2 | 8 Page

1.5 Unauthorised Modification

Modifications of or other technical alterations to the

instrument by the customer are not permitted. This

also applies to replacement parts. Any modifica-

tions/alterations required will be carried out by

Fischer Mess- und Regeltechnik GmbH only.

1.6 Impermissible modes of operation

The operational safety of this instrument can only

be guaranteed if it is used as intended. The instru-

ment model must be suitable for the medium used

in the system. The limit values given in the technical

data may not be exceeded.

1.7 Safe working practices for mainte-

nance and installation work

The safety instructions given in this operating man-

ual, any nationally applicable regulations on acci-

dent prevention and any of the operating company's

internal work, operating and safety guidelines must

be observed.

The operating company is responsible for ensuring

that all required maintenance, inspection and instal-

lation work is carried out by qualified specialized

personnel.

1.8 Explanation of symbols

WARNING!

… indicates a potentially dangerous

situation, non-observance of which

could endanger persons, animals, the

environment or objects.

INFORMATION!

… highlights important information ef-

ficient and smooth operation.

TIP!

… indicates recommendations that are

not specifically necessary in certain

situations but which could be useful.

2 Application purpose

The ME01 is an electronic manometer with a ce-

ramic measuring cell for measuring over-pressure

and under-pressure with a local display and remote

signal transmission.

3 Product and function description

3.1 Design and mode of operation

A ceramic measuring cell acts as the pressure

transducer. The high resistance of the ceramic ma-

terials that are used allow use even for aggressive

media.

There is a resistance measuring bridge attached to

the side of the measuring diaphragm that faces

away from the medium. When pressure is exerted,

the membrane distorts in the elastic range. t the

same time, the resistance values of the bridge

change proportionally to the measuring pressure.

These values are implemented and displayed by

the installed electronics.

There are electrical uniform signals 0/4…20 mA

and 0…10 V in a 3-wire system available for remote

transmission.

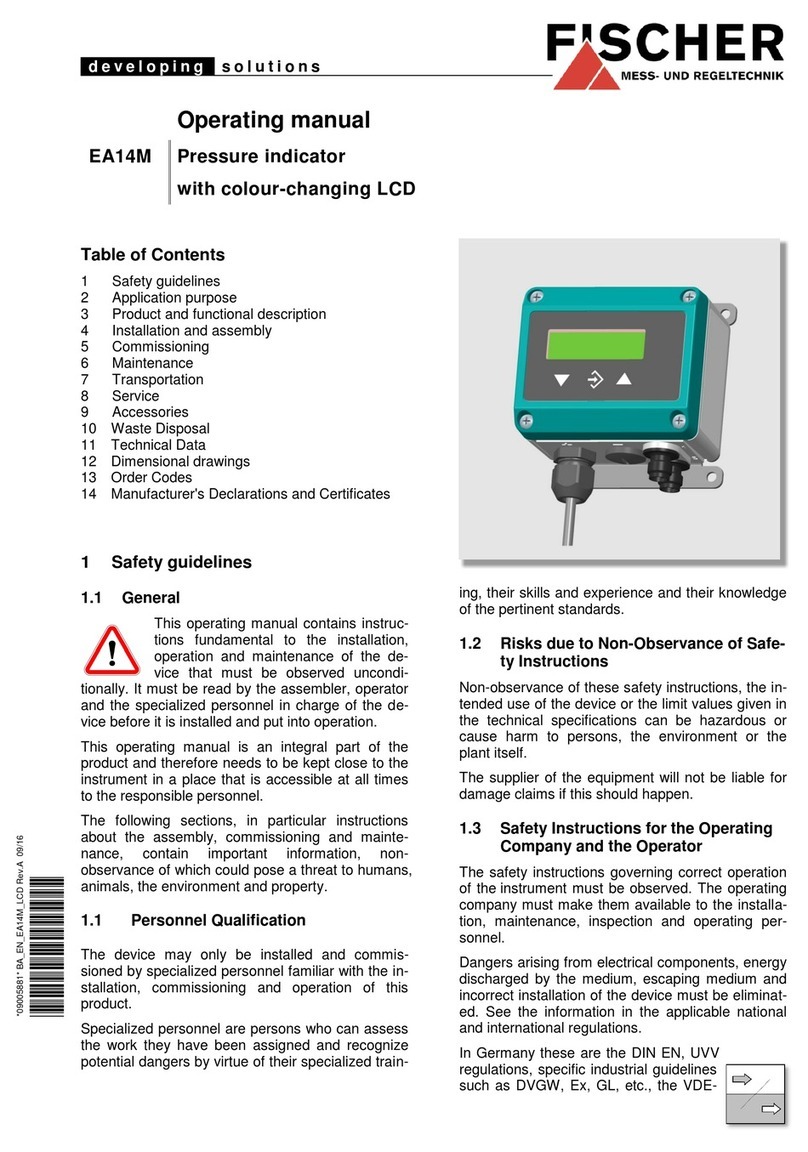

4 Installation and assembly

As standard, the device with the connecting port for

connection to pipes and other connection parts,

such as the welding sleeve, union nut with soldering

and welding nipples, is equipped with soldering and

welding nipples (see data sheet MZ...). It can be

mounted to a wall using the wall bracket (see data

sheet MZ...). Manometer screw connections for 10,

8, 6 mm dia. pipes can be supplied for connection

to pipes.

The enclosure protection type IP 65 is only guaran-

teed, if a suitable power supply cable is used.

4.1 Process connection

•By authorized and qualified specialized person-

nel only.

•Only for the designated mechanical process

connection - for the model, see the order code

on the device type plate.

•The pipes need to be depressurized when the

device is being connected.

•Appropriate steps must be taken to protect the

device from pressure surges.

•Check the suitability of the device for the media

to be measured.

•Observe the maximum pressure.

•Check that the pressure connections do not

leak before commissioning.