit. The values entered in option parameters 21.6

(22.6) and 21.7 (22.7) represent a deviation (i.e. offset) from the

setpoint 1 control value. This means that if the setpoint control

value is changed, the limits are automatically changed

correspondingly.

5. Use the left or right arrow key to move the cursor to the lower portion of the display then - using

the up/down arrow key, change the setting.

6. Press the ENTER key to accept the new set point.

7. To exit and return to the normal run mode press the RUN key followed by the ENTER key. See

two examples below:

Deviation Example:

Opt 21.1 (22.1)* ...............set to............... 100 psi

Opt 21.5 ...........................set to................... 2

Opt 21.6 (22.6)* ...............set to................. 10

Opt 21.7 (22.7)* ...............set to................. 10

Cut Out ..................................................... 110 psi

Set Point ................................................... 100 psi

Cut In .......................................................... 90 psi

New Set Point 60 psi

Cut Out ....................................................... 70 psi

Set Point ..................................................... 60 psi

Cut In .......................................................... 50 psi

4

Absolute Example:

Opt 21.1 (22.1)* .............. set to ............... 100 psi

Opt 21.5 .......................... set to ................... 1

Opt 21.6 (22.6)* .............. set to ............... 110

Opt 21.7 (22.7)* .............. set to ................. 90

Cut Out............................. ........................ 110 psi

Set Point........................... ........................ 100 psi

Cut In................................ .......................... 90 psi

New Set Point 60 psi

Cut Out............................. ........................ 110 psi

Set Point........................... .......................... 60 psi

Cut In................................ .......................... 90 psi

NOTE: NEW Cut In and Cut Out values may need

to be entered to achieve desired results.

5 Manual Modulation

Pressing AUTO/MAN key toggles the burner in and out of manual or automatic modulation. To place the

boiler in manual from automatic no password is required.

1. Press the AUTO/MAN key

2. Use the up/down arrow keys to set the firing rate.

3. Press the AUTO/MAN key again to place in automatic

Note: The firing rate will be shown on the display. This function can be disabled via option

parameter 1.1. To do so requires the suppliers (highest) passcode.

6 Resetting the Control

To reset the Nexus, the MUTE/RESET key will have to be pressed and held for three seconds to first silence

(mute) the alarm and then a second press for three seconds to clear the fault. A prolonged key press will do

both.

If for some reason the Nexus detects a fault, the cause of the fault will be displayed if still present. If not

displayed, pressing the ENGINEERS key once will reveal the fault, a second press will reveal the fault and

subset in the upper right hand corner. The ENGINEERS key is hidden behind the Fireyelogo on the display.

Pressing the logo will show the EK # to the right of which will be the fault # and any subset. Using the

up/down arrow keys scrolls through the EK #’s to view other information.

5

Engineer’s key parameter list

No. Name Description

EK1 Low Voltage Digital Input 1 (PA5–PA11) Shows the state of each input.

EK2 Low Voltage Digital Input 2 (PA6–PA11) Where :

EK3 Low Voltage Digital Input 3 (PA7–PA11) 0 = OFF (Open circuit)

EK4 Low Voltage Digital Input 4 (PA8–PA11) 1 = ON

EK5 Low Voltage ‘HIGH’ input (PA9–PA11)

EK6 Low Voltage ‘AUTO input (P10–PA11)

EK11 Profile 1 Select – Line Voltage (PE9)

EK12 Profile 2 Select – Line Voltage (PE10)

EK13 Profile 3 Select – Line Voltage (PE11)

EK14 Profile 4 Select – Line Voltage (PE12)

EK16 Warming limit 0 - Measured value above warming limit, burner

free to modulate.

1 - Measured value below warming limit, burner

held at low fire if the control is in auto or

sequencing mode.

EK18 Boiler status 0 - Burner will not fire because the temperature /

pressure measured value has exceeded the high

control value.

1 - Burner will fire because the temperature /

pressure measured value has fallen below the

low control value.

EK19 Confirm to adjust 0 - Control not in commission mode or control is

in commission mode and drives moving to

setpoints.

1 - Control in commission mode and drives may

be adjusted using the UP/DOWN keys.

EK20 Drive moved 0 - Control not in commission mode or control is

in commission mode and drives have not been

moved using the UP/DOWN keys.

1 - Control in commission mode and drives have

been moved using the UP/DOWN keys.

6

No. Name Description

EK21 Positions proved 0 - Drives have stopped moving, ready for

position prove test.

1 - Ready for position prove test but drives still

moving.

EK22 Fault alarm 0 – No un-muted alarms (faults) present.

+1 - Un-muted fault alarm present (prefix : F)

+2 - Un-muted limit alarm present (prefix : L)

+4 – Un-muted flue-monitoring alarm present

(faults 50 to 59).

EK23 Oxygen Trim Enable 0 – Oxygen trim off or not working.

1 – Oxygen trim on and working.

EK25 CAN_TX Failures A count of the number of times the can bus

controller has failed to send a message since

power-up. This should be zero unless there has

been a problem.

EK26 Commission status Current commissioning mode, where :

0 - Normal run mode.

1 - Adjust ratio mode.

2 - Commission ratio mode.

EK27 Commission setpoint The current setpoint being commissioned.

0 - Closed setpoint.

1 - Purge setpoint.

2 - Ignition setpoint.

3 - Low fire setpoint.

4 - 24 - profile setpoints

EK28 Commission Setpoints entered The number of setpoints that have been

successfully entered during this commission ratio

session.

EK29 Modulation rate (%) The current modulation rate of the burner.

0 = Low Fire

100 = High fire

EK30 Burner Status Status of the start-up sequence. See section 4.2

of Fireye Bulletin PPC-6001

EK31 Fuel Profile Selected The currently selected fuel profile.

7

No. Name Description

EK32 Number of commission setpoints The number of setpoints entered in the current

commission ratio session :

0 - No setpoints entered.

1 - Close setpoint only.

2 - Close and purge setpoints.

3 - Close, purge and ignition.

4 - 24 - profile setpoints.

EK33 Modulation mode The current modulation mode :

0 - Auto mode.

1 - Manual from external input.

2 - Manual from keyboard.

3 - Boiler sequencing control.

4 - Low fire hold.

EK36 Nearest setpoint The number of the profile setpoint which is

nearest to the current modulation position.

EK37 Voltage reference error (V) The error between the measured voltage

reference and the calibrated value.

0.12 is the limit. The displayed value shows volts

NOTE: If value goes to 0.13, F19 will be

generated.

EK38 Boiler Sequencing Status Currently unused.

EK39 Fuel Swap Status Currently unused.

EK40 Shutdown setpoint The nearest setpoint (EK36) when the burner

last locked out.

EK42 Adjust ratio counter The number of times adjust ratio mode has been

used.

EK43 Commission ratio counter The number of times commission ratio mode has

been used.

EK44 Oxygen measured value The current flue oxygen value as measured by

the FIREYE probe (if fitted).

8

No. Name Description

EK45 Oxygen probe status +1 - Internal fault.

+2 - Internal fault.

+4 - Heater fault. Causes F50.

+8 - Cell temperature out of range.

+16 - Cell millivolts out of range.

+32 - CANbus error.

+64 - Probe calibrating in reference gas. See

option parameter 30.6.

+128 - Probe calibrating in air. See option

parameter 30.6.

EK46 Oxygen trim status 0 - O2trim working, or

+1 – no oxygen interface connected.

+2 – no oxygen probe serial number entered,

or option 30.5 not 1, or option 30.8 not 0

or trim not selected via aux input

or trim not selected via serial comms

+4 – O2setpoints or flow values incorrect

+8 - Option 30.6 not 0

+16- Not modulating

+32- In commission mode

+64- Probe faulty (see EK45)

EK47 Oxygen setpoint (%) Current oxygen setpoint. This is only available if

trim is enabled and working.

EK48 Excess air (%) Excess combustion air at the current firing

position.

EK49 Oxygen error (%) Error between O2measured value and O2

setpoint.

EK50 Trim deviation (% flow) Deviation in air flow imposed by trim (-25 to

+25%)

EK55 Main PCB issue The issue number of the main circuit board.

EK57 CPU serial number (low 3 digits)

EK58 CPU serial number (low 3 digits)

The 6 digit CPU board serial number. The serial

number is displayed in 2 blocks of 3 digits.

9

No. Name Description

EK59 Digital (relay) outputs on. Represents which drives are currently at their

setpoints, where:

0 – All drives are at their setpoints and are not

moving.

Non- zero – One or more drives are not at their

setpoint.

EK60 Spare The combination of digital outputs currently

switched on.

+1 : Digital Output 1 ON. Display, PR6(COM),

PR7(NO), PR8(NC). Low voltage or line voltage.

+2 : Digital Output 2 ON. Display, PR6(COM),

PR4(NO), PR5(NC). Low voltage or line voltage.

+4 : Digital Output 3 ON. Display, PR1(COM),

PR2(NO), PR3(NC). Low voltage or line voltage.

+8 : Digital Output 4 ON. Main Unit, PE4 (line

voltage out).

+16 : Digital Output 5 ON. Not implemented.

+32 : Digital Output 6 ON. Not implemented.

+64 : Digital Output 7 ON. Daughterboard, PZ15

– PZ16. LOW VOLTAGE AND CURRENT

ONLY.

+128 : Digital Output 8 ON. Daughterboard,

PZ17 – PZ17. LOW VOLTAGE AND CURRENT

ONLY.

EK61 Analog Input 1.

Main Unit Terminal PB9 (also boiler

measured value).

The raw ADC counts from analog input 1.

0 to 1023 for 0 to 5.00 volts.

EK62 Analog Input 2.

Main Unit Terminal PA12 (also remote

setpoint).

The raw ADC counts from analog input 2.

0 to 1023 for 0 to 5.00 volts.

EK67 Analog input 7.

Daughterboard terminal PZ12(-)

PZ13(+). Also VFD1.

The raw ADC counts from analog input 7.

0 to 1023 for 0 to 5.00 volts.

EK68 Analog input 8.

Daughterboard terminal PZ13(-)

PZ14(+). Also VFD2.

The raw ADC counts from analog input 8.

0 to 1023 for 0 to 5.00 volts.

EK69 Daughter board Frequency input 1

(PZ7). 0 to 12 volts.

Gives the measured frequency in Hz on this

input. If the input is not changing, this value will

be 0 for OFF (open circuit) and 1 for ON.

10

No. Name Description

EK70 Daughter board Frequency input 2

(PZ9). 0 to 12 volts.

Gives the measured frequency in Hz on this

input. If the input is not changing, this value will

be 0 for OFF (open circuit) and 1 for ON.

EK71 Daughter board Frequency input 3

(PZ11). 0 to 12 volts.

Gives the measured frequency in Hz on this

input. If the input is not changing, this value will

be 0 for OFF (open circuit) and 1 for ON.

EK72 Oxygen probe cell temperature. The temperature of the zirconia cell inside the

FIREYE oxygen probe, if fitted. This value should

be very close to 650ºC for accurate operation.

EK73 Ambient temperature. The temperature measured by the inlet

temperature sensor, if fitted. Units are ºC/ºF per

Option 30.4.

EK74 CPU utilisation. The percentage utilisation of the CPU. Should be

less than 95% at all times.

EK75 Longest task time. The current longest internal software task time.

This is provided for manufacturers diagnostics

only and may be removed in future versions.

EK76 Longest task number. The current longest internal software task

number. This is provided for manufacturers

diagnostics only and may be removed in future

versions.

EK77 Last program byte address. This is the length of the currently running user /

manufacturers program. If a user program is

selected, this should match the program length

given by the ‘abacus’ software.

EK78 Software issue. The current revision of the main product

firmware.

EK79 EEPROM writes counter. The number of writes to (any) EEPROM since

the unit powered up. This is provided for

manufacturers diagnostics only and may be

removed in future versions.

EK80

to

EK89

Drive Error values for drives 0 to 9. The current error value for drives 0 to 9. These

values will freeze when the control performs a

safety shutdown, so it may be possible to look at

these values after a lockout to help determine

the cause.

11

7 Fault and Fault Finding

Should the Nexus determine a fault has occurred that required the burner be shut down, the bottom portion of

the display will indicate the cause. Pressing the ENGINEERS key will display more information, which will be

found in the upper right of the display. See Section 6.0 of Fireye Bulletin PPC-6001 for more details. Using the

ENGINEERS key the last 33 faults or limits can be reviewed. The fault history begins with the most recent

which can be found after EK200 and will be date and time stamped. There are three aspects to each record;

when it was reset, when it changed from a fault to a cleared fault and when the fault occurred. The portion of

the record at the “Fxx” will also include the subset if any. See Fault Subsets.

Many of the faults detected and displayed by the unit will cause a safety shutdown of the burner. Other faults

will be displayed as a warning, but operation of the burner will not be affected.

All fault numbers are prefixed by a letter. This letter describes the status of the fault:

F - This means that a fault (e.g. PSU calibration fault) has occurred and is still present. The fault

may be internal or external to the unit.

L - This means that an alarm limit fault (e.g. smoke level exceeding the high limit) has occurred

and is still present.

C - This means that a fault or alarm limit did occur but has been cleared.

For example:

F60 - Means fault 60 has occurred and still exists.

L75 - Means alarm limit 75 has been exceeded and is still being exceeded

C73 - Means fault or alarm limit 73 has occurred but has subsequently been cleared.

When the unit is in a safety shutdown state both the controlled shutdown triac and safety shutdown relay will

be turned off, to prevent the burner from firing.

8 Fault subsets

As an aid to fault finding, most faults have a fault subset that gives additional information about the type of fault

or what the burner was doing when the fault occurred. Where applicable, the subsets are given in the fault

listing in section 6 - Faults and Fault Finding, of Fireye Bulletin PPC6001. For details of how to view a subset,

refer to Section 6.0 of this bulletin or Fireye Bulletin PPC6001.

12

9 Fault listing

Fault

Number

Cause Description

F01

F02

F03

F04

External Alarm

Fault 1

External Alarm

Fault 2

External Alarm

Fault 3

External Alarm

Fault 4

See Option parameters 19.1 to 19.4.

Subset : burner status.

F18 Not enough

setpoints entered

A fuel/air ratio profile has been selected which does not have at

least four setpoints commissioned.

xUse commission ratio mode to enter more setpoints.

Subset : fuel code

F19 Circuit board

voltage reference

fault

The circuit board has an incorrect on-board reference level.

xEnsure ALL analog inputs (4-20mA, 0 – 5v) are in the

range 0 to 5.0 volts. It is critical that none of the inputs

are higher than 5.0 volts.

xIf the problem persists even when all analog inputs are

disconnected, check EK37 and contact supplier.

Subset : +1 out of range, +2 zero check failed, +4 span check

failed.

13

Fault

Number

Cause Description

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

Drive 0 position

fault

Drive 1 position

fault

Drive 2 position

fault

Drive 3 position

fault

Drive 4 position

fault

Drive 5 position

fault

Drive 6 position

fault

Drive 7 position

fault

Drive 8 position

fault

Drive 9 position

fault

A drive-positioning fault has occurred, which will cause a non-

volatile lockout of the burner. This fault has occurred for one of

the following reasons:

1. During close position prove, when a drive stops at a position

that is outside the close set position by more than five

degrees.

2. During purge position prove, when a drive stops at a position

that is outside the purge set position by more than five

degrees.

3. During pre-purge, ignition or post-purge, when a drive moves

from its setpoint.

4. During modulation, when a drive is not at its correct setpoint

as defined by the commissioned fuel/air ratio for the selected

profile.

A drive is defined as having moved from its setpoint if its

positional error is more than 1° for 15s, or more than 5° for 1s.

For positional errors between 1° and 5°, the detection time is

variable between 15s and 1s.

Note : Only the selected drives are checked. The other drives

are ignored.

Subset : burner status.

F32 Safety input fault One or more of the fail-safe low voltage inputs is registering a

fault.

Subset : Combination of failed inputs.

F33 Burner input fault One or more of the high voltage (profile select) inputs is

registering a fault.

Subset : Failure mode.

F34 Primary relay fault One or more of the internal relays is not responding correctly.

Subset : Failed Relay.

14

Fault

Number

Cause Description

F35 ADC fault One of the internal checks on the analog to digital converter has

failed.

Subset : Failure mode.

F37 RAM test fault The main memory in the control has malfunctioned.

xInterrupt power to the control.

xThis could be due to high levels of electrical interference

getting into the product. Check all cables are correctly

screened, and screens are terminated correctly. Ensure the

mains supply is not excessively noisy.

xIf this fault persists, the control must be returned to the

supplier.

Subset : Failed Page.

F38 Program memory

CRC fault

The program memory in the control has been corrupted.

xInterrupt power to the control.

xThis could be due to high levels of electrical interference

getting into the product. Check all cables are correctly

screened, and screens are terminated correctly. Ensure the

mains supply is not excessively noisy.

xIf this fault persists, the control must be returned to the

supplier.

Subset : Failed Page.

F39 Profile table CRC

fault

The profile table memory in the control has been corrupted.

xInterrupt power to the control.

xErase the system using option parameter 45.1 = 5 and re

commission (or restore with option parameter 45.2).

xThis could be due to high levels of electrical interference

getting into the product. Check all cables are correctly

screened, and screens are terminated correctly. Ensure the

mains supply is not excessively noisy.

xIf this fault persists, the control must be returned to the

supplier.

Subset : Failed Page.

15

Fault

Number

Cause Description

F41 Boiler safety limit

exceeded

The boiler’s measured value has exceeded the

pressure/temperature safety limit.

Subset : 4 - safety limit exceeded

F44 Burner not OFF. This fault will lock the burner out if the AUTO input (PA10 –

PA11) is made when the control thinks the burner should not be

firing. It will also occur if the AUTO input stays ON for three

seconds after this control has opened the ‘controlled shutdown

relay’ – i.e. tried to turn the burner off.

Subset : burner status.

F46 EEPROM memory

CRC fault

The EEPROM memory in the control has been corrupted. This

memory is used to store the option parameters,

xInterrupt power to the control.

xErase the system using option parameter 45.1 = 5 and

re commission (or restore with option parameter 45.2).

xThis could be due to high levels of electrical interference

getting into the product. Check all cables are correctly

screened, and screens are terminated correctly. Ensure

the mains supply is not excessively noisy.

xIf this fault persists, the control must be returned to the

supplier.

Subset : Failed Page.

F50 Oxygen probe

heater fault

The probe heater has failed to heat to the correct temperature

after 30 minutes of system power up.

xIs the probe heater wiring correct?

xIs the probe cell thermocouple wiring correct?

Once the fault is rectified, it will be necessary to interrupt the

power to the oxygen probe interface to make it attempt to heat

the probe once more.

Subset: O2 probe status.

L52 Oxygen low limit

alarm

The oxygen level measured value is below the oxygen setpoint

low alarm value for the current profile.

Subset: 0 = Limit violation, 1 = Probe Failed.

16

Fault

Number

Cause Description

L53 Oxygen high limit

alarm

The oxygen level measured value has exceeded the oxygen

setpoint high alarm value for the current profile.

Subset: 0 = Limit violation, 1 = Probe Failed.

L55 Trim limit alarm The trim drive has reached the allowed maximum deviation limit.

xChange trim limit.

xRe-commission fuel / air ratio.

Subset : Not applicable.

F57 Auto trim

commissioning fault

The measured oxygen level exceeded 15.0% during auto trim

commissioning. The burner is shutdown.

Subset : Last auto trim commission setpoint (+32 if adding air).

L58 Flue temperature

low alarm value

exceeded

The measured flue temperature is below the low alarm value for

the current profile, or the flue thermocouple is faulty.

Subset : Not applicable.

L59 Flue temperature

high alarm value

exceeded

The measured flue temperature has exceeded the high alarm

value for the current profile.

Subset : Not applicable.

F60 – F69 User Faults These fault numbers are generated by the user programmable

section of the control and will vary with the application.

17

Fault

Number

Cause Description

F74 Profile Invalid This fault means that the control can’t fire the currently selected

profile because it isn’t sure it still matches the burner / site

configuration. It could lead to a hazardous situation.

There are three possible causes to this fault :

1 – A drive has been commissioned in this profile but has now

been deselected. If a profile is commissioned with two air

dampers but then the second air damper is de-selected with

option parameter 4.0 to 4.9, obviously the profile is no longer

valid.

Subset : Drive number (0 to 9)

2 – Servo / Drive changed. If the system is commissioned then

later one of the servos is changed for a new one (i.e. different

serial number), any profiles that use that servo are now

considered invalid. This is to force the engineer to ensure the

new servo is mechanically fixed the same way as the original

one.

Subset : Invalid profile + 100 (101 to 104).

3 – The selected profile has been uploaded from a PC, but has

not been verified on this burner.

Subset : Invalid profile + 100 (101 to 104).

In all cases the F74 can be cleared by switching to another

(good) profile, or by re-commissioning the profile in ‘commission

ratio’ mode, making sure all points up to and including high fire

are acknowledged using the ‘NEXT’ key (or ‘ENTER’ if the points

are adjusted).

F75 Power-up Lockout The control has locked out on power-up. This will normally be

because option parameter 1.0 is set to 1.

Subset :

0 – See option parameter 1.0.

254 – Serial EEPROM write failure.

255 – NV Lockout verification failed.

F77 Secondary relay

fault

A secondary fault has occurred with the main 1, main 2, pilot,

vent or non-volatile lockout relays. If the fault persists for 23

hours, the burner will shutdown.

xContact supplier

Subset : Failed relay number.

18

Fault

Number

Cause Description

F78 Secondary program

memory checksum

fault

A fault has occurred with the program memory in the control. If

the fault persists for 11 consecutive tests then the burner will

shutdown.

xContact supplier

Subset : Not applicable.

F79 Secondary

watchdog fault

A fault has occurred with the CPU watchdog. If the fault persists

for 11 consecutive tests then the burner will shutdown.

xContact supplier

Subset :

1 = Late test failed.

2 = Early test failed.

10 PID Tutorial

PID Adjustment

The PPC6000 utilizes and advanced algorithm in order to maintain set point over a variety of load conditions.

This three term PID can be infinitely adjusted to suit almost any application. The operator should have a basic

understanding of the relationship between the three terms; proportional, integral and derivative.

Proportional

Typical older modulating systems employ only proportional control. This would be similar to the slide wire type

found on most steam boilers. When using only a proportional control the system rarely achieves set point as

the burner firing rate is lowered as the pressure comes up. At some point the input meets the actual demand

and the pressure no longer raises or lowers, thus an offset between desired set point and actual operating

pressure occurs. The only time the pressure and set point are the same is if the actual load equals the lowest

firing rate of the burner, this is rare. An example of proportional only set up might be; Set point is 100 PSI,

proportional range is 10 PSI. That is low fire is at 100 PSI, high fire is at 90 PSI with a 1:1 relationship in

between, e.g.: 95PSI equals 50% rate.

Integral

If the integral term is turned on, the control compares the actual pressure against set point at an adjustable

interval. If there is an offset, the firing rate is increased by a small percentage until the next interval. This will

continue until the pressure equals the set point. The same routine occurs as the pressure rises above the set

point. Too much or too little integral will cause over and undershoot of the set point. Integral is set in second

per repeat in the PPC6000.

19

Derivative

Enabling the derivative has the effect of sensing the rate of change in the process variable (pressure or

temperature) and increasing or holding up the firing rate output despite the integral term. This in effect

amplifies the output to anticipate the effect of a sudden change in load demand. Derivative acts inversely when

the set point is exceeded. Derivative is set in seconds on the PPC6000.

A rule of thumb is; start with a P value of about 10% of set point, an I value of 10 seconds and a D value of 5

seconds. After observing the operation through normal load swings adjusting each value, usually one at a

time, and observing the results. When making a change it is recommended the value be doubled or halved to

determine which direction you need to go. Bear in mind, the burner should not continuously hunt or swing to

maintain the desired set point. It is normal for a slight over and undershoots of set point during serious load

changes.

The values for the PID’s are found at option parameters 21.2, 21.3 and 21.4 for set point 1 (PID1), and 22.2,

22.3 and 22.4 for set point 2 (PID2). These values are adjustable using the Site Passcode 154.

11 The Startup / Shutdown Stages

The startup / shutdown stages are as follows:

Stage

no.

Stage name Description

0. Non-volatile

lockout / safety

shutdown

The burner is held in this state until all faults are removed.

The ‘safety shutdown’ output (PE5 – PE6) will be open. The

‘controlled shutdown’ output on PE3 will also be OFF during this time,

however if the burner was running when the fault occurred, the ‘safety

shutdown’ output will have opened first.

1. Burner off

(EK18)

The burner is checked to make sure that it has switched off

completely. The fuel/profile select inputs must all go OFF when the

burner is switched off (or at the end of post-purge). This provides a

feedback to confirm that the burner is off, and ensures that this control

is always synchronised with the burner controller.

The ‘controlled shutdown’ output on PE3 will be OFF during this time,

however the ‘safety shutdown’ output PE5 – PE6 will be closed during

this time.

The control will advance to status 2 when :

-All fuel/profile select inputs are OFF

-The ‘boiler status’ is equal to 1 (call for heat). See engineers key

18.

-The ‘AUTO’ input (PA10 – PA11) is OFF (open).

20

Stage

no.

Stage name Description

2. Wait for purge

(EK5)

(EK11-14)

(EK31)

The ‘controlled shutdown’ output on PE3 will be switched on, to tell

the burner controller there is a call for heat.

This control waits for a fuel/profile select signal on one of the (line

voltage) terminals PE9, PE10, PE11 or PE12 and a purge request

(HIGH input, PA9 - PA11 closed. This input is low voltage). This

would normally come from the burner controller.

If the fuel/profile select input is removed (PE9, 10, 11 or 12), the

control will immediately move to status 1.

3. & 4. N/A Not Applicable to PPC6000

Note : Statuses 3 and 4 are reserved for a gas valve proving system

and are not implemented on this control. This control will advance

directly to status 5 once the conditions above have been met.

5. Prove closed

positions

(EK80-89)

The fuel and air motors are moved down until they are stopped by the

‘closed position’ micro-switches in the servos. The final positions are

compared with the closed positions stored in memory, and must be

within r5º of the stored values otherwise the control will lockout.

Variable frequency drives must read zero. (4 mA)

When all drives have stopped moving, the control will advance to

status 7. The ‘HIGH’ input (PA9 to PA11)still must be made during

this time.

If the fuel/profile select input is removed (PE9, 10, 11 or 12), the

control will immediately move to status 1.

6. N/A Not Applicable to PPC6000

Note : Status 6 is reserved for air pressure detection, and is not

implemented in this control. This function must be provided by the

burner controller.

7. Moving to Purge The selected motors are moved up towards the purge position. When

the drives have all stopped, the control moves to status 8.

If the fuel/profile select input is removed (PE9, 10, 11 or 12), the

control will immediately move to status 1.

Other manuals for PPC6000 Series

2

Table of contents

Other Fireye Controllers manuals

Fireye

Fireye FX Series User manual

Fireye

Fireye SB Series User manual

Fireye

Fireye NEXUS NX6100 series User manual

Fireye

Fireye PPC5000 User manual

Fireye

Fireye MicroM Series User manual

Fireye

Fireye PPC6000 Series User manual

Fireye

Fireye NEXUS NX6100 series User manual

Fireye

Fireye BurnerPRO BP110 User manual

Fireye

Fireye BurnerPRO BP110 User manual

Fireye

Fireye PPC4000 SERIES User manual