Fireye BurnerPRO Operating instructions

BURNERPRO

TROUBLESHOOTING

August2020

Proprietary and Confidential

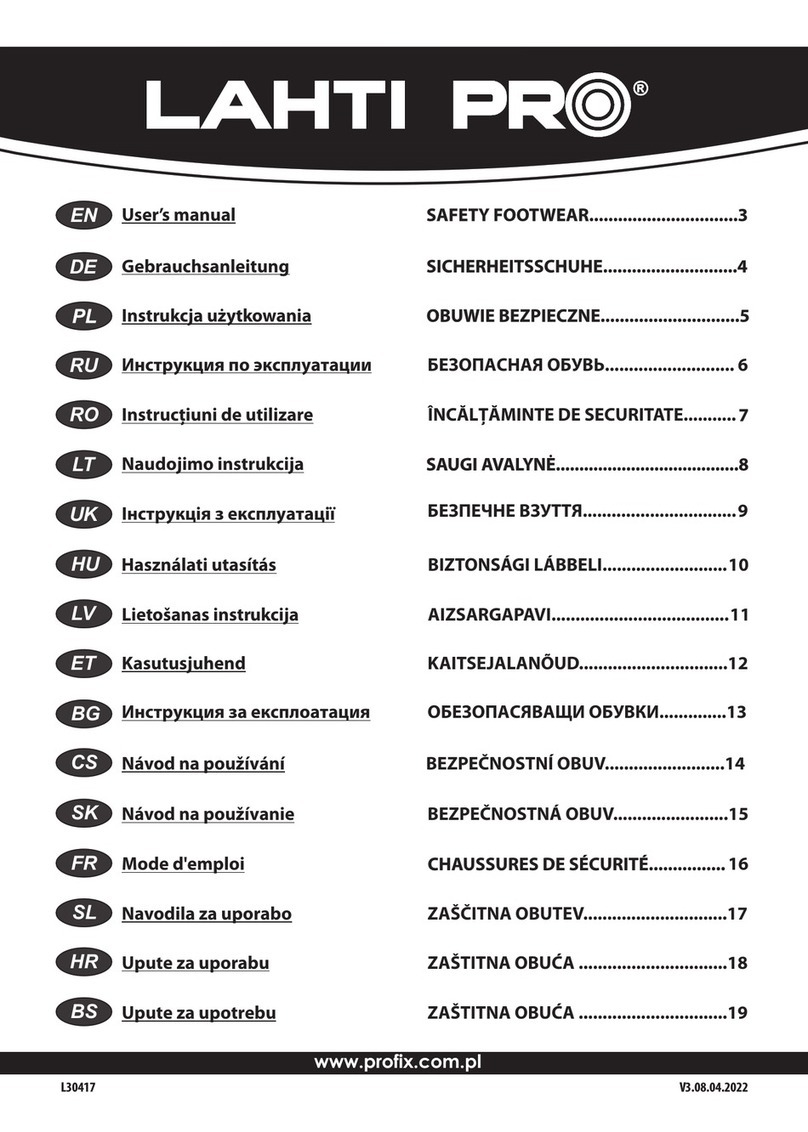

Sequence diagram

2

Without valve proving

Interrupted pilot

Proprietary and Confidential

Sequence diagram

3

With valve proving

Proprietary and Confidential

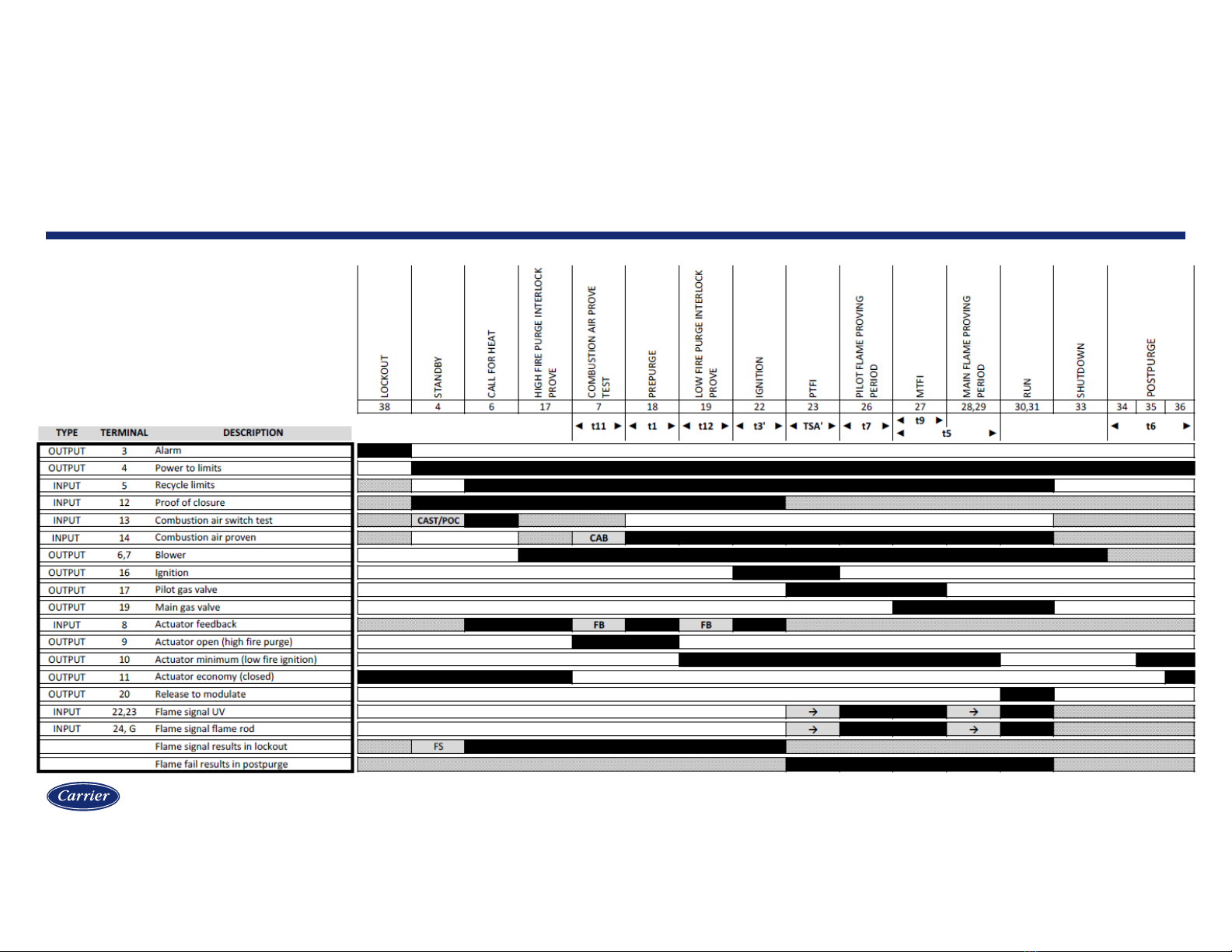

Standard timings S1-S6

Without valve proving:

With valve proving:

Sequence timings

4

Proprietary and Confidential

Terminal designations

5

Without valve proving

Proprietary and Confidential

Terminal designations

6

With valve proving

Proprietary and Confidential

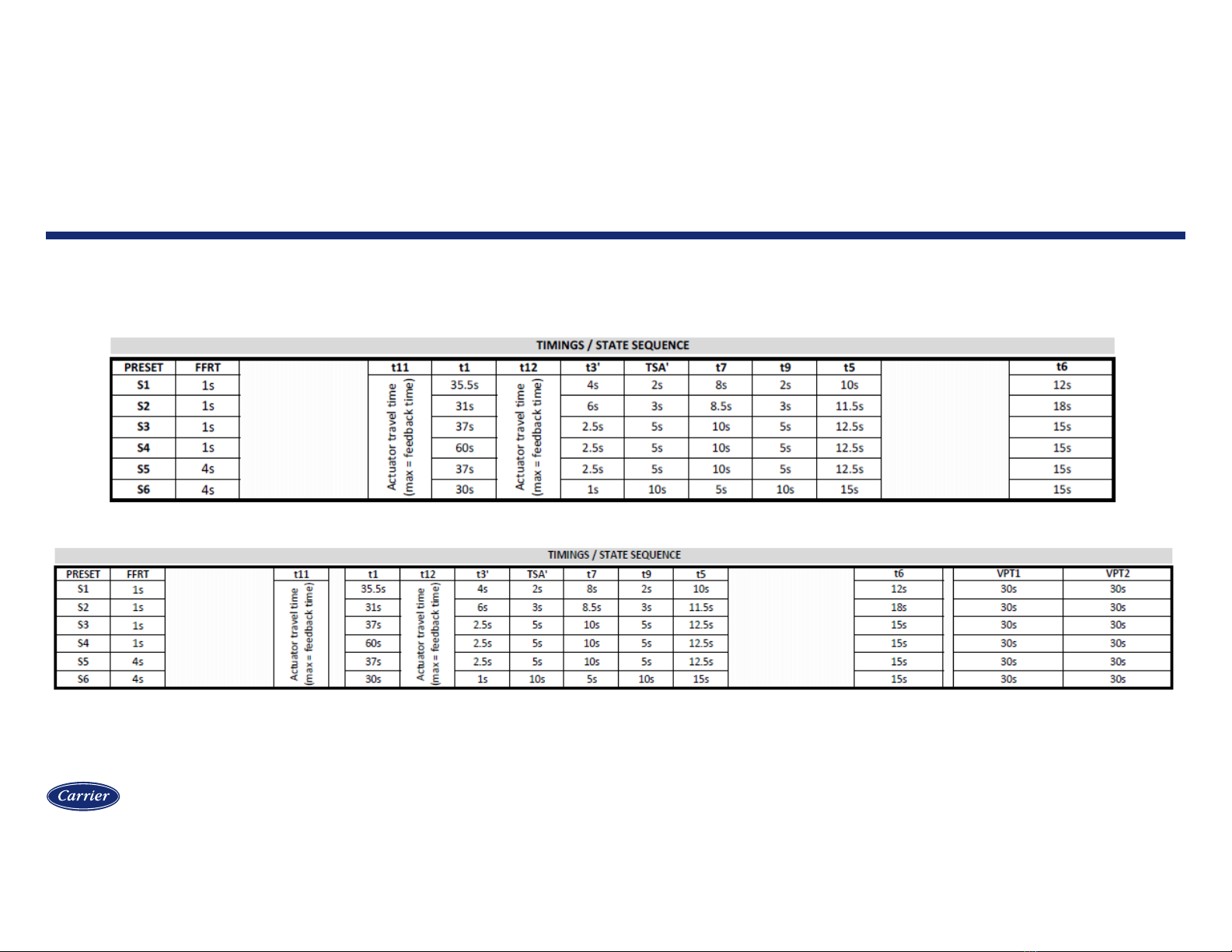

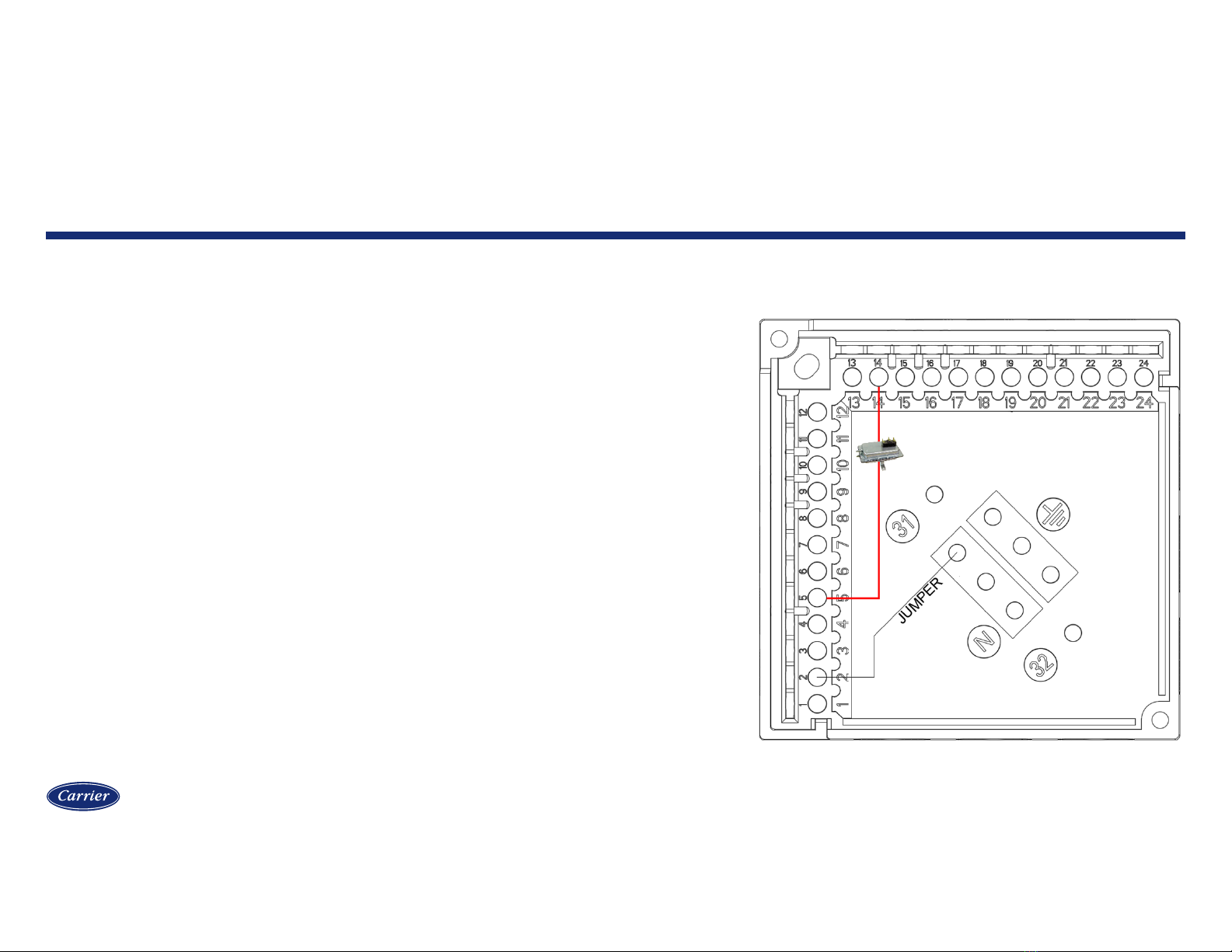

Wiring base

7

Common to Siemens LFL

The wiring base is common with the Siemens LFL

and the BurnerPRO is listed to function as a drop-in

replacement for the LFL.

Three common neutral and three common

grounding terminals are provided for use in

connecting external devices.

Proprietary and Confidential

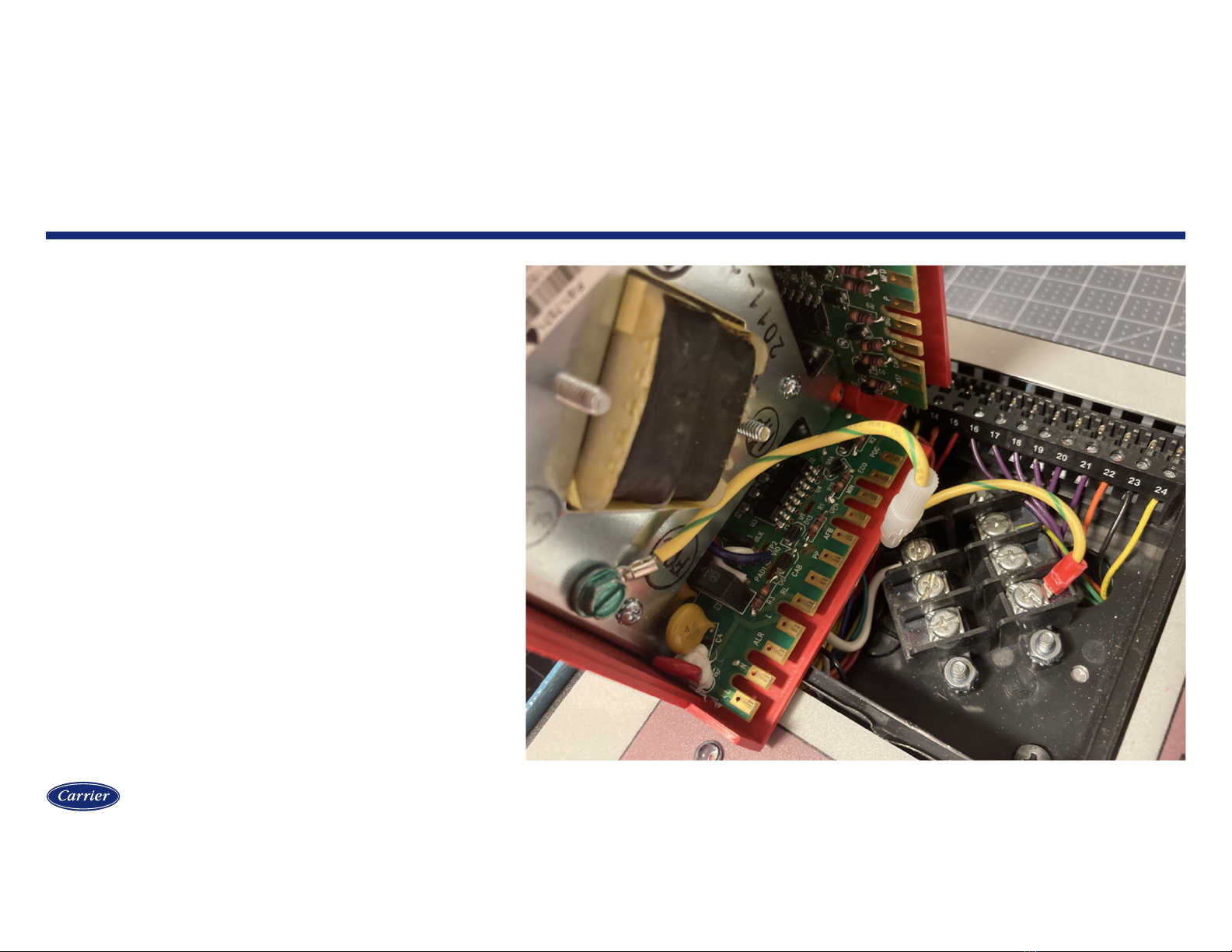

Wiring base

8

Grounding leash

The BurnerPRO is grounded using a

quick-disconnect plug on a wired

grounding leash. This provides a more

positive ground over a copper spring,

which can lose contact over time.

Proprietary and Confidential

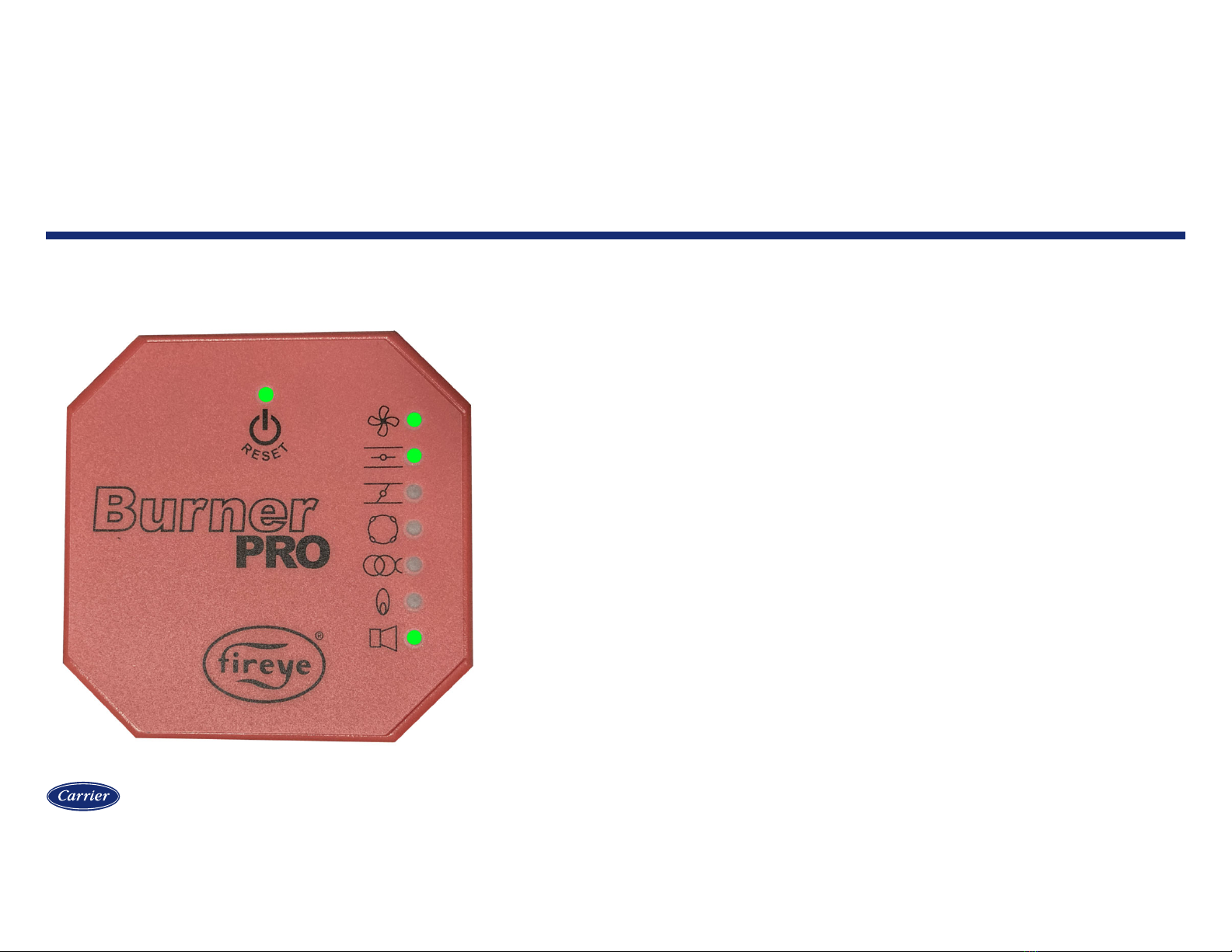

Smart LEDs

9

IGNITION

DAMPER OPEN

DAMPER CLOSED OR ECONOMY

AUTO MODE

STATUS

FLAME DETECTED

FAN

DEMAND

RESET BUTTON

Proprietary and Confidential

Sequence of operation

10

Standby

LED STATE The standby state is when there is not a call for heat.

Terminal 11 (ACTUATOR ECONOMY OUTPUT) is powered

with line voltage in this state.

Proprietary and Confidential

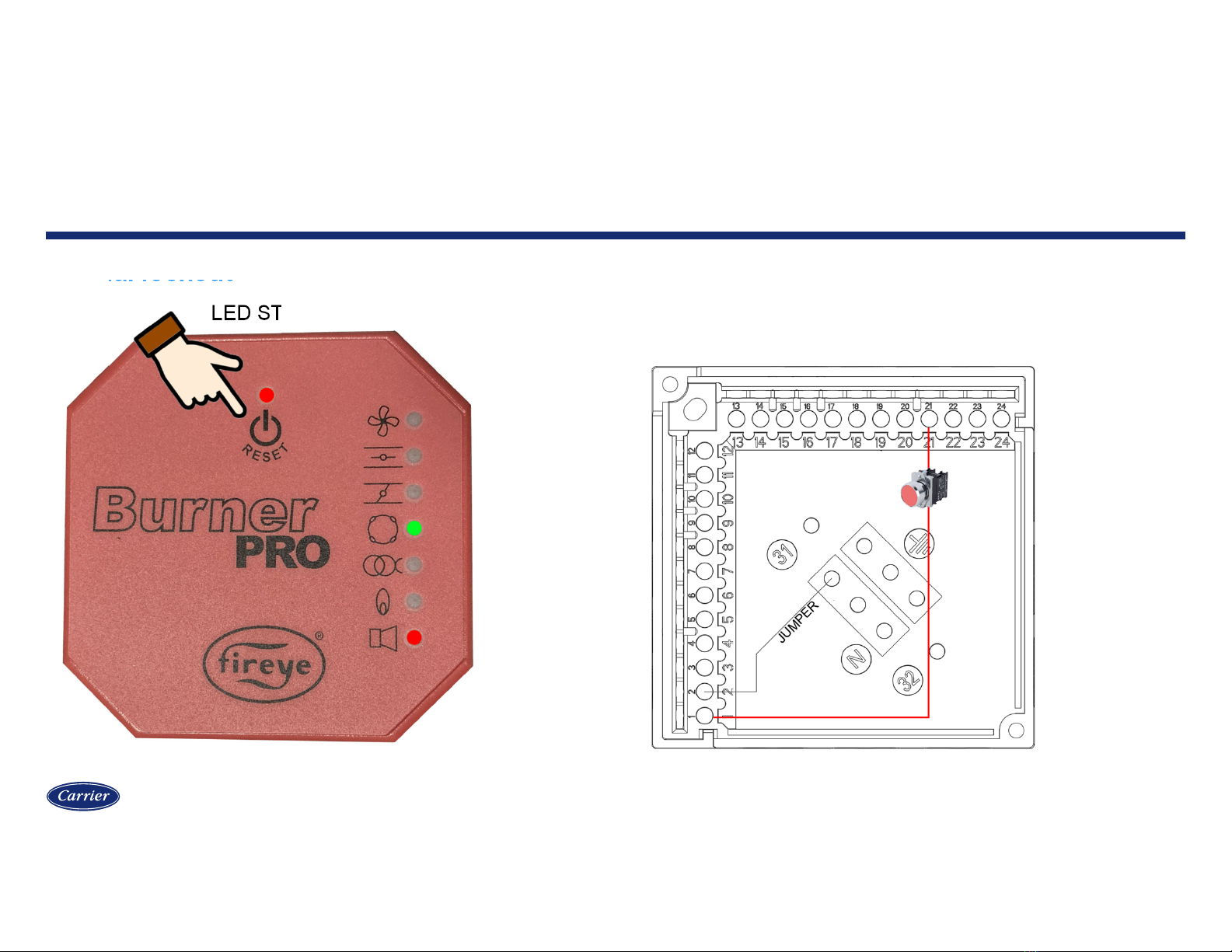

Sequence of operation

11

Lockout

LED STATE When in the lockout state, the combination of LEDs will

indicate the lockout code. These codes can be found in the

bulletin for the specific model. Shown is the lockout code for

STANDBY FALSE FLAME (flame detected while in standby

for more than 60 seconds).

Proprietary and Confidential

Sequence of operation

12

Lockout reset methods

LED STATE

A lockout condition can be reset by either pressing the reset button

on the control, or by applying line voltage to terminal 21 (REMOTE

RESET INPUT).

Proprietary and Confidential

Sequence of operation

13

Manual lockout

LED STATE

A lockout condition can be manually initiated by either pressing the reset

button on the control or by providing voltage to terminal 21. The lockout

code (shown here) indicated REMOTE RESET INPUT as the source of the

lockout. This can be used as a form of emergency shutdown.

Proprietary and Confidential

Sequence of operation

14

Call for heat input

Terminal 4 provides line voltage that is used to power the

operating limit string. After passing through all the limits in

series, line voltage is applied to terminal 5 to indicate that

the limits are complete and that there is a call for heat.

Proprietary and Confidential

Sequence of operation

15

Call for heat, checking air switch and POC

LED STATE When there is a call for heat, voltage must be detected on

both terminals 12 (PROOF OF CLOSURE INPUT) and

terminal 13 (AIR SWITCH NC INPUT) within 60 seconds.

Failure of either input to prove in time will result in a lockout.

For models with valve proving, both functions are wired in

series to terminal 13.

The air switch check is performed to verify that the air

switch is changing from closed to open (i.e., not jumpered

or stuck) between cycles.

Wire terminal 11 to terminals 12 and/or 13 to bypass

these checks. This works because terminal 11

(ACTUATOR ECONOMY OUTPUT) provides voltage

during this state.

BLINK

Proprietary and Confidential

Sequence of operation

16

Driving actuators to purge

LED STATE When the air switch check input and proof of closure input

prove, the sequence begins. Terminals 6 and 7 (FAN

OUTPUT) both energize. The LED above the reset button

lights green and the fan LED also lights green. The output

for terminal 11 (ACTUATOR ECONOMY OUTPUT) is no

longer powered. Instead, terminal 9 (ACTUATOR HIGH

FIRE OUTPUT) is powered instead as the BurnerPRO is

commanding the actuator to the purge position.

The LEDs for actuator open and actuator closed will

alternate as the control waits for feedback on terminal 8

(ACTUATOR FEEDBACK INPUT).

ALTERNATE

Proprietary and Confidential

Sequence of operation

17

Safety limits input

The safety limits must all be proven within the amount of

time specified for actuator travel time (timing t11). The count

begins when feedback is received to indicate that the

actuator is at the high fire position for purging.

The BurnerPRO will lockout if this input is not proven within

the specified duration.

Proprietary and Confidential

Sequence of operation

18

Purge

LED STATE When feedback is received to confirm that the actuator is at

the purge position, input must be received from the air

switch on terminal 14 (SAFETY LIMIT INPUT) within the

actuator travel time duration (timing t11). If the fan LED is

blinking, the control is waiting for this input. If the fan LED is

solid, this input has been received and the control is

counting the purge time (timing t1).

Proprietary and Confidential

Sequence of operation

19

CHECK MODE – purge

LED STATE Check mode can be applied to hold the burner in purge. To

do so, press and hold the reset button until the status LED

changes from green to amber. The fan LED will also blink

while in check mode.

Check mode in purge can be useful when a longer manual

purge is desired, or while checking other devices that

require the combustion air fan to run.

To exit check mode, simply press the reset button one time.

Check mode will automatically exit after 20 minutes.

Check mode will exit with a lockout (CHECK MODE

TIMEOUT).

BLINK

Proprietary and Confidential

Sequence of operation

20

Driving actuators to ignition

LED STATE After the purge timing is complete, the BurnerPRO will drive

the actuator to the ignition position. The output for terminal 9

(ACTUATOR HIGH FIRE OUTPUT) is no longer powered.

Instead, terminal 10 (ACTUATOR LOW FIRE OUTPUT) is

powered instead as the BurnerPRO is commanding the

actuator to the ignition position.

The LEDs for actuator open and actuator closed will

alternate as the control waits for feedback on terminal 8

(ACTUATOR FEEDBACK INPUT).

ALTERNATE

Other manuals for BurnerPRO

1

Table of contents