2

1.5. Modifications Forbidden

Modification or other technical alteration of the product is

not permissible. This also applies to the use of unautho-

rized spare parts for repair / maintenance of the product.

Any modifications to this product, if and as necessary,

should be done only by Fischer Mess- und Regeltechnik

GmbH.

1.6. Operational Restrictions

The operational reliability of the product is guaranteed

only when used for intended purposes. The product must

be selected and configured for use specifically with defi-

ned process media. The limiting values of operating pa-

rameters, as given in the product specification sheet,

must never be crossed.

1.7. Safety Considerations during Installation and

Maintenance

The safety instructions given in this manual, existing na-

tional regulations relating to accident prevention, and the

internal safety rules and procedures of the user organi-

zation regarding safety during installation, operation and

servicing must all be followed meticulously.

It is the responsibility of the users to ensure that only sui-

tably qualified and experienced technical personnel are

used for installation, operation and servicing of this

equipment.

2. Intended Applications

This differential pressure measuring instrument is inten-

ded as an indicator for differential pressure measure-

ment. The product must be used only for applications

and under conditions specified by the manufacturer.

Please confer with Fischer Mess- und Regeltechnik prior

to using this transmitter along with polluted or aggressive

media. For use with this media it needs to be adapted in

every part with direct contact to the media.

3. Product Description and Functions

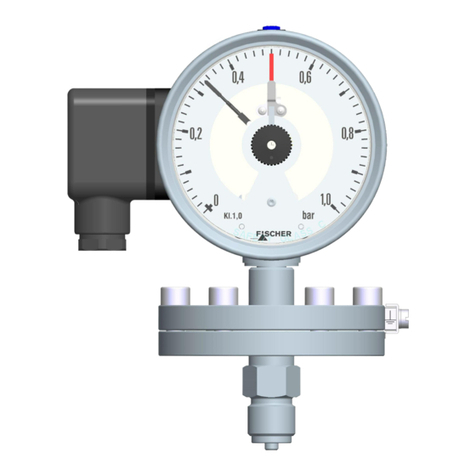

3.1. Block Schematic Diagram

3.2. Principles of Operation

This differential pressure instrument is based on a rug-

ged and uncomplicated diaphragm movement, suitable

for overpressure-, partial vacuum- and differential pres-

sure measurements. Operating principle of system is

identical for all applications of this type.

In a state of balance, forces of springs on both sides of

diaphragm are balanced. Pressure or differential pressu-

re to be measured creates an unbalanced force of

springs for measuring range until a new balance is rea-

ched.

When subjected to excessive pressure, diaphragm rests

on metal supporting plates.

A centre-mounted tappet transfers motion of the dia-

phragm system to indicator movement.

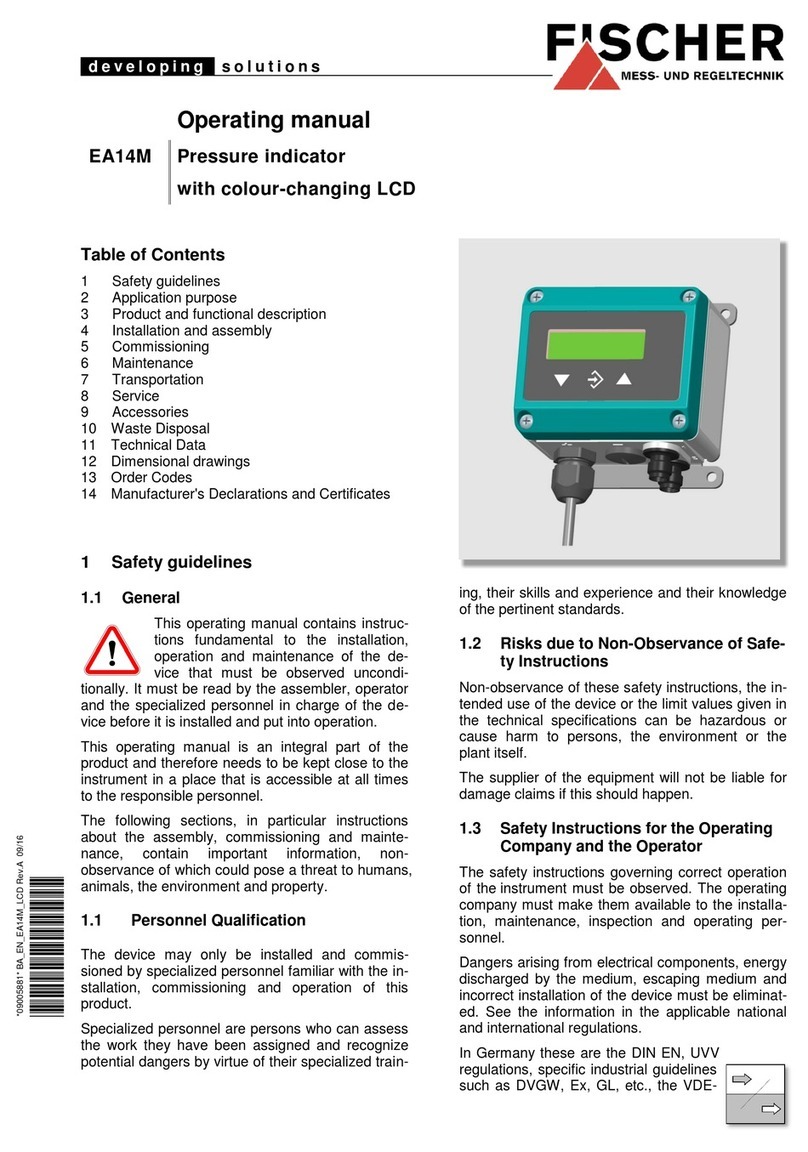

4. Installation

The instrument is intended for wallmounting by default. It

can be mounted immediately by 3 fastening elements ca-

sted on housing. Optional panel mounting with panel

mounting device DZ11 (see 9.). The instrument is factory

calibrated while mounted upright, pressure ports down-

ward. No other mounting orientation is allowed.

To ensure safety during installation and maintenance in-

tegrate adequate shut-off valves. By recommended

accessories (see. 9.) like three- and four-spindle shut-off

and equalizing valves DZ13/14 the instrument can be

• depressurized or shut down,

• cut off a plant to enable controlling or repairing,

• operational checked on site.

4.1. Process connections

• Only qualified technicians authorized for this type of

work should undertake installation.

• Only for intended mechanical process connection (for

model information see Type Plate of instrument).

• Ensure that process equipment and pressure lines

are at atmospheric pressure before making pressure

connections.

• The instrument should be provided with suitable pro-

tection against pressure surges (e.g., snubber or pul-

sation damper).

• Ensure that the mechanical configuration and materi-

als of construction of the instrument are compatible

with the process media.

• Ensure that process pressure is always less than the

specified safe pressure rating.

1. Pressure chamber

2. Movement

3. Tappet

4. Measuring springs

5. Measuring

diaphragm