FKI GL 9000 Series User manual

Users Manual

Turbomatic contact grill

GL 9000 series

Version 2.4 – SEP 2016

2

3

Content of this manual

Content of this manual .............................................................................3

1.Introduction ...............................................................................4

2.Generally ...................................................................................4

2.1.Manufacturer .......................................................................................................... 4

2.2.Machine plate ......................................................................................................... 4

Machine plate is placed in the back on the left side ........................................4

3.Overview and application .................................................................5

3.1.Generel description ................................................................................................ 5

3.2.The contact grill purpose and intended use .................................................................. 5

3.3.Warning on foreseeable misuse ............................................................................. 5

3.4.Technical specifications and consumption ............................................................. 5

3.5.Placement of the contact grill ................................................................................. 6

4.Safety and residual risks ...............................................................6

4.1.Safety precautions to be taken by the user ............................................................ 6

4.1.1.Personal safety equipment ................................................................................. 6

4.2.Residual risks ......................................................................................................... 6

5.Operation...................................................................................7

5.1.Quick-guide ............................................................................................................ 7

5.2.Programming .......................................................................................................... 7

5.3.Locking display ....................................................................................................... 8

5.4.Operating ............................................................................................................... 9

5.5.Stop ........................................................................................................................ 9

5.6.Emergency stop ..................................................................................................... 9

5.6.1.Restart efter emergency stop ............................................................................. 9

5.7.Adjustment ............................................................................................................. 9

5.8.Frying ..................................................................................................................... 9

6.Transport and installation............................................................10

6.1.Transport ...............................................................................................................10

6.2.Installation .............................................................................................................10

6.3.Demands to the installation place .........................................................................10

6.4.Connection ............................................................................................................10

7.Maintenance, fault-finding and repair .............................................11

7.1.Cleaining and order ...............................................................................................11

7.2.Preventive maintenannce ......................................................................................11

7.2.1.Fault finding .......................................................................................................12

7.3.Repair ....................................................................................................................12

7.3.1.Specifications on spare parts ............................................................................13

8.End of use ...............................................................................21

8.1.Destruction ............................................................................................................21

21

9.Annex .....................................................................................21

9.1.Labels, symbols and pictograms ...........................................................................21

9.2.EC Declaration of Conformity ................................................................................22

9.4.Wirering diagrams .................................................................................................23

4

1. Introduction

Original manual

This manual is FKI Fast Food Teknik A/S translation to the original instructions for Turbomatic

contact grill, hereinafter called the contact grill.

Purpose

The purpose of this manual is to ensure proper installation, use, handling and maintenance of con-

tact grill.

Accessibility

The instructions must be kept in a known place for staff where it is easily accessible to opera-

tors and maintenance personnel.

Knowledge

It is the employer's (owner of the contact grill) obligation to ensure that all who serve, main-

tain or repair the contact grill, read the instructions, at least those parts of it that are relevant to

their work.

Additionally, all who serve, maintain or repair the contact grill, must themselves seek information in

the instructions.

2. Generally

2.1. Manufacturer

The contact grill is manufactured by

Company name: FKI Fast Food Teknik A/S

Adress: Byghøjvej 5, Verninge

5690 Tommerup

Name of the contact grill:

The full name of the contact grill is Turbomatic GL 90xx.

2.2. Machine plate

Machine plate is placed in the back on the left side

5

3. Overview and application

3.1. Generel description

Turbomatic contact grill has been designed for simultaneous cooking on both sides, since the ma-

chine have an upper and a lower fry pan. The contact grill is made of stainless steel with an easy

to clean surface.

3.2. The contact grill purpose and intended use

The contact grill is for roasting meat with a uniform thickness, also directly from the frozen state.

3.3. Warning on foreseeable misuse

Do not use the contact grill for any purpose than frying meat products.

3.4. Technical specifications and consumption

Dimensions

GL 9001 GL 9002 GL 9003 GL 9010

Dimension W

x D x H [mm] 400 x 630 x 480 600 x 630 x 480 400 x 630 x 480 490 x 730 x 480

Weight 62 kg 85 kg 65 kg 95 kg

Note the height is set in the closed state (represented by frying). When open, an additional 200

mm space, so the maximum height is 680 mm.

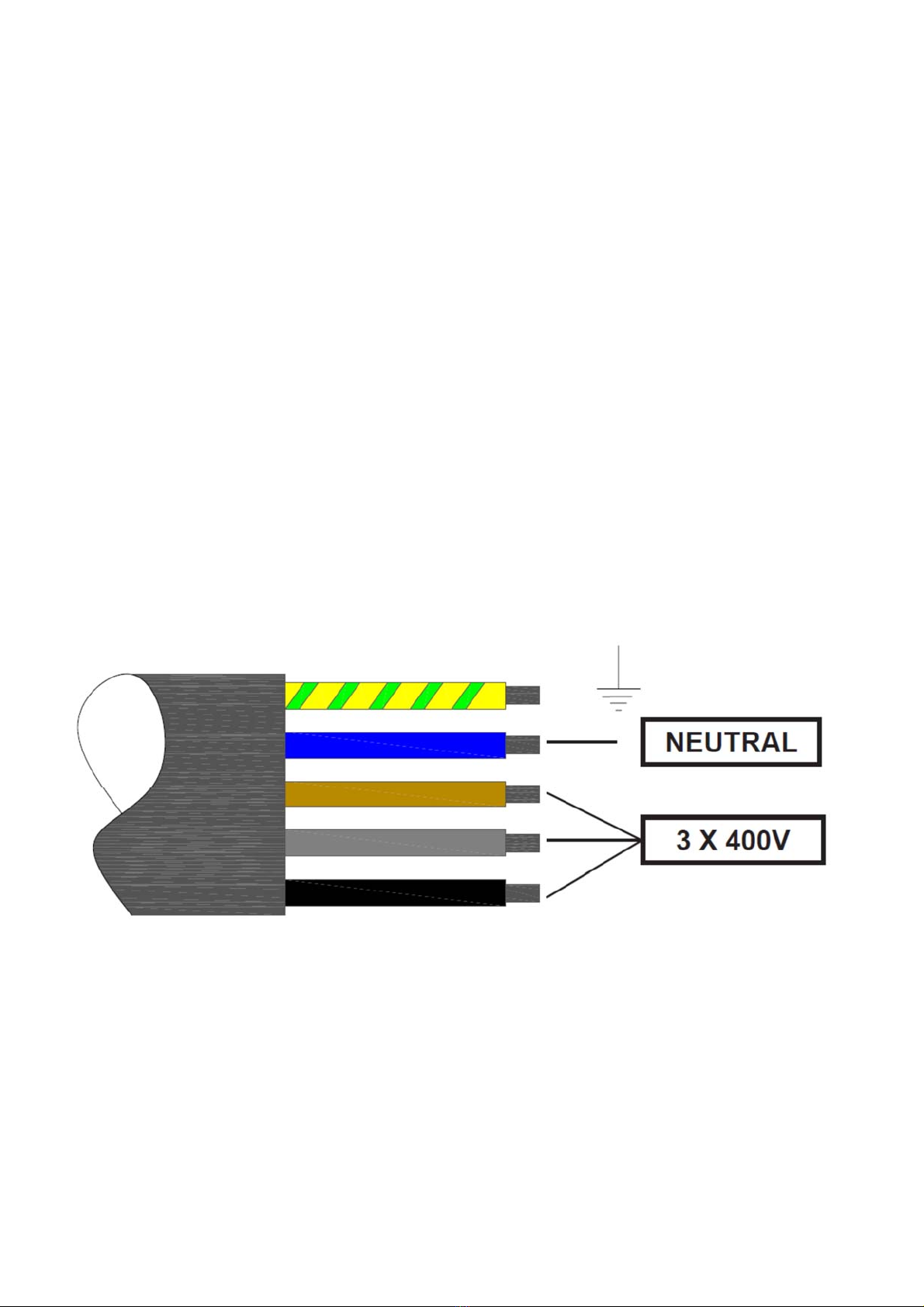

Electricity

The contact grill must be earth connected and RCD through connection socket.

Connection power: 3 x 400 V AC (3L + N + EG)

Connection frequency: 50/60 Hz

Connection

power

Absorbed

power

Absorbed

current

Min. Fuse in in-

stallation

GL 9001 400 V 8,8 kW 18,5 A 20 A

GL 9002 400 V 13,7 kW 19,2 A 20 A

GL 9003 400 V 9,8 kW 15,2 A 20 A

GL 9010 400 V 11,1 kW 16 A 16 A

Noise

Airborne noise coming from the contact grill:

6

Measured sound pressure level dB(A): < 70.

3.5. Placement of the contact grill

The contact grill must be set up on a table or the like in an appropriate working height.

Operation is done from the front of the contact grill.

For the sake of ventilation, allow free passage of air under and behind the machine.

The contact grill must be placed under hoods or other suction of cooking smells.

4. Safety and residual risks

4.1. Safety precautions to be taken by the user

4.1.1. Personal safety equipment

It is recommended to use gloves during the operation of the grill since there are several hot sur-

faces on the contact grill.

4.2. Residual risks

The surfaces, especially upper and lower fry pan, but also the housing of the upper

fry pan is very hot. Therefore take care not to touch these during operation of the

contact grill.

7

5. Operation

5.1. Quick-guide

The main switch mounted at the rear turns on the contact grill.

The contact grill will move the upper pan(s) to opened position and is

now in the Off mode. The display shows a small dot at bottom's right corner of the display,

indicating that there is power on the contact grill.

The contact grill is operated by pressing ON, and upper frying pan will close. The contact grill goes

into standby mode and begin heating to the preset standby temperature.

When this temperature is reached, the contact grill is ready for use.

Switch from standby to operation mode is done by pressing the + / Nor-

mal button. Then the upper fry pan opens, and the grill is ready for use, if

the standby temperature and normal temperature are equal pro-

grammed.

Place the meat on the bottom pan and press one of the program buttons

(1-3). The upper will close and the meat will fry on both sides in the pre-set time, as the display

counts down to 0, after which the upper pan opens, while a sound signal indicates that cooking is

completed.

If the contact grill is not used for a long time, it is recommended to put it on hold. This is done by

pressing the - / standby button and the upper pan will be closed to save energy.

5.2. Programming

All programming can only be done when the contact grill are in standby mode.

Programming of frying times:

1. Press [2] and hold for more than 10 sec. upper display will now show -2 –

2. Press (1-3) for the program that is to be changed. The display now showing the set-

ting value (in seconds) for the program.

3. Value is changed by pushing [+] or [-].

4. The program will return to the menu after 5 seconds. Wait until this happens and

changes are saved.

5. To leave the menu press [Reset].

8

Programming of temperatures:

1. Press [3] and hold for more than 10 sec. upper display will now show -3 –

2. Press button [1] to show the operation set temperature for the upper pan. Change the set-

ting by pushing + or -.

3. Press button [2] to show the operation set temperature for the lower pan. Change the set-

ting by pushing + or -.

4. Press button [3] to show the standby set temperature for both pans. Change the setting by

pushing + or -. Notice! Standby temperature shall be set close to the operation temperature

to avoid waiting for the temperature to rise when going from stand by to normal.

5. The program will return to the menu after 5 seconds. Wait until this happens and

changes are saved.

6. To leave the menu press [Reset].

.

Factory settings:

Standby temp. 240 °C

Normal temp.

upper pan 250 °C

Normal temp.

lower pan 240 °C

Program 1 130 sec.

Program 2 130 sec.

Program 3 130 sec.

5.3. Locking display

The display shows as well in standby as in normal mode the temperature off the lower pan. Show-

ing the temperature of the upper pan will occur shortly when turning from standby to normal opera-

tion.

During frying, there are major temperature fluctuations, which is quite normal. To let the user not

need to become confused about this, the view of the temperature is locked so that temperatures

above the preset appears as the preset. This means that when temperature exceeds the preset

temperature, this excess will not be displayed.

The lock can be revoked by in the stand-by mode to keep the ON button pressed for min. 10 sec.

The next time the contact grill off at OFF and switching ON will lock again be active.

9

5.4. Operating

The main switch on the backside of the contact grill turns on the Power to the contact grill.

By pushing the ON button, the contact grill is set to standby mode.

By pushing the +/Normal button the contact grill is set to operation mode.

5.5. Stop

The contact grill is stopped by pressing OFF, and the upper pan opens and all functions are

switched off.

If you wish to shut off the contact grill with the pan(s) down, turn to standby mode and thereafter

turn the main switch to OFF.

Interrupting a program (countdown of the cooking time) can be stopped by pressing the RESET.

Subsequently, the upper pan open and frying on the top stop. Note however that frying on the un-

derside is ongoing.

To shut off power to the contact grill turn the main switch on the back side to OFF.

5.6. Emergency stop

The upper pan can be stopped during movement by turning the main switch to OFF

5.6.1. Restart efter emergency stop

When the main switch is turned to ON, the contact grill will go in start up position with open pans.

5.7. Adjustment

The distance between the upper and lower pan should be ad-

justed to suit the thickness of the meat.

The distance is continuously adjustable between 5 and 25 mm,

by turning the adjustment knob on the top arm on the upper pan.

Turnning the knob clockwise will increase the distance and

countercloclwise reduces the distance.

5.8. Frying

By frying, the meat is placed as close as possible in the middle

of the upper pan. If there is more than one piece of meat it is

placed "symmetrically" around the centre. This is to avoid that

the upper pan "flips" and thus do not get full contact with the meat.

10

6. Transport and installation

6.1. Transport

The contact grill should only be transported when fastened to a pallet or similar.

6.2. Installation

The contact grill is to be installed on flat ground, counter top or the like. The legs shall be adjusted

so that the contact grill is higher in the rear than in front, so excess fat can drain to the fat drain.

6.3. Demands to the installation place

The surface of the contact grill must have sufficient capacity. See the technical data section. 3.4.

In particular, if the counter top is hanging on the wall be aware that this is firmly attached and that

the wall is suitable for fixing of heavy loads.

Note that there must be free passage of air behind the machine, underneath the machine and in

front of the machine. Do not place any objects, cloths, gloves or the like that can prevent a free cir-

culation of air.

6.4. Connection

Only authorized personnel shall connect the contact grill. Plug are not part of the delivery but can

be ordered separately.

Be aware that the installation is done properly with adequate fuse and be-protection against fault

current and grounding.

11

7. Maintenance, fault-finding and repair

7.1. Cleaining and order

It is important that the fat drawer is regularly emptied of excess fat, as this will overflow.

Use the provided spatula to periodically scrape excess grease into the grease drain. If possible,

use paper to dry pans of, like after every 5th-10th frying.

Daily cleaning is performed when the contact grill has cooled of. Dry cabinets with a damp cloth

with a mild detergent. Wipe dry with a dry cloth or paper.

Grease drawer is emptied and cleaned in hot water with a mild detergent if necessary. Or in the

dishwasher.

Once a day must pans thoroughly be cleaned so that all food residues are removed. If possible,

use a stainless steel sponge with mild detergent. The pan must be completely cleaned and appear

"blank". Wipe dry with clean cloth or paper.

If Teflon sheet is used in the pans, clean them with a damp cloth with a mild cleaning agent. We

recommend using Teflon sheet (supplied) as it prevents burn-in, and facilitate subsequent clean-

ing.

7.2. Preventive maintenannce

Replacing the Teflon sheet on the upper pan is performed as needed. Always do this when the

contact grill is cold.

The teflon sheet is mounted with adhesive tape. Remove the foil from the pan on both sides.

Possibly residual adhesive from the tape, can be removed with a scraper. Heating of the machine

to about 50°C can ease that process. Use a damp cloth or steel sponge with detergent to com-

pletely remove glue residue. Remember to turn off the machine before it becomes too hot.

When the contact grill again cools down, the new film is mounted. Remove the tape on one side

and place the teflon sheet on the edge of the upper pan cabinet. Remove the tape on the other

side, and set the adhesive film in place.

12

7.2.1. Fault finding

Problem Cause / Possible solution

Display shows 1 Sensor on lower heat element is short circuited – Change the sensor

Display shows 2 Sensor on lower heat element is disconnected – Check connection

Display shows 3 Sensor on upper heat element is short circuited – Change the sensor

Display shows 4 Sensor on upper heat element is disconnected – Check connection

The are no light in the display Make sure the power cord is plugged in and that any safety switch is

turned on and the main power switch on the back of the machine is ON.

Still no light in the display Check the fuse on the back of the machine

Still no light in the display Check the power switch on the back of the machine if there is live volt-

age on all phases.

There is no light in one display

(other is OK)

Check the power switch on the back of the machine if there is live volt-

age on all phases.

Still no light in one display

(other is OK) Check the TRAFO for the PCB

Still no light in one display

(other is OK) Check the fuse on the PCB

Still no light in one display

(other is OK)

Try to connect a new keypad, to check if it's the keyboard that is defec-

tive.

The plug must be installed correctly on the PCB, the shiny side must face the pan

Still no light in one display

(other is OK)

Try to connect a new PCB in order to check if the PCB is defective.

If you change the PCB it must be checked that the new PCB is programmed correctly

with Temperatures and times, check the operating instructions.

The pan(s) are not functioning

(open/close) Check the ring trafo for actuators (motors).

The pan(s) are not functioning

(open/close) Check rectifyer for actuators (motors).

One of the pans are still not

functioning (other is OK)

Check wiring from PCB to actuator. (Meassuring 1 and 2 on the rear

terminal blocks must show 24V DC)

One of the pans are still not

functioning (other is OK) Change actuator

There are no heat in one or

more heat elements

Check solid state relay, to the heat element that is not heating up

There are no heat in one or

more heat elements Check the heat element by measuring directly on the element

7.3. Repair

Authorized service personnel with knowledge of electrical appliances should always perform re-

pair.

13

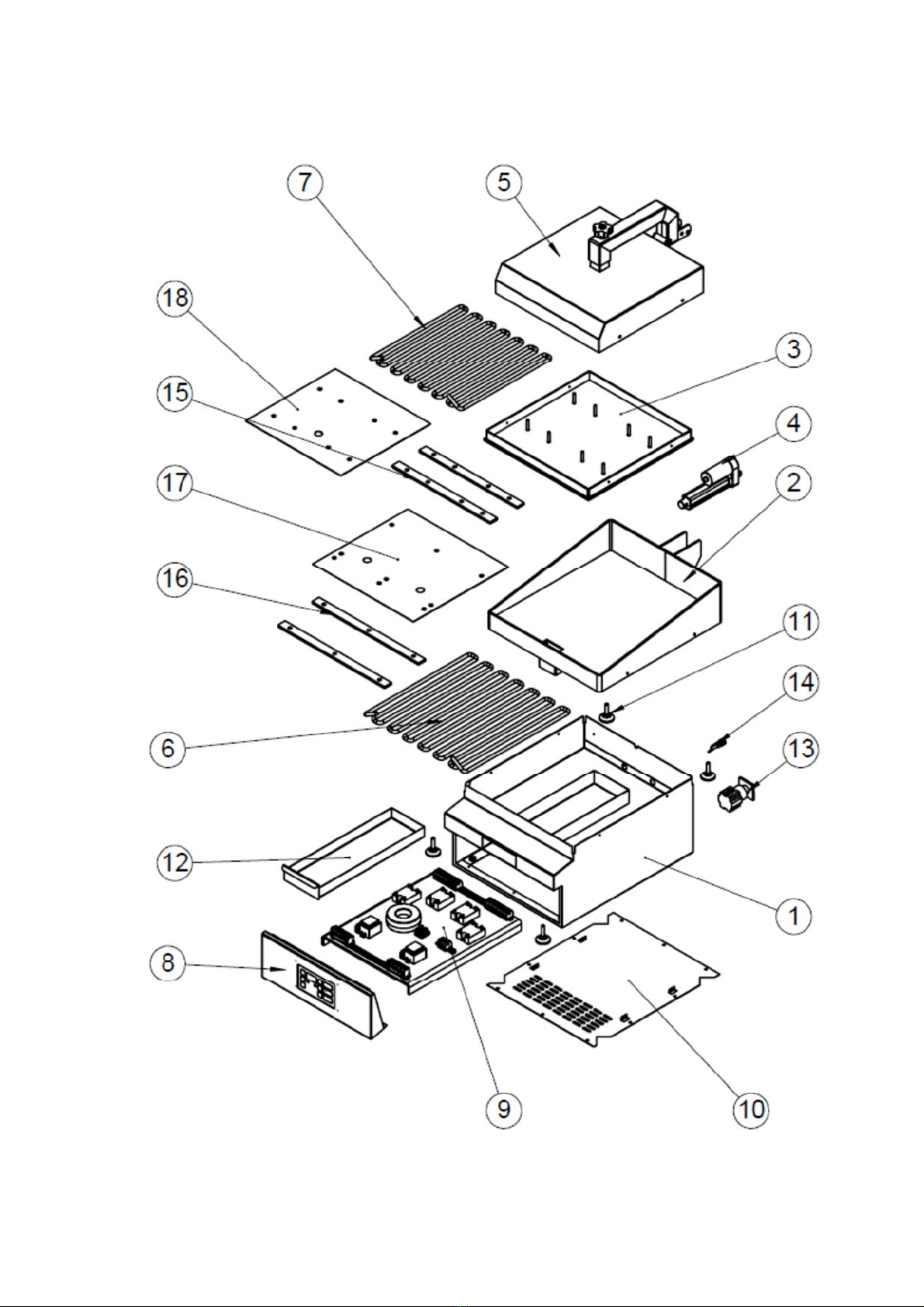

7.3.1. Specifications on spare parts

GL 9001

14

Pos. Part no. Pcs. Description

1 83-10314 1 Bottom cabinet GL 9001

2 83-10315 1 Pan GL 9001, lower

3 83-10279 1 Pan upper large

4 83-10022 1 Actuator MLA-2

5 83-10237 1 Top cabinet large incl. arm

6 83-09322 1 Heatelement lower 4,7 kW 400V

7 83-09320 1 Heatelement upper 4,1 kW 400V

8 83-10323 1 Frontpanel incl. PCB and key.pad

9 83-20103 1 Electrical components – see wiring diagram

10 83-09975 1 Bottom plate GL 9001/3

11 82-06510 4 Leg M8 adjustable

12 83-09980 1 Fat drawer

13 84-00067 1 Switch 4-polet CA25 32 A

13a 84-00292 1 Handle for switch

14 84-00290 1 Fuse holder

14a 84-00289 1 Fuse 2A

15 83-09313 2 Tension piece large upper

16 83-09312 2 Tension piece lower

17 83-09119 1 Cover plate upper large

18 83-10194 1 Cover plate lower

15

GL 9002

Pos. Part no. Pcs. Description

1 83-10292 1 Bottom cabinet GL 9002

2 83-10293 1 Pan GL 9002 lower

3 83-10237 1 Top cabinet large incl. arm

4 83-10279 1 Pan upper large

5 83-10325 1 Top cabinet small incl. arm

6 83-10324 1 Frontpanel double incl. PCB and key-pad

16

Pos. Part no. Pcs. Description

7 83-10022 2 Actuator MLA-2

8 83-20104 1 Electrical components – see wiring diagram

9 83-09980 1 Fat drawer

10 83-10288 1 Bottom plaet 600 mm

11 83-09981 1 Pan small

12 83-09320 1 Heat element upper 4,1 kW 400V

13 83-09322 1 Heat element lower 4,7 kW 400V

14 83-09323 1 Heat element lower 2,6 kW 400V

15 83-09323 1 Heatelement upper 2,3 kW 400V

16 82-06510 4 Leg M8 adjustable

17 84-00067 1 Switch 4-polet CA 25 32A (400V)

17a 84-00292 1 Handle for switch type CA

18 84-00290 1 Fuse holder

18a 84-00289 1 Fuse 2A

19 83-09119 1 Cover plate lower large

20 83-10194 1 Cover plate upper large

21 83-09120 1 Cover plate lower small

22 83-10195 1 Cover plate upper small

23 83-09313 2 Tension piece upper large

24 83-09312 2 Tension piece lower large

25 83-09329 2 Tension piece upper small

26 83-09135 2 Tnsion piece lower small

17

GL 9003

18

Pos. Part no. Pcs. Description

1 83-09984 1 Bottom cabinet GL 9003

2 83-10325 2 Top cabinet small incl. arm

3 83-10324 1 Frontpanel double incl. PCB and key-pad

4 83-10022 2 Actuator MLA-2

5 83-20105 1 Electrical components – see wiring diagram

6 83-09980 1 Fat drawer

7 83-09296 2 Pan GL 9003 lower

8 83-09320 2 Pan upper small

9 83-09321 2 Heat element upper 2,3 kW 400V

10 83-09323 2 Heat element lower 2,6 kW 400V

11 82-06510 4 Leg M8 adjustable

12 84-00067 1 Switch 4-polet CA25 32 A

12a 84-00292 1 Handle for switch

13 84-00290 1 Fuse holder

13a 84-00289 1 Fuse 2A

14 83-10195 2 Cover plate upper small

15 83-09120 2 Cover plate lower small

16 83-09312 2 Tension piece lower

17 83-09329 4 Tension piece upper small

18 83-09975 1 Bottom plate GL 9001/3

19

GL 9010

20

Pos. Part no. Pcs. Description

1 83-10332 1 Bottom cabinet GL 9010

2 83-10330 1 Pan GL 9010

3 83-10335 1 Top pan GL 9010

4 83-10337 1 Top cabinet GL 9010

5 83-10346 1 Arm GL 9010

6 83-10352 1 Adjusting bracket for actuator GL 9010

7 83-10353 2 Fat drawer GL 9010

8 83-10326 1 Bottom plate GL 9010

9 83-20103 1 Electrical components – see wiring diagram

10 83-10323 1 Frontpanel incl. PCB and key-pad

11 83-10333 6 Heat element 1,85 kW 400V

12 83-10325 1 Actuator LA 23

13 83-10096 1 Adjustingbolt for pan

14 83-10336 4 Tension piece GL 9010

15 83-10355 1 Cover plate lower GL 9010

16 83-10354 1 Cover plate upper GL 9010

17 84-00068 1 Seitch 4-pole CA20 25A

18 83-00086 1 Cooling fan80x80x25 24V DC

19 84-00290 1 Fuse holder

19a 84-00289 1 Fuse 2A

20 83-10099 1 Mounting plate for 25A switch

21 83-10317 1 Cover back

22 82-06510 4 Leg M8 adjustable

This manual suits for next models

4

Table of contents

Other FKI Grill manuals

Popular Grill manuals by other brands

MaxxGarden

MaxxGarden 20732 Manual instruction

CONTINENTAL EDISON

CONTINENTAL EDISON CERP6PERS2 Instruction booklet

Nexgrill

Nexgrill 720-0441-LP Assembly & operating instructions

Targa

Targa TGR 2000 A1 User manual and service information

George Foreman

George Foreman GR100VC Use and care book

Brinkmann

Brinkmann TRAILMASTER 30" owner's manual