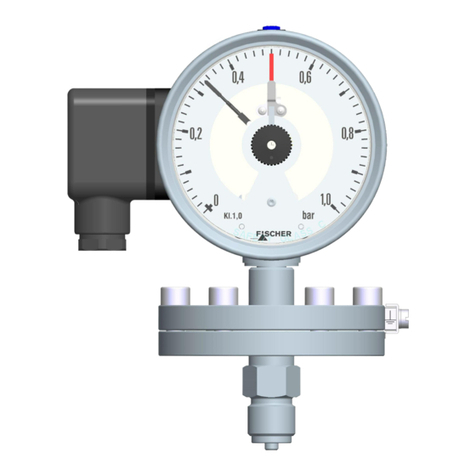

MMS® Inspection SPG

12

Description

The gage models MMS Inspection SPG measure the depths of surface profiles easily, quick,

non-destructively and with the precision that is typical for all Fischer instruments. The SPG

gages measure the peak-to-valley distances according ASTM D4417, Method B. Therefore,

measurements of the depths of surface profiles by using the SPG gages are conform to many

standards and guidances, e.g., SSPC-PA17.

Gage properties • Ideal for onsite applications (outside and inside) due to the compact size and the robust

and durable instrument design

• Probe integrated in the gage for single-handed operation

• IP65, dust-tight and water repellant and resistant

• A large touchdown table ensures a sure positioning on the surface

• Intuitive operation of the menu navigation and graphic display

• The measurement presentation flips automatically and thus allows optimum reading in dif-

ferent measuring positions

• Different languages selectable

• Measurements according to ASTM D4417, Method B

Applications

Examples • Measuring the depths of surface profiles

• Inspection, whether the surface profile depth is within the specifications

• Assessment of blasted surfaces whether they are appropriate for varnishing

Variants Start High

Entry level gage with small data memory for

max. 10,000 measured values in one batch,

display of measurement acquisition (audible

and optical) and USB interface for data

transfer

High-end gage with large data memory for

250,000 measured values in 2500 batches,

display of measurement acquisition (audible

and optical) additional by gage vibration,

USB interface and WiFi for data transfer

Metrological Standard Functions Measurement Tasks

Batch File containing all metrological function settings and the linking to calibration necessary for

the measurement task as well as the measured readings and evaluations

Block creation Measured readings grouped in measurement blocks

Tolerance limits Adjustable, upper and lower limit values

Representativ measurement reading

(Measurement Settings)

Display and storage of the representative measurement reading of a specified number (n)

of measurements, the n measured readings are not stored.

Methods for determination of the representative measurement reading:

• Mean value from n measurements

• Maximum value from n measurements

• Middle value, determined by the maximum and minimum values of n measurements

Measurement reading acquistion Automatic upon placement of the gage probe

Measurement reading storage On/Off switchable

Measurement units µm/mm or mils/inches

Resolution of measurement reading Low (up to 1 decimal place), Medium (up to 2 decimal places), High (up to 3 decimal

places)

Air reference value acquisition During measurement, the air reference value is used to detemine the maximum depth value.

Regular measurement of the air reference value is necessary to achieve high measurement

accuracy.