41-101.3A Type CKO Overcurrent Relay

2

switch, which allows the operation indicator target to

drop.

The front spring, in addition to holding the target, pro-

vides restraint for the armature and thus controls the

pickup value of the switch.

2.3 Instantaneous Overcurrent Unit

2.3.1 Construction

The instantaneous overcurrent unit consists of an in-

duction cylinder unit, capacitor, varistor, and a trans-

former. The components are connected such that a

contact closing torque is produced when the current

exceeds a specified value.

2.3.2 Induction Cylinder Unit

Mechanically, the cylinder unit is composed of four

basic components: a diecast aluminum frame, an

electromagnet, a moving element assembly, and a

molded bridge.

The frame serves as the mounting structure for the

magnetic core. The magnetic core which houses the

lower pin bearing is secured to the frame by a locking

nut. The bearing can be replaced, if necessary, with-

out having to remove the magnetic core from the

frame.

The electromagnet has two pairs of coils. The coils

of each pair are mounted diametrically opposite one

another, and a capacitor is connected in series with

one pair of coils. In addition, there are two locating

pins. The locating pins are used to accurately posi-

tion the lower pin bearing, which is threaded into the

bridge. The electromagnet is secured to the frame by

four mounting screws.

The moving element assembly consists of a spiral

spring, contact carrying member, and an aluminum

cylinder assembled to a molded hub which holds the

shaft. The shaft has removable top and bottom jewel

bearings. The shaft rides between the bottom pin

bearing and the upper pin bearing with the cylinder

rotating in an air gap formed by the electromagnet

and the magnetic core.

The bridge is secured to the electromagnet and

frame by two mounting screws. In addition to holding

the upper pin bearings, the bridge is used for mount-

ing the adjustable stationary contact housing. The

stationary contact housing is held in position by a

spring type clamp. The spring adjuster is located on

the underside of the bridge and is attached to the

moving contact arm by a spiral spring. The spring ad-

juster is also held in place by a spring type clamp.

With the contact closed, the electrical connection is

made through the stationary contact housing clamp,

to the moving contact, through the spiral spring out

to the spring adjuster clamp.

2.3.3 Saturating Transformer

The transformer is a saturating type consisting of a

tapped primary winding and a secondary winding. A

varistor is connected across the secondary winding

to reduce the voltage peaks applied to the induc-

tion cylinder unit and phase shifting capacitor.

2.4 Operation

Operation of the instantaneous overcurrent unit oc-

curs when the primary current of the transformer ex-

ceeds a value as marked on the tap plate. Upon ap-

plication of current to the transformer, a voltage is

induced in the secondary winding. This voltage is im-

pressed upon the parallel connected pairs of cylinder

unit coils. The capacitor connected in series with one

pair of coils shifts the current flowing in these coils in

reference to the current flowing in the other pair of

coils. As a result, the air gap fluxes of the cylinder

unit are out of phase and a contact closing torque is

produced.

The primary of the transformer is tapped and brought

out to a tap connector block for ease in changing the

pickup current of the relay. The use of a tapped

transformer provides approximately the same ener-

gy level at a given multiple of pickup current for any

tap setting, resulting in one time curve throughout

the range of the relay.

Two terminals, 6 and 7, across one pair of pole wind-

up are brought out so that operating current can be

short circuited around the pole windings preventing

the unit from developing torque.

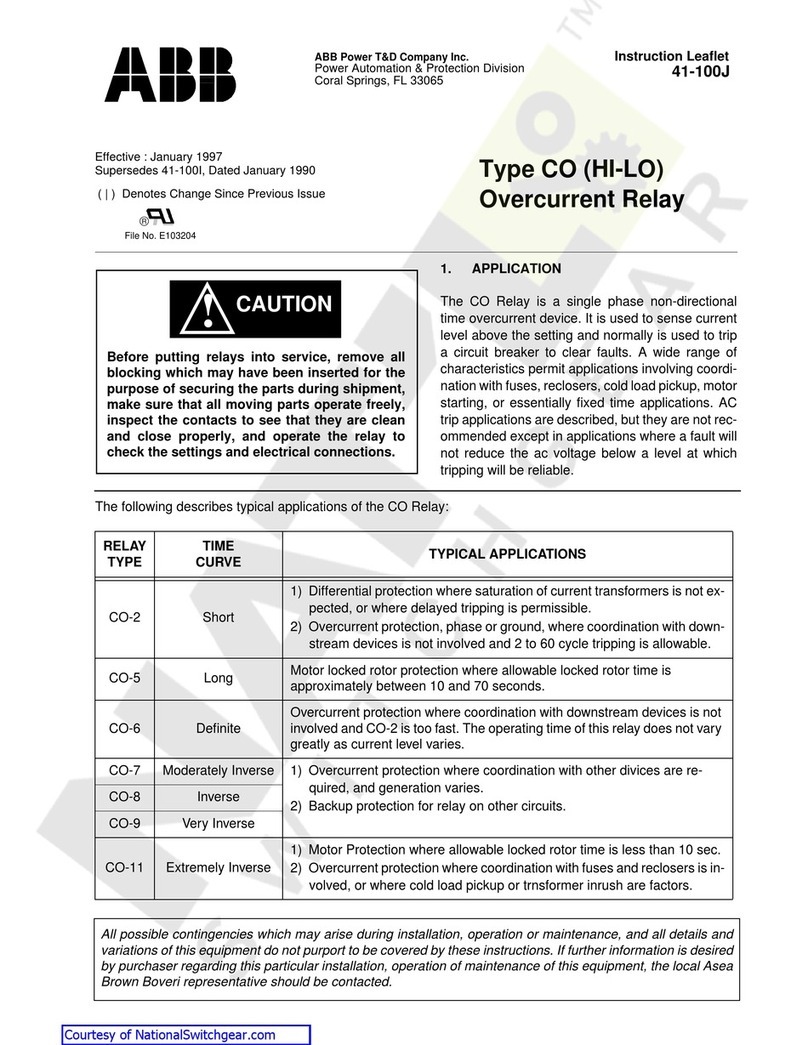

3.0 CHARACTERISTICS

The time characteristics of the overcurrent relays are

designated by specific numbers as indicated below

(e.g., CKO-8).