FISCHER ER76 User manual

Operating manual

ER76

Control relay for level probes

DNV-GL version

09015289 • BA_EN_ER76 • Rev. ST4-D • 10/23

*09015289*

| Masthead FISCHER Mess- und Regeltechnik GmbH

2/20 BA_EN_ER76

Masthead

Manufacturer: FISCHER Mess- und Regeltechnik GmbH

Bielefelderstr. 37a

D-32107 Bad Salzuflen

Telephone: +49 5222 974 0

Telefax: +49 5222 7170

eMail: [email protected]

web: www.fischermesstechnik.de

Technical editorial team: Documentation representative: T. Malischewski

Technical editor: R. Kleemann

All rights, also those to the translation, reserved. No part of this document may

be reproduced or processed, duplicated or distributed using electronic systems

or any other form (print, photocopy, microfilm or another process) without the

written consent of the company FISCHER Mess- und Regeltechnik GmbH, Bad

Salzuflen.

Reproduction for internal use is expressly allowed.

Brand names and procedures are used for information purposes only and do

not take the respective patent situation into account. Great care was taken

when compiling the texts and illustrations; Nevertheless, errors cannot be ruled

out. The company FISCHER Mess- und Regeltechnik GmbH will not accept any

legal responsibility or liability for this.

Subject to technical amendments.

© FISCHER Mess- und Regeltechnik 2020

Version history

Rev. ST4-A 10/20 Version 1 (first edition)

Rev. ST4-B 04/21 Version 2 (new housing)

Rev. ST4-C 07/21 Version 3 (CE declaration updated)

Rev. ST4-D 10/23 Version 4 (DNV certificate updated)

FISCHER Mess- und Regeltechnik GmbH Table of contents

BA_EN_ER76 3/20

Table of contents

1 Safety instructions.......................................................................................................... 4

1.1 General................................................................................................................................... 4

1.2 Personnel Qualification .......................................................................................................... 4

1.3 Risks due to Non-Observance of Safety Instructions............................................................. 4

1.4 Safety Instructions for the Operating Company and the Operator ......................................... 4

1.5 Unauthorised Modification...................................................................................................... 4

1.6 Inadmissible Modes of Operation........................................................................................... 4

1.7 Safe working practices for maintenance and installation work............................................... 5

1.8 Pictogram explanation............................................................................................................ 5

2 Product and functional description............................................................................... 6

2.1 Delivery scope........................................................................................................................ 6

2.2 Device versions ...................................................................................................................... 6

2.3 Intended use........................................................................................................................... 7

2.4 Function diagram.................................................................................................................... 7

2.5 Design and mode of operation ............................................................................................... 8

3 Assembly ......................................................................................................................... 9

3.1 General................................................................................................................................... 9

3.2 Electrical connection .............................................................................................................. 9

4 Start-up ............................................................................................................................ 11

5 Servicing .......................................................................................................................... 12

5.1 Maintenance........................................................................................................................... 12

5.2 Transport ................................................................................................................................ 12

5.3 Service ................................................................................................................................... 12

5.4 Disposal.................................................................................................................................. 12

6 Technical data ................................................................................................................. 13

6.1 General................................................................................................................................... 13

6.2 Input variables ........................................................................................................................ 13

6.3 Output sizes ........................................................................................................................... 13

6.4 Auxiliary energy...................................................................................................................... 13

6.5 Operating conditions .............................................................................................................. 13

6.6 Construction design................................................................................................................ 14

7 Order codes ..................................................................................................................... 15

7.1 Accessories ............................................................................................................................ 15

8 Attachment ...................................................................................................................... 16

1 | Safety instructions FISCHER Mess- und Regeltechnik GmbH

4/20 BA_EN_ER76

1 Safety instructions

1.1 General

This operating manual contains basic instructions for the installation, operation

and maintenance of the device that must be followed without fail. It must be

read by the installer, the operator and the responsible specialist personnel be-

fore installing and commissioning the device.

This operating manual is an integral part of the product and therefore needs to

be kept close to the instrument in a place that is accessible at all times to the re-

sponsible personnel.

The following sections, in particular instructions about the assembly, commis-

sioning and maintenance, contain important information, non-observance of

which could pose a threat to humans, animals, the environment and property.

The instrument described in these operating instructions is designed and manu-

factured in line with the state of the art and good engineering practice.

1.2 Personnel Qualification

The instrument may only be installed and commissioned by specialized person-

nel familiar with the installation, commissioning and operation of this product.

Specialized personnel are persons who can assess the work they have been

assigned and recognize potential dangers by virtue of their specialized training,

their skills and experience and their knowledge of the pertinent standards.

1.3 Risks due to Non-Observance of Safety Instructions

Non-observance of these safety instructions, the intended use of the device or

the limit values given in the technical specifications can be hazardous or cause

harm to persons, the environment or the plant itself.

The supplier of the equipment will not be liable for damage claims if this should

happen.

1.4 Safety Instructions for the Operating Company and the

Operator

The safety instructions governing correct operation of theinstrument must be

observed. The operating company must make them available to the installation,

maintenance, inspection and operating personnel.

Dangers arising from electrical components, energy discharged by the medium,

escaping medium and incorrect installation of the device must be eliminated.

See the information in the applicable national and international regulations.

Please observe the information about certification and approvals in the Tech-

nical Data section.

1.5 Unauthorised Modification

Modifications of or other technical alterations to the instrument by the customer

are not permitted. This also applies to replacement parts. Only the manufacturer

is authorised to make any modifications or changes.

1.6 Inadmissible Modes of Operation

The operational safety of this instrument can only be guaranteed if it is used as

intended. The instrument model must be suitable for the medium used in the

system. The limit values given in the technical data may not be exceeded.

The manufacturer is not liable for damage resulting from improper or incorrect

use.

FISCHER Mess- und Regeltechnik GmbH Safety instructions | 1

BA_EN_ER76 5/20

1.7 Safe working practices for maintenance and installation work

The safety instructions given in this operating manual, any nationally applicable

regulations on accident prevention and any of the operating company's internal

work, operating and safety guidelines must be observed.

The operating company is responsible for ensuring that all required mainten-

ance, inspection and installation work is carried out by qualified specialized per-

sonnel.

1.8 Pictogram explanation

DANGER

Type and source of danger

This indicates a direct dangerous situation that could lead to death or serious

injury (highest danger level).

1. Avoid danger by observing the valid safety regulations.

WARNING

Type and source of danger

This indicates a potentially dangerous situation that could lead to death or ser-

ious injury (medium danger level).

1. Avoid danger by observing the valid safety regulations.

CAUTION

Type and source of danger

This indicates a potentially dangerous situation that could lead to slight or seri-

ous injury, damage or environmental pollution (low danger level).

1. Avoid danger by observing the valid safety regulations.

NOTICE

Note / advice

This indicates useful information of advice for efficient and smooth operation.

2 | Product and functional description FISCHER Mess- und Regeltechnik GmbH

6/20 BA_EN_ER76

2 Product and functional description

2.1 Delivery scope

• ER76 according to specification (see order code)

• Operating Manual

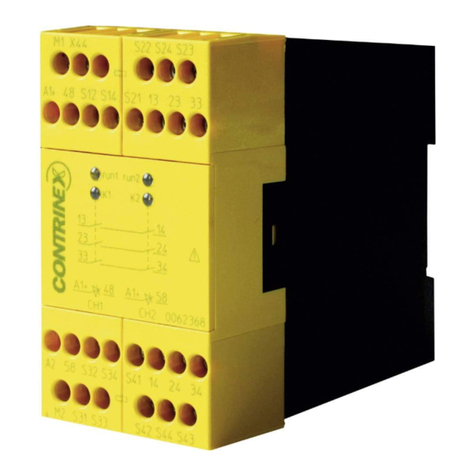

2.2 Device versions

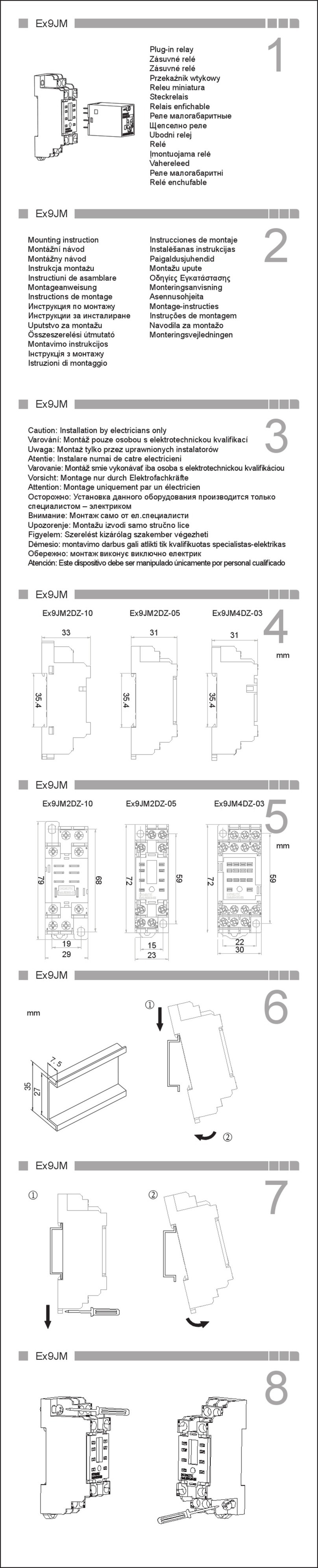

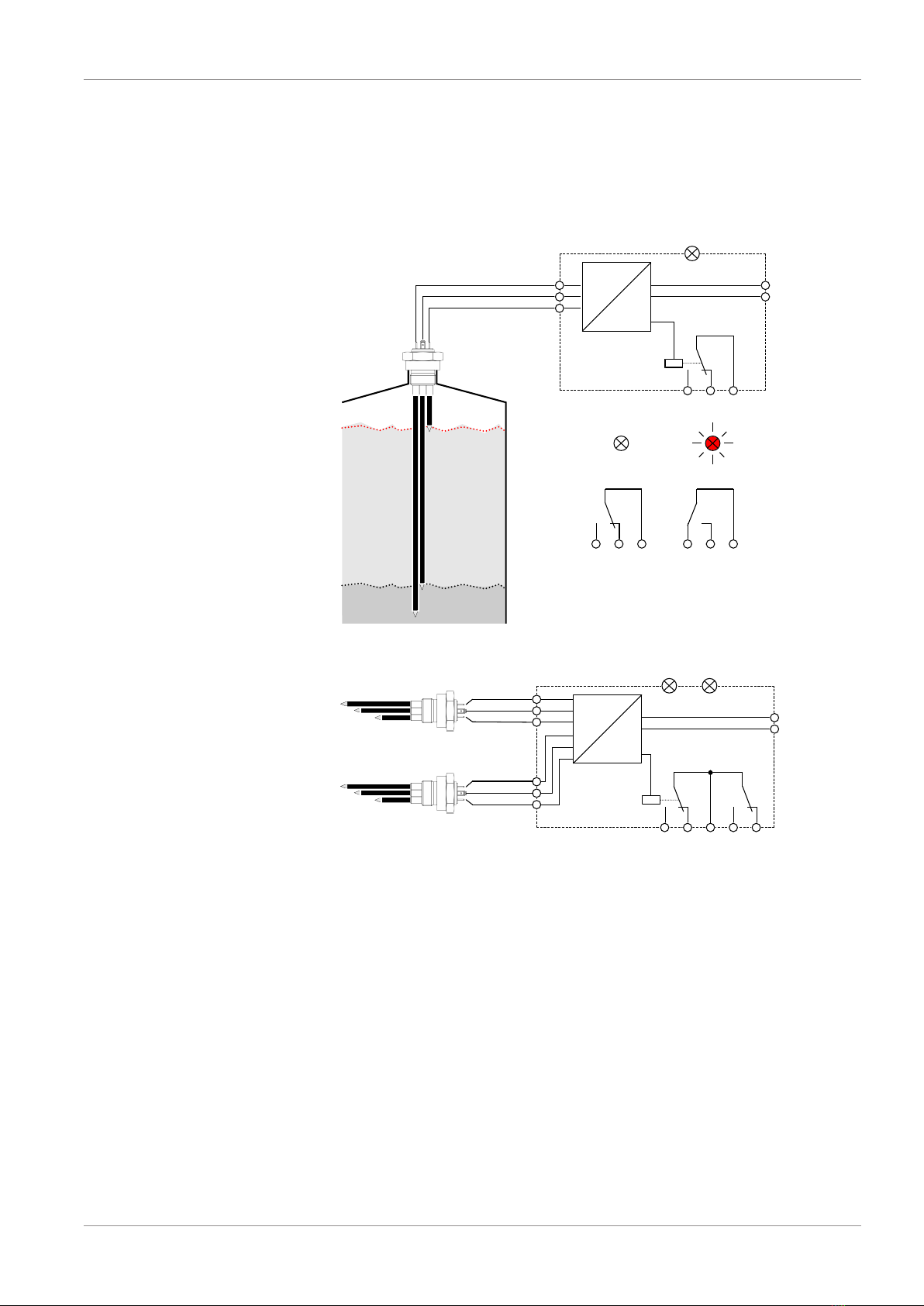

Probe connection Probe connection 1+2

Status LED 1+2

1 Channel 2 Channel

Status LED

Supply

Switching output

Supply

Switching output 1+2

Fig.1: Device versions

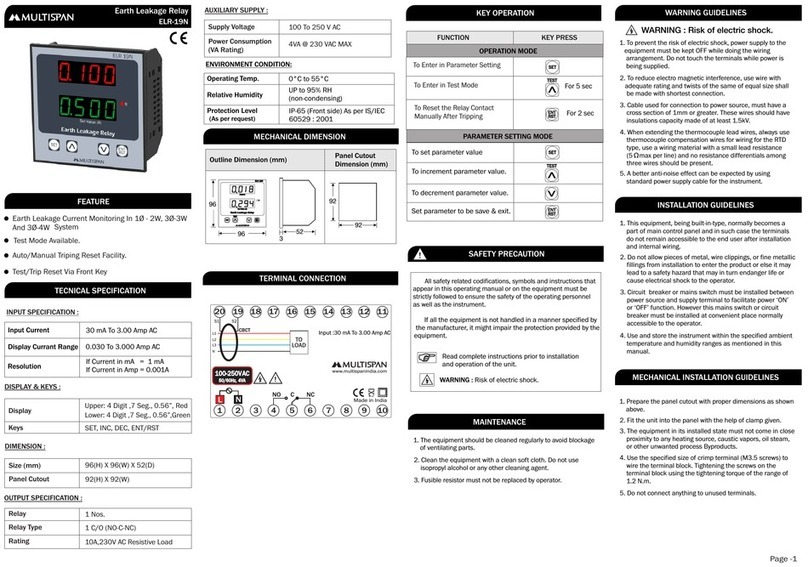

Bestellnummer Switch output Supply Ub

ER76 1 000000 1 1 relay contact 230 V AC

ER76 1 000000 4 1 relay contact 24 V AC

ER76 2 000000 1 2 relay contacts 230 V AC

ER76 2 000000 4 2 relay contacts 24 V AC

2.2.1 Type plate

This type plate serves as an example of the information that is stated. The data

shown is purely fictive, but does correspond to the actual conditions. For more

information, please see the order code at the end of these instructions.

Art. No.

Supply

Power

Input

Function

Load data

Temp. range

Prod.-Nr.

ER7610000001

230 VAC 50/60 Hz

max. 5 VA

0 ... 200 kOhm

interval

250 VA

-10 .... +70 °C

2106821.00.002

FISCHER Mess- und Regeltechnik GmbH Bielefelder Str. 37a D32107-Bad Salzuflen

Order codes

Serial number

Technical data

Fig.2: Type plate

FISCHER Mess- und Regeltechnik GmbH Product and functional description | 2

BA_EN_ER76 7/20

2.3 Intended use

Control relay ER76 can be used in connection with type NK06 level probes for

the automatically controlling and regulating conductive liquid filling levels in tank

systems.

2.4 Function diagram

min

max

NK06

com

max

min 230 V AC

24 V AC

2

3

1

ER76 1 ...

L

N

-K1

K1

Rest position Working contact

ER76 2 ...

com1

L

N

max1

min1

230 V AC

24 V AC

K1 K2

com2

max2

min2

NK06

-K1 -K2

Container 1

Container 2

Fig.3: Function diagram

2 | Product and functional description FISCHER Mess- und Regeltechnik GmbH

8/20 BA_EN_ER76

2.5 Design and mode of operation

ER76 is controlled by the medium using a type NK06 probe. Input sensitivity is

factory-adjusted to 70 kΩ. In order for the relay to switch properly, the medium-

conductivity must not fall below a value of 14µS/cm.

When contact is made, an alternating voltage without a direct voltage compon-

ent flows through the medium, preventing galvanic erosion of the probe mater-

ial.

Depending on the application, location or national regulations, the control elec-

trodes' reference potential can be represented by a common electrode as well

as by the container itself.

After the level probe has been installed and the control relay has been electric-

ally connected, the contact switches to the working position. LED is on.

If the maximum level is reached, the output relay switches to the rest position.

LED is off. This state remains until the level falls below the minimum level and

the contact switches to the working position again.

If the supply voltage fails, there is a defect in the control circuit or an interruption

in the measuring line, the system goes into the safe state (normally closed con-

tact) and thus prevents the container from being overfilled.

FISCHER Mess- und Regeltechnik GmbH Assembly | 3

BA_EN_ER76 9/20

3 Assembly

3.1 General

CAUTION

Risks connected to medium or system

The builder or operator of the tank system must take suitable protective meas-

ures for installation and maintenance.

3.2 Electrical connection

• By authorized and qualified specialized personnel only.

• When connecting the unit, the national and international electro-technical

regulations must be observed.

• Disconnect the system from the mains, before electrically connecting the

device.

• Install the consumer-adapted fuses.

• Do not connect the connector if strained.

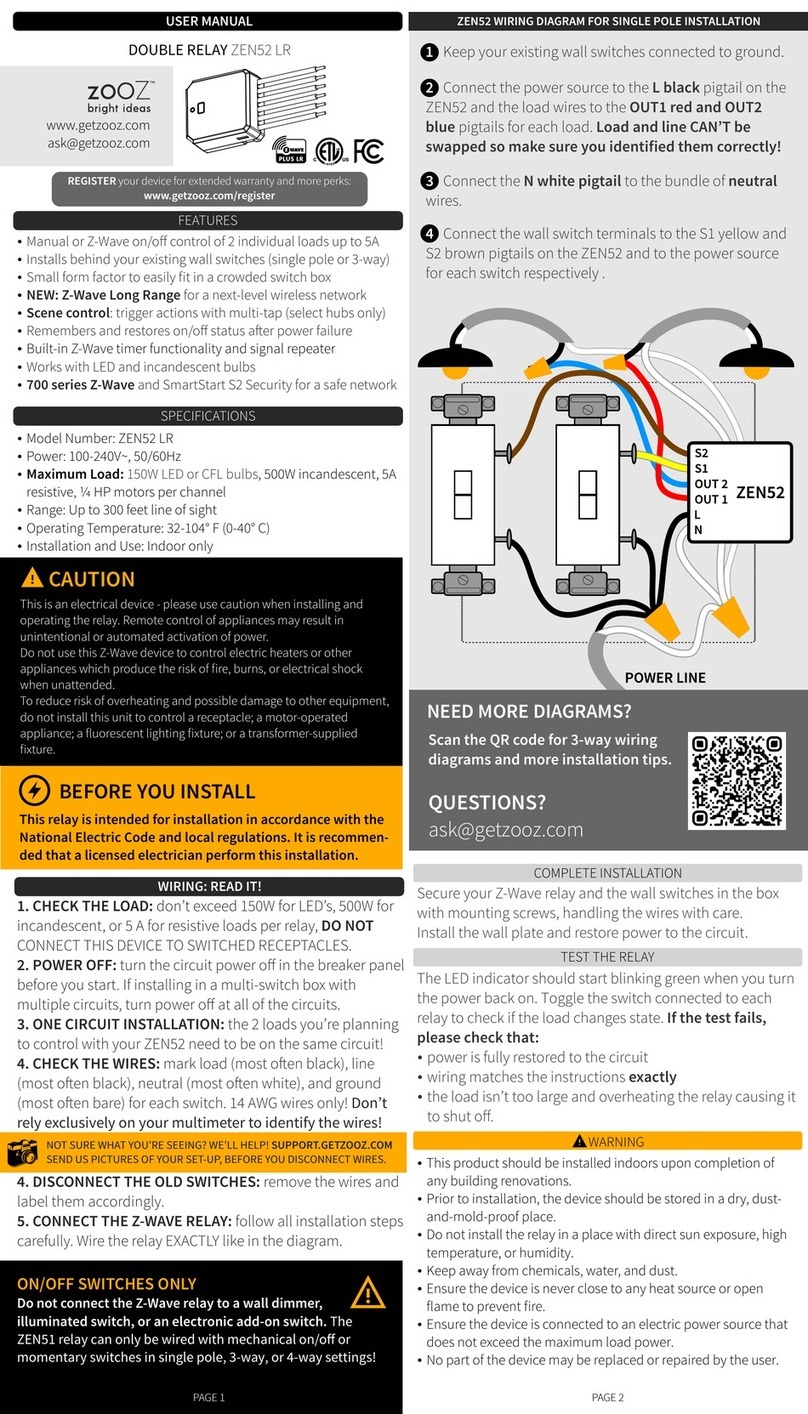

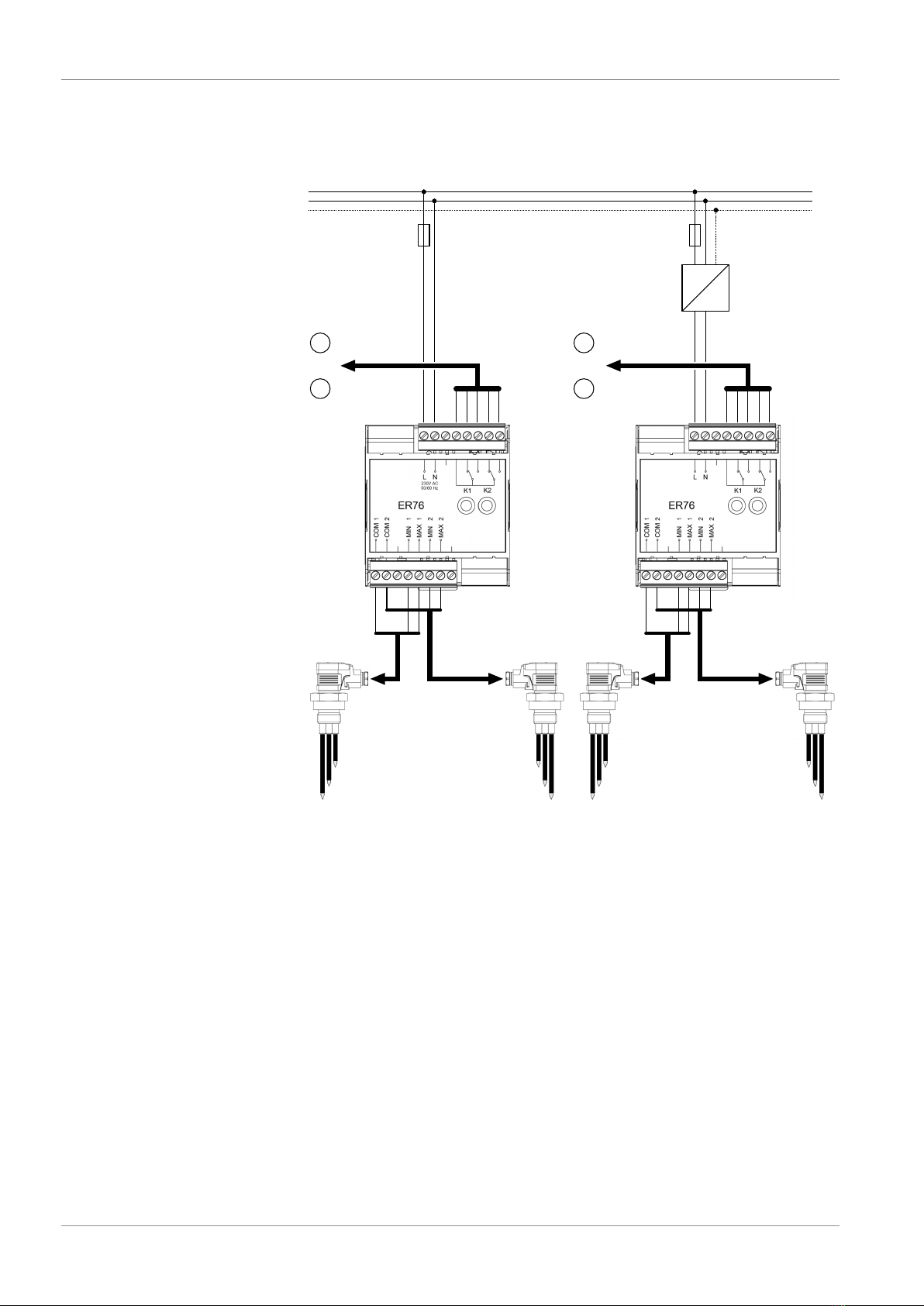

3.2.1 ER76 with one relay

L1

N

PE

F

M

24 V AC

230 V AC

F

NK06 NK06

M

Pump Pump

230 V AC 24 V AC

24 V AC

Fig.4: Automatic level control with a relay (example)

3 | Assembly FISCHER Mess- und Regeltechnik GmbH

10/20 BA_EN_ER76

ER76 switch output does not necessarily have to be used for direct pump con-

trol. It can also be used as a monitoring signal for an electronic control system.

3.2.2 ER76 with two relays

L1

N

PE

F

M1

24 V AC

230 V AC

F

NK06

Pumps

230 V AC 24 V AC

24 V AC

NK06

Tank 2Tank 1

NK06 NK06

Tank 2Tank 1

M2

M1

Pumps

M2

Fig.5: Automatic level control with two relays (example)

With the ER762… two containers can be monitored with one relay. One pos-

sible application would be, for example, controlling a tank for crude oil dewater-

ing and a storage tank for separated water at the same time.

Here, too, switch outputs can be used as monitoring signals for an electronic

control system.

FISCHER Mess- und Regeltechnik GmbH Start-up | 4

BA_EN_ER76 11/20

4 Start-up

Proper installation of all electrical supply and signal lines is a prerequisite for

commissioning. All connections are arranged so that there are no mechanical

forces acting on the device.

ER76 is a control relay for NK06 conductive level probes. Please check the tank

system for leaks before commissioning.

The function test for the ER76 with one relay is described below. For devices

with two relays, the second channel works the same as the first channel.

Function test:

1. Switch on the ER76 supply.

ÊRelay K1 switches and the associated LED lights up.

2. Fill the tank until the maximum filling level is reached.

ÊRelay K1 drops out and the associated LED goes out.

3. Empty the tank until it falls below the minimum level.

ÊRelay K1 switches and the associated LED lights up.

uThis ends the function test.

Malfunctions

ER76 control relay is a very reliable device. If an error occurs during commis-

sioning, first check the electrical connections. A cable may be mixed up or there

is an interruption.

5 | Servicing FISCHER Mess- und Regeltechnik GmbH

12/20 BA_EN_ER76

5 Servicing

5.1 Maintenance

The instrument is maintenance-free. We recommend the following regular in-

spection to guarantee reliable operation and a long service life:

• Check the function in combination with downstream components.

• Check the electrical connections.

The exact test cycles need to be adapted to the operating and environmental

conditions. In combination with other devices, the operating instructions for the

other devices also need to be observed.

5.2 Transport

The measuring device must be protected against impacts. It should be transpor-

ted in the original packaging or a suitable transport container.

5.3 Service

All defective or faulty devices should be sent directly to our repair department.

Please coordinate all shipments with our sales department.

WARNING

Process media residues

Process media residues in and ondismantled devices can be a hazard to

people, animals and the environment. Take adequate preventive measures. If

required, the devices must be cleaned thoroughly.

Return the device in the original packaging or a suitable transport container.

5.4 Disposal

Please help to protect the environment by always disposing of the work pieces

and packaging materials in compliance with the valid national waste and recyc-

ling guidelines or reuse them.

FISCHER Mess- und Regeltechnik GmbH Technical data | 6

BA_EN_ER76 13/20

6 Technical data

6.1 General

Type designation ER76

Inputs for conductive probes 1 or 2

Switch outputs 1 or 2

Measurement principle Conductive

6.2 Input variables

Measuring range The measuring range (fill level) is de-

termined by the connected conductive

probe.

Input signal

COM, MIN, MAX

Probe rods covered: A current flows

between the rods.

Probe rods uncovered: No current

flows between the rods.

Adjustment range Set

Input sensitivity 0 … 200 kΩ 70 kΩ

Medium conductivity --- ≥ 14 µS/cm

Input sensitivity is preset at the factory and cannot be changed on site.

6.3 Output sizes

Switching function 2-point controller

Switch output 1 or 2 potential-free changeover con-

tacts

Max. switching voltage 250 V AC

Max. switching current 2 A

Max. switching output 250 VA

Switching status display LED

6.4 Auxiliary energy

Nominal voltage 230 V AC

24 V AC

Absorbed power Max. 5 VA

6.5 Operating conditions

Ambient temperature range -10 °C … +70 °C

Storage temperature range -10 °C … +70 °C

Housing protection class

Terminal protection class

IP40

IP20

NSR EN 61010-1:2010 + A1:2019 +

A1:2019/AC:2019

EMC EN 61326-1:2013

EN 61326-2-3:2013

RoHS EN IEC 63000:2018

DNV-GL On all vessels in accordance with the

provisions of the DNVGL (class

guideline: DNVGL-CG-339)

Certificate No. TAA00001ZU

6 | Technical data FISCHER Mess- und Regeltechnik GmbH

14/20 BA_EN_ER76

6.6 Construction design

Electrical connection Screw terminals

Installation position User-defined

Assembly *) Assembly of the mounting rails

Dimensions 68 x 75 x 110 mm

Weight (max.) 280 g

380 g

ER76 1-Channel

ER76 2-Channel

*) A cut-to-size mounting rail and end clamps are available as accessories for

wall mounting.

6.6.1 Materials

Housing Polycarbonate / acrylonitrile butadiene

styrene (ABS-PC)

Terminals Polyamide (PA), Cu alloy

6.6.2 Dimension drawing

All dimensions in mm unless otherwise stated

68

75

110

Fig.6: Dimension drawing ER76 1 channel

The 2-channel version has the same dimensions.

FISCHER Mess- und Regeltechnik GmbH Order codes | 7

BA_EN_ER76 15/20

7 Order codes

0 0E R 7 6 0 0 00

12 567834

Version

Operating voltage

Type

Identification No.

Design:

[1] (Code no.)

11-way relay

22-way relay

Operating voltage:

[8] (Code no.)

1230 V AC

424 V AC

7.1 Accessories

Order no. Discription

NK06 Conductive level probe

09001380 35 mm mounting rail perforated; 122 mm long

09001479 End clamp 6mm wide

8 | Attachment FISCHER Mess- und Regeltechnik GmbH

16/20 BA_EN_ER76

8 Attachment

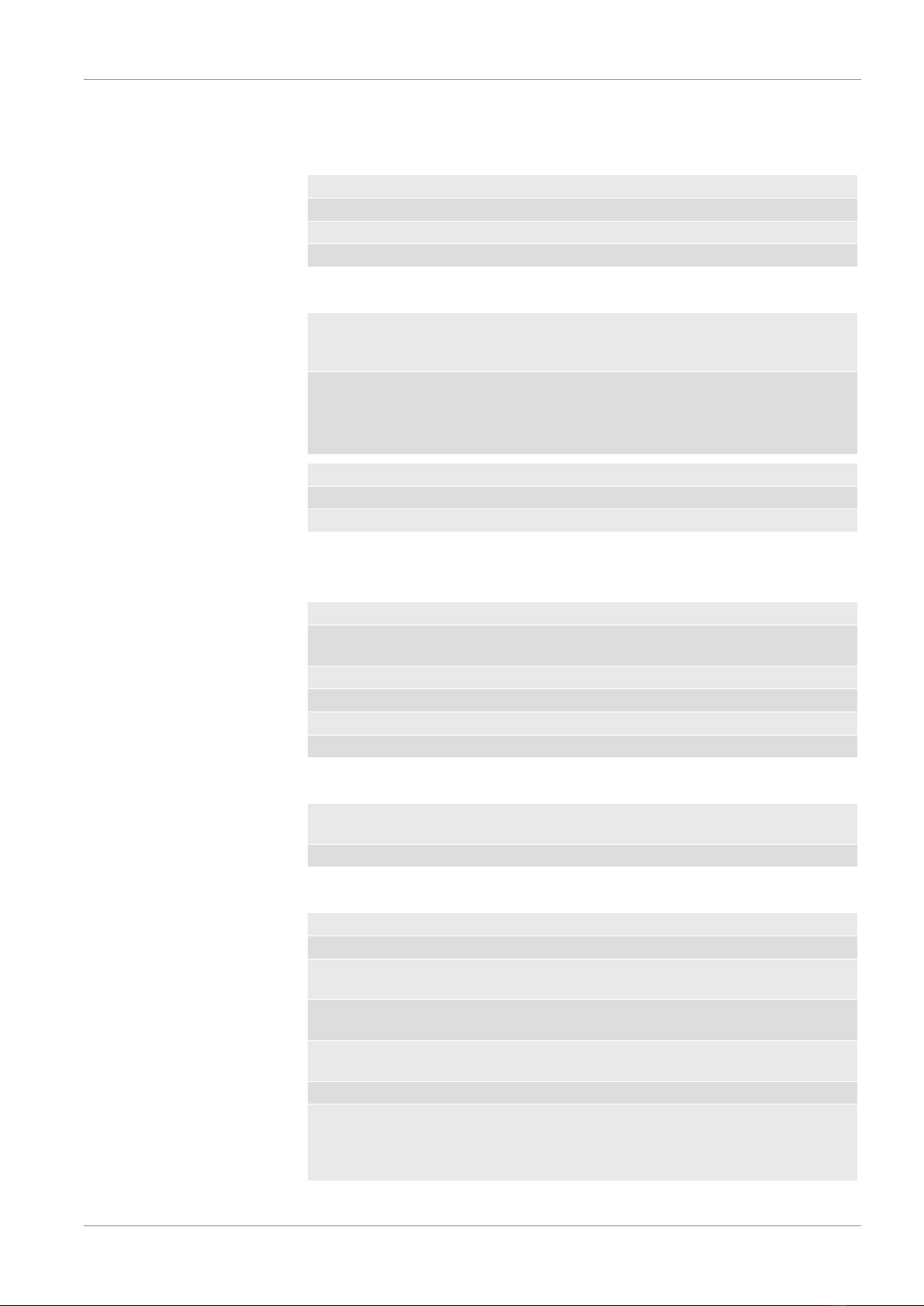

Fig.7: CE_DE_ER76

FISCHER Mess- und Regeltechnik GmbH Attachment | 8

BA_EN_ER76 17/20

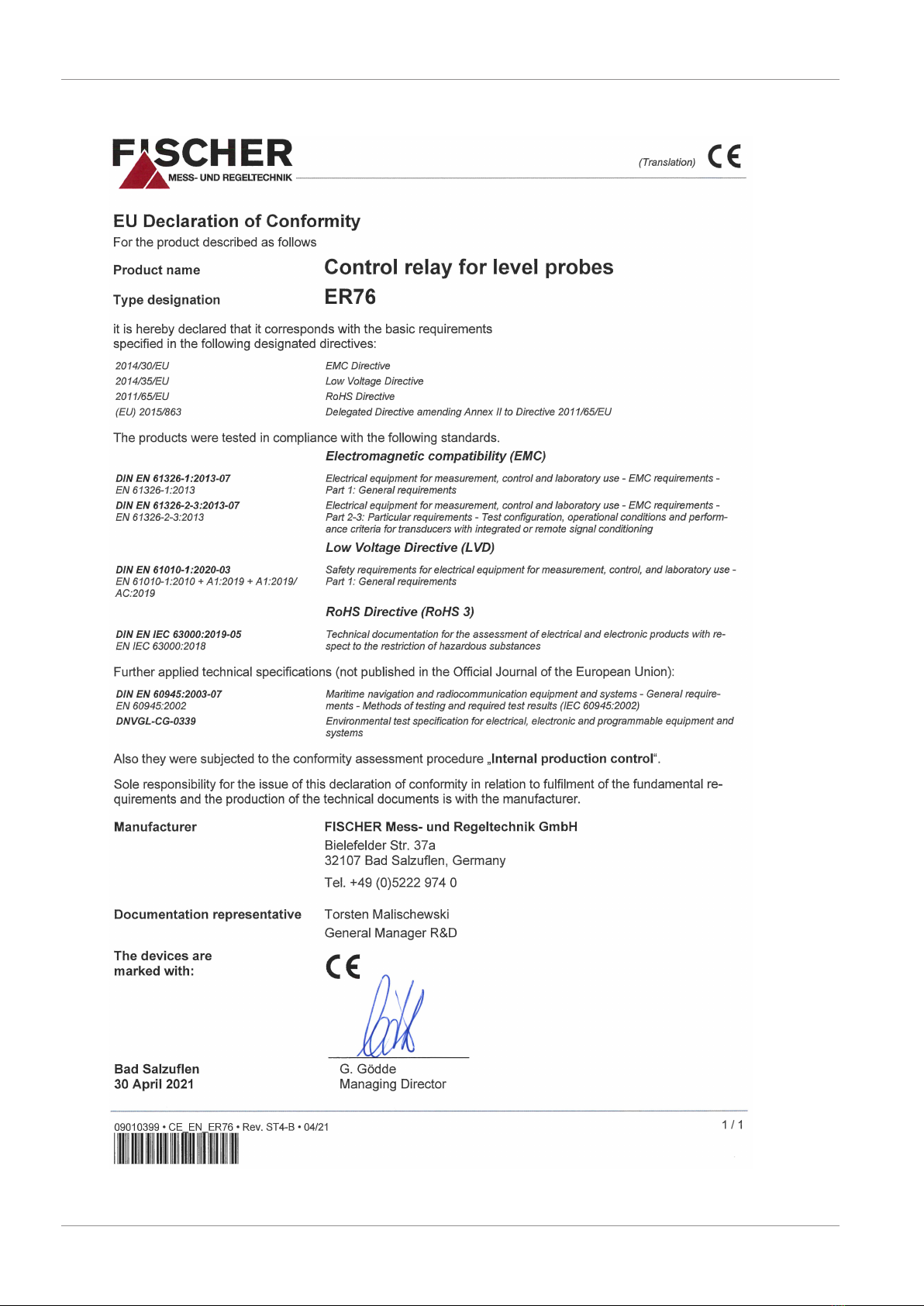

Fig.8: TAA00001ZU-page_1

8 | Attachment FISCHER Mess- und Regeltechnik GmbH

18/20 BA_EN_ER76

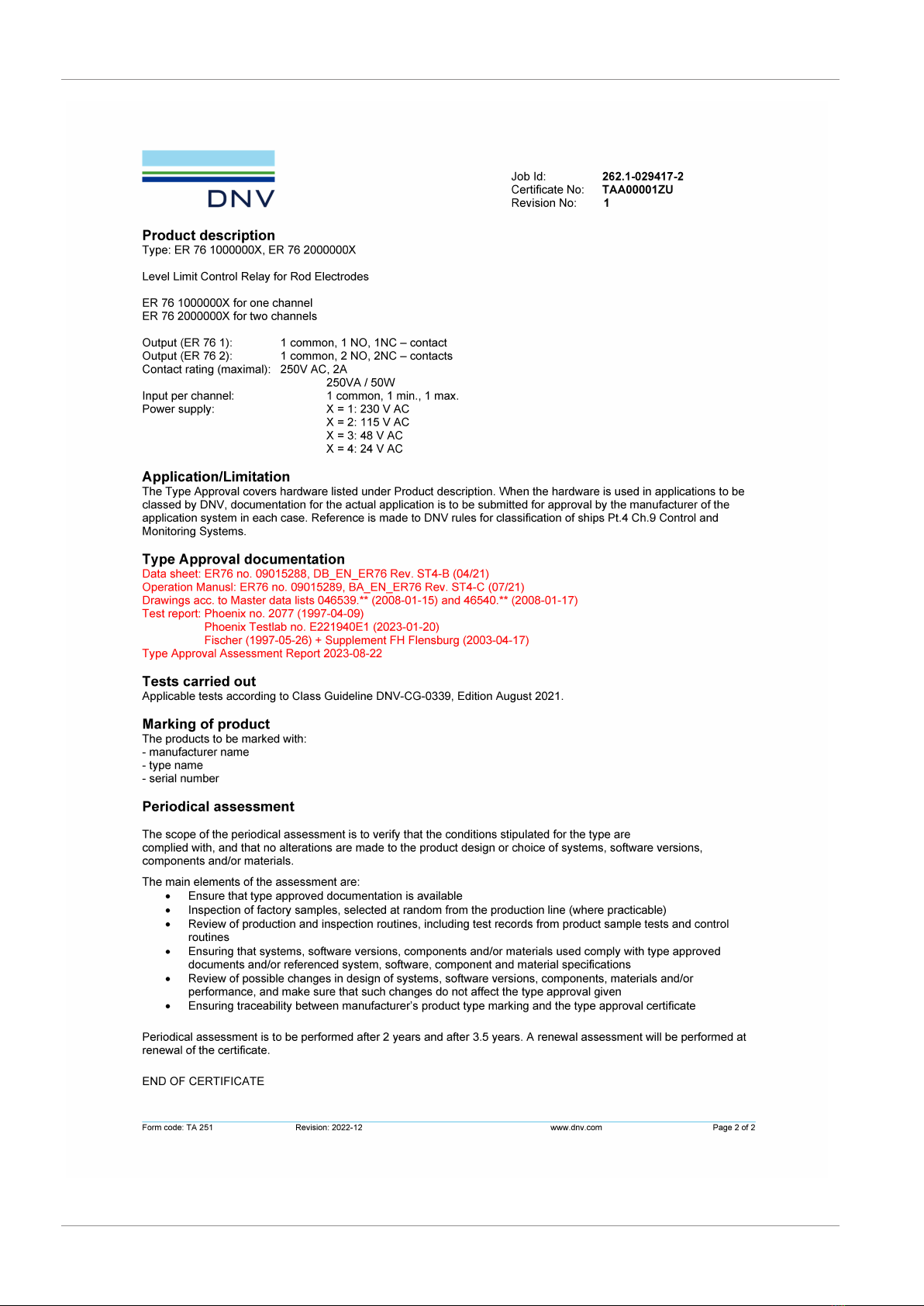

Fig.9: TAA00001ZU-page_2

FISCHER Mess- und Regeltechnik GmbH

BA_EN_ER76 19/20

Notes

Mess- und Regeltechnik GmbH

Bielefelder Str. 37a

D-32107 Bad Salzuflen

Tel. +49 5222 974-0

Fax +49 5222 7170

www.fischermesstechnik.de

Technische Änderungen vorbehalten. Subject to technical changes. Sous réserve de modifications techniques.

Table of contents