FiT SUPER SESI User manual

SUPER SESI

Airborne Molecules & Metabolites Analysis

User Manual

Revision 2.1 -February 2020

Page 1 of 34

SUPER SESI, by FIT User manual, Revision 2.0

©2020 Fossil Ion Technology S.L. All rights reserved.

Release history: Revision β.1 (pre-certification release), January 2017

Revision β.2 (pre-certification, after certification comments) March 2017

Revision β.3 (pre-certification, more certification comments) March 2017

Revision 1.0 (product release) April 2017

Revision 2.0 Update after product improvements February 2019

Revision 2.1 Correction of typos February 2020

Fossil Ion Technology S.L. provides this document to its customers with the purchased product

to assist in the operation of said product. This document is copyright protected. Its reproduction

is prohibited, except with the written authorization of Fossil Ion Technology S.L.

The contents of this document may be subject to change without notice. All technical

information in this document is for reference purposes only. The system configurations and

specifications in this document supersede all previous information received by the purchaser.

This document is not a sales contract between Fossil Ion Technology S.L. and a purchaser. This

document shall in no way govern or modify any Terms and Conditions of a Sale. The terms and

conditions of any Sale shall govern all conflicting information between this document and the

Sale document.

SUPER SESI is a registered trademark of Fossil Ion Technology S.L. The following are registered

trademarks in the United States and other countries: Alicat, Swagelok is a registered trademark

of Crawford Fitting Company. Delrin, Kalrez, Teflon, Tefzel, and Viton are registered trademarks

of E.I. du Pont de Nemours & Co. Upchurch Scientific is a registered trademark of Upchurch

Scientific, Inc. PEEK is a trademark of Victrex PLC., Ion Max, Orbitrap, Exactive, QExactive and

LTQ are trademarks of Thermo Fisher Scientific Inc.

For Research Use Only. Not for use in diagnostic procedures.

Page 2 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Page 3 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Table of Contents

Preface.................................................................................................................... 4

Related Documentation .................................................................................................. 4

Compatible Mass Spectrometers ..................................................................................... 4

WEEE compliance: Directive 2002/96/EC ........................................................................ 4

EMC Compliance: Directive EMC 2014/30/EC................................................................... 5

Low Voltage Safety Compliance: Directive LVD 2014/35/EC ............................................. 5

Notices and symbols used in this manual......................................................................... 5

Contacting us.................................................................................................................. 5

General safety precautions and important notes ............................................................. 6

SUPER SESI, general description............................................................................... 7

Principle of operation ..................................................................................................... 7

Intended use................................................................................................................... 7

Complete system: SUPER SESI ......................................................................................... 8

Components: Main Body................................................................................................. 9

Components: Electrospray vial holder ........................................................................... 10

Components: Electrospray Probe................................................................................... 10

Components: Sample inlet protection cover .................................................................. 11

Components: Nano-amperemeter................................................................................. 11

Components: nano-amperemeter charging unit............................................................. 12

Symbols used in the SUPER SESI .................................................................................... 12

Technical specifications................................................................................................. 13

Installation ............................................................................................................ 14

Installation requirements.............................................................................................. 14

Unboxing the SUPER SESI .............................................................................................. 14

Coupling the SUPER SESI and the Mass Spectrometer .................................................... 14

Changing the electrospray liquid ................................................................................... 16

Changing the electrospray silica capillary....................................................................... 18

Operation.............................................................................................................. 21

Adjusting the temperature............................................................................................ 21

Adjusting the clean gas flow and the sample gas flow .................................................... 22

Starting the electrospray............................................................................................... 25

Introducing samples and acquiring data......................................................................... 26

Stopping the electrospray ............................................................................................. 28

High temperature cleaning cycle.................................................................................... 28

Removing the SUPER SESI from the MS.......................................................................... 28

Maintenance ......................................................................................................... 29

Required materials........................................................................................................ 29

Cleaning the vapor path ................................................................................................ 29

Charging the Nano-amperemeter .................................................................................. 31

Resetting overheating protection relays ........................................................................ 32

Replacing the fuses ....................................................................................................... 32

Trouble-shooting ................................................................................................... 32

Page 4 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Preface

This User Manual describes how to install, remove, use and maintain the SUPER SESI source

developed and commercialized by Fossil Ion Technology.

If you would like to suggest a change in this document, or if you need further assistance, please

email us at info@fossiliontech.com. You can also contact us through our online contact form:

http://www.fossiliontech.com/contact-us/

Related Documentation

The SUPER SESI source works in tandem with the mass spectrometers of Thermo Fisher

Scientific. Please read the corresponding instruction manual of the mass spectrometer and

observe its indications when using the SUPER SESI.

Compatible Mass Spectrometers

SUPER SESI is compatible with the following mass spectrometers:

•Orbitrap Q-Exactive Series

•Orbitrap Exactive series

•LTQ Series

•LCQ Fleet Series

•Orbitrap LTQ

•Orbitrap Elite

We are working to increase the number of compatible mass spectrometers. If you have

instrument compatibility questions, please contact us via email: info@fossiliontech.com You can

also contact us through the contact form in Fossil Ion Technology web page:

http://www.fossiliontech.com/contact-us/

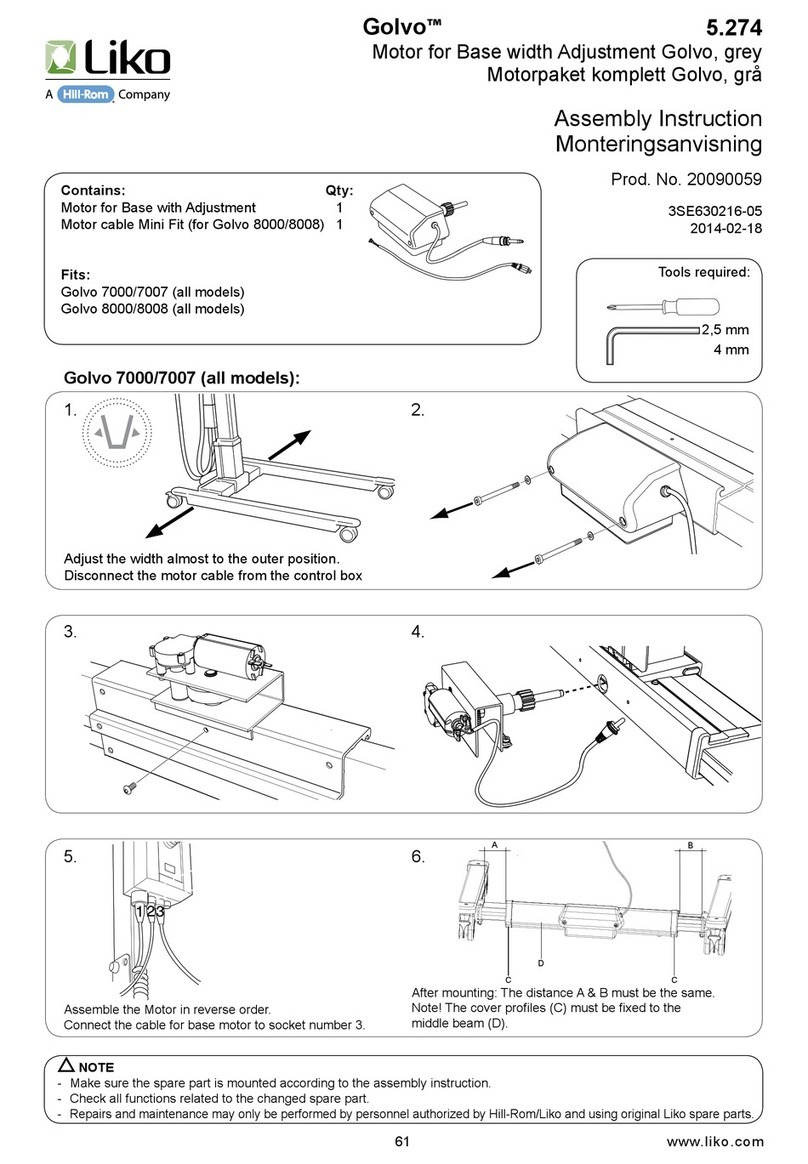

WEEE compliance: Directive 2002/96/EC

This product complies with the European Union’s Waste Electrical & Electronic Equipment

(WEEE) Directive 2002/96/EC. It is marked with the following symbol:

If this product is located in Europe and you want to discard it, please send an email request to

info@fossiliontech.com with the following information:

•Product specification

•Number of product pieces and estimated total weight and volume

•Pick-up address and contact person (please include contact information)

•Declaration of decontamination, stating that all hazardous fluids or materials have been

removed from the product.

Page 5 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Fossil Ion Technology shall contact you and arrange a pick-up service at the most convenient

time to recycle your product at no cost for you. Please note that this recycling program is not

for biological hazard products and contaminated products. You must treat these types of

products as biohazard waste and dispose of them in accordance with your local regulations.

SUPER SESI is specifically designed solely for the purposes of research and development.

EMC Compliance: Directive EMC 2014/30/EC

SUPER SESI meets the requirements of the directive EMC 2014/30/EC. It has been tested, and it

is in accordance with the norm IEC 61326-1.

Low Voltage Safety Compliance: Directive LVD 2014/35/EC

SUPER SESI meets the requirements of the directive LVD 2014/35/EC. It has been tested, and it

is in accordance with the norm IEC 61010-1.

Notices and symbols used in this manual

Please make sure that you understand the special notices, symbols, and caution labels in this

guide. Most of the special notices and cautions appear in boxes; those pertaining to safety also

have corresponding symbols. Some symbols are also marked on the SUPER SESI source itself and

can appear in color or in black and white. Some safety and notices used in this user manual

include the following:

CAUTION NOTE highlights hazards to humans, property, or the environment. Each

CAUTION warning is accompanied with the corresponding CAUTION symbol.

IMPORTANT NOTE highlights information to prevent invalid test results, damage to

software or loss of data.

INTERESTING NOTE highlights information of general interest

TIPS & TRICKS highlights key information that can be useful to complete of a task or to improve

the quality of the results.

Contacting us

If you need further assistance, please contact us.

Address: Fossil Ion Technology S.L.: Calle la Gitanilla No. 17, Nave 22; ZIP 29004, Malaga, Spain.

Technology web page: http://www.fossiliontech.com/contact-us/

Page 6 of 34

SUPER SESI, by FIT User manual, Revision 2.0

General safety precautions and important notes

CAUTION Do not perform any servicing that is not contained in this manual. In order to

avoid injury or damage to the instrument, do not perform any servicing that is not

specified in this manual unless you are qualified to do so.

CAUTION Some parts of the SUPER SESI are heated for optimum performance. The

sample line and the ionization chamber are heated by electric resistors. The

electrospray probe can be heated by thermal conduction. These parts may cause burns

if touched. Allow heated components to cool before touching them, and prevent other

persons to touch them.

CAUTION The tip of the electrospray silica capillary is very sharp and small. It can

puncture the skin, and it can be harmful to the eye. Handle it with care and wear safety

glasses when handling the silica capillary.

CAUTION The recommended electrospray liquid is high purity water with 0.1% formic

acid, but other solvents can also be used, including flammable solvents such as

methanol or ethanol. Use care when handling these solvents. Also, be cautious when

handling the system in the presence of flammable materials. The SUPER SESI could

produce small glow discharges that could ignite flammable atmospheres.

CAUTION The SUPER SESI uses the high voltage that is provided by the Mass

Spectrometer. The SUPER SESI incorporates three high resistors (1 GOhm each) to

reduce the currents down to 0.03mA in the event that an electrode is exposed to ground

or to a person. This current is well below the hazardous threshold and the threshold

that can be felt by a human. Nevertheless, to prevent damage to the instrument, the

electrodes should not be touched when the voltage is applied.

IMPORTANT NOTE The SUPER SESI is a very sensitive instrument. It is very vulnerable

to contamination, which can be observed as background signals. Even if no chemically

hazardous substances are used, always use gloves when handling the SUPER SESI to

avoid contaminating it.

Page 7 of 34

SUPER SESI, by FIT User manual, Revision 2.0

SUPER SESI, general description

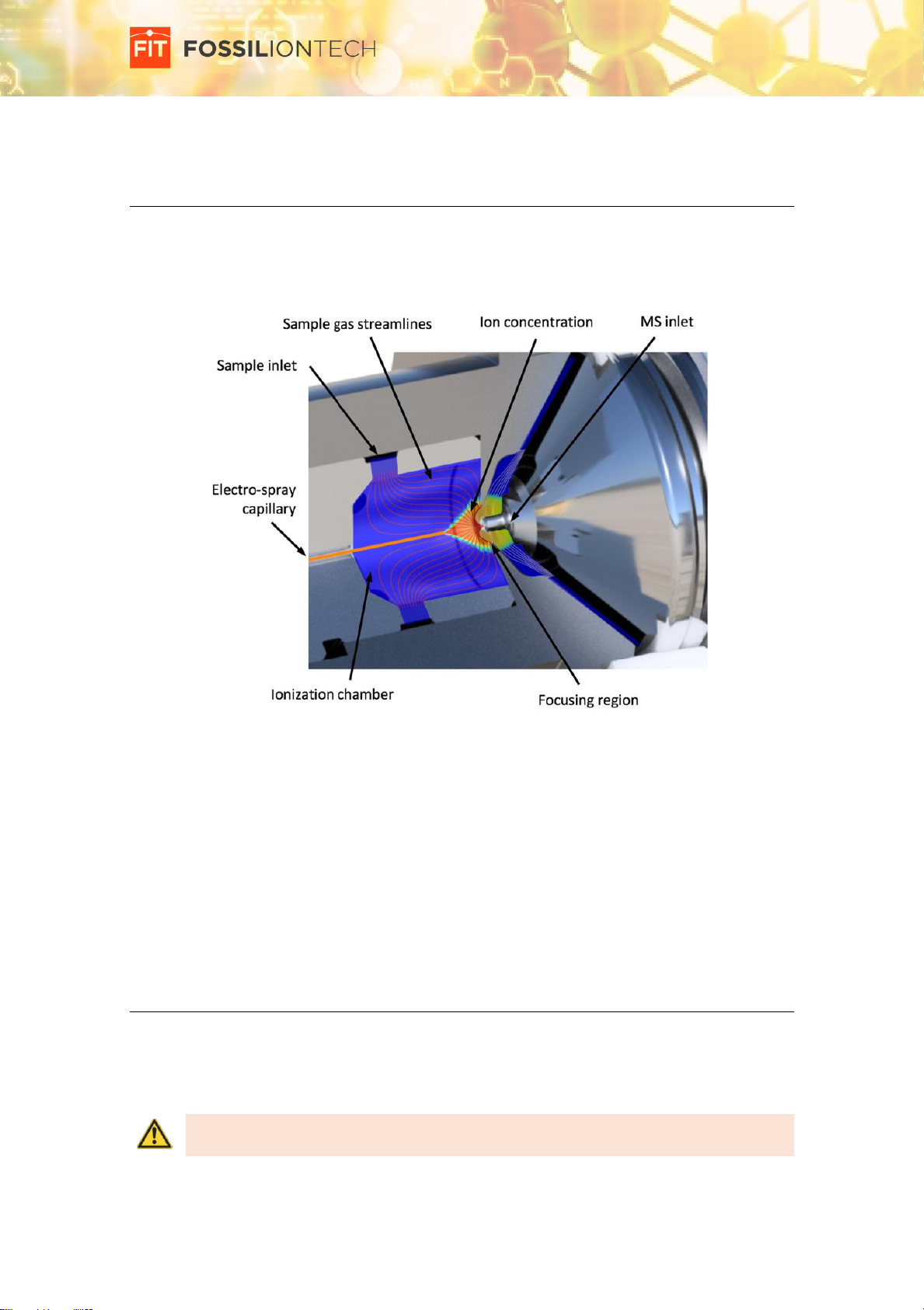

Principle of operation

A nano-electrospray creates the ions that are used to charge the molecules of interest, which

are introduced though the sample line. The molecules of interest and the charging ions react at

ambient pressure to form analyte ions. These ions are then passed to the mass spectrometer

for analysis.

Ions are not fragmented, enabling for MS-MS analysis and reliable analyte identification.

An accelerated flow is used to radially confine the ions and focus them to the mass inlet, without

perturbing the ionization region. The fast response of the ionizer enables kinetic studies, which

eases to identify specific responses to controlled stimuli, and to differentiate confounding

variables from real discoveries.

SUPER SESI incorporates all the components and controls in one single unit. It is ready to connect

with the MS and start analyzing. Very little sample preparation and virtually no laboratory

consumables are required. SUPER SESI is designed to easily replace the capillary when required.

A nano-ampere meter is used to monitor the stability of the electrospray.

Intended use

SUPER SESI is designed to be coupled with a mass spectrometer and to be used by trained

personnel in a laboratory environment. The purpose of SUPER SESI is to enable analysis of VOCs

at trace concentration. It is not intended for use with concentration of substances that could be

harmful or corrosive.

CAUTION The safety of this equipment could be compromised if it is not used in the

manner specified in this manual.

Page 8 of 34

SUPER SESI, by FIT User manual, Revision 2.0

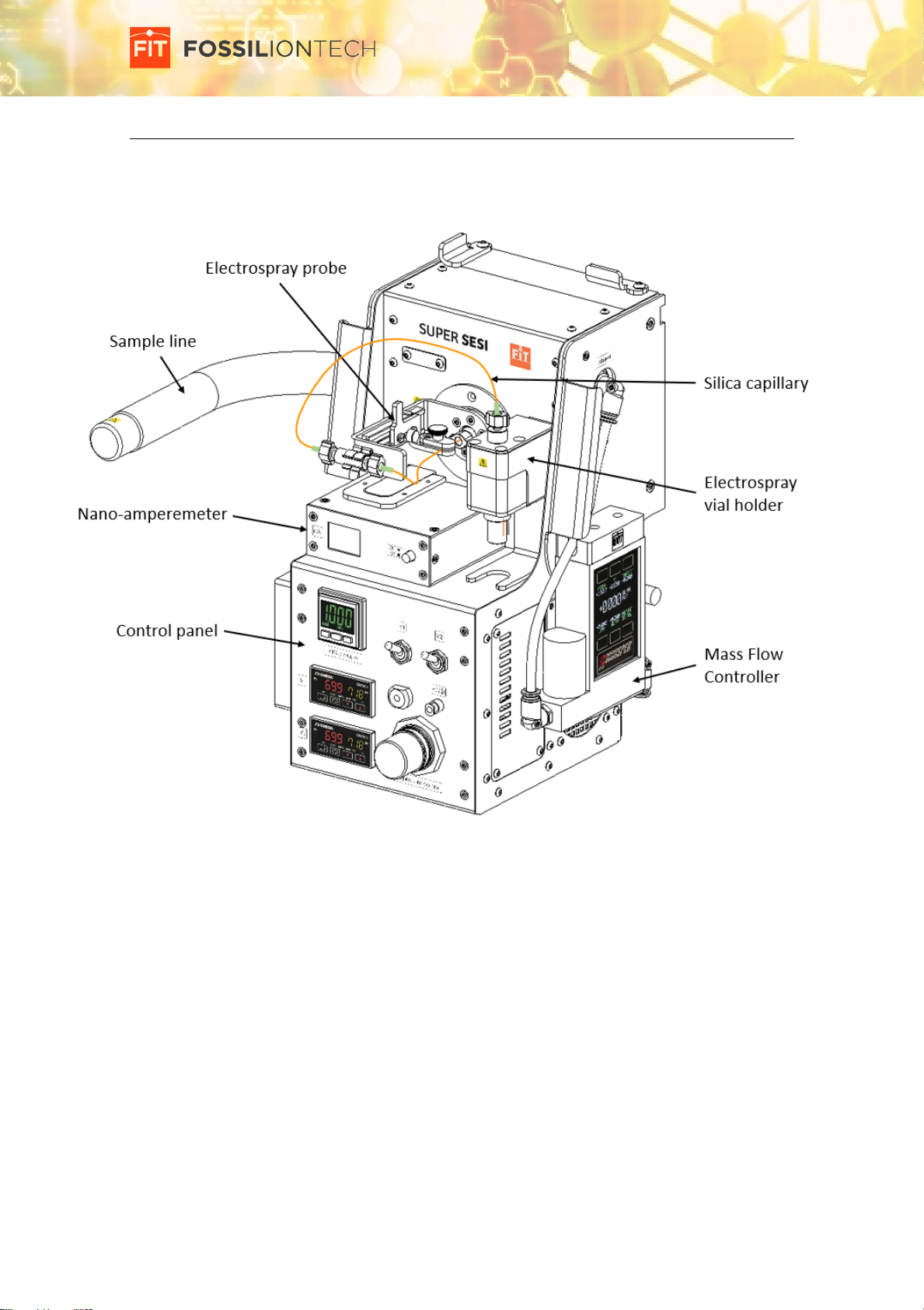

Complete system: SUPER SESI

Figure 1. SUPER SESI front view.

Page 9 of 34

SUPER SESI, by FIT User manual, Revision 2.0

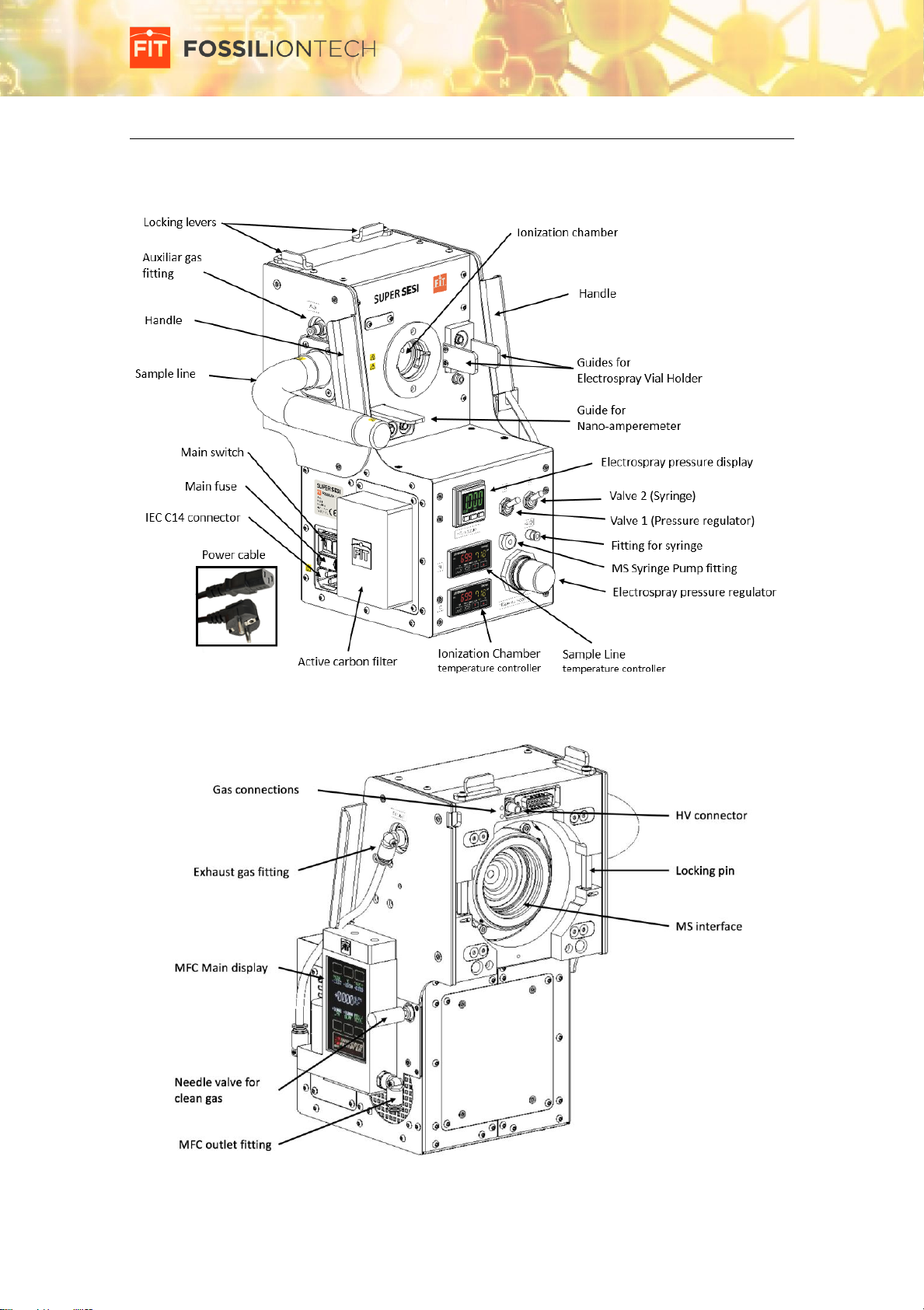

Components: Main Body

The main body incorporates the ionization chamber, the sample line, all the controls, and the

coupling with the mass spectrometer.

Figure 2. Main body, front view.

Figure 3. Main body, rear view.

Page 10 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Components: Electrospray vial holder

The electrospray vial holder incorporates all the connections and fittings required to produce

the electrospray. It can be seamlessly coupled and decoupled with the main body to ease

operation and cleaning procedures.

Figure 4. Electrospray vial holder

Components: Electrospray Probe

The electrospray probe houses the tip of the silica capillary, and incorporates a positioning

system that allows repeatable and optimum conditions. It closes the ionization chamber and

guides the sample gas smoothly to the electrospray tip to minimize convective evaporation at

the meniscus of the spray, thereby improving the stability of the spray at temperatures close to

the boiling point of the electrospray liquid.

The handgrip is thermally insulated with ceramic spacers to ensure that the parts in contact with

the sample gas can be maintained at high temperature while the parts in contact with the user

remain at safe temperatures.

Figure 5. Electrospray probe.*The figure may differ from the latest design.

Page 11 of 34

SUPER SESI, by FIT User manual, Revision 2.0

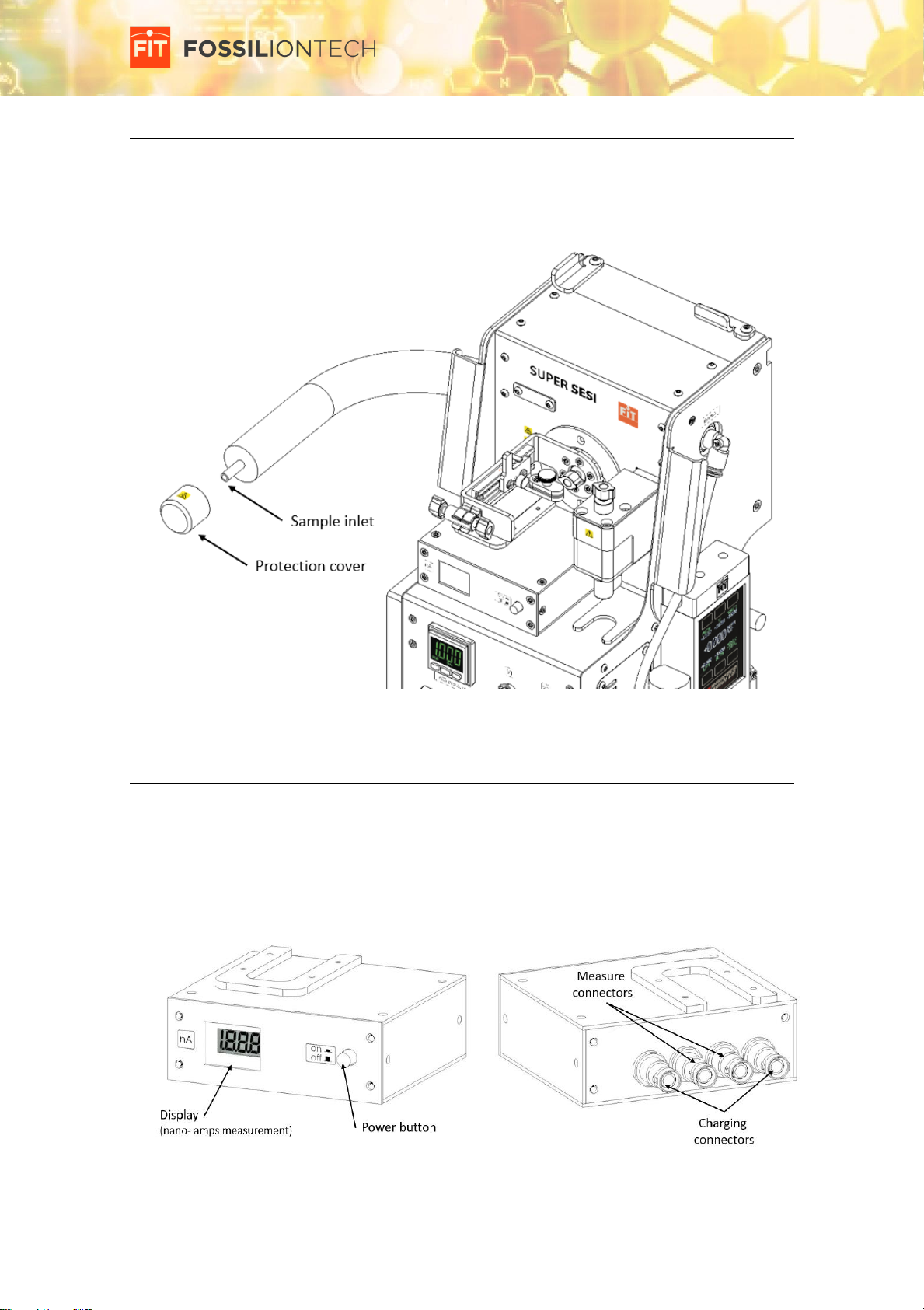

Components: Sample inlet protection cover

The inlet of the sample line is protected with a Teflon cover to prevent contamination when it

is not being used and to protect the user from high temperature surfaces. This cover must be

removed in normal usage.

Figure 6. Sample inlet protection cover.

Components: Nano-amperemeter

The nano-amperemeter provides a measurement of the electrospray current. This parameter

and the current measured by the mass spectrometer are used to evaluate the stability of the

electrospray. The nano-amperemeter is not externally powered. Instead, it uses rechargeable

batteries to avoid any leaked currents. It can be easily connected with the main body, and with

the charging unit when the batteries need to be recharged.

Figure 7. Nano-amperemeter

Page 12 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Components: nano-amperemeter charging unit

This unit charges the nano-amperemeter while they are connected. A Status LED indicate if the

nano-amperemeter batteries are charging (red light) or fully charged (green light).

Figure 8. Nano-amperemeter charging unit

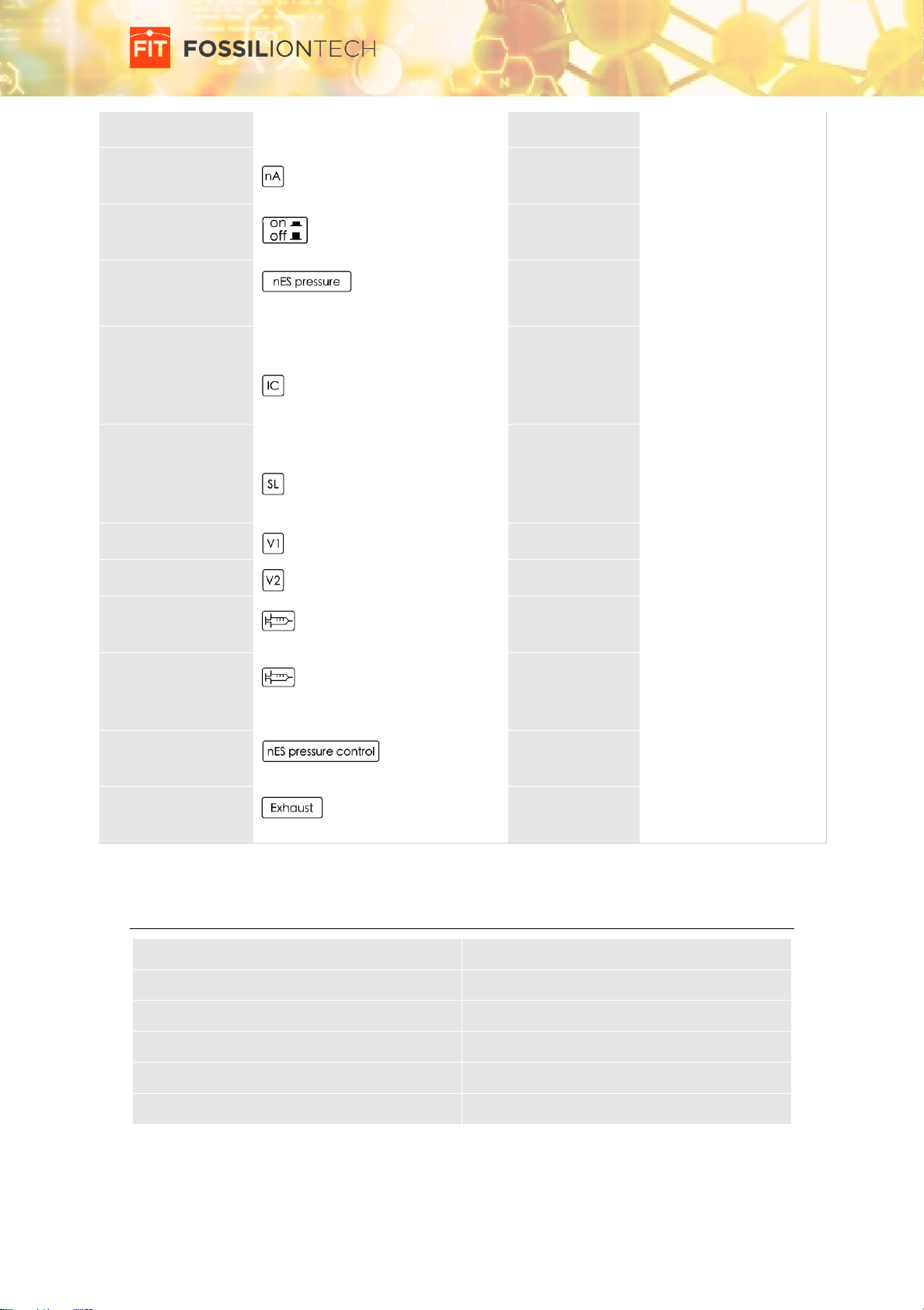

Symbols used in the SUPER SESI

Label Name

Label design

Location

Purpose

Identification label

Besides power

connector

Identification.

Contact us

Rear panel

Contact info. for

technical assistance.

General warning

Front panel

Identify potential risks.

Hot surface

warning

Near ionization

chamber &

sample line

Identify potential hot

surface.

High voltage

warning

Near power

input

Identify power voltage.

Ruler

Electrospray

probe

To position the tip of

the electrospray

Aux gas outlet

identifier

Near aux gas

Identify aux gas outlet

Page 13 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Label Name

Label design

Location

Purpose

NanoAmp units

Near nanoAmp

display

Identify nanoAmp units

NanoAmp on/off

Near nanoAmp

on/off button

Identify button

nES pressure

display

Near nESI

pressure display

Identify display

Ionization chamber

temperature

control identifier

Near ionization

chamber

temperature

controller

Identify controller

Sample line

temperature

control identifier

Near sample

line

temperature

controller

Identify controller

Valve V1 identifier

Near valve V1

Identify valve V1

Valve V2 identifier

Near valve V2

Identify valve V2

Syringe inlet

identifier

1

Near syringe

inlet

Identify syringe inlet

Syringe pump

steam cleaning

inlet

2

Near syringe

inlet

Identify syringe inlet

nES pressure

control identifier

Near Pressure

control

Identify pressure

control

Exhaust identifier

Near exhaust

outlet

Identify exhaust outlet

Technical specifications

Power:

220-240 V, 50-60 Hz, 250VA

Dimensions:

207x200x291 mm

Weight:

10Kg

Max. temperature of sample line:

180ºC

Max. temperature of ionization chamber:

130ºC

Protection level:

IP20

Page 14 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Installation

Installation requirements

The SUPER SESI is an ion source for mass spectrometry analysis. In order to function, it must be

coupled with a compatible mass spectrometer. It requires an electric power receptacle 230 V

ac, ±10%, frequency of 50/60 Hz, single phase. The SUPER SESI must be powered with the same

ground connection, and the same phase as the mass spectrometer.

A small table located near the working area is required to place the source and the different

components during initial installation and routine operation.

SUPER SESI is designed to operate under the following conditions:

•Indoor use; altitude up to 2 000 m; temperature 5°C to 40°C; maximum relative humidity

80% for temperatures up to 31°C, decreasing linearly to 50% at 40°C;

•TRANSIENT OVERVOLTAGES up to the levels of OVERVOLTAGE CATEGORY ll;

•applicable POLLUTION DEGREE of the intended environment (POLLUTION DEGREE 2).

IMPORTANT NOTE SUPER SESI does not incorporate circuit breakers or residual current

breakers. It only incorporates protection overcurrent fuses (1A). The user must ensure

that the electrical power installation for SUPER SESI provides the required electrical

protections, in accordance with local legislation.

Unboxing the SUPER SESI

The SUPER SESI is packed with the nano-amperemeter, the vial holder, the electrospray probe

and the Mass Flow Controller in their working position. In order to protect the SUPER SESI from

contamination during shipping, the MS interface is covered with a stainless steel cover. To get

the SUPER SESI out of its original packaging, grab the Handles and lift the SUPER SESI. Remove

the parafilm before using the SUPER SESI.

CAUTION Do not grab the sample line to lift the SUPER SESI.

IMPORTANT NOTE Make sure that no Parafilm is left on the SUPER SESI before you

start using it. In particular, make sure that all Parafilm is removed before you start the

SUPER SESI heaters.

Along with the SUPER SESI, you will also find the following: a power cord, a syringe and the

battery charger for the nano-amperemeter.

IMPORTANT NOTE Keeping the original packaging to store the SUPER SESI is strongly

advisable to prevent contamination of your SUPER SESI when it is not being used. The

SUPER SESI should be transported in its original package.

Coupling the SUPER SESI and the Mass Spectrometer

Before coupling the SUPER SESI to the Mass Spectrometer, the original Ion source and the ion

sweep cone must be removed. Remove the Thermo ion source housing and the ion sweep cone

from the mass spectrometer following the instructions indicated in the Operating Manual of the

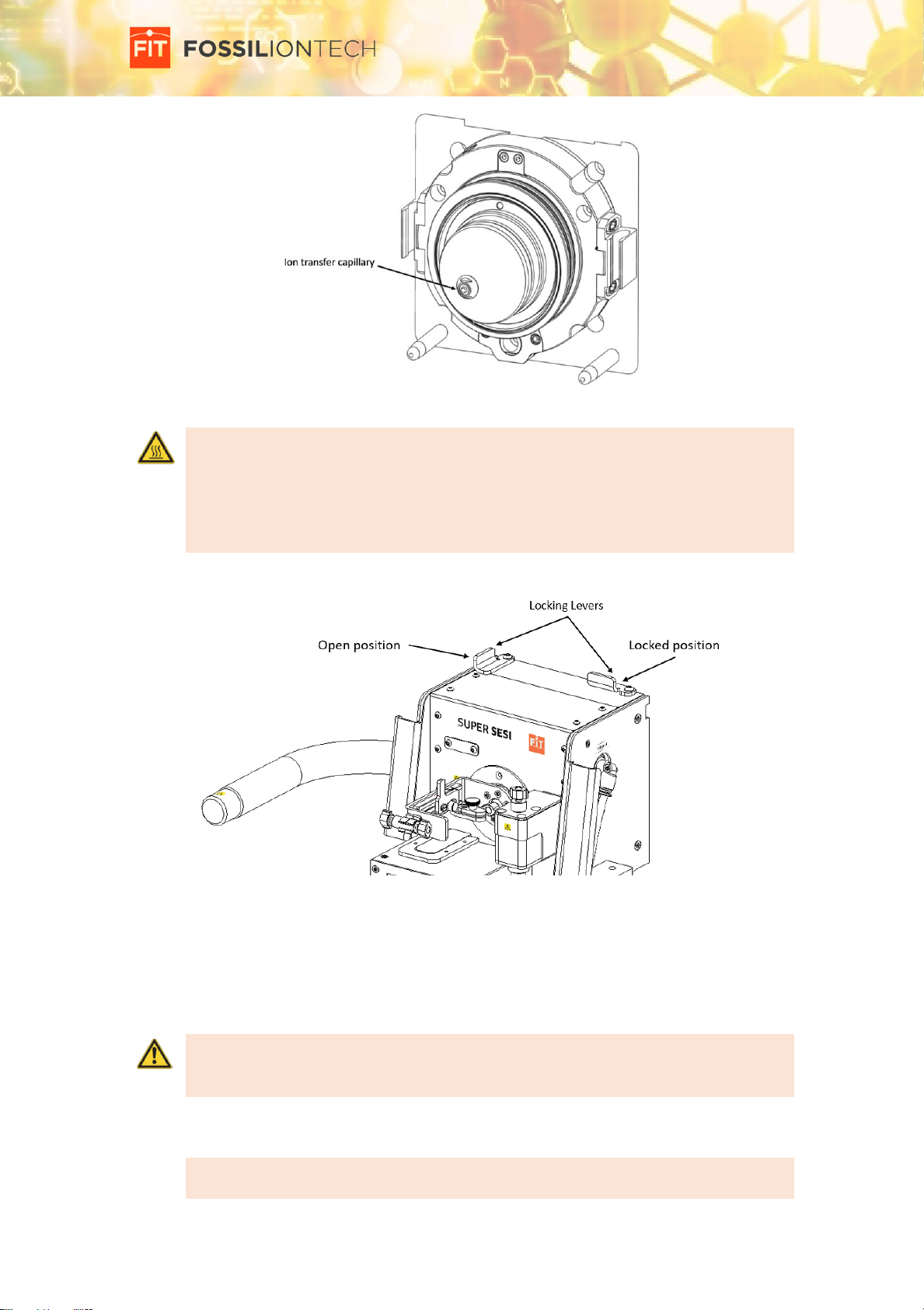

instrument. Once these components are removed, the inlet of your mass spectrometer should

have the appearance of the figure 9:

Page 15 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Figure 9. Inlet of the mass spectrometer

CAUTION Hot Surface. The ion transfer capillary typically operates at 250 to 400 ºC. Be

careful not to touch the capillary or the cone while it is hot. Before removing the sweep

cone, reduce the capillary temperature by setting the capillary temperature to 25 ºC,

and wait for the ion transfer capillary. Allow the ion transfer capillary to cool to room

temperature for approximately 60 minutes before you touch or remove either

component.

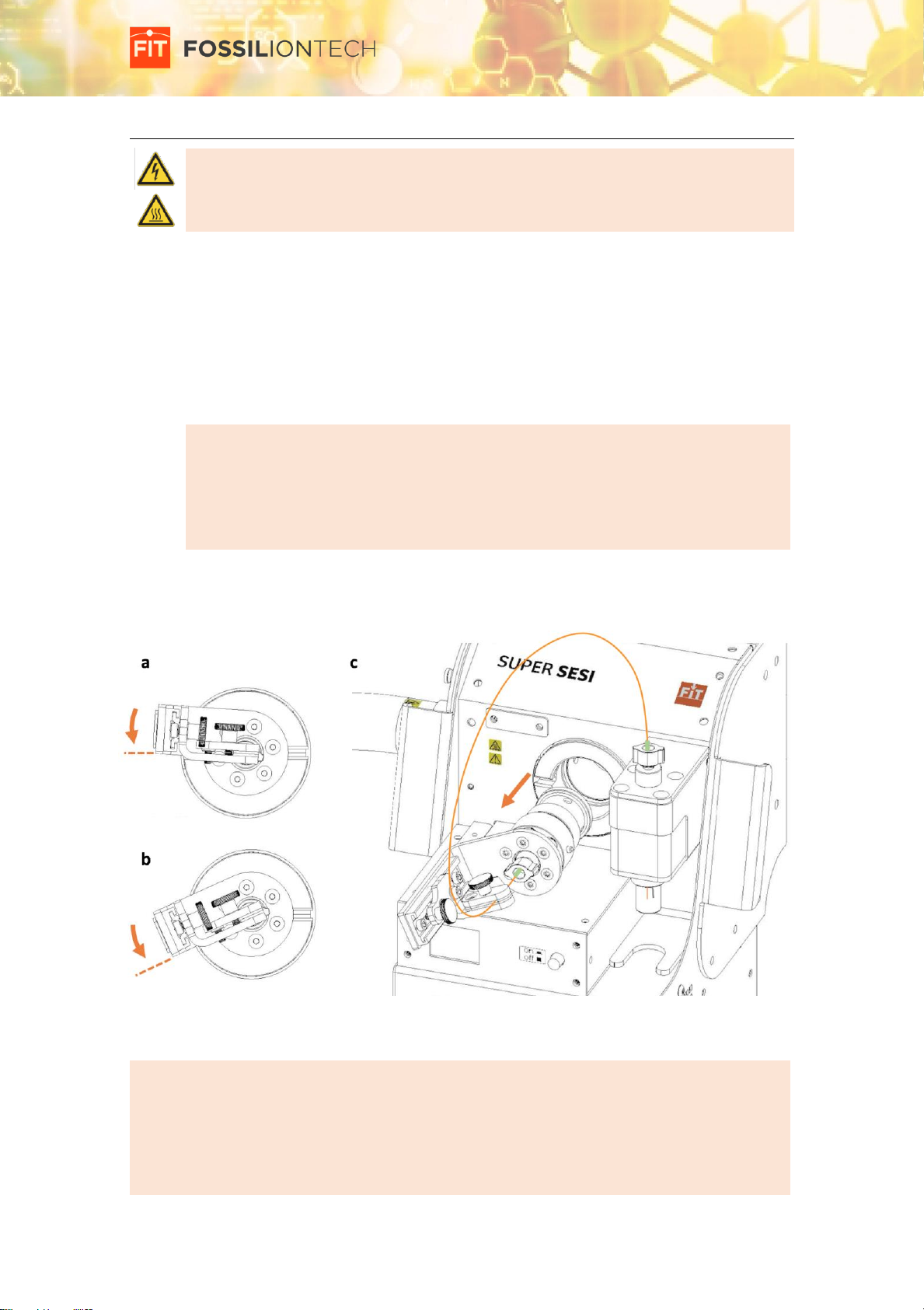

Make sure that the SUPER SESI locking levers are placed in the open position. See figure below:

Figure 10. SUPER SESI Locking Levers in open position.

Install the SUPER SESI on the mass spectrometer in the same way as the original Thermo ion

source. For this: Carefully align the two guide pin holes on the rear of the SUPER SESI with the

ion source housing guide pins on the mass spectrometer; Carefully press the SUPER SESI onto

the ion source mount using the handles; Rotate the SUPER SESI locking levers 90 degrees to lock

the SUPER SESI onto the ion source mount assembly.

CAUTION Use the SUPER SESI handles to lift the SUPER SESI and to press it against the

Mass Spectrometer. Do not grab the sample line or other parts to lift the SUPER SESI.

Doing so could damage the sample line.

Finally, connect the power cable from the IEC C14 connector in SUPER SESI to the wall power

receptacle.

IMPORTANT NOTE the SUPER SESI and the mass spectrometer must be connected to

the same line, and they must share a common ground and a common phase.

Page 16 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Changing the electrospray liquid

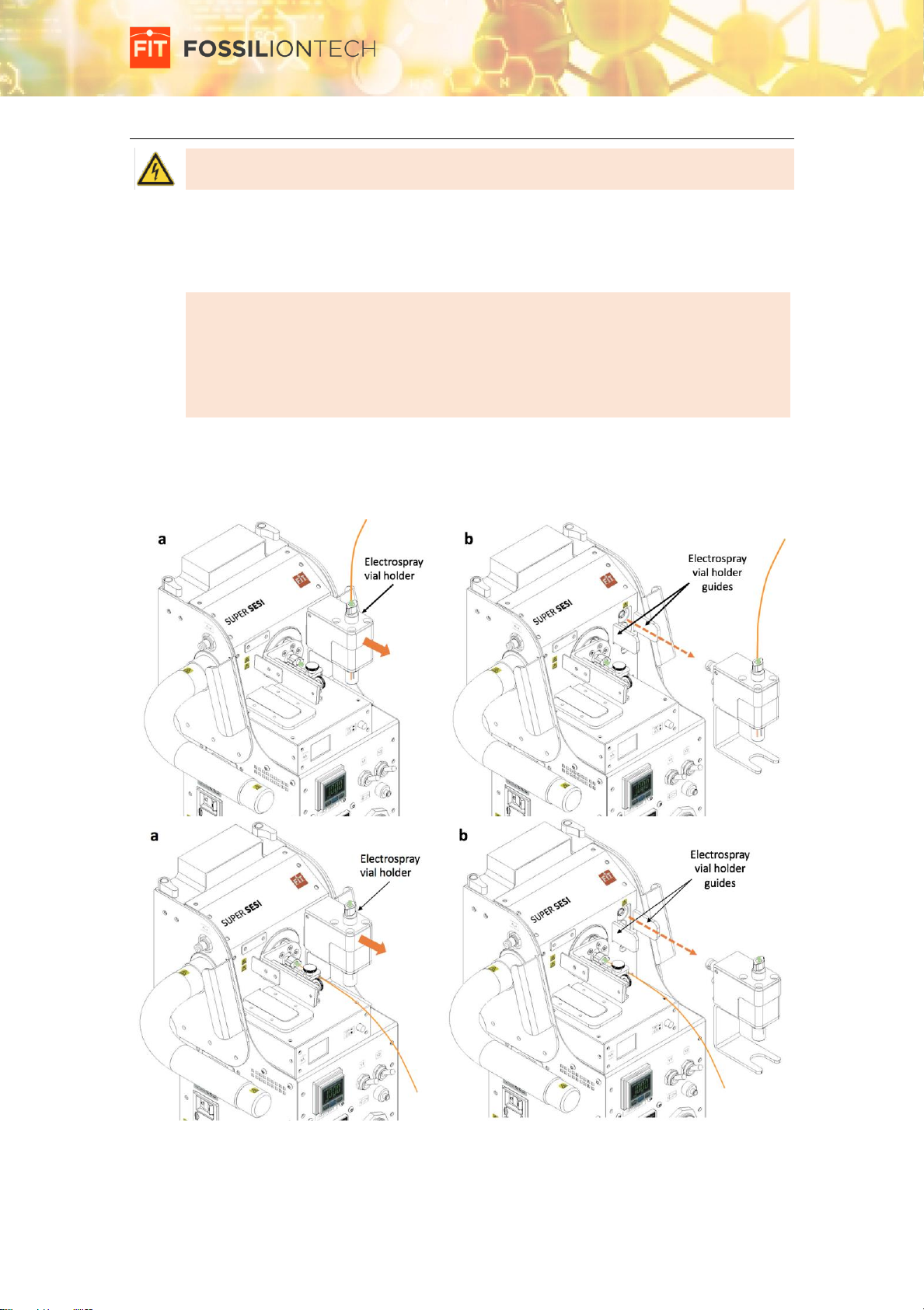

CAUTION During this operation, the electrospray voltage must be set to zero and the

pressure of the electrospray vial holder must be set to zero.

If the spray voltage is on, set it to zero. See section ‘Stopping the electrospray´ for more details.

If the MS is acquiring, set the MS to stand-by mode. Refer to the user manual of your mass

spectrometer for this. If the vial holder is pressurized, depressurize it. For this, make sure that

the syringe is not connected to the syringe port and open the syringe valve 2 (up position).

IMPORTANT NOTE It is very important to make sure that the electrospray liquid and

the vial holder are free from contamination. Always use gloves when manipulating

them, and make sure that all surfaces are very clean and free from any contamination

that could affect your measurements. If the vial holder or the electrospray liquid is

contaminated, the background of your measurements will be affected until you clean

the vial or change to a new liquid.

If required, the electrospray vial holder can be removed before changing the electrospray liquid.

For this, take the vial holder, and pull gently towards you. Before removing the vial holder, make

sure that the silica capillary is not simultaneously attached to the vial holder and the

electrospray probe.

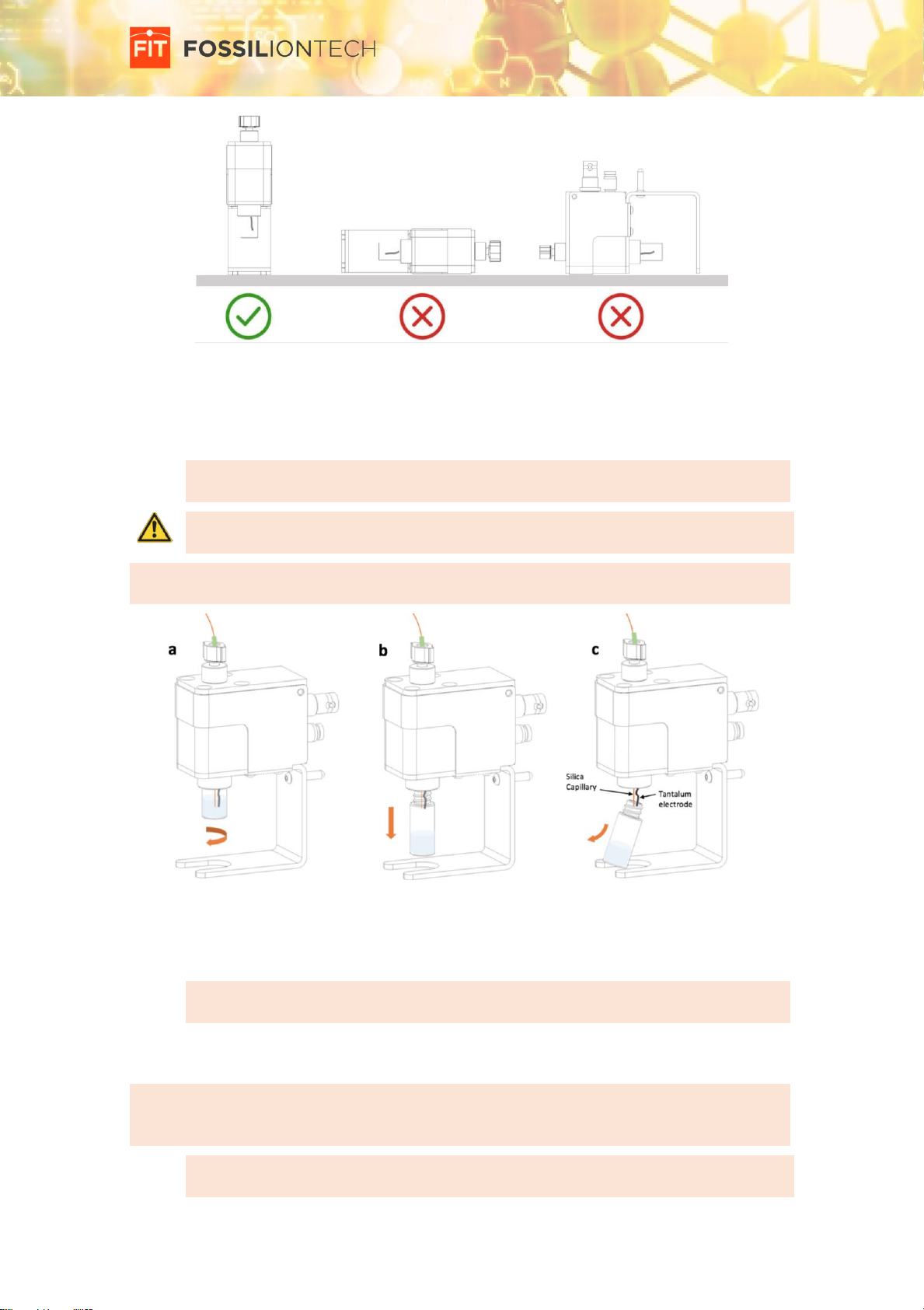

Figure 11. Removing Vial Holder. *The figure may differ from the latest design.

Use a horizontal and clean surface to place and store the Vial Holder. Always place the Vial

Holder vertically as shown in figure 12.

Page 17 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Figure 12. Storing the Vial Holder.

In order to change the liquid, with the voltage set to zero and the vial holder depressurized,

unscrew the vial using your fingers, gently pull the vial down, and the remove it making sure

that the tantalum electrode and the silica capillary are not bended.

IMPORTANT NOTE Be careful not to bend the Tantalum Electrode and the Silica

Capillary when removing the glass vial from the Vial Holder.

CAUTION. The vial is made of glass. If broken, sharp edges may by produced. Be careful

when handling the vial, specially when screwing, unscrewing and tightening it.

TIPS & TRICKS you can clean the tantalum electrode and the silica capillary by gently wiping it

with a Kimwipe soaked with new charging liquid.

Figure 13. Changing the electrospray liquid

Clean the vial or use a new clean vial with new liquid. The maximum level of liquid shall be 3/4

parts of the total glass vial capacity.

IMPORTANT NOTE Use a solution of 0.1% formic acid in H2O. Use only high purity (HPLC

grade) solvents and reagents.

Introduce the Tantalum Electrode and the Silica Capillary through the bore of the new vial. Be

careful of not to bend them. Slide the vial up to the top, and screw it until it is gas tight.

TIPS & TRICKS In order to check that the vial is gas tight, close the valve 1 (down position), open

the valve 2 (up position), pressurize the vial with the syringe, and close the valve 2 (down

position). If the vial is properly tightened, the pressure should be stable

CAUTION. The vial must be finger tight. Do not use tools to tighten or loose the vial.

Doing so could damage the vial and the vial holder.

Page 18 of 34

SUPER SESI, by FIT User manual, Revision 2.0

Changing the electrospray silica capillary

CAUTION During this operation, the electrospray voltage must be set to zero, the

pressure of the electrospray vial holder must be set to zero, and the temperature of the

ionization chamber must be set below 40ºC. Once the ionization chamber set

temperature is changed, wait for at least 30 min until it cools down.

If the spray is on, set the electrospray voltage to zero. See section ‘Stopping the electrospray´

for more details.

If the MS is acquiring, set the MS to stand-by mode. Refer to the user manual of your mass

spectrometer for this.

If the vial holder is pressurized, depressurize it. For this, make sure that the syringe is not

connected to the syringe port and open the syringe valve 2 (up position).

If the ionization chamber temperature is high, set it to a safe value and wait for it to cool down.

IMPORTANT NOTE It is very important to make sure that the silica capillary, the

electrospray probe and the electrospray vial holder are free from contamination.

Always use gloves when manipulating them, and make sure that all surfaces are very

clean and free from any contamination that could affect your measurements. If these

parts get contaminated by accidental contact with the skin or with other contaminated

surface, the background of your measurements will be affected until you clean them.

Once the system is cooled, the voltage is switched off, and the vial holder is depressurized,

unlock the electrospray probe, gently pull it out from the ionization chamber, and put it on the

maintenance position.

Figure 14. Unlocking the electrospray probe. *The figure may differ from the latest

design.

TIPS & TRICKS In order to reduce the pressure needed to pressurize the vial holder and create

the Electrospray, we recommend to use a sharp silica capillary (20um id) as short as

possible*, and an extension of silica capillary (50um id) unto the vial holder. For this, we

provide a Union fitting that is attached to the Electrospray Probe Handgrip, so the two

capillaries described previously can be connected at this point.

*This length must be long enough to reach the Fitting union (Figure 15).

Table of contents