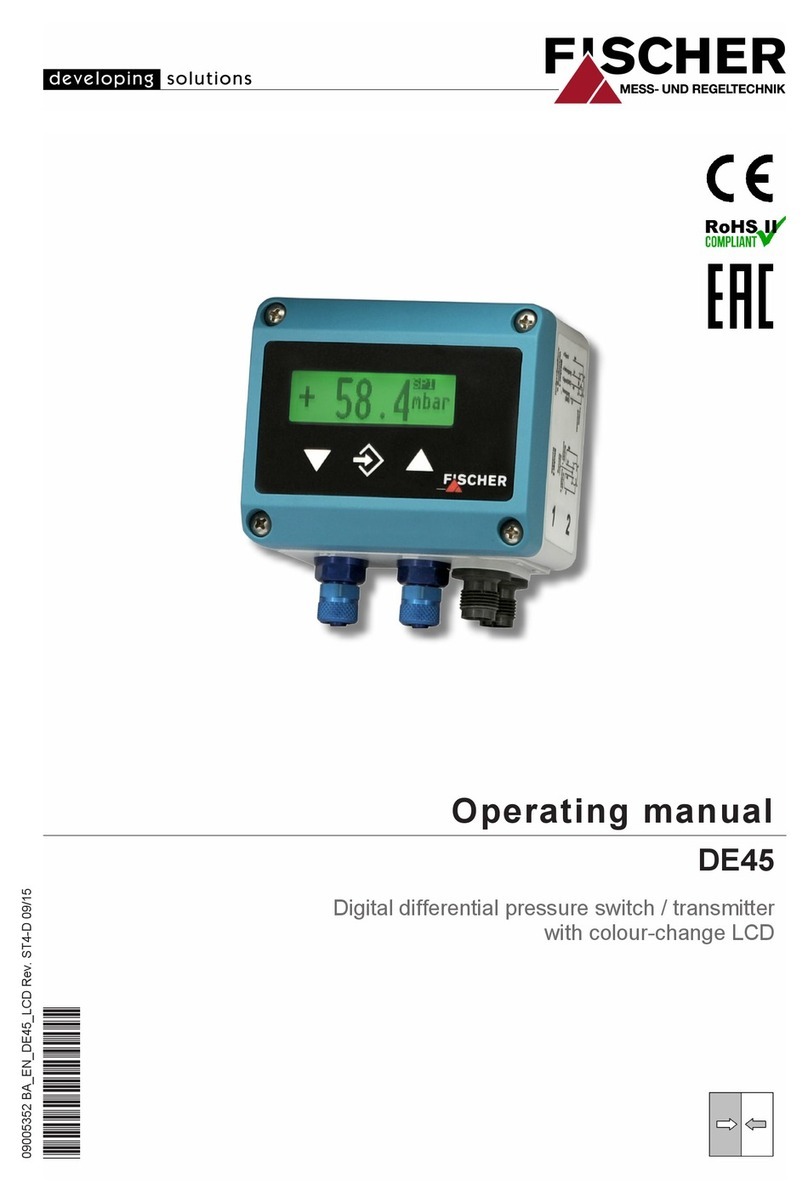

FISCHER DS 11 User manual

d e v e l o p i n g s o l u t i o n s

*09005104* BA_EN_DS11 Rev.E 11/19

*09005104*

Contents

1Safety guidelines

2Application purpose

3Product and functional description

4Installation and assembly

5Commissioning

6Maintenance and Repeat Tests

7Transport

8Service

9Accessories

10 Waste Disposal

11 Technical data

12 Dimensional drawings

13 Order Codes

14 Manufacturer's Declarations and Certificates

1 Safety guidelines

1.1 General

This operating manual contains instruc-

tions fundamental to the installation,

operation and maintenance of the de-

vice that must be observed uncondi-

tionally. It must be read by the fitter, the operator

and the responsible technical personnel before in-

stallation and commissioning of the device.

This operating manual is an integral part of the

product and therefore needs to be kept close to the

instrument in a place that is accessible at all times

to the responsible personnel.

The following sections, in particular instructions

about the assembly, commissioning and mainte-

nance, contain important information, non-

observance of which could pose a threat to hu-

mans, animals, the environment and property.

1.2 Personnel Qualification

The device may only be installed and commis-

sioned by specialized personnel familiar with the in-

stallation, commissioning and operation of this

product.

Specialized personnel are persons who can assess

the work they have been assigned and recognize

potential dangers by virtue of their specialized train-

ing, their skills and experience and their knowledge

of the pertinent standards.

1.3 Risks due to Non-Observance of Safe-

ty Instructions

Non-observance of these safety instructions, the in-

tended use of the device or the limit values given in

the technical specifications can be hazardous or

cause harm to persons, the environment or the

plant itself.

The supplier of the equipment will not be liable for

damage claims if this should happen.

1.4 Safety Instructions for the Operating

Company and the Operator

The safety instructions governing correct operation

of the instrument must be observed. The operating

company must make them available to the installa-

tion, maintenance, inspection and operating per-

sonnel.

Dangers arising from electrical components, energy

discharged by the medium, escaping medium and

incorrect installation of the device must be eliminat-

ed. See the information in the applicable national

and international regulations.

1.5 Unauthorized Modification

Modifications of or other technical alterations to the

instrument by the customer are not permitted. This

also applies to replacement parts. Only

the manufacturer is authorized to make

any modifications or changes.

User Manual

DS11

Differential pressure switch

2 | 16 Page

1.6 Inadmissible Modes of Operation

The operational safety of this instrument can only

be guaranteed if it is used as intended. The instru-

ment model must be suitable for the medium used

in the system. The limit values given in the technical

data may not be exceeded.

1.7 Safe working practices for mainte-

nance and installation work

The safety instructions given in this operating man-

ual, any nationally applicable regulations on acci-

dent prevention and any of the operating company's

internal work, operating and safety guidelines must

be observed.

The operating company is responsible for ensuring

that all required maintenance, inspection and instal-

lation work is carried out by qualified specialized

personnel.

1.8 Pictogram explanation

WARNING!

… indicates a potentially dangerous

situation, non-observance of which

could endanger persons, animals, the

environment or objects.

INFORMATION!

… highlights important information ef-

ficient and smooth operation.

TIP!

… indicates recommendations that are

not specifically necessary in certain

situations but which could be useful.

2 Application purpose

The DS 11 is a combined display and switching de-

vice for differential pressure, over-pressure and un-

der-pressure. This series is ideally suited for vari-

ous measuring tasks in industrial applications or the

sanitary field.

Typical applications are measuring differential pres-

sure between the supply and return in heating sys-

tems and monitoring filters and pumps. Pressure

chamber and measuring diaphragms are available

in various materials. This allows the devices to be

adapted to the various requirements.

3 Product and functional description

3.1 Function diagram

Item

Description

1

Pressure chamber

2

Motion train

3

Tappet

4

Micro-switch

5

Switch point setting

6

Measuring diaphragm

7

Measuring springs

3.2 Design and mode of operation

A robust and durable membrane measuring instru-

ment is used as a measuring system, which is suit-

able for overpressure and underpressure meas-

urements. The units use the same measuring prin-

ciple for all three measuring applications.

In the rest position, the spring forces on both sides

of the membrane are balanced out. Due to the

pressure or underpressure to be measured, a sin-

gle-sided force is created on the membrane which

shifts the membrane system against the measure-

ment range springs up to equalization of the spring

forces. In case of overload, the membrane supports

against the metallic support surfaces.

A centrally positioned tappet transfers the move-

ment of the membrane system on the motion train

and operating elements of the micro-switches.

4 Installation and assembly

The standard device is designed for wall mounting.

The device can be mounted to even walls using the

assembly foot that is cast to the middle of the de-

vice. It is also possible to fit the device in switch

cabinets using the switch panel installation kit

DZ11.

It is calibrated ex-works for vertical installation; this

is the only allowed installation position.

To ensure safety during installation and mainte-

nance, we recommend installing a suitable shut-off

3 | 16 Page

valve on the system (see accessories section). This

means that

the device can be depressurized or taken out of

operation

the device can be disconnected from the power

supply within the applicable system for repairs

or inspections.

•a function test of the device can be performed

on-site.

4.1 Process connection

•By authorized and qualified specialized person-

nel only.

•Only for the designated mechanical process

connection (for the model, see the order code

on the device type plate)

•The pipes need to be depressurized when the

device is being connected.

•Appropriate steps must be taken to protect the

device from pressure surges.

•Check the suitability of the device for the media

to be measured.

•Maximum pressures must be observed.

•Check that the pressure connections do not

leak before commissioning.

4.1.1 Pressure sensing lines

Remark

Commissioning and repeat tests can be

carried out more efficiently by using a

suitable shut-off device.

The pressure connections are marked with (+) and

(-) symbols on the device. For differential pressure

measurements, the higher pressure is connected to

the (+) side and the lower pressure to the (-) side of

the device. When measuring the pressure, only the

(+) connection is used; the (-) connection is used to

measure under-pressure.

The pressure sensing lines need to be kept as short

as possible and installed without sharp bends to

avoid interfering delay times.

The pressure sensing lines must be installed on a

gradient so that no air pockets e.g. for liquid meas-

urements or water pockets e.g. for gas measure-

ments can be created. If the required inclination is

not reached, water or air filters must be installed at

suitable places.

If liquid measuring media are used the pressure

connection lines must be deaerated, as liquid col-

umns of different heights in the pipes can cause

measuring errors. The instrument must be protect-

ed against frost if water is used as a medium.

4.1.2 Pressure surge absorption

Pulsating pressure on the system side can lead to

wear and functional problems. To safeguard this,

we recommend installing absorption elements in the

pressure pipe line.

Fluid media

In the operational status, the reactor pins need to

be set so that the measurement display follows the

pressure changes with a delay.

Gaseous media

4.2 Electrical connections

•By authorized and qualified specialized person-

nel only.

Settable reactor pins below the clos-

ing cap

G¼

Capillary throttle coil MZ 401

4 | 16 Page

•The electrical connection of the device shall be

performed according to relevant VDE and local

electricity board regulations.

•Disconnect the system from the mains before

connecting the device.

•Add a fuse adapted to the energy requirements.

4.2.1 Cable socket and plug connection

Cable socket

Plug connection

4.2.2 Numbered cables

For models with numbered cables, the cable num-

bers correspond with the presented terminal num-

bers.

5 Commissioning

All electrical supply, operating and measuring lines,

and the pressure connections must have been cor-

rectly installed before commissioning. All supply

lines are arranged so that there are no mechanical

forces acting on the device.

Check that the pressure connections do not leak

before commissioning.

5.1 Control Elements

5.2 Zero point correction

Depressurize the measuring chamber.

Remove the hood

Set the measurement value pointer to the zero-

point scale using the zero point correction

screw.

Re-mount the hood.

5.3 Switch point setting

Remove the plug in the hood.

The required switch points can be set guide

value scales according to the markings by us-

ing a screwdriver. The achievable setting accu-

racy is ± 5 %.

1

Replace the plug after completing the settings.

5.4 Function test

Remove both plugs in the hood for testing.

If the unit has two micro-switches, the stated test

steps must be carried out for both switches.

After the test, the switch points need to be reset

acc. to 5.3.

5.4.1 Checking the switch points when the

system is depressurized.

No measurement is shown and the measurement

display points to zero.

Turn the switch point setting button toward the zero-

point until the micro-switch is activated.

1

More accurate settings can be made either in the factory or on

site using suitable aids (test manometer, ohm meter etc.)

Ground connection

Zero-point correction screw

Switch point setting

switch 1

Switch point setting

switch 2

Switch 1

Switch 2

5 | 16 Page

5.4.2 Testing when the system is operational

A measurement is shown. If despite operational

pressure, no measurement is shown, you can gen-

erate a differential pressure by blocking the differ-

ential pressure lines on one side.

Turn the switch point setting button toward the

measurement until the micro-switch is activated.

6 Maintenance and Repeat Tests

The instrument is maintenance-free.

To ensure reliable operation and a long service life,

we recommend carrying out an annual test. The

purpose of this test is to ensure that it functions cor-

rectly. There are instructions on how to carry out a

function test in the commissioning section.

7 Transport

The measuring device must be protected against

impacts. It should be transported in the original

packaging or a suitable transport container.

8 Service

All defective or faulty devices should be sent direct-

ly to our repair department. Please coordinate all

shipments with our sales department.

Warning

Process media residues in and

on dismantled devices can be a hazard

to people, animals and the environment.

Take adequate preventive measures. If

required, the devices must be cleaned thoroughly.

Return the device in the original packaging or a

suitable transport container.

9 Accessories

•DZ11 Switch panel installation kit Ø 132

•DZ13/14 Blocking and equalization valve

10 Waste Disposal

Incorrect disposal may pose a risk to the environ-

ment.

Please help to protect the environ-

ment by always disposing of the work

pieces and packaging materials in

compliance with the valid national

waste and recycling guidelines or re-

use them.

6 | 16 Page

11 Technical data

General points

Admissible ambient temperature

-10 … +70 °C

Admissible media temperature

-10 … +70 °C

Admissible storage temperature

-15 … +75 °C

Enclosure protection class

IP55 acc. to DIN EN 60529

Weight

1.2 kg (Pressure chamber in aluminium)

3.5 kg (Pressure chamber in stainless steel 1.4305)

Measuring system

Measuring range ≤ 16 bar

Pressure spring measuring diaphragm system made of fabric-reinforced elastomers

Measuring range 0 … 25 bar

Plate spring measuring system, plate spring made of DURATHERM©

Measuring range

0 … 400 mbar to 0 … 25 bar (see order code)

Rated pressure of the

measuring system

25 bar

Max. static operating pressure

depending on measuring range (see order code)

Max. pressure load

on-sided over-pressure-proof up to the rated pressure of the measuring system

resistance to under-pressure on the (+) and (-) side

Measurement accuracy

± 2.5% of the upper range value

Zero-point adjustment

Arranged in the front panel of the scale

Switch contacts

Contact output

1 or 2 micro-switches with 1-pin changeover contact.

Switch point setting

can be set to reference scales from outside

Smallest settable value approx. 5% of the end value of the measuring range.

Switch hysteresis

approx. 2.5% of the upper range value

Load data/contact

AC

DC

Umax

250V

30V

Imax

5A

0.4A

Pmax

250 VA

10 W

Ports

Process connection

Inner thread G 1/4

Connecting shank G¼ DIN EN 837

Cutting ring connections for 6, 8, 10 mm (brass, steel galvanized or stainless steel)

electr. connection

Fixed wire numbered cables

Cable connection socket

7-pole plug connection

Materials

Pressure chamber

Aluminium GkAlSi10(Mg), painted black

Aluminium GkAlSi10(Mg) with HART-COAT©-surface protection

Chromium nickel steel 1.4305

Measuring diaphragm

Measuring diaphragm and sealsmade of NBR or Viton©

Plate spring made of DURATHERM© NiCrCo alloy

Inner parts in contact with

mediums

Stainless steel 1.4310, 1.4305

Hood

Makrolon

Mounting

Installation position

vertical

Wall mounting - three mounting feet

Control panel assembly - control panel installation set DZ11 Ø132mm

Pipe connection, pressure connections acc. to attached symbols

- via screwed-in cutting or clamp screw connections

- via screwed-in connection shanks acc. to DIN EN 837

for nipple connections acc. to DIN 16284

Approvals

type testing according to the regulations of Det Norske Veritas and the Germanischen Lloyd,

test symbol DNV-GL

EAC Declaration of conformity

EN 61508 2001 Functional safety of safety-related electrical/electronic/

programmable electronic systems requirements for SIL2

7 | 16 Page

12 Dimensional drawings

Cutting ring screw connection

DS11 Wall mounting (Standard model)

(all dimensions in mm unless otherwise specified)

M16x1.5

plastic

screw connection

Bolt circle (LK)

EL-connection variants

Process connection variants

M20x1.5 Cable screw connection

Cable connection socket or

7-pin plug connection

SW19

Connection

G¼ inner thread

Connection spigot

G¼ according to DIN EN 837

DZ 13/14 Four spindle equalization and shut-off valve

Mounting the control panel

opened

opened

Measuring

device

Venting

Function diagram

DZ 13/14

Venting (n/a for DZ13)

Cutting ring screw connection

Control panel cut-out

Bolt circle (LK)

8 | 16 Page

13 Order Codes

Differential pressure measuring and switching device

Type DS11

0

0

Measuring range

Max. stat. operating

pressure

0 …400..mbar.....................................................

.. 6 bar..........................>

8

3

0 …0.6..bar........................................................

10 bar..........................>

0

1

0 …1..bar........................................................

16 bar..........................>

0

2

0 …1.6..bar........................................................

25 bar..........................>

0

3

0 …2.5..bar........................................................

25 bar..........................>

0

4

0 …4..bar........................................................

25 bar..........................>

0

5

0 …6..bar........................................................

25 bar..........................>

0

6

0 …10..bar........................................................

25 bar..........................>

0

7

0 …16..bar........................................................

25 bar..........................>

0

8

0 …25..bar........................................................

25 bar..........................>

0

9

- 0.6 …0..bar........................................................

10 bar..........................>

3

0

- 1 …0..bar........................................................

16 bar..........................>

3

1

- 1 …+0.6.bar........................................................

25 bar..........................>

3

2

- 1 …+1.5.bar........................................................

25 bar..........................>

3

3

- 1 …+3..bar........................................................

25 bar..........................>

3

4

- 1 …+5..bar........................................................

25 bar..........................>

3

5

0 …30..psi.........................................................

25 bar..........................>

H

5

Measuring membrane / Seal

NBR NBR.................................................>

N

Viton®Viton®..............................................>

V

DURATHERM®NBR (Mb 0-25 bar)..........................>

D

DURATHERM®Viton®(Mb 0-25 bar)........................>

E

Pressure chamber

Aluminium ...........................................................................................>

A

Aluminium HART COAT®...................................................................>

D

Chromium nickel steel 1.4305..............................................................>

W

Discharge port

Inner thread G 1/4 .......................................................................................>

0

1

Inner thread 1/4 - 18 NPT............................................................................>

0

4

Connection shanks with external thread G 1/4 B, brass...............................>

0

6

Connection shanks with external thread G 1/4 B, Chrome-Nickel-Steel.......>

1

1

Connection shanks with external thread 1/4 - 18 NPT EXT Chrome-Nickel-

Steel............................................................................................................>

1

4

Cutting ring screw connection made of steel for 6 mm pipe .........................>

2

0

Cutting ring screw connection made of steel for 8 mm pipe .........................>

2

1

Cutting ring screw connection made of steel for 10 mm pipe .......................>

2

2

Cutting ring screw connection made of 1.4571 for 6 mm pipe......................>

2

4

Cutting ring screw connection made of 1.4571 for 8 mm pipe......................>

2

5

Cutting ring screw connection made of 1.4571 for 10 mm pipe....................>

2

6

Cutting ring screw connection in brass for 6 mm pipe..................................>

2

8

Cutting ring screw connection in brass for 8 mm pipe..................................>

2

9

Cutting ring screw connection in brass for 10 mm pipe................................>

3

0

Switching Elements

1 adjustable micro-switch ............................................................................................>

A

2 adjustable micro-switches.........................................................................................>

B

Electrical connection

1 metre numbered cable, permanently wired.......................................................................>

1

2.5 metre numbered cable, permanently wired ....................................................................>

2

5 metre numbered cable, permanently wired.......................................................................>

5

Cable connection socket......................................................................................................>

K

Plug connection (7-pin)........................................................................................................>

W

DNV-GL-approved version with 3 m connection cable ........................................................>

Z

SEV-approved version, 2 m connection cable VDE NYSLYO ...........................................>...

U

Casing protection class

IP55.............................................................................................................................................>

0

IP65 (only with cable socket).......................................................................................................>

P

Assembly options

Panel mounting set..............................................................................................................................>

T

Wall mounting......................................................................................................................................>

W

9 | 16 Page

13.1 Accessories

DZ11

Control panel installation set Ø 132, comprising a front ring, distance columns and at-

tachment screws.

DZ13/14

The shutoff and equalization valves DZ13/14 in three and four spindle versions are highly

suitable when mounting differential pressure devices. The following can be used for ex-

ample:

•is a system is to be depressurized or taken out of operation

•for repairs or tests to disconnect differential pressure devices within the affected

systems from the mains supply

The shutoff devices can therefore also be used for function tests on site. In contrast to

DZ13, the DZ14 also has a venting valve to vent the conected pipe system. The shutoff

and venting valves are designed for the rated pressure level PN40. The housing can be

selected in aluminium, brass or chrome-nickel-steel 1.4301. There are various pressure

connections (see order code) available for process-side screw connections.

10 | 16 Page

14 Manufacturer's Declarations and Certificates

14.1 EC Declaration of conformity

11 | 16 Page

14.2 Certificate functional security SIL2

12 | 16 Page

13 | 16 Page

14.3 GL approval

14 | 16 Page

15 | 16 Page

Technische Änderungen vorbehalten • Subject to change without notice • Changements techniques sous réserve

Fischer Mess- und Regeltechnik GmbH • Bielefelder Str. 37a • D-32107 Bad Salzuflen • Tel. +49 5222 9740 • Fax +49 5222 7170

eMail: [email protected] • www.fischermesstechnik.de

14.4 EAC Declaration of conformity

Other manuals for DS 11

2

Table of contents

Other FISCHER Switch manuals

FISCHER

FISCHER DS 11 User manual

FISCHER

FISCHER DE45 series User manual

FISCHER

FISCHER DS31 User manual

FISCHER

FISCHER DE45 series Instruction Manual

FISCHER

FISCHER DS 11 User manual

FISCHER

FISCHER DS13 User manual

FISCHER

FISCHER ME50 R Series User manual

FISCHER

FISCHER DS31 User manual

FISCHER

FISCHER DS34 User manual

Popular Switch manuals by other brands

HP

HP A5500 HI Series installation guide

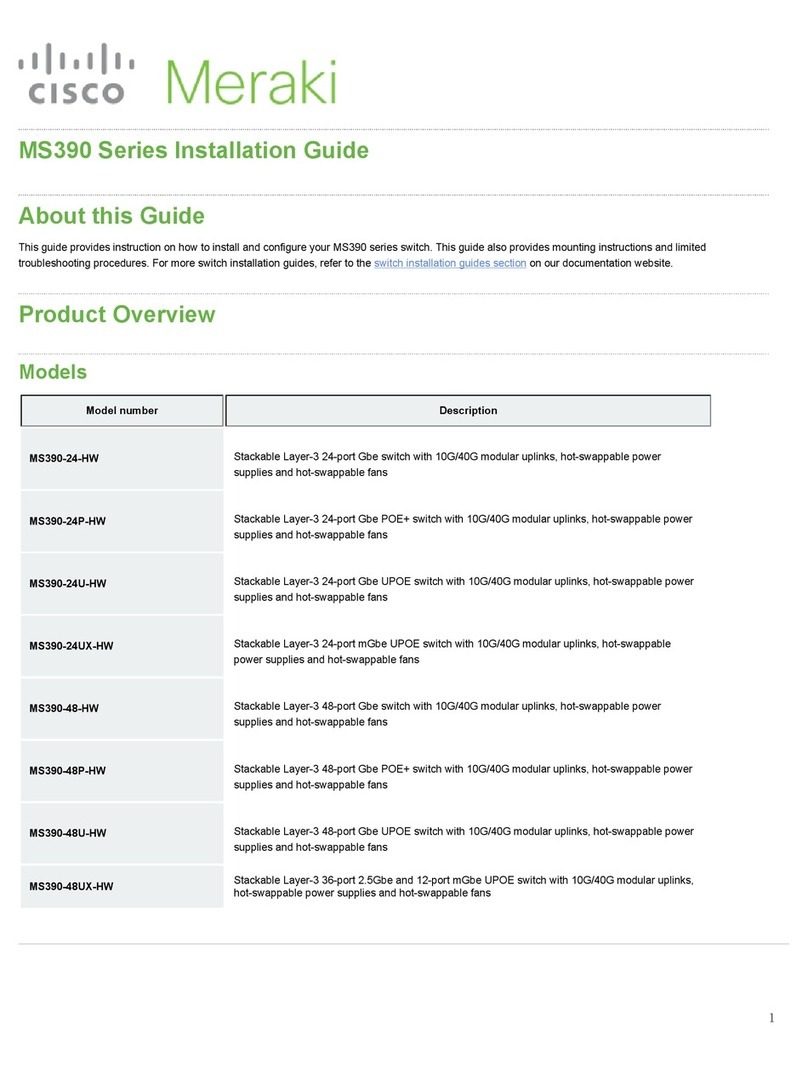

Cisco MERAKI

Cisco MERAKI MS390-24-HW installation guide

ZyXEL Communications

ZyXEL Communications ES-315 quick start guide

Moxa Technologies

Moxa Technologies EtherDevice EDS-G205A-4PoE Quick installation guide

Cypress

Cypress CLUX-41AT Operation manual

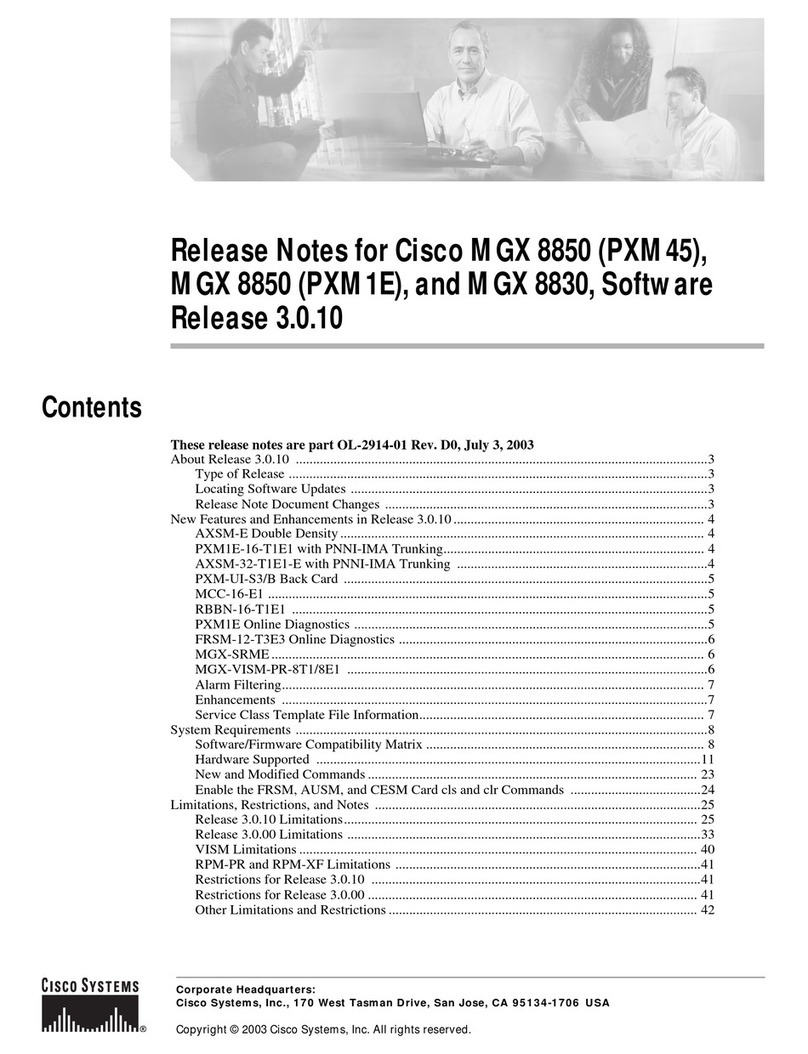

Cisco

Cisco MGX 8850 PXM45 Release notes