Petzl I'D S Installation instructions

Other Petzl Safety Equipment manuals

Petzl

Petzl CORAX User manual

Petzl

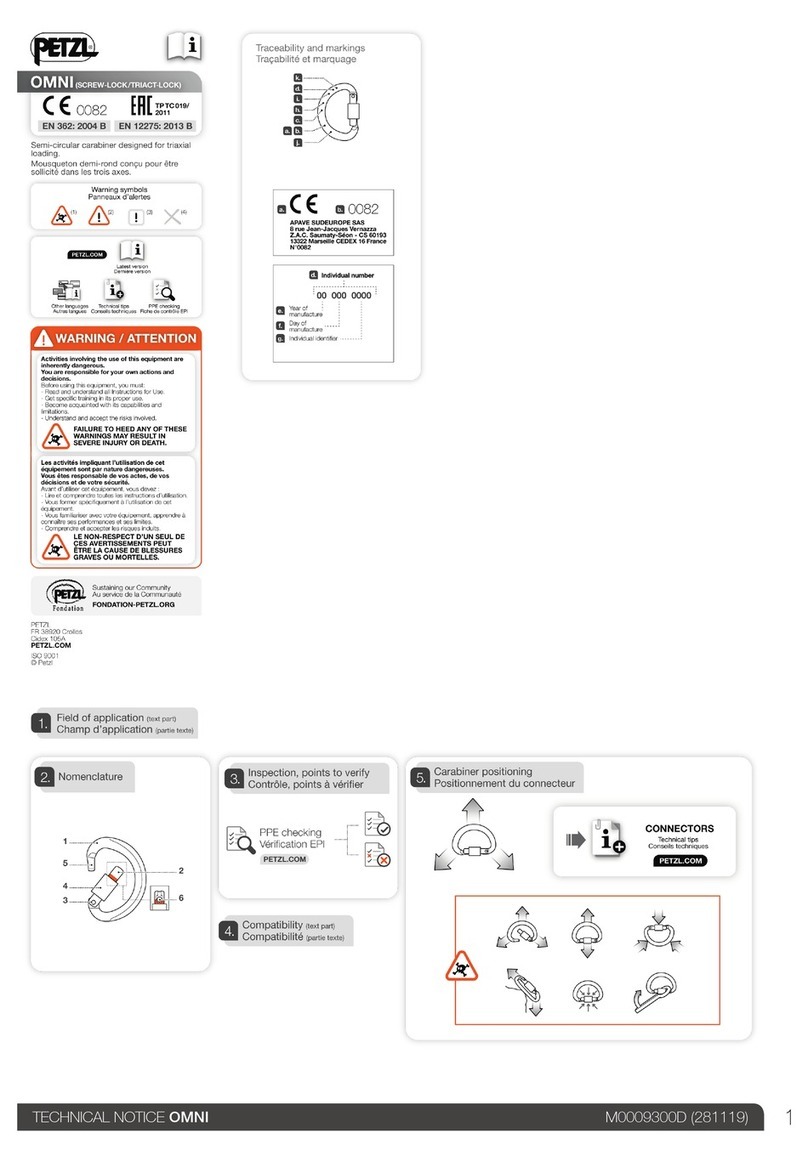

Petzl OMNI User manual

Petzl

Petzl LYNX T24A LLU Installation instructions

Petzl

Petzl RAY 11 mm User manual

Petzl

Petzl DUAL CONNECT VARIO User manual

Petzl

Petzl TIKKA User manual

Petzl

Petzl NEWTON INT User manual

Petzl

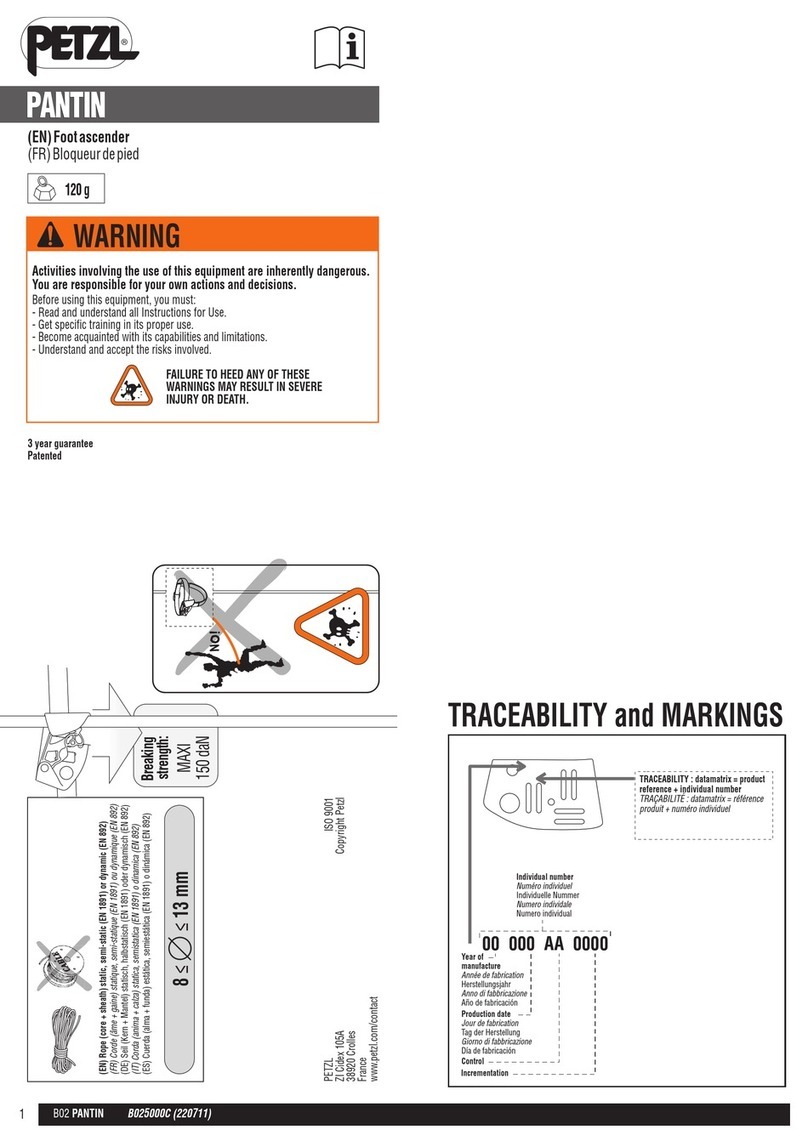

Petzl B02 User manual

Petzl

Petzl ZYPER-Y User manual

Petzl

Petzl TOP User manual

Petzl

Petzl ABSORBICA-I User manual

Petzl

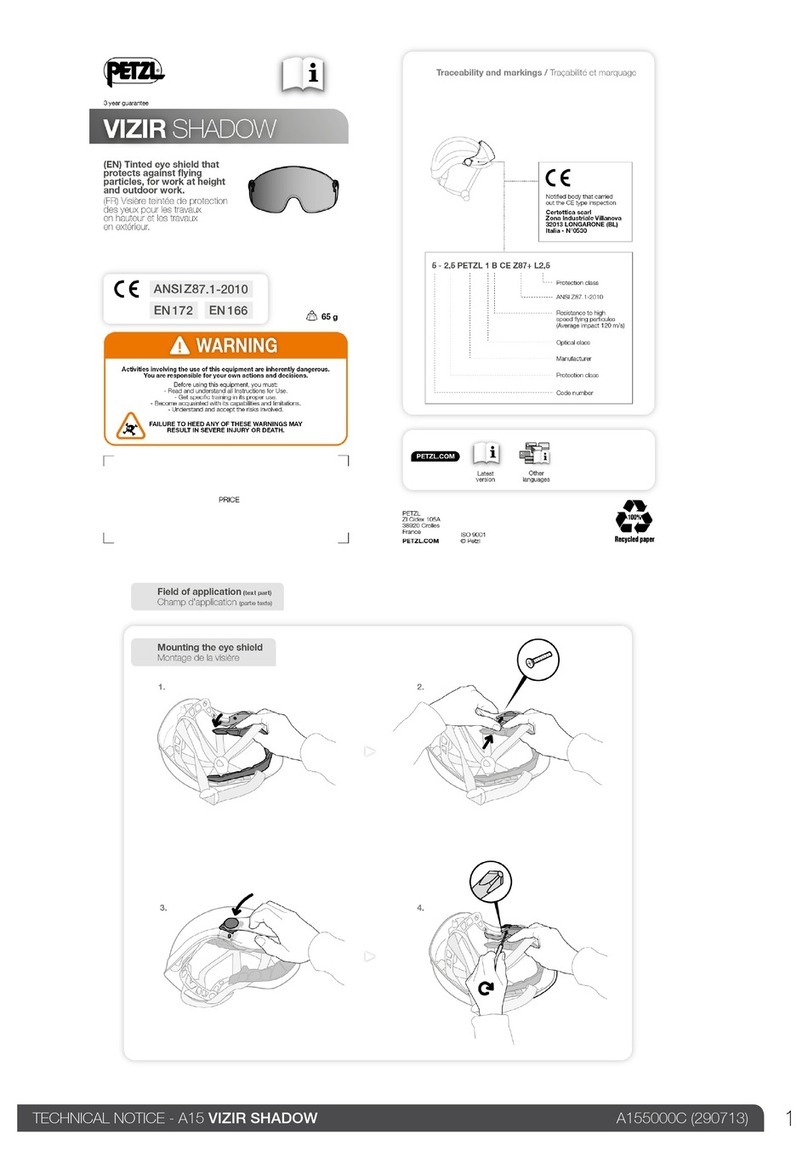

Petzl VIZIR SHADOW User manual

Petzl

Petzl ABSORBICA-I User manual

Petzl

Petzl Oxan Series User manual

Petzl

Petzl I'D EVAC User manual

Petzl

Petzl TREESBEE User manual

Petzl

Petzl AVAO SIT User manual

Petzl

Petzl FREINO Z RL User manual

Petzl

Petzl MINI P59A User manual

Petzl

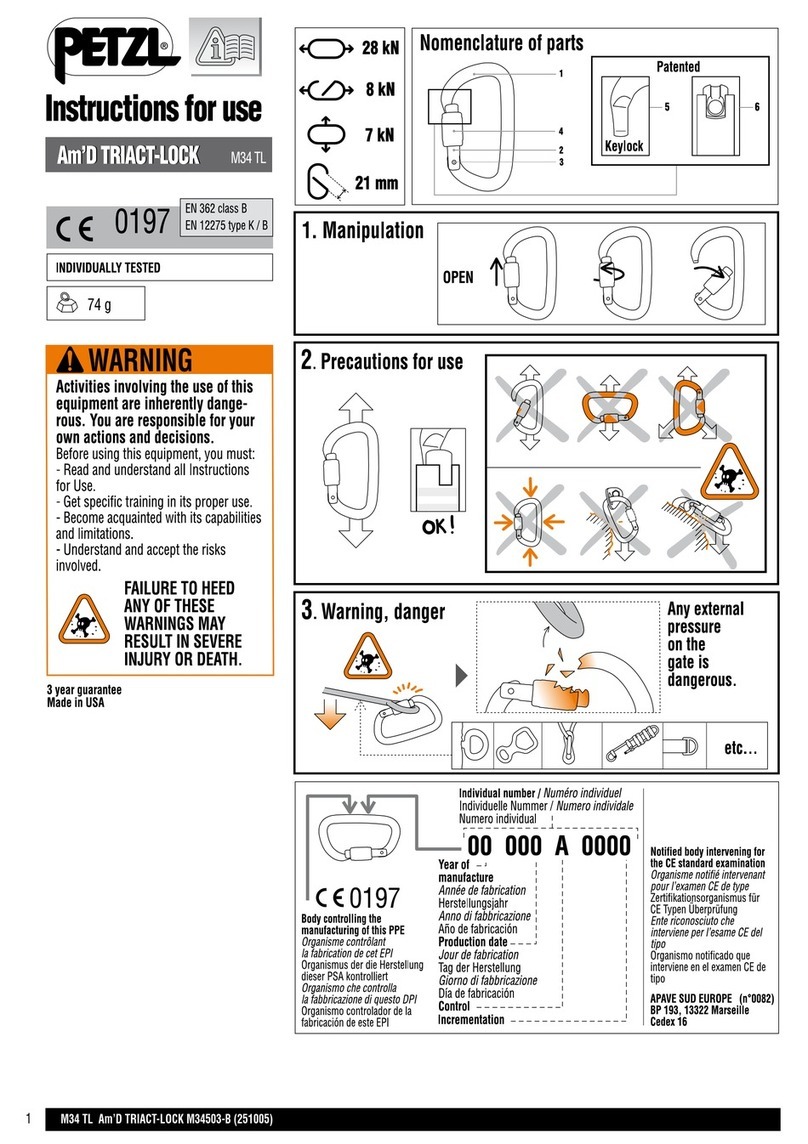

Petzl M34 TL User manual

Popular Safety Equipment manuals by other brands

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual