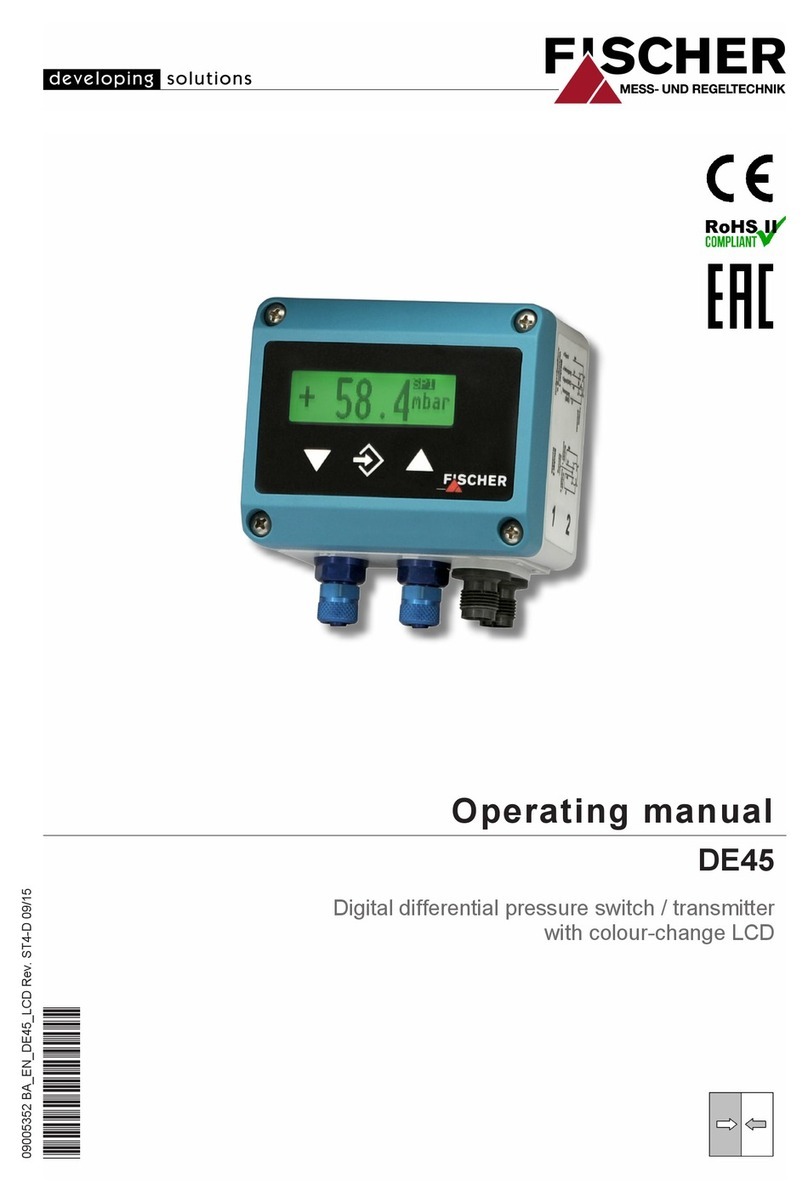

FISCHER DS34 User manual

Operation manual

DS34

Differential pressure switch

09005751 • BA_EN_DS34 • Rev. ST4-E • 08/22

*09005751*

| Masthead FISCHER Mess- und Regeltechnik GmbH

2/16 BA_EN_DS34

Masthead

Manufacturer: FISCHER Mess- und Regeltechnik GmbH

Bielefelderstr. 37a

D-32107 Bad Salzuflen

Telephone: +49 5222 974 0

Telefax: +49 5222 7170

eMail: [email protected]

web: www.fischermesstechnik.de

Technical editorial team: Documentation representative: T. Malischewski

Technical editor: R. Kleemann

All rights, also those to the translation, reserved. No part of this document may

be reproduced or processed, duplicated or distributed using electronic systems

or any other form (print, photocopy, microfilm or another process) without the

written consent of the company FISCHER Mess- und Regeltechnik GmbH, Bad

Salzuflen.

Reproduction for internal use is expressly allowed.

Brand names and procedures are used for information purposes only and do

not take the respective patent situation into account. Great care was taken

when compiling the texts and illustrations; Nevertheless, errors cannot be ruled

out. The company FISCHER Mess- und Regeltechnik GmbH will not accept any

legal responsibility or liability for this.

Subject to technical amendments.

© FISCHER Mess- und Regeltechnik 2015

Version history

Rev. ST4-A 12/15 Version 1 (first edition)

Rev. ST4-B 08/20 Version 2 (corrections)

Rev. ST4-C 07/21 Version 3 (Technical data connection cable)

Rev. ST4-D 03/22 Version 4 (UKCA conformity)

Rev. ST4-E 08/22 Version 5 (micro switch (Z) added)

FISCHER Mess- und Regeltechnik GmbH Table of contents

BA_EN_DS34 3/16

Table of contents

1 Product and functional description............................................................................... 4

1.1 Delivery scope........................................................................................................................ 4

1.2 Product summary ................................................................................................................... 4

1.3 Intended use........................................................................................................................... 5

1.4 Function diagram.................................................................................................................... 5

1.5 Design and mode of operation ............................................................................................... 5

2 Assembly and Starting Operation ................................................................................. 6

2.1 General................................................................................................................................... 6

2.2 Process connection ................................................................................................................ 6

2.3 Electrical connections............................................................................................................. 6

2.4 Start-up................................................................................................................................... 7

3 Servicing .......................................................................................................................... 8

3.1 Maintenance........................................................................................................................... 8

3.2 Transport ................................................................................................................................ 8

3.3 Service ................................................................................................................................... 8

3.4 Disposal.................................................................................................................................. 8

4 Technical data ................................................................................................................. 9

4.1 General................................................................................................................................... 9

4.2 Input variables ........................................................................................................................ 9

4.3 Output parameters ................................................................................................................. 9

4.4 Measuring accuracy ............................................................................................................... 9

4.5 Electrical connection .............................................................................................................. 9

4.6 Operating conditions .............................................................................................................. 10

4.7 Construction design................................................................................................................ 10

5 Order codes ..................................................................................................................... 12

5.1 Accessories ............................................................................................................................ 12

6 Attachment ...................................................................................................................... 13

1 | Product and functional description FISCHER Mess- und Regeltechnik GmbH

4/16 BA_EN_DS34

1 Product and functional description

1.1 Delivery scope

• DS34 Differential pressure switch

• Operating Manual

1.2 Product summary

12

3

4

5

6

7

8

9

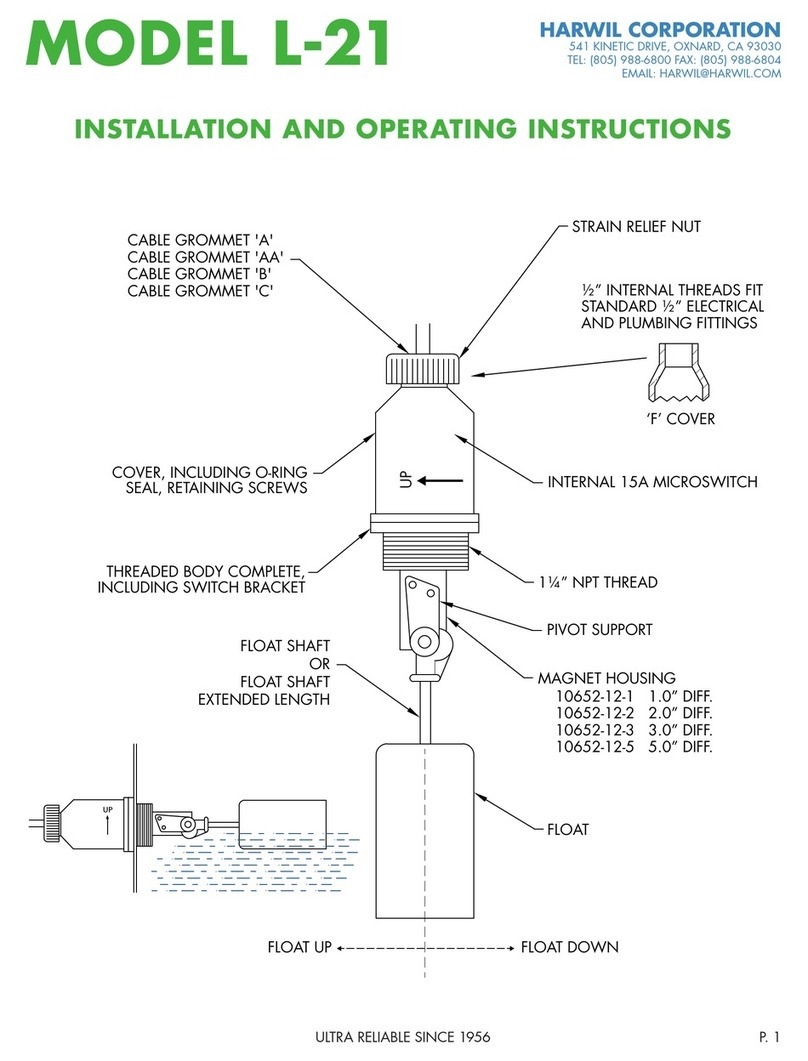

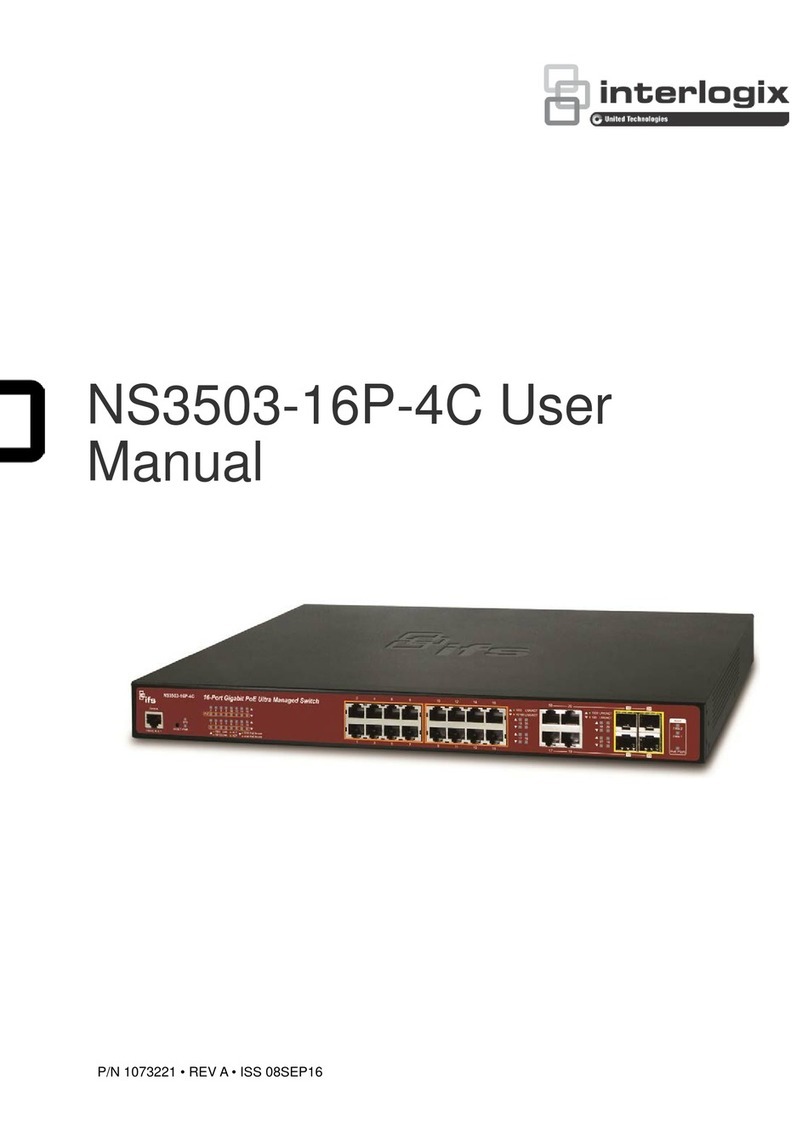

Fig.1: Product summary

1 Connection cable 2 Housing

3 Mounting foot 4 Setting mark

5 Adjustment spindle 6 Scale plate

7 Pneumatic plug-in connection 8 Type plate

9 Cable screw connection

1.2.1 Process connection

The device has a process connection G⅛ inch internal thread as standard. The

device can also be supplied with pneumatic plug connections for 6 or 8 mm

hose.

CAUTION

Maximum tightening torque

The maximum tightening torque for the G⅛ inch internal thread is 5 Nm.

FISCHER Mess- und Regeltechnik GmbH Product and functional description | 1

BA_EN_DS34 5/16

1.2.2 Type plate

Marking

Process connection

Order code

Serial number

Labelling

Article no.

Switching range

Breaking capacity

Pmax

Prod.-no.

DS34ABF043A1

0,1 ... 1 bar

3A/250V~

16 bar

1506640.01.005

Made in Germany

+

1 2 3

D-32107 Bad Salzuflen

Techn. data

Connection

diagram

Fig.2: Type plate

1.3 Intended use

The DS34 is a differential pressure switch for overpressure, underpressure and

differential pressure measurements. The uncomplicated and robust membrane

measuring mechanism is suitable for all neutral media, such as service water,

heating water, neutral gases and oils.

1.4 Function diagram

1234

5

6

Fig.3: Functional Schematic

1 Micro-switch 2 Switch tappet

3 Diaphragm 4 Measuring range spring

5 Adjustment spindle 6 Pressure chamber

1.5 Design and mode of operation

Due to the pressure or differential pressure to be measured, a one-sided force

acts on the membrane. This force moves the membrane system against the

pre-tensioned measuring range spring. A switch tappet mounted on the mem-

brane actuates a micro switch.

The switch point can be set with an adjustment spindle. A scale plate and a set-

ting mark attached to the housing indicate the respective set switch point.

2 | Assembly and Starting Operation FISCHER Mess- und Regeltechnik GmbH

6/16 BA_EN_DS34

2 Assembly and Starting Operation

2.1 General

The device is intended for installation on flat walls and mounting plates. The

device can be equipped with a mounting foot for screwing to the mounting plate.

2.2 Process connection

• By authorized and qualified specialized personnel only.

• The pipes need to be depressurized when the instrument is being connec-

ted.

• Appropriate steps must be taken to protect the device from pressure surges.

• Check that the device is suitable for the medium being measured.

• Maximum pressures must be observed (cf. Tech. data)

The pressure lines must be installed at an inclination so that when fluids are

measured no air pockets are created or when measuring gases, no water pock-

ets are created. If the required inclination is not reached, water or air filters must

be installed at suitable places.

If water is used as a measuring medium, the unit must be protected against

frost.

The pressure lines must be kept as short as possible and installed without any

tight bends to avoid delays.

Pulsating pressure on the system side can lead to wear and functional prob-

lems. To safeguard this, we recommend installing absorption elements in the

pressure line.

The process connections are marked with (+) and (-) symbols on the device.

The pressure lines must be mounted according to these symbols.

1. Differential pressure measurement

Higher pressure

lower pressure

2. Pressure measurement

Pressure

open

2.3 Electrical connections

• By authorized and qualified specialized personnel only.

• When connecting the unit, the national and international electro-technical

regulations must be observed.

• Disconnect the system from the mains, before electrically connecting the

device.

• Install the consumer-adapted fuses.

• A permanently wired number cable is used for the electrical connection.

Fig.4: Electrical connection

FISCHER Mess- und Regeltechnik GmbH Assembly and Starting Operation | 2

BA_EN_DS34 7/16

2.4 Start-up

2.4.1 General

A prerequisite for commissioning is correct installation of all electrical supply

lines and the differential pressure lines. All connections are arranged so that

there are no mechanical forces acting on the device.

CAUTION

Leak test

The differential pressure lines need to be checked for leaks before commission-

ing.

In the case of fluid measuring media, the differential pressure lines must be

vented because different fluid columns in the lines will distort the measure-

ments.

If water is used as a measuring medium, the unit must be protected against

frost.

2.4.2 Switch point setting

The desired switch point is set by turning the scale plate with the adjustment

spindle. The setting mark is then brought into line with the desired value on the

scale.

Scale plate

Setting mark

Adjustment spindle

1 x 5.5 mm

Switch point 035 bar Switch point 0.5 bar

Setting mark

smallest

adjustable value

Fig.5: Switch point setting

3 | Servicing FISCHER Mess- und Regeltechnik GmbH

8/16 BA_EN_DS34

3 Servicing

3.1 Maintenance

The instrument is maintenance-free. We recommend the following regular in-

spection to guarantee reliable operation and a long service life:

• Check the function in combination with downstream components.

• Check the leak-tightness of the pressure connection lines.

• Check the electrical connections.

The exact test cycles need to be adapted to the operating and environmental

conditions. In combination with other devices, the operating instructions for the

other devices also need to be observed.

3.2 Transport

The measuring device must be protected against impacts. It should be transpor-

ted in the original packaging or a suitable transport container.

3.3 Service

All defective or faulty devices should be sent directly to our repair department.

Please coordinate all shipments with our sales department.

WARNING

Process media residues

Process media residues in and ondismantled devices can be a hazard to

people, animals and the environment. Take adequate preventive measures. If

required, the devices must be cleaned thoroughly.

Return the device in the original packaging or a suitable transport container.

3.4 Disposal

Please help to protect the environment by always disposing of the work pieces

and packaging materials in compliance with the valid national waste and recyc-

ling guidelines or reuse them.

FISCHER Mess- und Regeltechnik GmbH Technical data | 4

BA_EN_DS34 9/16

4 Technical data

4.1 General

Reference conditions (acc. to IEC 61298-1)

Temperature +15 to +25 °C

Relative humidity 45 … 75 %

Air pressure 86 to 106 kPa 860 to 1060 mbar

Installation position User-defined

4.2 Input variables

Pressure range Adjustment

range

Nominal

pressure

Bursting

pressure

10 … 100% SI unit

0 to 0.6 bar 0.06 to 0.6 bar 6 to 60 kPa PN16 64 bar

0 to 1 bar 0.10 to 1.0 bar 10 to 100 kPa

0 to 1.6 bar 0.16 to 1.6 bar 16 to 160 kPa

0 to 2.5 bar 0.25 to 2.5 bar 25 to 250 kPa

0 to 4 bar 0.40 to 4.0 bar 40 to 400 kPa

0 to 6 bar 0.60 to 6.0 bar 60 to 600 kPa

4.3 Output parameters

Micro-switch AC DC

Max. switching voltage 250 V 30 V

Max. switching current 3 A 0.4 A

Min. switching current 0.1A 0.1A

Max. switching output 250 VA 10 W

Mech. life span 106 switching cycles

4.4 Measuring accuracy

Switching point Adjustment range 10 ... 100 % of the pressure range

Switching point accuracy 3% of the setting range

Hysteresis Switching element (A) 5% of the setting range

Switching element (Z) 12% of the setting range

4.5 Electrical connection

Hard-wired, silicone and halogen-free number cable

Core number 3

Conductor nominal cross-section 0,5 mm2

AWG 21

Outer diameter 6,8 mm

4 | Technical data FISCHER Mess- und Regeltechnik GmbH

10/16 BA_EN_DS34

4.6 Operating conditions

Ambient temperature range -10 to +70 °C

Storage temperature range -10 to +80 °C

Medium temperature range

(for non-freezing media)

-10 to +80 °C

Low-Voltage Directive EN 61010-1:2010 + A1:2019 +

A1:2019/AC:2019

RoHS EN IEC 63000:2018

Protection class IP 65 acc. to EN 60529

Materials of the parts that come into contact with the surroundings

Housing Grivory® GV

Cable screw connection Polyamide

Connection cable Silicone and halogen-free polymer

Mounting foot Stainless steel 1.4301

Materials of the parts that come into contact with the measuring medium

Pressure chamber Grivory® GV

Diaphragm, measuring range spring Stainless steel 1.4310

Adjustment spindle, switch tappet, etc. Brass CW614N (formerly 2.0402)

Seals EPDM

Other parts PTFE

4.7 Construction design

All dimensions in mm unless otherwise stated

Dimension drawing

Fig.6: Dimension drawing

FISCHER Mess- und Regeltechnik GmbH Technical data | 4

BA_EN_DS34 11/16

G⅛

Ø15.5

6

19

25

Hose Ø 6/4

Hose Ø 8/6

Fig.7: Pneumatic plug-in connection

Accessories

32

60°

1.5

6

Ø4.2

30°

30

20

5.5

10

18

50

60

Fig.8: Mounting foot

5 | Order codes FISCHER Mess- und Regeltechnik GmbH

12/16 BA_EN_DS34

5 Order codes

F 0

Process connection

Switch elements

Electrical connection

D S 3 4

Type

Setting range

0000

1 2 5 6 7 8 9 10 11 123 4Reference No.

Nominal pressure

Measuring system

[1,2] Setting range Measuring range

AA 0.06 … 0.6 bar 0 … 0.6 bar

AB 0.10 … 1.0 bar 0 … 1 bar

AC 0.16 … 1.6 bar 0 … 1.6 bar

AD 0.25 … 2.5 bar 0 … 2.5 bar

AE 0.40 … 4.0 bar 0 … 4 bar

AF 0.60 … 6.0 bar 0 … 6 bar

[3] Nominal pressure

FPN16

[4] Measuring system

0Standard

[5,6] Process connection

00 Internal thread G⅛

43 Pneumatic plug-in connection for 6/4 mm hose

44 Pneumatic plug-in connection for 8/4 mm hose

[7] Switching contacts

A1 adjustable microswitch

Z1 adjustable microswitch with increased switching hysteresis (12%)

[8] Electrical connection

11.0 m long number cable, hard-wired

22.5 m long number cable, hard-wired

55.0 m long number cable, hard-wired

5.1 Accessories

Art. No. Designation

02006023 Assembly foot

FISCHER Mess- und Regeltechnik GmbH Attachment | 6

BA_EN_DS34 13/16

6 Attachment

Fig.9: CE_EN_DS34

6 | Attachment FISCHER Mess- und Regeltechnik GmbH

14/16 BA_EN_DS34

Fig.10: UKCA_EN_DS34

FISCHER Mess- und Regeltechnik GmbH

BA_EN_DS34 15/16

Notes

Mess- und Regeltechnik GmbH

Bielefelder Str. 37a

D-32107 Bad Salzuflen

Tel. +49 5222 974-0

Fax +49 5222 7170

www.fischermesstechnik.de

Technische Änderungen vorbehalten. Subject to technical changes. Sous réserve de modifications techniques.

Table of contents

Other FISCHER Switch manuals

FISCHER

FISCHER DE45 series Instruction Manual

FISCHER

FISCHER DS31 User manual

FISCHER

FISCHER DS31 User manual

FISCHER

FISCHER DE45 series User manual

FISCHER

FISCHER ME50 R Series User manual

FISCHER

FISCHER DS 11 User manual

FISCHER

FISCHER DS 11 User manual

FISCHER

FISCHER DS 11 User manual

FISCHER

FISCHER DS13 User manual

Popular Switch manuals by other brands

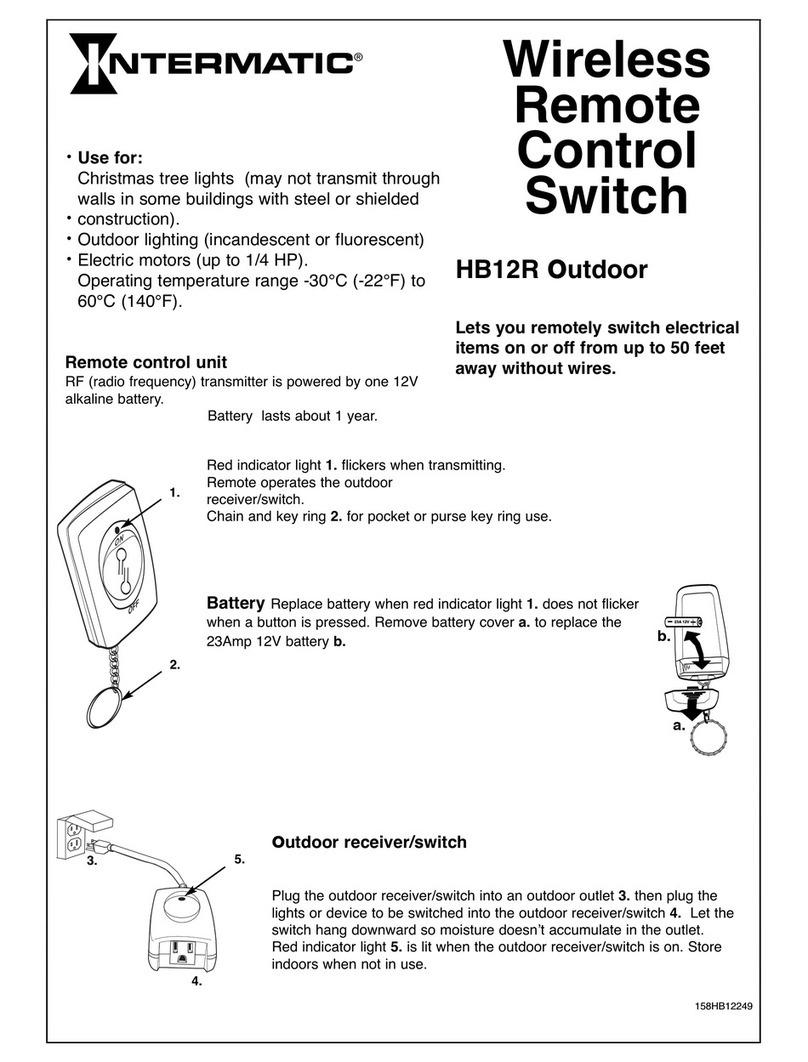

Intermatic

Intermatic HB12R supplementary guide

HP

HP 6125XLG installation guide

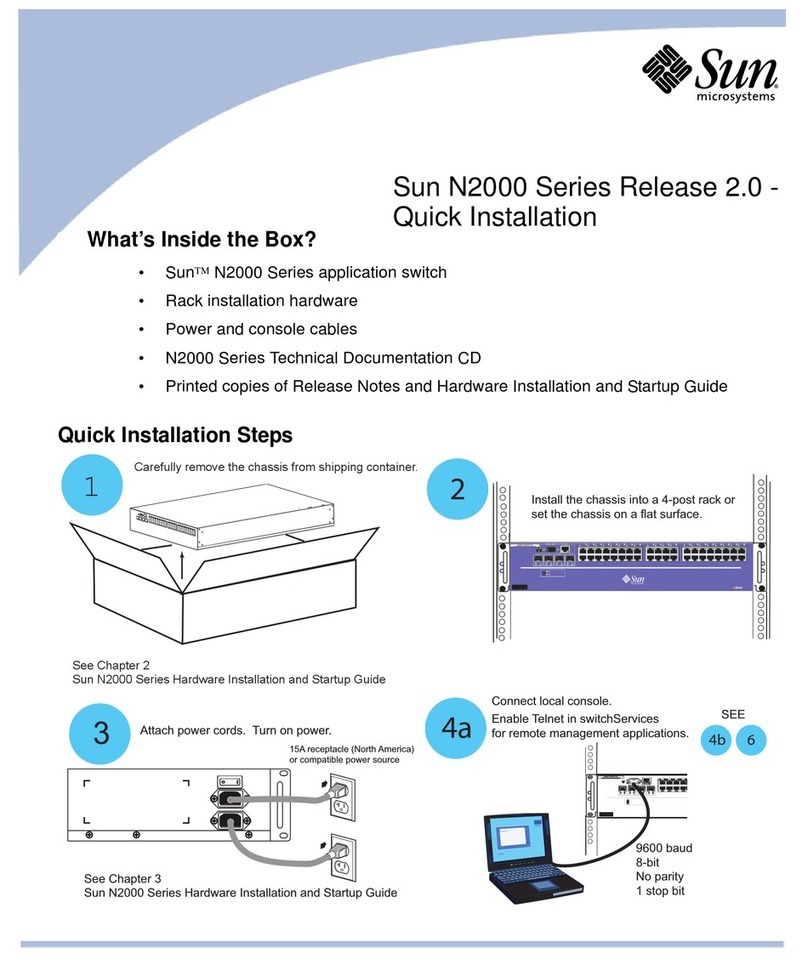

Sun Microsystems

Sun Microsystems N2000 Series Quick installation

Cerio

Cerio CS-1005G-PD user guide

Leviton

Leviton vizia+ decora VPS15-1L installation instructions

Allied Telesis

Allied Telesis AT-9800 Series Quick install guide