LAST FAULT MODE

To retrieve fault codes, push and release the "LAST ERROR"

button for more than 1/5 second and less than 5 seconds.

(Control will indicate this period by solid GREEN for 1/5 to

5seconds).TheLEDwillashuptovestoredfaultcodes,

beginning with the most recent. If there are no fault codes in

memory,theLEDwillashtwogreenashes.Thecontrolwill

ashthemostrecenterrorrstandtheoldesterrorlast(lastin

rstout).Thereshallbe2secondsbetweencodes.SolidLED

error codes will not be displayed.

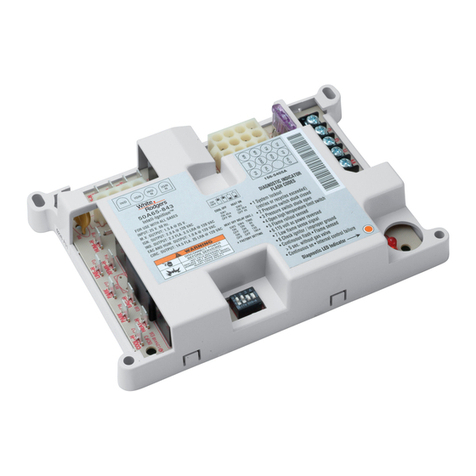

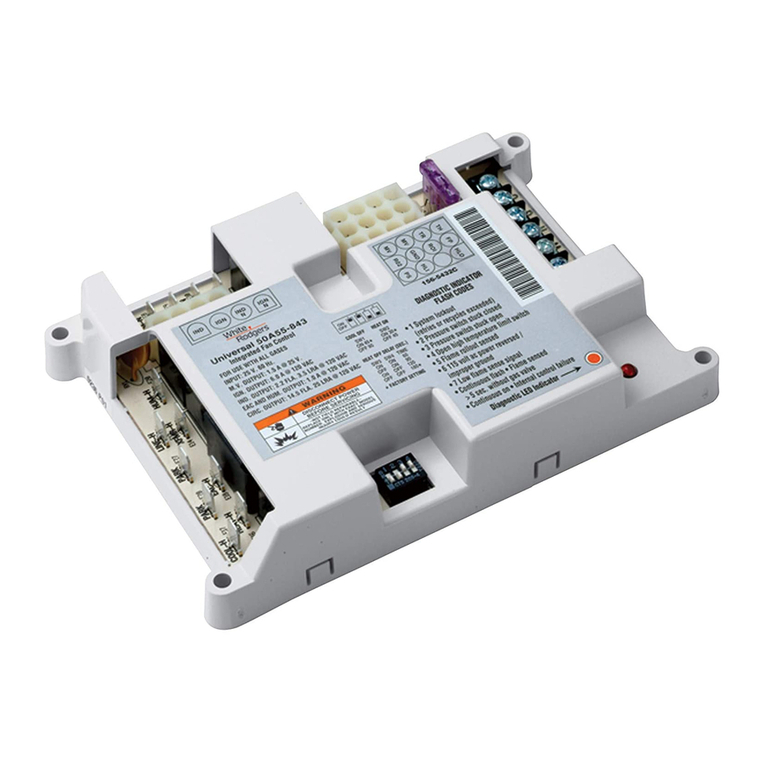

DIAGNOSTIC FEATURES

The 50M51 control continuously monitors its own operation and

the operation of the system. If a failure occurs, the red LED on the

controlwillashafailurecode.If the failure is internal to the

control, the light will stay on. In this case, the entire control

should be replaced, as the control is not eld-repairable.

If the sensed failure is in the system (external to control), the

LEDwillashinthefollowingash-pausesequencestoindicate

failurestatus(eachashwilllastapproximately0.25seconds,

and each pause will last approximately 2 seconds.)

During a second-stage error condition, the red LED when in

lockoutwillashgroupsofdoublepulses.TheredLEDwillash

on for approximately 1/15 second then off for 1/15 second then

on for 1/15 second, then off for 3/10 second.The pause between

groupsofashesisapproximately2seconds.

DIAGNOSTIC TABLE

Green

LED

Flash

Amber

LED

Flash

Red LED

Flash Error/Condition Comments/Troubleshooting

1Flamesensedwhennoameshould

be present

Verify the gas valve is operating and shutting down properly. Flame in burner

assembleshouldextinguishpromptlyattheendofthecycle.Checkoricesand

gas pressure.

2Pressureswitchstuckclosed/inducererror Pressureswitchstuckclosed.Checkswitchfunction,verifyinduceristurningoff.

31st-stagepressureswitchstuckopen/inducer

error

Checkpressureswitchfunctionandtubing.Verifyinduceristurningonthepulling

sufcientvacuumtoengageswitch.

4 Open limit switch Verify continuity through rollout switch circuit.

5 Open rollout/open fuse detect Verifycontinuitythroughrolloutswitchcircuit,checkfuse.

61st-stagepressureswitchcyclelockout iftherststagepressureswitchcycles5times(open,closed)duringonecall

forheatfromthethermostatthecontrolwilllockout.Checkpressureswitchfor

uttering,inconsistentclosureorpoorvacuumpressure.

7Externallockout(retries) Failuretosenseameisoftencausedbycarbondepositsontheamesensor,a

disconnectedorshortedamesensorleadorapoorlygroundedfurnace.Carbon

deposits can be cleaned with emery cloth. Verify sensor is not contacting the

burnerandislocatedinagoodpositiontosenseame.Checksensorleadfor

shorting and verify furnace is grounded properly.

8Externallockout(ignitionrecyclesexceeded

whereameisestablishedandthenlost) Checkitemsforexceededretrieslistedaboveandverifyvalveisnotdroppingout

allowingametobeestablishedandthenlost.

9 Grounding or Reversed polarity Verifythecontrolandfurnaceareproperlygrounded.Checkandreversepolarity

(primary) if incorrect.

10 Module gas valve contacts energized with no

call for heat

Verify valve is not receiving voltage from a short. If a valve wiring is correct and

condition persists, replace module.

11 Limit switch open – possible blower failure

overheating limit

Possibleblowerfailure,restrictedairowthroughapplianceorductwork.Verify

continuity through limit switch circuit and correct overheating cause.

12 Module Ignitor contact failure Fault code indicates the module ignitor contacts are not functioning properly.

Replace module.

Solid Module - internal fault condition Module contacts for gas valve not operating or processor fault. Reset control. if

condition persists replace module.

Rapid Twinning error Checkwireconnections.Ifconditionpersists,replacemodule.

3 double 2nd-stagePressureSwitchStuckOpen/Inducer

Error

Checkpressureswitchfunctionandtubing.Verifyinduceristurningonand

pullingsufcientvacuumtoengageswitch.

1NormalOperationwithcallforrststageheat Normaloperation-rststage

2Normal Operation with call for second stage heat Normaloperation-rststage

3 W2 present with no W1 Secondstagecallforheatonthermostatcircuitwithnocallforrststage.Verify

dipswitchesaresetfortwostagethermostatandcheckthermostatrststage

circuit.Conguredforamulti-stagethermostattheModulewillnotinitiateheating

unlessrststagecallfromthermostatisreceived.

4YpresentwithnoGcall Modulewillallowcoolingtooperatewithonlya"Ysignalfromthethermostatbut

willalsotriggerthiscode.Verifythermostatisenergizingboth"Y"and"G"oncall

forcool.Check"G"terminalconnections.

Rapid Lowamesensecurrent Lowamesensecurrentisoftencausedbycarbondepositsontheamesensor,

apoorlygroundedfurnaceoramis-alignedamesenseprobe.Carbondeposits

canbecleanedwithemerycloth.Checkforimprovefurnaceandmoduleground.

Verifysensorislocatedinorverynearameasspeciedbytheappliance

manufacturer.

1 Standby or Call for Cool Normal operation. Waiting for call from thermostat or receiving thermostat

call for cool.

INTEGRATED

FURNACE CONTROLS

21M51U-843

DIAGNOSTIC TABLE

www.white-rodgers.com

180

TECHNICAL HELP