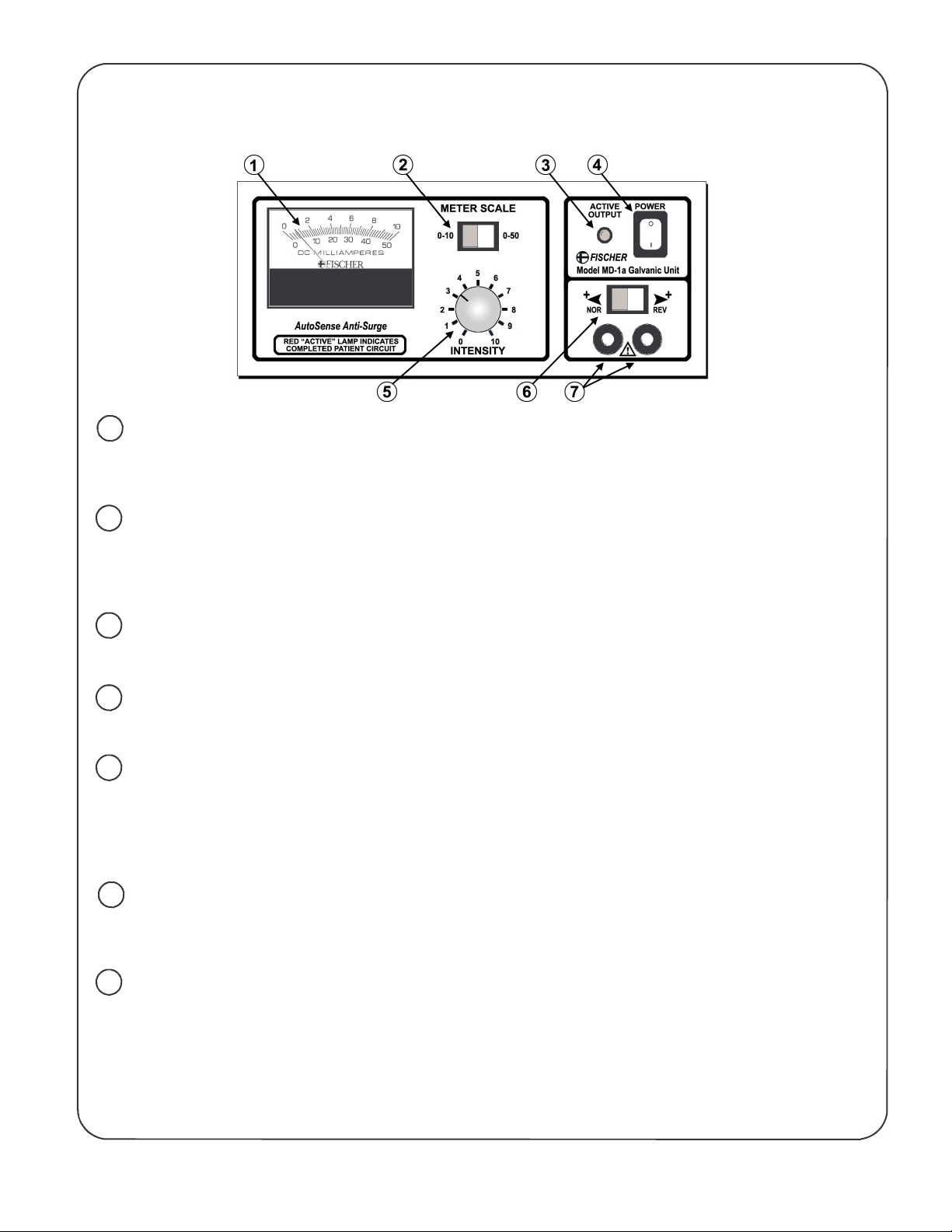

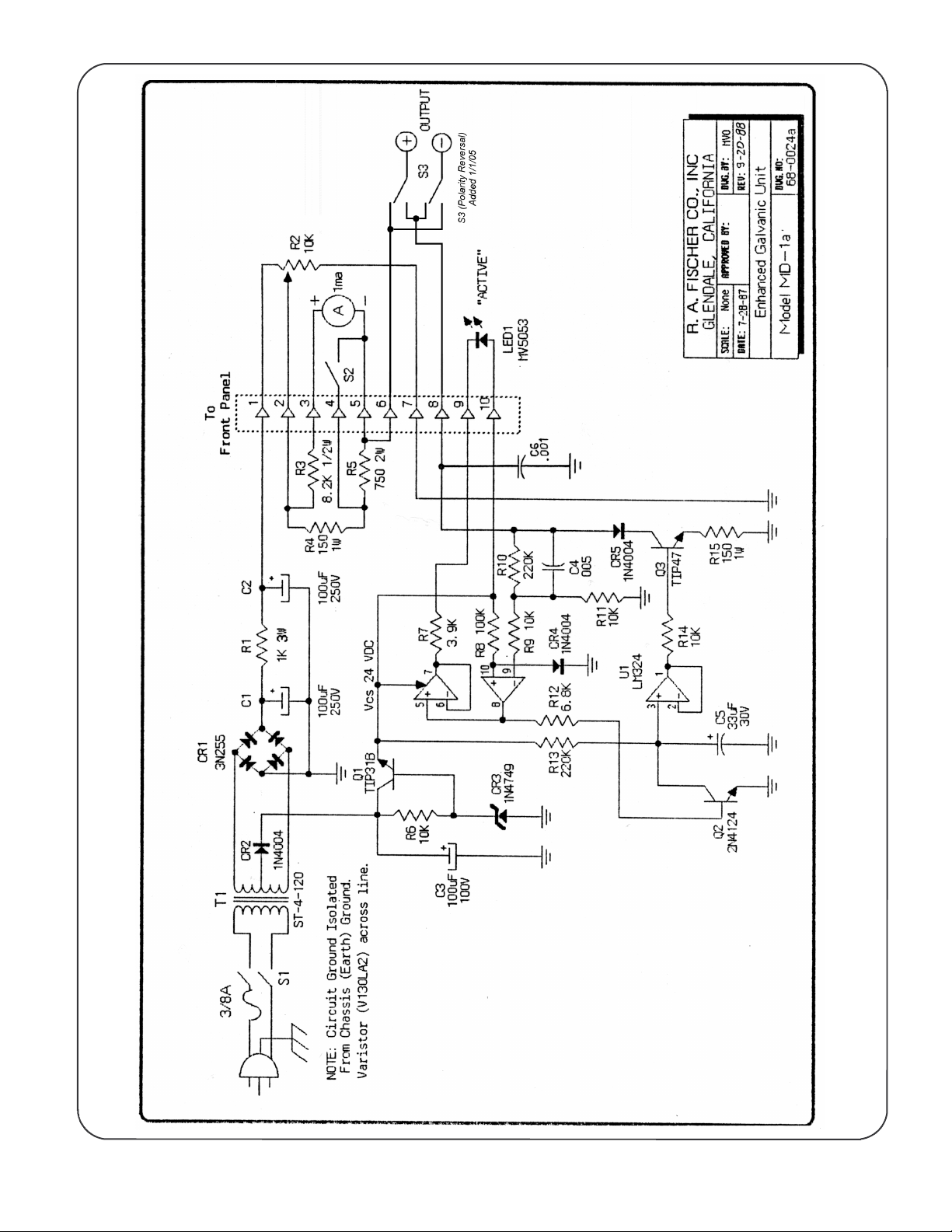

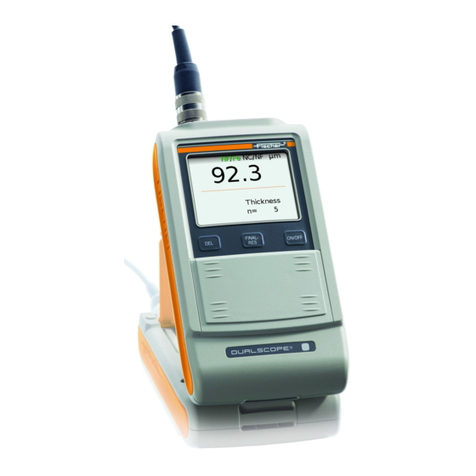

FISCHER MD-1a Product manual

Other FISCHER Measuring Instrument manuals

FISCHER

FISCHER MA15F ... A Series User manual

FISCHER

FISCHER ECO-LINE FT80 User manual

FISCHER

FISCHER ME01 Series Instruction Manual

FISCHER

FISCHER MS11 User manual

FISCHER

FISCHER Me01 Series User manual

FISCHER

FISCHER PERMASCOPE MP0R User manual

FISCHER

FISCHER MMS Inspection DPM User manual

FISCHER

FISCHER DA12 User manual

FISCHER

FISCHER DA30 User manual

FISCHER

FISCHER DAREX 715000 User manual

FISCHER

FISCHER MMS User manual

FISCHER

FISCHER NC56 User manual

FISCHER

FISCHER DA12 User manual

FISCHER

FISCHER DA03 GKT/HLP User manual

FISCHER

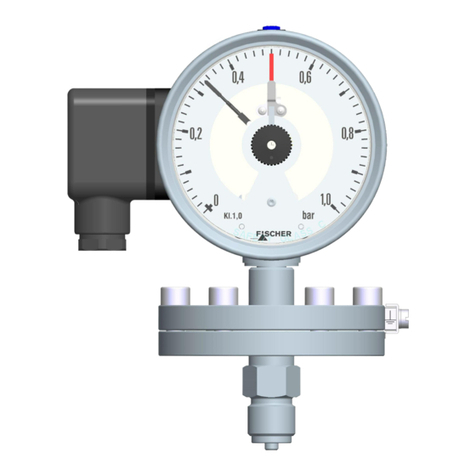

FISCHER MS10 User manual

FISCHER

FISCHER DA09 series User manual

FISCHER

FISCHER DA09 series User manual

FISCHER

FISCHER ME49F Series User manual

FISCHER

FISCHER NC57 User manual

FISCHER

FISCHER DELTASCOPE FMP10 User manual

Popular Measuring Instrument manuals by other brands

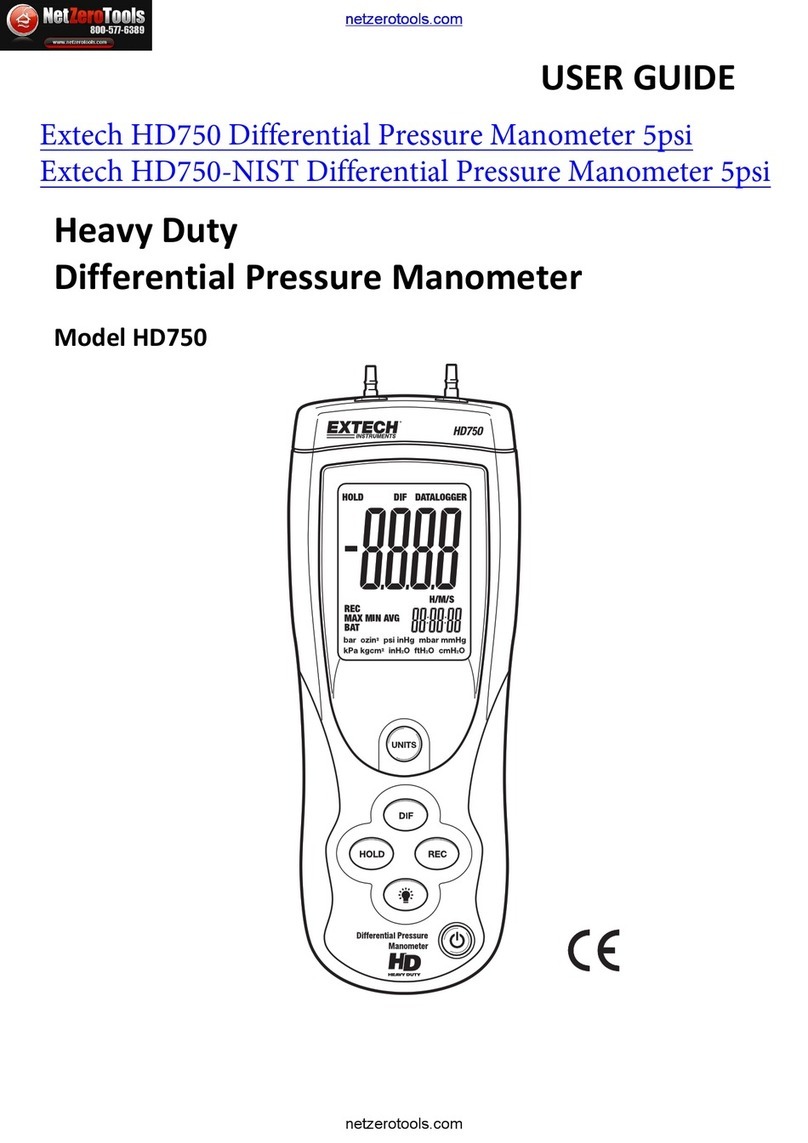

Extech Instruments

Extech Instruments HD750-NIST user guide

EPA

EPA LW-MK3 Driver installation

Interscan Corporation

Interscan Corporation GasD 8000 Series instruction manual

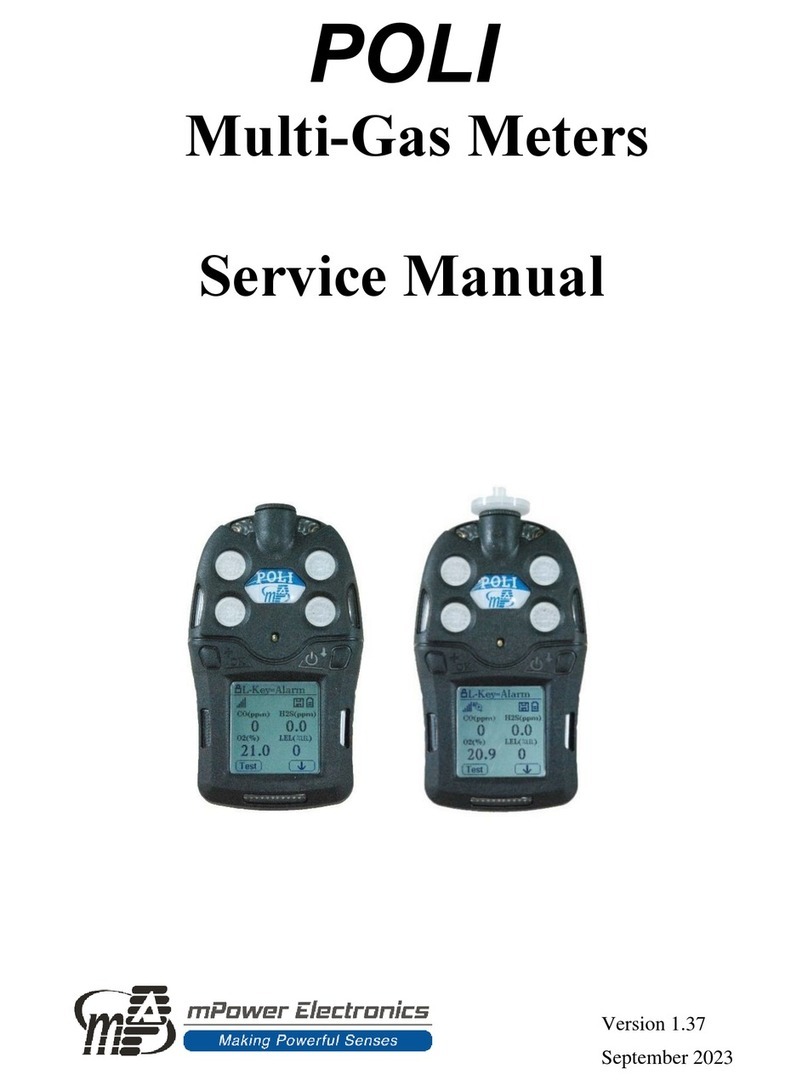

mPower Electronics

mPower Electronics POLI Service manual

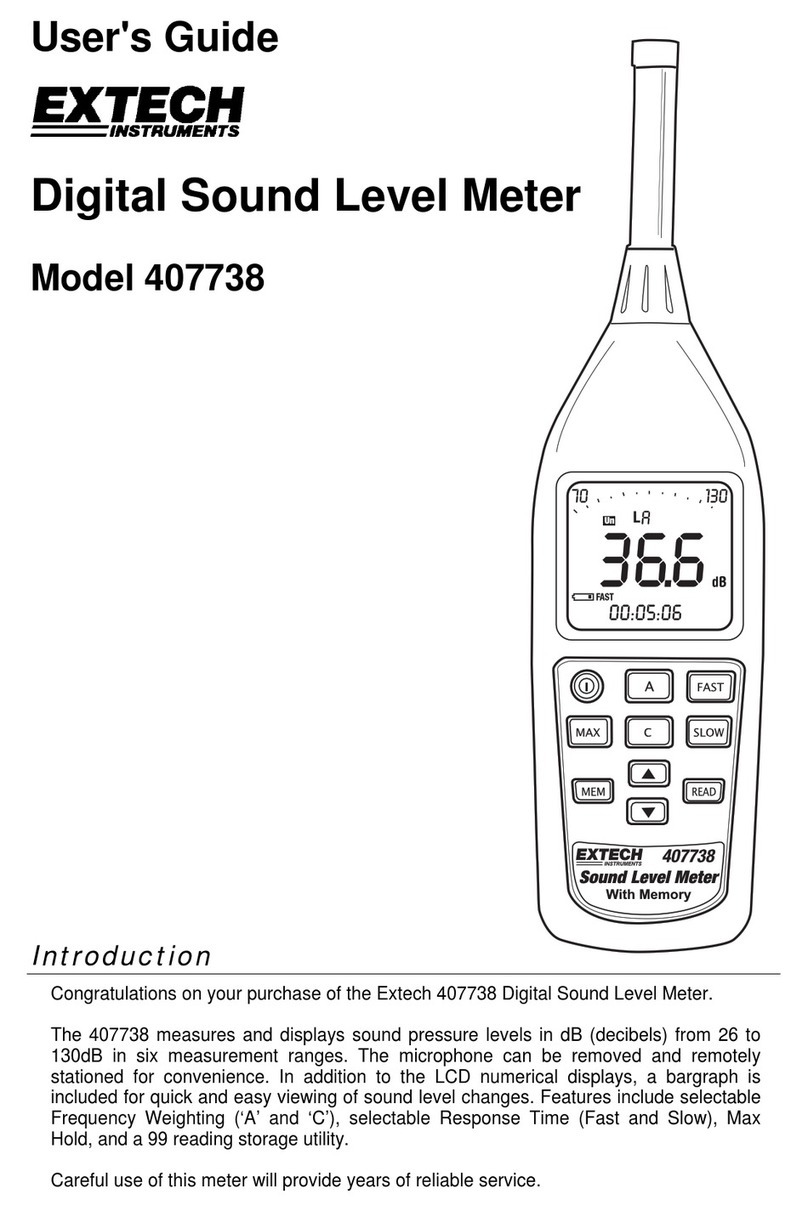

Extech Instruments

Extech Instruments 407738 user guide

VDO

VDO 333.001 FITTING INSTRUCTION