Page 2

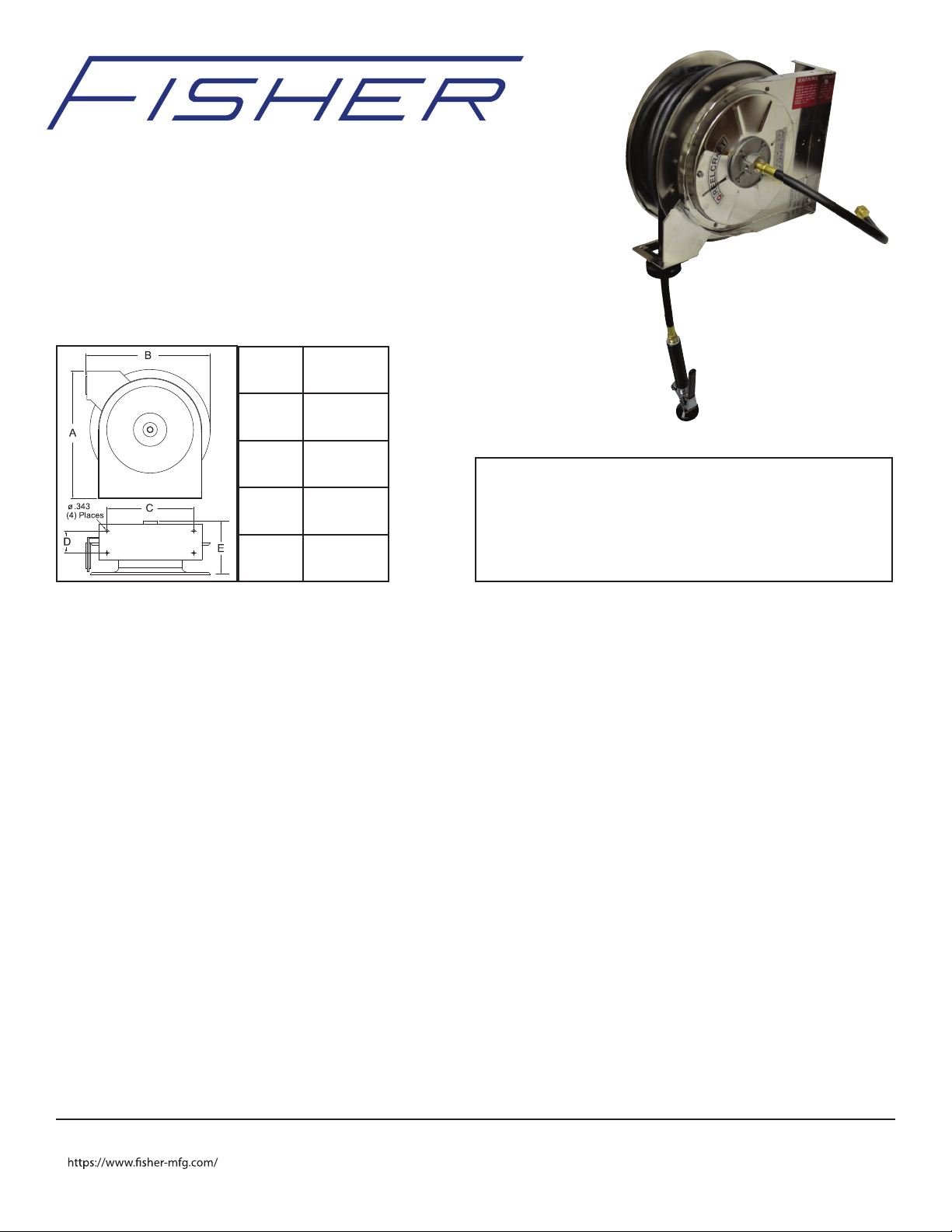

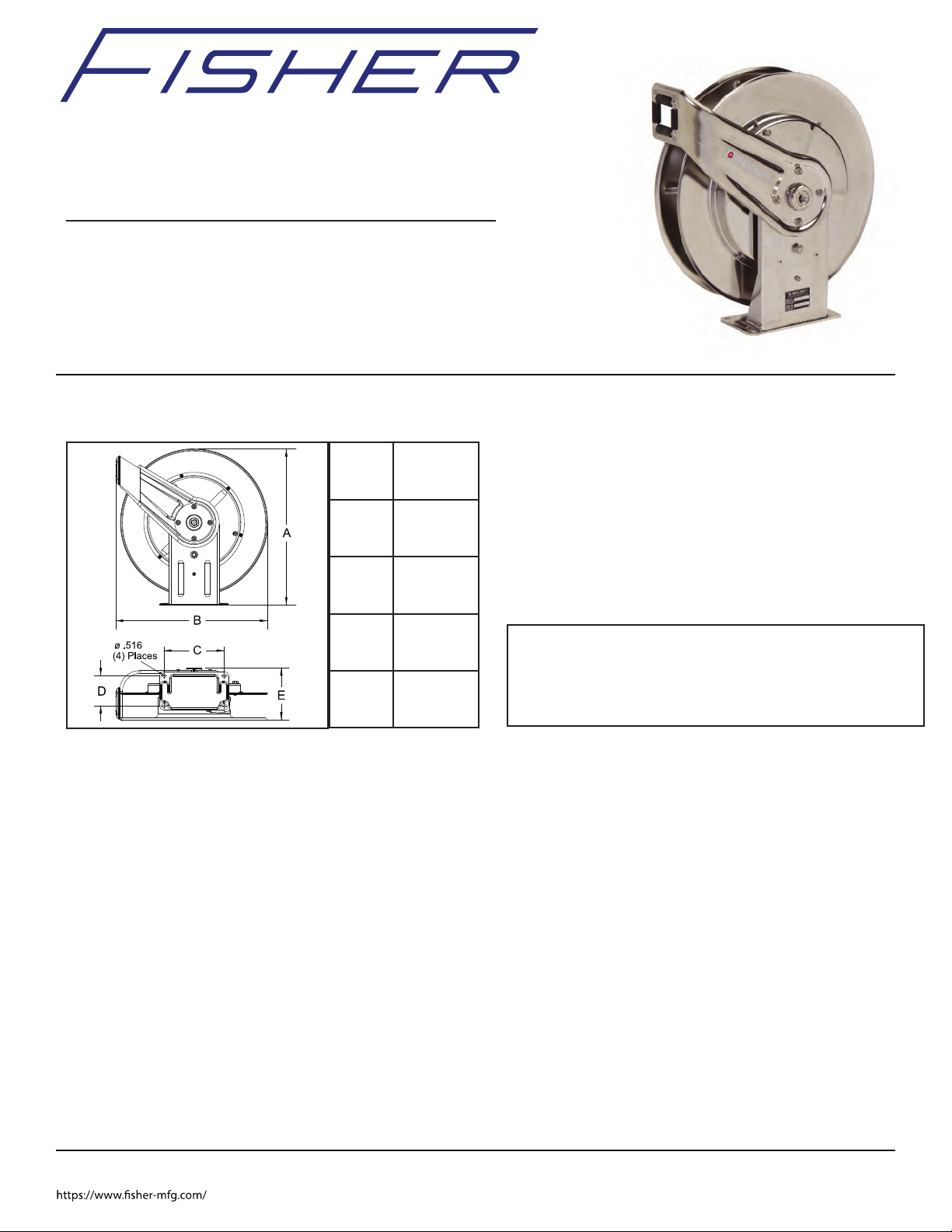

Spring Driven Hose Reels

INSTALLATION INSTRUCTIONS

MOUNTING

Caution: Unless reel was specified

differently when ordering, maximum

installation height is 16 feet. Do not

exceed this distance.

1. Unpack and inspect reel for damage.

Turn by hand to check for smooth

operation. Check for completeness.

2. Configure reel for top, side or

bottom-wind hose dispensing by

removing nuts (1) securing guide arm

bracket (2). Position guide arm bracket

to desired location, and replace nuts.

Caution: When changing guide arm

positions, the U-bolt must be placed in

the proper location as instructed in

figure A below. The reel can

“latch out” during use if this

instruction is not adhered to.

3. Position reel on floor, wall, or ceiling.

Secure into place using four (customer

supplied) bolts (3).

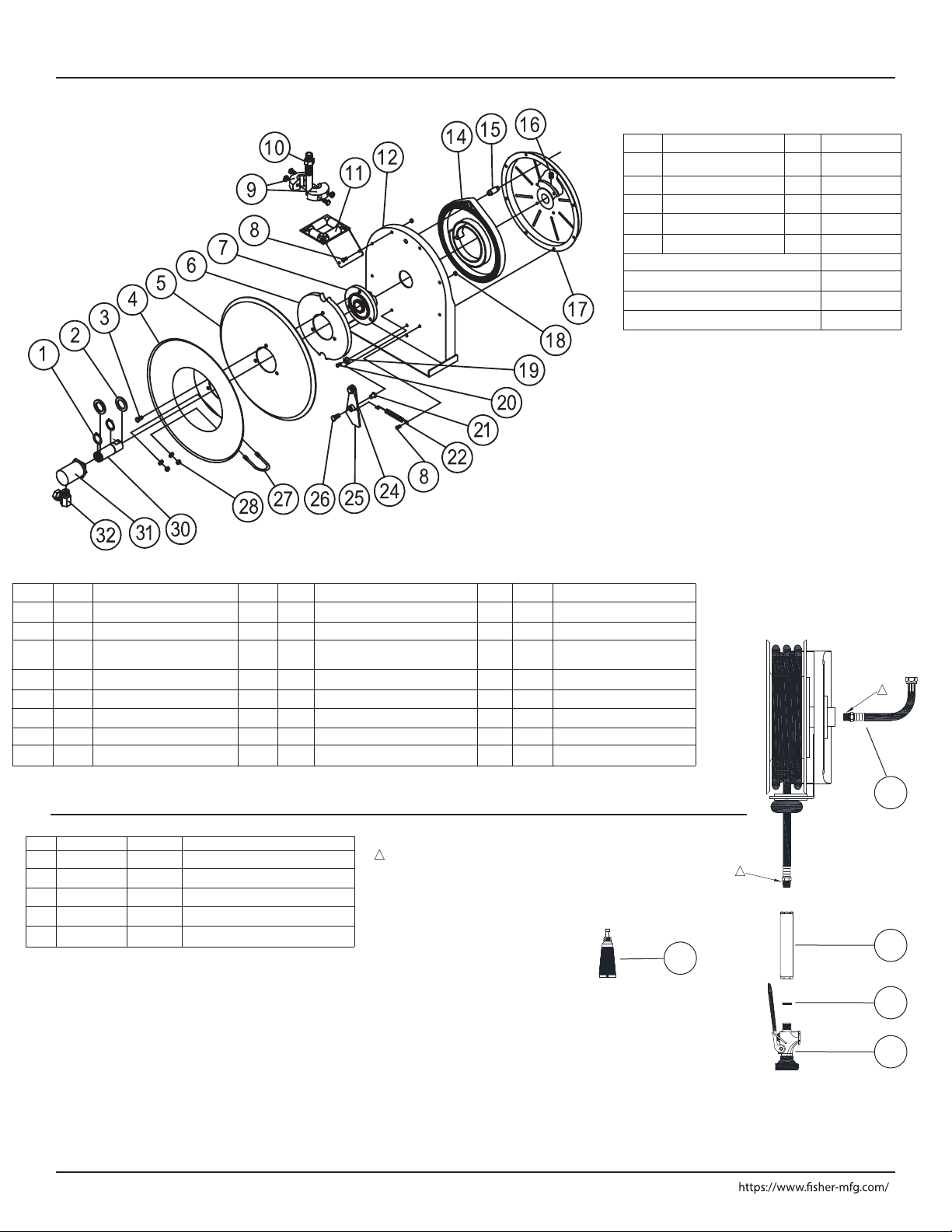

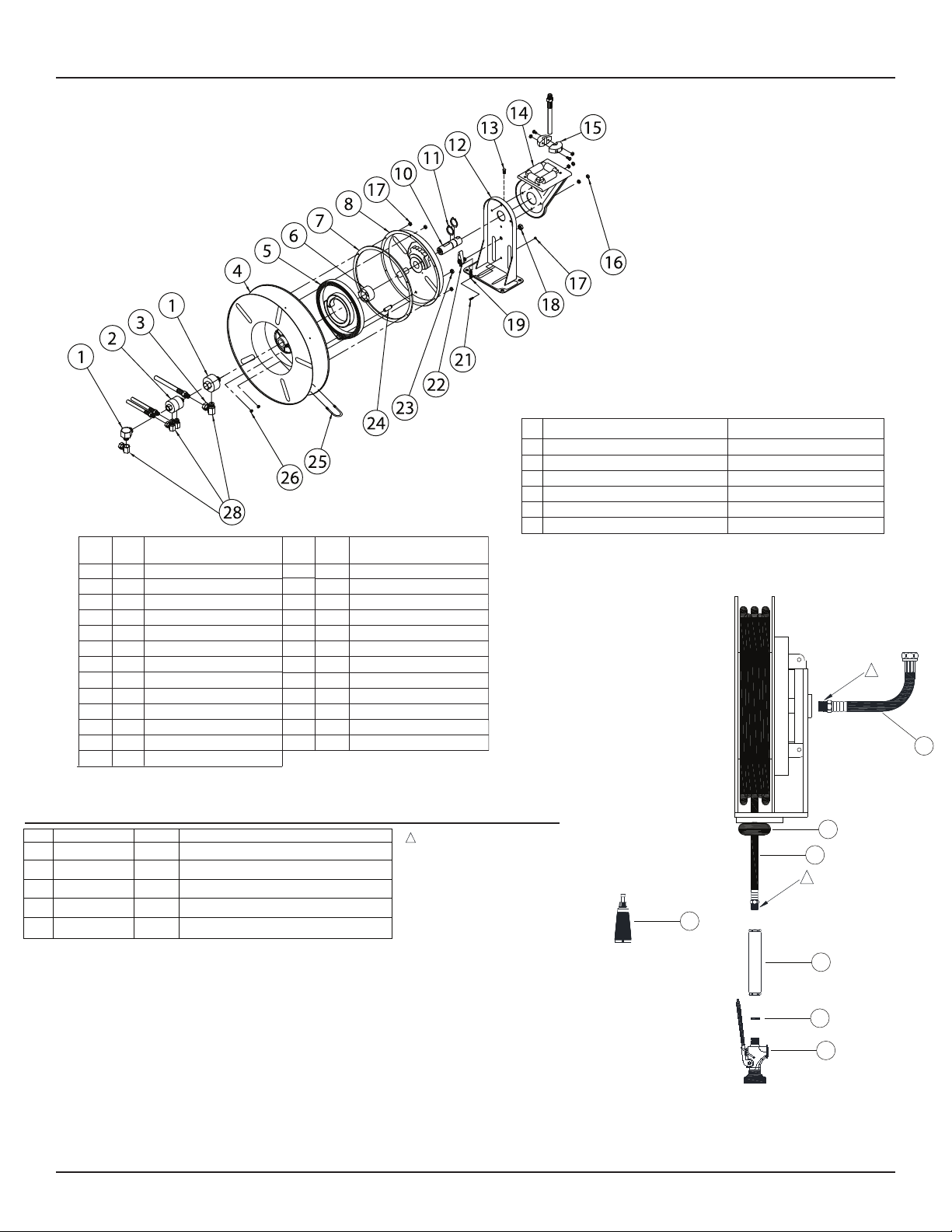

INSTALLING THE INPUT HOSE(S)

Warning: Ensure that supply line

pressure does not exceed maximum

working pressure rating of reel. Apply

pipe thread sealant to all threads.

Caution: Use flexible hose connection at

input. Do not use rigid plumbing.

1. Connect supply line hose (4) to main

shaft input (5) as indicated in

illustration.

INSTALLING THE OUTPUT HOSE(S)

Warning: Use extreme caution; reel

under tension. Avoid releasing latch

mechanism. Apply pipe thread sealant to

all threads.

1. Manually turn sheave (10) until spring

is tight, back off 3 turns, then latch.

2. Route output hose(s) (11) through

guide arm bracket (2), U-bolts (12),

then through cutout (13) in spool as

indicated in illustration.

3. Connect output hose(s) (11) to swivel

(14) as indicated in illustration.

4. Tighten U-bolts (12).

5. Charge hose(s). Momentarily open

control valve to purge hose(s) of gases.

When fluid appears at control valve,

close valve. With hose(s) fully charged,

release latch and wind output hose(s)

onto reel.

ADJUSTMENTS

Warning: Use extreme caution; reel

under tension. Avoid releasing latch

mechanism. If necessary, adjust spring

tension on reel by adding or removing

wraps of hose from spool, one wrap at a

time, until desired tension is obtained.

Add wraps to increase tension. Remove

wraps to decrease tension.

SERVICE INSTRUCTIONS

User servicing of the reel is limited to

replacing input/output hoses only. Refer

all other repairs to an authorized service

person or directly to Reelcraft. Failure to

do so can result in personal injury and/or

equipment damage and may void the

warranty. Warning: Rewind hose on

reel, then bleed pressure from system

before performing the following proce-

dures.

1. Replace hoses in accordance with

procedures given in “Installation

Instructions” section of this manual

Caution: When replacing drive spring,

hold the center of the spring down as the

hub is pulled out. If the center is allowed

to raise up, the spring may escape from

it’s container with enough force to cause

injuries.

When disposing of old or broken spring

assemblies, the coils should be welded or

wired together to prevent possible injury

to scrap handling personnel.

2. All mating moving parts are to be

lubricated with Perma Bond or Loctite

anti-seize compound.

Figure A

3

1

5

2

4

14

10

11 15

13

12

2