5

General Work Products LLC | 6000 Jefferson Hwy | Harahan, LA 70123 www.PalmerSafetyUS.com

•Fall Protection •Training •Netting •PPE

system is not laid out properly prior to installation, the system may have to be disassembled and reinstalled. Do

not try to move a fully assembled system.

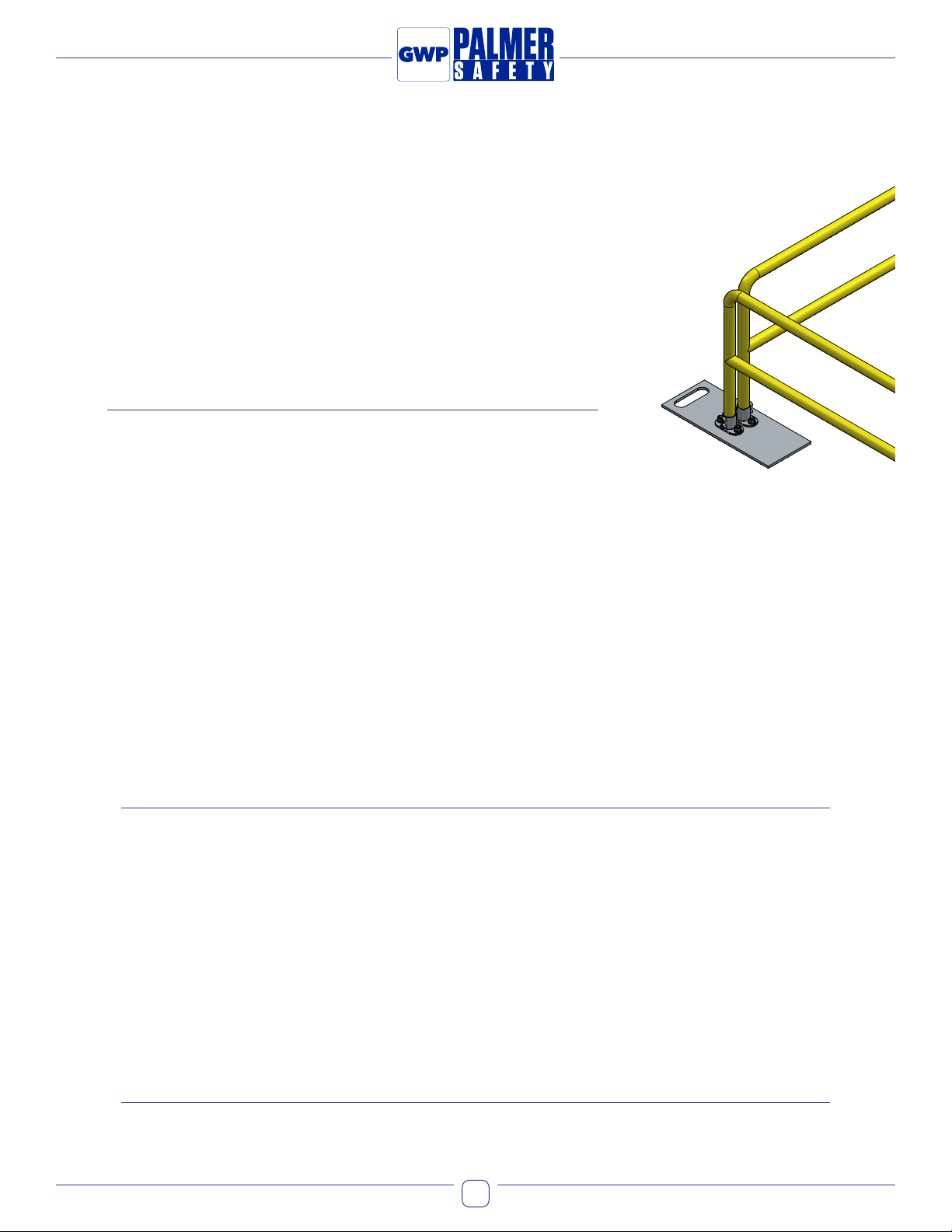

6) Make sure to orient the baseplates correctly. They must be perpendicular to the guardrails. For outriggers, one

baseplate will be parallel, and one baseplate will be perpendicular to the main

run of guardrails. See gure to the right.

7) GUARDRAIL4WBASE has slots to accept toe boards. Toe boards, if

used, should run parallel to the guardrail.

8) Outriggers must be used on all runs of guardrail. Install outriggers at each

end of a continuous run of guardrail including at both sides of an interruption.

An Outrigger is a Guardrail installed perpendicular to the continuous run.

9) Wind load rating is 70mph. Do not use if there is the possibility of winds

more than 70mph.

Installation and Use

1.First layout your system. Place your selected baseplates spaced according to the guardrail you are installing,

6’, 8’, 10’ or 12’, on the working surface. Measure accurately. Do not try to move a fully assembled guardrail

system. The baseplates should be oriented perpendicular to the guardrail (except for outriggers). The baseplates

must be a minimum of 2 feet from the leading-edge of any opening or leading-edge hazard. The baseplates must

be at least 10’ from power lines or other electrical dangers.

2.Remove the locking pins or loosen the set screws on the baseplates.

3. Hold the guardrail between you and the leading edge of the fall hazard. Insert one leg of the guardrail into the

baseplate socket. Insert the 2nd guardrail leg into the socket on the opposing baseplate.

4.Continue to install all guardrails following this procedure.

5. Install locking pins / tighten all set screws. Make sure each guardrail is rmly connected to the baseplate and

does not move.

6.If using toe boards, make sure they run parallel with guardrails.

Maintenance, Cleaning, and Storage

If Guardrail System fails inspection in any way, immediately remove it from service, and contact Palmer Safety to inquire

about its return or repair.

Cleaning after use is important for maintaining the safety and longevity of Guardrail System. Remove all dirt, corrosives,

and contaminants from Guardrail System before and after each use. If Guardrail System cannot be cleaned with plain

water, use mild soap and water, then rinse and wipe dry. NEVER clean Guardrail System with corrosive substances.

Prior to use, store equipment where it will not be affected by heat, light, excessive moisture, chemicals, or other degrading

elements.