Fisher-Rosemount 3024S User manual

Design 3024S

Design 3024S Diaphragm Actuator

Content

Introduction .................................... 1

ScopeofManual ...................................... 1

Description............................................... 1

Specifications ................................. 2

Installation....................................... 3

ActuatorMounting.................................... 3

Travel Adjustments ................................... 5

Maintenance ................................... 5

Disassembly ............................................ 5

Assembly................................................. 6

ChangingActuatorAction ......................... 8

SideMountedHandwheel......................... 8

AdjustableTravel Stops ............................ 10

Parts Ordering ................................ 10

Parts List ................................................. 14

Figure 1. Type 3024S Actuator with

Design 1018S Valve

Instruction Manual

Form5421

June1999

Introduction

Scope of Manual

This instruction manual provides information on installa-

tion, adjustment, maintenance and parts ordering for the

Type GA 1.21, GA 1.31 and GA 1.41 actuators.

Description

The direct acting(extends stem) actuator (figure6and9)

and the reverse acting (retracts stem) actuators (figure 7

and10)arespring-opposedpneumaticdiaphragmactua-

tors that provide throttling or on-off operation of sliding-

stem control valves. The Type 3024S ATC actuator

springs are located under the diaphragm plate, and they

fully retract the actuator stem for fail action upon loss of

diaphragmcasingpressure.TheType3024SATOactua-

torspringsarelocatedontopofthediaphragmplate,and

theyfullyextendtheactuatorstemuponlossofdiaphragm

casingpressure.

Only personnel qualified through training or experience

should install, operate and maintain Type 3024S actua-

tors.

W6681b

D102625X012

2

Design 3024S

Figure 2. Type 3024S Actuator Nameplate

Specifications

Specifications for the Type 3024S actuators are shown

intable1.Someofthespecificationsforagivenactuator

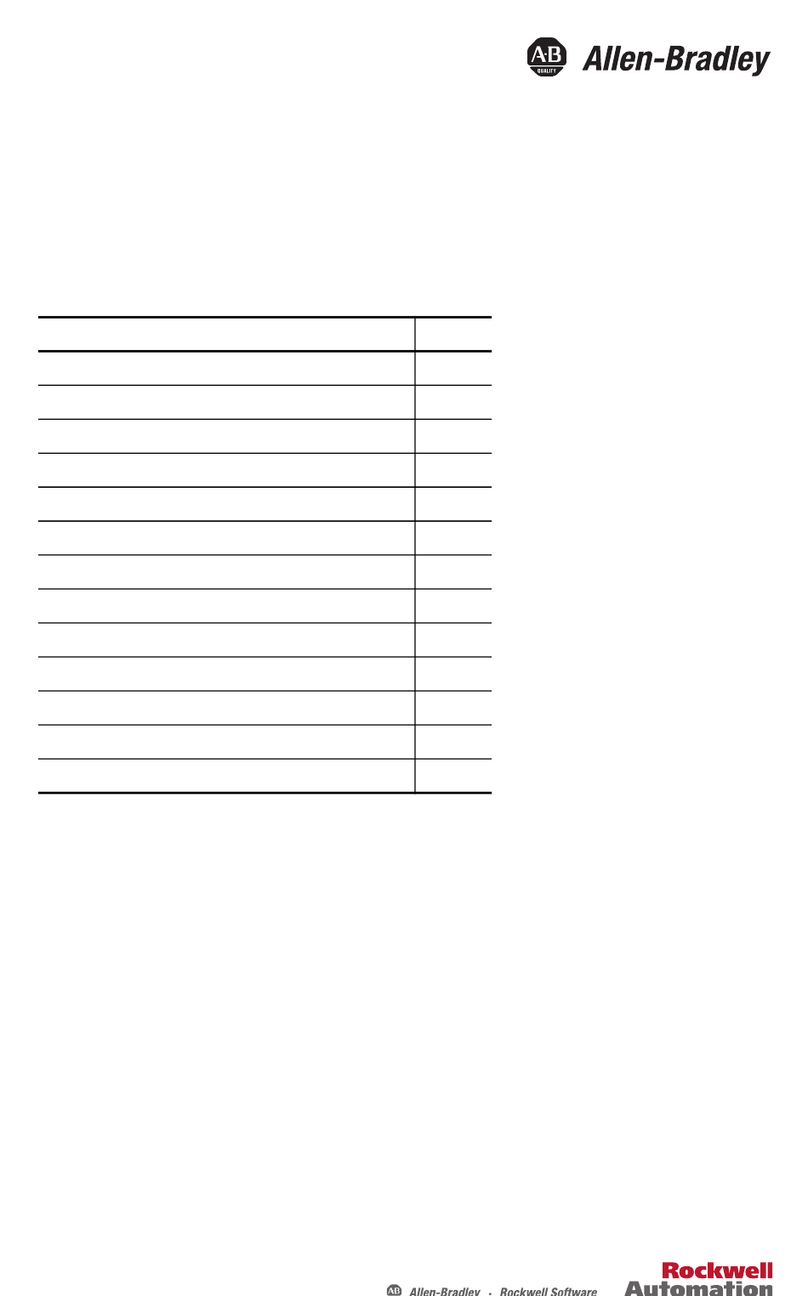

Table 1. Specifications

Actuator SizesActuator Sizes

Actuator SizesActuator Sizes

Actuator Sizes

GA 1.21

GA 1.31

GA 1.41

MaximumMaximum

MaximumMaximum

Maximum Actuator TActuator T

Actuator TActuator T

Actuator Travelsravels

ravelsravels

ravels

Size GA 1.21 and GA 1.31:Size GA 1.21 and GA 1.31:

Size GA 1.21 and GA 1.31:Size GA 1.21 and GA 1.31:

Size GA 1.21 and GA 1.31: 16 mm (0.63 inch)

Size GA 1.31 and GA 1.41 :Size GA 1.31 and GA 1.41 :

Size GA 1.31 and GA 1.41 :Size GA 1.31 and GA 1.41 :

Size GA 1.31 and GA 1.41 : 32 mm (1.26 inch)

Standard Operating Pressure Range

See table 2a (ATC) and 2b (ATO)

Maximum Operating Pressure

See table 2a (ATC) and 2b (ATO)

Maximum Output Thrust

(Maximum Actuator Stem Force)

See table 2a (ATC) and 2b (ATO)

MaterialTemperature Capabilities

W ith Nitrile Diaphragm and Steel studs and nuts :

-40°C to +90°C (-40°F to 194°F)

Signal Connections

Standard: G1/4 inch Withworth female thread

(ISO 7-1/BS 21/DIN2999)

Actuator Stem Diameters

Size GA 1.21 and GA 1.31: 12mm (0.472 inch)

Size GA 1.41: 16mm (0.630 inch)

Acceptable Valve Stem Threads

Size GA 1.21 and GA 1.31: M12 X 1.75 (2 1/8"

yoke boss & 16mm travel)

Size GA 1.31 and GA 1.41: M16 X 2 (2 13/16"

yoke boss & 32mm travel)

Approximate Weights

Size GA 1.21: 7.1 kg (15.6 pounds)

Size GA 1.31: 16.5 kg (36.4 pounds)

Size GA 1.41: 33.5 kg (73.9 pounds)

assembly as it originally comes from the factory are

stamped on a nameplate (figure 2.) attached to the

actuator.

nameplate

Design 3024S

3

manual when installing the valve in the pipeline. If the

actuatorisshippedseparatelyorifitisnecessarytomount

the actuator on the valve, perform the Actuator Mounting

procedure given below. For information on mounting the

positioner,refer tothepositionerinstructionmanual.

The Type 3024S actuators are designed to

mount on push-down-to close valves. Do

not mount these actuators on any other

type of valve without first contacting the

Fisher-Gulde sales office or sales repre-

sentative.

ActuatorMounting

The following procedure describes how to mount a Type

3024Sactuatoron a push-down-to-close valvesothatthe

actuatorstemandvalvestemthreadengagementallowsfull

travel and proper shutoff. Refer to figure 5 for actuator

dimensions.Keynumbersreferencedinthefollowingsteps

are shown in figures 6, 7, 9 & 10.

1. Thread the stem hex nut (key 54/52) first and then the

connector (key 50) onto the valve stem and run them

down.

2. Push the valve stem down until the valve plug is fully

closed.

3. Carefullyplacetheactuatorwiththeflange(key45)on

thevalvebonnet.

When moving the actuator stem with dia-

phragm loading pressure use caution to

keep hands and tools out of the actuator

stem travel path. Personal injury and/or

propertydamageispossibleifsomethingis

caughtbetweentheactuatorstemandother

control valve assembly parts.

Besurethatthelengthoftheactuatorstem

orthevalvestemintheconnector(key50or

53) is equal to or greater than the diameter

of that stem.

In the following procedure, do not rotate

the valve plug while it is seated. This may

damage the seating surface and thereby

allow excessive leakage. Also, during ad-

justment, use tools carefully to avoid dam-

aging the valve stem. A damaged stem

could cut the packing and allow leakage.

4. Perform one of the following procedures as

appropriate:

For aType3024SAir-To-Closeactuator with a push-

down-to-closevalve:

a. Tightenthevalvebonnetlocknut.

b. Adjustthetravel: rotate theconnector halves(key 53

and 50) so that the distance between them (with the

valveontheseatandthetravelindicator-key51be-

tweentheconnectors)isequaltothevalvetravel.

c. Pressurise the actuator slowly and adjust the stem

connector half (key 50) so the connecting bolts will

lineup.

d. Tighten all bolts (key 55/56) and nuts (key 56/57).

e. Apply bench set pressure to the top of the diaphragm

andcheckthevalvestemtravel.

f. Tighten the valvestem hex nut (key 54/52) against the

stem connector (key 50).

For aType3024SAir-To-Openactuator with a push-

down-to-closevalve:

a. Applyapproximately0.5barabovethehighestsettingof

thebenchsetpressuretothebottomofthediaphragm.

This positions the actuator stem (key 8) at the highest

point.

Installation

Personal injury or equipment damage

causedby sudden releaseof pressuremay

result if the valve assembly is installed

whereservice conditions could exceedthe

limitsgiven intable 1and 2or theappropri-

ate nameplates. To avoid such injury or

damage, provide a relief valve for

overpressureprotection as required byac-

cepted industry or local, state and federal

codes and good engineering practices.

A Type 3024S diaphragm actuator is normally shipped

mountedonavalve.Refertotheappropriatevalveinstruction

!WARNINGWARNING

WARNINGWARNING

WARNING

!WARNINGWARNING

WARNINGWARNING

WARNING

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

4

Design 3024S

Table 2a. Additional Specifications .

Action - Air to Close (ATC)

epyTepyT epyT epyTepyT teSgnirpSteSgnirpS teSgnirpS teSgnirpSteSgnirpS ruoloC/.ytQ/.oN

levarTlevarT levarT levarTlevarTegnaRegnaR egnaR egnaRegnaR gnitarepOmumixaMgnitarepOmumixaM gnitarepOmumixaM gnitarepOmumixaMgnitarepOmumixaM mgarhpaiDoterusserP

)1()1( )1( )1()1(

tsurhTtuptuOmumixaMtsurhTtuptuOmumixaM tsurhTtuptuOmumixaM tsurhTtuptuOmumixaMtsurhTtuptuOmumixaM metSrotautcAmumixaM( )ecroF

)1()1( )1( )1()1(

hcnIhcnI hcnI hcnIhcnImmmmmm mmmmgisPgisP gisP gisPgisPraBraB raB raBraBgisPgisP gisP gisPgisPraBraB raB raBraBbLbLbLbLbLNN

N

NN

12.1AG R/3/712 G/5/812 G/7/812 36.06151-3 43-91 44-32

0.1-2.0 3.2-3.1 0.3-6.1 786 8251 1311 719

0086 2305 0804

13.1AG

B/3/912 R/6/112 G/5/212 G/7/212

36.061

51-3 51-6 53-22 64-92

0.1-2.0 0.1-4.0 4.2-5.1 2.3-0.2

786

5934 5934 4613 1642

05591 05591 67041 84901

R/3/112 G/5/212 G/7/212 62.12351-3 33-01 64-31

0.1-2.0 3.2-7.0 2.3-9.0 786 9154 4433 1352

00102 47841 65211

14.1AG

R/4/022 G/8/122 G/01/122 G/21/122 G/41/122

62.123

51-3 62-01 53-51 14-81 64-12

0.1-2.0 8.1-7.0 4.2-0.1 8.2-2.1 2.3-4.1

786

1618 5586 6785 3225 0754

00363 29403 63162 23232 82302

)1(

.%0levartevlavdnarotautcaS4203epyTrofmgarhpaidoterusserpgnitarepomumixamnodesaB

.sdaolgnilkcubmetssahcusevlavehtotsnoitatimilredisnoctonseodsihT

Table 2b. Additional Specifications .

Action - Air to Open (ATO)

epyTepyT epyT epyTepyT teSgnirpSteSgnirpS teSgnirpS teSgnirpSteSgnirpS ruoloC/.ytQ/.oN levarTlevarT levarT levarTlevarTegnaRegnaR egnaR egnaRegnaR gnitarepOmumixaMgnitarepOmumixaM gnitarepOmumixaM gnitarepOmumixaMgnitarepOmumixaM mgarhpaiDoterusserP

tsurhTtuptuOmumixaMtsurhTtuptuOmumixaM tsurhTtuptuOmumixaM tsurhTtuptuOmumixaMtsurhTtuptuOmumixaM metSrotautcAmumixaM( )ecroF

)1()1( )1( )1()1(

hcnIhcnI hcnI hcnIhcnImmmmmm mmmmgisPgisP gisP gisPgisPraBraB raB raBraBgisPgisP gisP gisPgisPraBraB raB raBraBbLbLbLbLbLNN

N

NN

12.1AG R/5/812 G/7/812 36.06133-91 44-32 3.2-3.1 0.3-6.1 786164 865 4502 8252

13.1AG

B/3/912 R/6/112 G/5/212 G/7/212

36.061

51-3 51-6 53-22 64-92

0.1-2.0 0.1-4.0 4.2-5.1 2.3-0.2

786

412 924 8061 4412

459 8091 5517 0459

R/3/112 G/5/212 G/7/212 62.12333-01 64-31

0.1-2.0 3.2-7.0 2.3-9.0 786022 967 989

879 3243 1044

14.1AG

R/4/022 G/8/122 G/01/122 G/21/122 G/41/122

62.12362-01 53-51 14-81 64-12

0.1-2.0 8.1-7.0 4.2-0.1 8.2-2.1 2.3-4.1

786

193 0731 8591 9432 1472

2471 7906 0178 25401 49121

)1(

%0levartevlavdnarotautcaS4203epyTrofmgarhpaidoterusserpgnitarepooreznodesaB

.sdaolgnilkcubmetssahcusevlavehtotsnoitatimilredisnoctonseodsihT

Design 3024S

5

b. Tighten the valve bonnet lock nut.

c. Adjust the travel: rotate the connector halves (key 53

and50)sothatthedistancebetweenthem(withtheplug

ontheseatandthetravelindicatorkey51betweenthe

connectors)isequaltothevalvetravel.

d. Exhaust the actuator slowly and adjust the stem con-

nectorhalf(key50)sotheconnectingboltswilllineup.

e. Completely exhaust the actuator and tighten all bolts

(key 55/56) and nuts (key 56/57).

f. Applyapproximately0.5barabovetheheighestbench

setpressuretothetopofthediaphragmandcheckthe

valvestemtravel.

g. Tightenthevalvestemhexnut(key54/52)againstthe

stem connector (key 50).

For aType3024SAir-To-Open&Air-To-Close

actuators:

5. Cycle the actuator several times to check for proper

operation.

6. Adjustthe travelindicatorscale(key 26)upordown to

correspondwiththetravelindicator.

TravelAdjustments

Althoughmakingtraveladjustmentsshouldnotbeneces-

sary if previous section on Actuator Mounting has been

followed, use the following procedure when the actuator

travelisdifferentfromthatstampedontheactuatorname-

plate(figure2).

Whenadjustingthetravelofapush-down-to-closevalveair-

to-open actuator combination, slightly pressurise the ac-

tuator.Thismovesthevalveplugofftheseat,reducingthe

chanceof damagingthevalveplugor seat during adjust-

ment.

1. Back off the stem hex nut (key 54/52) from the valve

stem connector, and slightly loosen both/all 4 cap

screws (key 55/56) from the connectors.

2. Screw the connector (key 50) clockwise (to lengthen

travel)orcounter-clockwise(toshortentravel).

3. Tighten the stem connector cap screw (key 55/56).

4. Cycletheactuatortocheckforthespecifiedtravel.Ifthe

travel is not equal to the specified travel, adjust and

checkituntilitiscorrect.Tightenthestemhexnut(key

54/52) against the stem connector.

Maintenance

Actuator parts are subject to normal wear and must be

inspected and replaced as necessary. The frequency of

inspectionandreplacementdependsupontheseverityof

the service conditions. Due to the care Fisher takes in

meeting all manufacturing requirements (heat treating,

dimensionaltolerances,etc.),useonlyreplacementparts

manufacturedorfurnishedbyFisher.

Thissectiondescribeshowtheactuatorcanbecompletely

disassembledandassembled.Wheninspectionorrepairs

are required, disassemble only those parts necessary to

accomplish the job; then start the assembly at the appro-

priatestep.

Key numbers refer to figure 6 for a Size 1.21/1.31 Air-To-

Close actuator, to figure 7 for a 1.21/1.31 Air-To-Open

actuator,figure9 for aSize1.41Air-To-Closeactuator,to

figure10for a 1.41Air-To-Openactuator.

Disassembly

Avoid personal injury or damage to prop-

erty from sudden release of pressure, un-

controlledprocessfluid,orprecompressed

springforce.Beforestartingdisassembly:

· Isolate the valve from the process,

· Releaseprocesspressure,

· Ventallinternalpressure from the actua-

tor,

· Release all spring preloading force,

·Use lock-out procedures to be sure that

the above measures stay in effect while

you work on the equipment.

1. For complete disassembly, the positioner and all ac-

cessories (if attached) must be removed from the

actuator.Followtheappropriateremovalproceduresin

theinstructionmanualssuppliedwiththepositionerand

accessories.

2. Bypassthecontrolvalve.Reducetheloadingpres-

suretoatmospheric,andforabottom-loadedType

3024SAir-To-Open actuator,removethetubingor

pipingfromtheconnectioninthelowerdiaphragm

casing (key 1).

Foratop-loadedType3024SAir-To-Closeactuator,

removethepiping or tubing fromtheconnectioninthe

upperdiaphragmcasing(key16).

3. Slightlyloosenalldiaphragmcasingcapscrews(key19

and21).Removetheplastichose(key22).Unscrewthe

shortandlong diaphragmcasingcapscrewsand nuts

(key19,20and21)alternately,untilonlythelongcasing

cap screws (key 21) remain engaged. Then allow the

remainingspringcompressiontobeslowlyandevenly

releasedbyalternatelyunscrewingthelongcasingcap

screws.

!WARNINGWARNING

WARNINGWARNING

WARNING

6

Design 3024S

4.When removing the diaphragm and actuator springs

performoneofthefollowingproceduresasappropriate:

ForaType3024SAir-To-Open actuator

(figure 7 & 10):

a. Liftofftheupperdiaphragm casing(key16)and re-

movethesprings(key15).

b. Usingastrapwrenchorsoft-jawedviceantheactuator

stem (key 8), remove the hex nut (key 14).

c. Removethediaphragmplate(key13),diaphragm(key

11), O-Ring (key 12), pressure plate (key 10) and the

ringhalves(key9).

ForaType3024SAir-To-Closeactuator

(figure 6 & 9) :

a. Liftofftheupperdiaphragm casing(key16).

b. Usingastrapwrenchorsoft-jawedviceantheactuator

stem (key 8), remove the hex nut (key 14).

c. Removethepressureplate(key10), O-Ring (key12),

diaphragm(key11),diaphragmplate(key13)andthe

ringhalves(key9).

d. Removethesprings(key15).

1. Carefullyslidetheactuatorstem(key8)outthebottom

of the lower diaphragm casing (key 1) and set it on a

protective surface to prevent damage to the O-ring

sealingsurface.

2. Removethe bellow(key31),ifused.

3. Unscrewthecheeseheadscrews(key7),thenremove

the bushing (key 6).

4. With the actuator disassembled, inspect all parts for

excessivewearand replace as necessary.

Assembly

This procedure assumes that the actuator is completely

disassembled. If it is not, start the instructions at the

appropriatestep.

For aType3024SAir-To-Open&Air-To-Close

actuator :

1. Beforestartingassembly,applyLubriplateMAG-1lubri-

cantorequivalenttotheO-ring(inthebushingkey6and

key12).Installthenew bushing (key 6) and assemble

with the cheese head screws (key 7) onto the lower

diaphragmcasing(key1).Useatorqueof0.4N.m(0.25

lbf.ft)

2. Carefullyslidetheactuatorstem(key8)downthrough

the bushing (key 6) .

3. When installing the diaphragm and actuator springs

performoneofthefollowingproceduresasappropriate:

ForaType3024SAir-To-Open:

a. Assemble the ring halves (key 9), pressure plate (key

10), O-Ring (Key 12), diaphragm (Key 11) and dia-

phragm plate (key 13) as shown in figure 7 or 10.

b.ApplyLoctite271orequivalenttotheactuatorstemtravel

stopthreadandtightenthetravelstopasfollows:Sizes

GA1.21/1.31tightento37N.m(28lbf.ft),sizeGA1.41

tighten to 90 N.m (66 lbf.ft).

c. Position the actuator springs (key 15) symmetrical on

the diaphragm plate (key 13) as shown in figure 3.

ForaType3024SAir-To-Close:

a. Assemble the ring halves (key 9), pressure plate (key

10), O-Ring (Key 12), diaphragm (Key 11) and dia-

phragm plate (key 13) as shown in figure 6 or 9.

b. Apply Loctite or equivalent to the actuator stem travel

stopthreadandtightenthetravelstopasfollows:Sizes

GA1.21/1.31tightento37N.m(28lbf.ft),sizeGA1.41

tighten to 90 N.m (66 lbf.ft).

c. Position the actuator springs (key 15) symmetrical on

the diaphragm plate (key 13) as shown in figure 3.

Overtightening the diaphragm cap screws

and nuts can damage the diaphragm. Do not

exceedatorqueof11N.m(8lbf.ft)forSizeGA

1.21 and 16N.m (12lb.ft_ for sizes GA 1.31 &

1.41.

ForaType3024SAir-To-Close&Air-to-Open:

4. Install the upper diaphragm casing (key 16) using the

long cap screws (key 21) and hex nuts (key 20) first.

Thensecurewithcap-screws(key19)andhexnuts(key

20). Be sure the supply connection is located directly

above the vent in the lower diaphragm. Fit the plastic

hose (key 22) over the cap screws (key 21).

Note

Be sure to use the long cap screws (key 21),

first installing them on the opposite sides of

the diaphragm casing. Tighten them evenly,

using a cisscross pattern to ensure a proper

seal.

5. Mounttheactuatoronthevalveinaccordancewiththe

Installationprocedures.

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

Design 3024S

7

Figure 3. Type 3024S Spring Arrangements

GA 1.21

3 SPRINGS

GA 1.21

5 SPRINGS

GA 1.21

7 SPRINGS

GA 1.31

3 SPRINGS

GA 1.41

8 SPRINGS

GA 1.31

7 SPRINGS

GA 1.31

6 SPRINGS

GA 1.31

5 SPRINGS

GA 1.41

14 SPRINGS

GA 1.41

12 SPRINGS

GA 1.41

4 SPRINGS

GA 1.41

10 SPRINGS

SPRING LOCATORSPRING

SPRING LOCATOR

SPRING

SPRING LOCATOR

SPRING

2Q57019

8

Design 3024S

Changing Actuator Action

TheActuatorcanbechangedfromaType3024SATOtoa

3024 ATC or vice versa by removing the pressure plate,

diaphragm, O-ring, diaphragm plate, hex nut, springs,

springlocator,selftappingscrewsandventassembly(key

10,11,12,13,14,15,17,18and23)andinstallingthemfor

appropriateaction.Seefigures6,7,9and10.Forhexnut

ortravelstop(key14)andpressureplate(key10)selection

refer to parts list. Follow the procedures in the Actuator

Mounting section and the Travel Adjustment section for

connectiontothevalve.

Side-Mounted Handwheel

Aside-mountedhandwheelassembly(figure4)is

usuallyused as amanualoperator. When mounted on

anATCtype3024Sactuator,turningthehandwheel

clockwise always closes the valve. When mounted on an

ATOactuator, turningthehandwheel clockwisealways

opensthe valve,Alever(key 49,figure12)on the

handwheelassemblyopensorclosesthevalveby

movingthevalvestem.

Instructionsaregivenbelowforcompletedisassembly

and assembly. Perform the disassembly only as far as

necessarytoaccomplishtherequiredmaintenance;then

begin the assembly at the appropriate step.

Refertofigure 12 for key numbers.

Disassembly

1.Ifdesired,thehandwheelassemblycanberemovedfrom

theactuatorlegpost.Todothis,removethehexnuts(key

62)andbackplates(key64)fromtheU-bolts(key61)that

hold the assembly to the leg-post.

2. Loosen the lock (key 63) that secures the drive screw

assembly (key 51).

3. Remove the retaining ring (key 58) and screw out the

drivescrewassembly(key51).

4. Removetheretainerring(key56)anddriveoutthepivot

pin (key 52).

5. Removethebushings(key 55) from thebody(key48).

6. There is a cap screw (key 59), hex nut (key 60), and

spacer(key53)thatholdthetwolevers(key49)together.

Removethecap-screwandhexnutandthetwoleverscan

beseparatedinordertoremovetheoperatingnut(key50).

Assembly

1. Assembletheoperatingnut(key50),thetwolevers(key

49),andthespacer (key 53) usingthecapscrew(key59)

and hex nut (key 60).

2. Install the bushings (key 55) in the body (key 48).

3. Attachthelevers(key49)tothebody(key48)usingthe

pivotpin (key 52)and theretaining ring(key56).

4. Apply lubricant Lubriplate MAG-1 or equivalent to the

drive screw assembly (key 51) and screw it on to the

operatingnut (key50).

5. Install the retaining ring (key 58. to secure the collar to

the body (key 48).

6. If the handwheel assembly was removed from the

actuatorlegposts,positiontheU-bolts(key61),backplate

(key 64) and handwheel body (key 48) to the actuator leg

postsasshowninfigures3&12.Tightenthehexnuts(key

62) to 19 N.m (14 lbf.ft). Clearance between the lower

diaphragm casing and the handwheel body are shown in

figure4.Withtheactuatorfullyopenthedistancebetween

the lower face of the actuator stem connector and the

actuatorflange shouldbeshownin figure4.

Design 3024S

9

Figure 4. Type 3024S Actuator Handwheel Mounting (GA 1.21 & 1.31 only)

ROTAUTCAROTAUTCA ROTAUTCA ROTAUTCAROTAUTCA EZIS levarTlevarT levarT levarTlevarT )mm( AA

A

AA BB

B

BB

sretemiliMsretemiliM sretemiliM sretemiliMsretemiliM

12.1AG 61 51 211

13.1AG 61 5 211

13.1AG 23 01 321

sehcnIsehcnI sehcnI sehcnIsehcnI

12.1AG 61 2/1 2/1-4

13.1AG 61 4/1 2/1-4

13.1AG 23 2/1 5

TYPE 3024S

AIR-TO-CLOSE

TYPE 3024S

AIR-TO-OPEN

A3554e

10

Design 3024S

Adjustable Travel Stops

Theadjustableuptravelstop(figure6)forGA1.21and1.31

actuatorslimitstheactuatorstrokeintheupwarddirection

(limits retraction of the actuator stem).

Loosenthehexnut(key25)andturntheadjuster(key24)

clockwise into the diaphragm case to move the actuator

stemdownwardorcounter-clockwisetoallowtheactuator

stemtomoveupward.Sincethevalvehaspush-down-to-

close action, full opening can be restricted. Check the

actuator travel and then tighten the hex nut (key 25).

For the GA 1.41 actuator up travel stop key numbers

referencedin thefollowingstepsareshowninfigure 9.

1. Loosen the head screws (key 8)

2.Unscrewthecapscrewsandnuts(key5and7)and

removethecoverplate(key4)

3.Loosentheheadscrew(key2)andturnthebush(key

3)clockwiseintotheadjustmentnut(key1)toallowthe

actuatorstem tomoveupwardor counterclockwiseto

shortentheactuatortravel.

4. Check the actuator travel and then tighten the head

screw (key 2).

5. Assemblethecoverplate(key4)andtightenthecap

screws and nuts (key 5 and 7).

Pinch Point!

6. Adjust the cover plate (key 4) so that there is no

gapbetweenthediaphragmcaseandthecover

plate

7. Tighten the head screw (key 8).

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

Parts Ordering

Eachactuatorhasaserialnumberstampedonthename-

plate(figure 2andkey34, figure6,7and 10).Refertothe

serial number when ordering replacement parts or when

correspondingwithyourFishersalesofficeorsalesrepre-

sentative for technical assistance. Also, specify the com-

plete7or11-characterpartnumberfromthefollowingparts

listwhenorderingreplacementparts.

Design 3024S

11

Figure 5. Actuator dimension (reverse acting)

ROTAUTCAROTAUTCA ROTAUTCA ROTAUTCAROTAUTCA EZIS levarTlevarT levarT levarTlevarT )mm( retemaidCretemaidC retemaidC retemaidCretemaidC EE

E

EE FF

F

FF RARARARARA

sretemiliMsretemiliM sretemiliM sretemiliMsretemiliM

12.1AG 61 512 *063 501 54

13.1AG 61 513 054 501 54

13.1AG 23 513 084 331 54

14.1AG 23 024 515 331 54

sehcnIsehcnI sehcnI sehcnIsehcnI

12.1AG 61 64.8 71.41 31.4 77.1

13.1AG 61 04.21 27.71 31.4 77.1

13.1AG 23 04.21 09.81 42.5 77.1

14.1AG 23 45.61 82.02 42.5 77.1

gnirgnitfiltuohtiw*

MATCH LINE FOR VALVE BODY

12

Design 3024S

Figure 6 : Size GA 1.21 & 1.31

direct acting actuator (ATC) Figure 7 : Size GA 1.21 & 1.31

reverse acting actuator (ATO)

Figure 8 : Adjustable up travel stop for size GA 1.21 & 1.31

* For travel 32 mm use here key 52 instead of key 54

**

Design 3024S

13

Figure 9. GA 1.41 direct acting actuator (ATC) Figure 10. GA 1.41 reverse acting actuator (ATO)

Figure 11. GA 1.41 Adjustable up travel stop

14

Design 3024S

Parts List

Actuator

Key Description Part Number

1 Lower Diaphragm Casing, steel

Size GA 1.21 0410632

Size GA 1.31 0449660

Size GA 1.41 0449687

3* Gasket (2 required)

Size GA 1.21 0409081

Size GA 1.31 & 1.41 0411426

4 Supporting Ring, steel

Size GA 1.21 -

Size GA 1.31 & 1.41 (2 required) 0411434

5 Leg Post, steel (2 required)

Size GA 1.21, Travel 16mm 0409090

Size GA 1.31, Travel 16mm 1066803

Size GA 1.31 & 1.41 , Travel 32mm 2539667

6* Bushing

Size GA 1.21 & 1.31 0409065

Size GA 1.41 0411159

7 Cheese Head Screw,

stainless steel (6 required) 0119512

8 Actuator Stem, stainless steel

Size GA 1.21 0410713

Size GA 1.31 0410284

Size GA 1.41 0411752

9 Ring Half, stainless steel (2 required)

Size GA 1.21 & 1.31 0410365

Size GA 1.41 0411876

10 Pressure Plate

Size GA 1.21, aluminium ATO and ATC 1136879

Size GA 1.31, steel, Travel 16 mm

0.2 - 1.0 bar (3 - 15 psig) ATO and ATC 0410373

0.4 - 1.0 bar (6 - 15 psig) ATO and ATC 0410373

1.5 - 2.4 bar (22 - 35 psig) ATO 2139839

1.5 - 2.4 bar (22 - 35 psig) ATC 0410373

2.0 - 3.2 bar (29 - 46 psig) ATO 2139839

2.0 - 3.2 bar (29 - 46 psig) ATC 0410373

10 Pressure Plate (continued)

Size GA 1.31,

steel, Travel 32 mm, ATO and ATC 0410373

Size GA 1.41, steel, ATO and ATC 0411884

11* Diaphragm, nitrile

Size GA 1.21 0410705

Size GA 1.31 0410357

Size GA 1.41 0411868

12* O-Ring, nitrile

Size GA 1.21 & 1.31 0409073

Size GA 1.41 0411736

13 Diaphragm Plate

Size GA 1.21, aluminium 1136887

Size GA 1.31, aluminium 2631032

Size GA 1.41, cast iron 0444987

14 Hex Nut, steel

Size GA 1.21, T ravel 16mm

1.3 - 2.3 bar (19 - 34 psig) A T O 0828939

1.6 - 3.0 bar (23 - 44 psig) A T O 0828661

0.2 - 1.0 bar (3 - 15 psig) ATC 0476986

1.3 - 2.3 bar (19 - 34 psig) ATC 0476986

1.6 - 3.0 bar (23 - 44 psig) ATC 0828939

Size GA 1.31, Travel 16mm

0.2 - 1.0 bar (3 - 15 psig) A T O 0411108

0.2 - 1.0 bar (3 - 15 psig) A T C 0476986

0.4 - 1.0 bar (6 - 15 psig) AT O and AT C 0411108

1.5 - 2.4 bar (22 - 35 psig) A T O 0127515

1.5 - 2.4 bar (22 - 35 psig) A T C 0411108

2.0 - 3.2 bar (29 - 46 psig) A T O 0127515

2.0 - 3.2 bar (29 - 46 psig) A T C 0828661

Size GA 1.31, T ravel 32 mm, ATO and

ATC

0.2 - 1.0 bar (3 - 15 psig) 0476986

0.7 - 2.3 bar (10 - 33 psig) 0127515

0.9 - 3.2 bar (13 - 46 psig) 0127515

Size GA 1.41, T ravel 32 mm

0.2 - 1.0 bar (3 - 15 psig) AT O and AT C 1768247

0.7 - 1.8 bar (11-26 psig) A T O 0127531

0.7 - 1.8 bar (11-26 psig) AT C 1768247

1.0 - 2.4 bar (15-35 psig) AT O and AT C 0127531

1.2 - 2.8 bar (17-41 psig) AT O and AT C 0127531

1.4 - 3.2 bar (20-46 psig) AT O and AT C 0127531

Key Description Part Number

Design 3024S

15

15 Spring, steel

Size GA 1.2, Travel 16 mm

0.2 - 1.0 bar ( 3 - 15 psig) (3 required) 0410853

1.3 - 2.3 bar (19 - 34 psig) (5 required) 0410861

1.6 - 3.0 bar (23 - 44 psig) (7 required) 0410861

Size GA 1.31, T ravel 16 mm

0.2 - 1.0 bar ( 3 - 15 psig) (3 required) 0411086

0.4 - 1.0 bar ( 6 - 15 psig) (6 required) 0409111

1.5 - 2.4 bar (22 - 35 psig) (5 required) 0410411

2.0 - 3.2 bar (29 - 46 psig) (7 required) 0410411

Size GA 1.31, T ravel 32 mm

0.2 - 1.0 bar ( 3 - 15 psig) (3 required) 0409111

0.7 - 2.3 bar (10 - 33 psig) (5 required) 0410411

0.9 - 3.2 bar (29 - 46 psig) (7 required) 0410411

Size GA 1.41, T ravel 32 mm

0.2 - 1.0 bar ( 3 - 15 psig) (4 required) 0411124

0.7 - 1.8 bar (11 - 26 psig) (8 required) 0411132

1.0 - 2.4 bar (15 - 35 psig) (10 required) 0411132

1.2 - 2.8 bar (17 - 41 psig) (12 required) 0411132

1.4 - 3.2 bar (20 - 46 psig) (14 required) 0411132

16 Upper Diaphragm Casing, steel

Size GA 1.21 0410756

Size GA 1.31 0411060

Size GA 1.41 0412007

For adjustable up stop (optional)

Size GA 1.21 0478873

Size GA 1.31 0478865

17 Spring Locator, stainless steel

Size GA 1.21 0411604

Size GA 1.31 0410322

Size GA 1.41 0411809

18 Convex Fillister Head Screw,

steel (2 required) 0410403

19 Cap Screw, steel

Size GA 1.21 (7 required) 0125385

Size GA 1.31 (12 required) 0125490

Size GA 1.41 (17 required) 0125490

20 Hex Nut, steel

Size GA 1.21 (10 required) 0127485

Size GA 1.31 (15 required) 0127493

Size GA 1.41 (20 required) 0127493

21 Hex Cap Screw, steel (3 required)

Size GA 1.21 0467235

Size GA 1.31 0464651

Size GA 1.41 0464643

22 Plastic Hose, PVC (3 required)

Size GA 1.21 0479748

Size GA 1.31 0479730

Size GA 1.41 0479721

23 V ent Assembly, plastic 0410233

24 Hex Cap Screw, steel 1.21 & 1.31 (optional) 0125628

25 Hex Nut, steel 1.21 & 1.31 (optional) 0410993

26 Travel Indicator Scale, stainless steel

Size GA 1.21, Travel 16 mm 2492431

Size GA 1.31, Travel 16 mm 2492474

Size GA 1.31, Travel 32 mm 2492466

27 Nut 10B1272X012

28 Screw 19A4786X012

30 Hex Nut, steel (2 required) 0127531

31* Bellows 0409154

33 W arning Label 0444375

34 Nameplate, stainless steel 2472503

35 Tab Washer, stainless steel

Size GA 1.21 1167731

Size GA 1.31 & 1.41 1167758

45 Actuator flange, steel

2 1/8" Y oke Boss (Travel 16 mm) 2484307

2 13/16" Yoke Boss (Travel 32 mm) 2539659

50 Valve Stem Connector, steel

Without Side Mounted Handwheel

Size GA 1.21, T ravel 16 mm, ATO and AT C 0319678

Size GA 1.31, T ravel 16 mm

0.2 - 1.0 bar (3 - 15 psig) A T O 0319678

0.2 - 1.0 bar (3 - 15 psig) A T C 1594842

0.4 - 1.0 bar (6 - 15 psig) A T O 0319678

0.4 - 1.0 bar (6 - 15 psig) A T C 1594842

1.5 - 2.4 bar (22 - 35 psig) A T O and AT C 1594842

2.0 - 3.2 bar (29 - 46 psig) A T O and AT C 1594842

Size GA 1.31, T ravel 32 mm, ATO and AT C 0458112

Size GA 1.41, T ravel 32 mm, ATO and AT C 0458112

With Side Mounted Handwheel

Size GA 1.21, T ravel 16mm ATO and AT C 0319678

Size GA 1.31, T ravel 16mm ATO and AT C 0319678

Size GA 1.31, T ravel 32mm ATO and AT C 0458112

51 Travel Indicator 0458180

52 Hex nut, GA 1.31, Travel 32 mm (1 required) 0127531

Key Description Part Number Key Description Part Number

16

Design 3024S

53 Actuator Stem Connector, steel

Without Side Mounted Handwheel

Size GA 1.21, T ravel 16 mm ATO and AT C 1594842

Size GA 1.31, T ravel 16 mm

0.2 - 1.0 bar (3 - 15 psig) A T O and AT C 1594842

0.4 - 1.0 bar (6 - 15 psig) A T O and AT C 1594842

1.5 - 2.4 bar (22 - 35 psig) AT O 0458120

1.5 - 2.4 bar (22 - 35 psig) AT C 1594842

2.0 - 3.2 bar (29 - 46 psig) AT O 0458120

2.0 - 3.2 bar (29 - 46 psig) AT C 1594842

Size GA 1.31, T ravel 32 mm, ATO and AT C 0458120

Size GA 1.41, T ravel 32 mm

0.2 - 1.0 bar (3 - 15 psig) A T O and AT C 0458112

All except 0.2 - 1.0 bar A T O and AT C 0458139

With Side Mounted Handwheel

Size GA 1.21, T ravel 16mm ATO and AT C 0319678

Size GA 1.31, T ravel 16mm ATO and AT C 1594842

Size GA 1.31, T ravel 32mm ATO and AT C 1594842

54 Hex Nut, steel

Size GA 1.21 & 1.31, Travel 16 mm 0127515

(2 required)

Size GA 1.31, T ravel 32 mm (1 required ) 0127515

Size GA 1.41, (2 required) 0127531

55 Hex Cap Screw, steel (2 required)

Without Side Mounted Handwheel 0125512

With Side Mounted Handwheel 1Q39761F012

Key Description Part Number Key Description Part Number

56 Hex Nut, steel

Size GA 1.21 & 1.31 (2 required) 0127493

Size GA 1.41 (4 required) 0127493

57 Hex Cap Screw, steel (2 required)

Size GA 1.41 0125490

60 Adjustable up travel stop for Size 1.41 (Optional)

1 Nut, adjustment (1 required) 0625850

2 Cap Screw (1 required) 0119504

3 Bush 0625876

4 Cover Plate (2 required) 1607758

5 Cap Screw 0262226

6 Washer 0120766

7 Hex nut 0127752

8 Cap screw 0450367

Side Mounted Handwheel

(GA 1.21 & 1.31 only)

48 Body, steel 49A7900X012

49 Lever, steel 2317435

50 Operating Nut, brass 2317443

51 Drive Screw Assembly, steel/stainless steel

GA 1.21 29A7908X012

GA 1.31 29A7912X012

52 Pivot Pin, stainless steel 19A7914X012

Figure 12. Side Mounted Handwheel for Type 3024S GA 1.21 and 1.31 Actuators

49A7913

Design 3024S

17

53 Spacer, steel (2 required) 2317427

54 Shim Ring, steel 19A7918X012

55 Bushing (2 required) composite 19A7919X012

56 Retaining Ring, steel (2 required) 19A7920X012

57 Thrust Washer, composite 19A7921X012

58 Retaining Ring, steel 19A7923X012

59 Cap Screw, steel (2 required) 0262072

60 Hex Nut, steel (2 required) 19A7927X012

61 U-Bolt, steel (4 required) 19A7930X012

62 Hex Nut, steel (8 required) 19A4838X012

63 Lock, stainless steel 19A7931X012

64 Back Plate, steel (4 required) 10B1554X012

65 Hex Nut, steel 19A4788X012

Stem Connector Spacer 1Y45607E012

* Recommended spare part.

18

Design 3024S

Design 3024S

19

20

Design 3024S

The contents of this publication are presented for information purposes only, and while every effort has been made to ensure their accuracy, they are not to be constructed as warranties or guarantees, express or

implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

For information, contact Fisher Controls :

Marshalltown, Iowa 50158 USA

Cernay 687010 France

Sao Paulo 05424 Brazil

Singapore 128461

Fisher Controls International, Inc, 1999; all rights reserved.

Table of contents