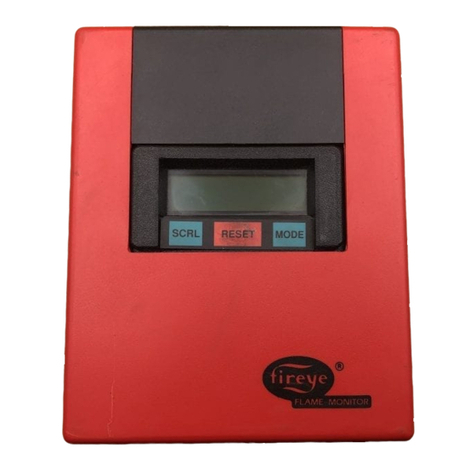

Fireye SB Series User manual

Other manuals for SB Series

2

Table of contents

Other Fireye Controllers manuals

Fireye

Fireye PPC4000 SERIES User manual

Fireye

Fireye PPC6000 Series Manual

Fireye

Fireye NEXUS NX6100 series User manual

Fireye

Fireye FX Series User manual

Fireye

Fireye PPC5000 User manual

Fireye

Fireye MicroM Series User manual

Fireye

Fireye PPC6000 Series User manual

Fireye

Fireye NEXUS NX6100 series User manual

Fireye

Fireye D10 Series User manual

Fireye

Fireye PPC6000 Series Operating instructions

Popular Controllers manuals by other brands

Samson

Samson 42-37 Mounting and operating instructions

LITELINE

LITELINE LC-CRTL-DIM-1 user manual

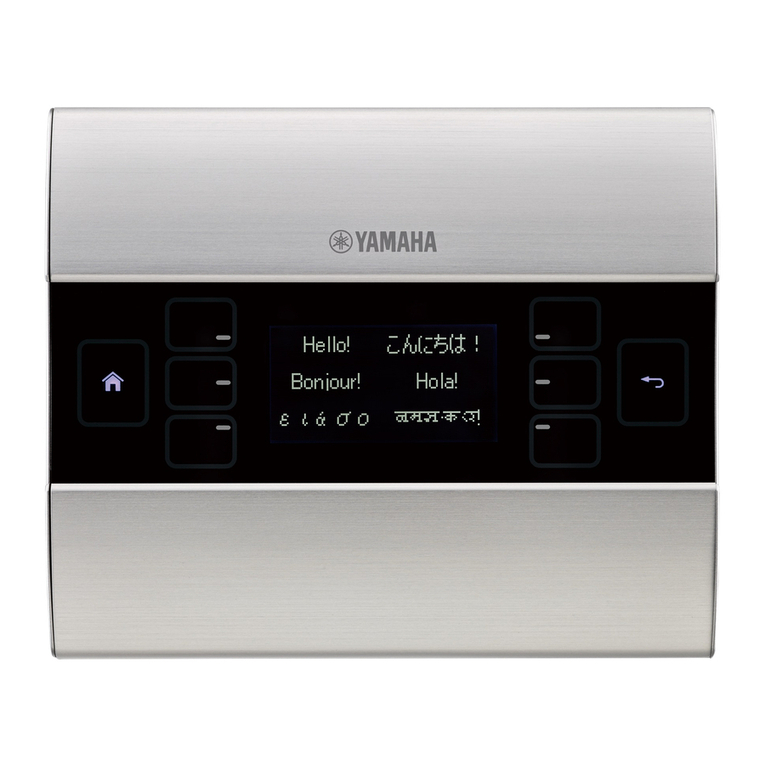

Yamaha

Yamaha MCP1 installation manual

SAF

SAF Solcon Opal LT Series Installation & Operating Procedures

Zaber Technologies Inc.

Zaber Technologies Inc. NA Series user manual

Morningstar

Morningstar ProStar MPPT TRAKSTAR PS-MPPT-15 Installation, operation and maintenance manual

FADAL

FADAL CNC 88 manual

Nectar

Nectar Sun S user manual

Philips

Philips Lightolier Controls Sunrise Whispurr installation instructions

LSI

LSI MegaRAID SAS 9260-16i RAID Controller Quick installation guide

Axel Larsson

Axel Larsson AL 79-045U Installation, Maintenance and Operating Instruction Manual

Datapath

Datapath VSN400 Series user guide