54

SPECIALIZED

HEALTHY

AIR SOLUTION

SPECIALIZED

HEALTHY

AIR SOLUTION

OWNER’S MANUAL OWNER’S MANUAL

ASCENDANT™ASCENDANT™

FIGURE 4. All gaskets, bolts, and other items required for

installation are shipped in a box located in the supply air

compartment. On top of the box you will find a packing list.

STORAGE

INSPECTION

In addition to inspecting modules and equipment

visually for possible shipping damage, be sure to

consult “Inspection” instructions described later in this

manual for each optional component.

exposed to still more grime on the construction

site. Therefore, it is imperative that the exterior

of each module be washed down with soap and

water soon after it arrives. Abrasives and solvents

should not be used without first consulting

FläktGroup SEMCO.

4) The interior of each module should also be

cleaned throughly and all equipment should be

lubricated before storing or beginning operation.

5) See other sections for specific lubrication

instructions.

If the system, or parts thereof, must be stored before

installation, indoor storage is preferred. If not possible,

modules should be located on a hard surface with

adequate drainage so that water cannot accumulate

under the modules. A solid paved surface would be

appropriate. Modules must be stored on blocks or

timbers that raise modules at least four inches above

the ground.

If stored indoors, modules should be protected from

damage. If stored outdoors, modules must be covered

with well-anchored canvas tarps. Heavy-mil plastic

tarps should be used with caution as they can trap

moisture against the unit.

MOISTURE MUST NOT BE ALLOWED TO ENTER THE

MODULES. Whether stored indoors or outdoors,

all openings must be closed tightly and piping

penetrations must be capped. However, drain

connections should be left open.

As noted previously, modules must be washed to

remove corrosive materials and dirt before storage.

During the storage period, modules should be opened

and inspected every 30 days. Fans must be inspected

and rotated a few times by hand and stopped in a

position other than the original position. Fans should

also be lubricated as prescribed on the fan label.

INSTALLATION

1) Prepare the installation site by cleaning it of all

debris. Supports, which the modules will be

installed on, should be level. The unit base is

designed either for mounting on a concrete pad or

onto a roof curb (See PAGE 10).

2) Consult drawings and submittal provided to

determine the location of each module. Plan to

lift modules in the order required for your

Installation and within the limitations of your lifting

equipment (see LIFTING on PAGE 3).

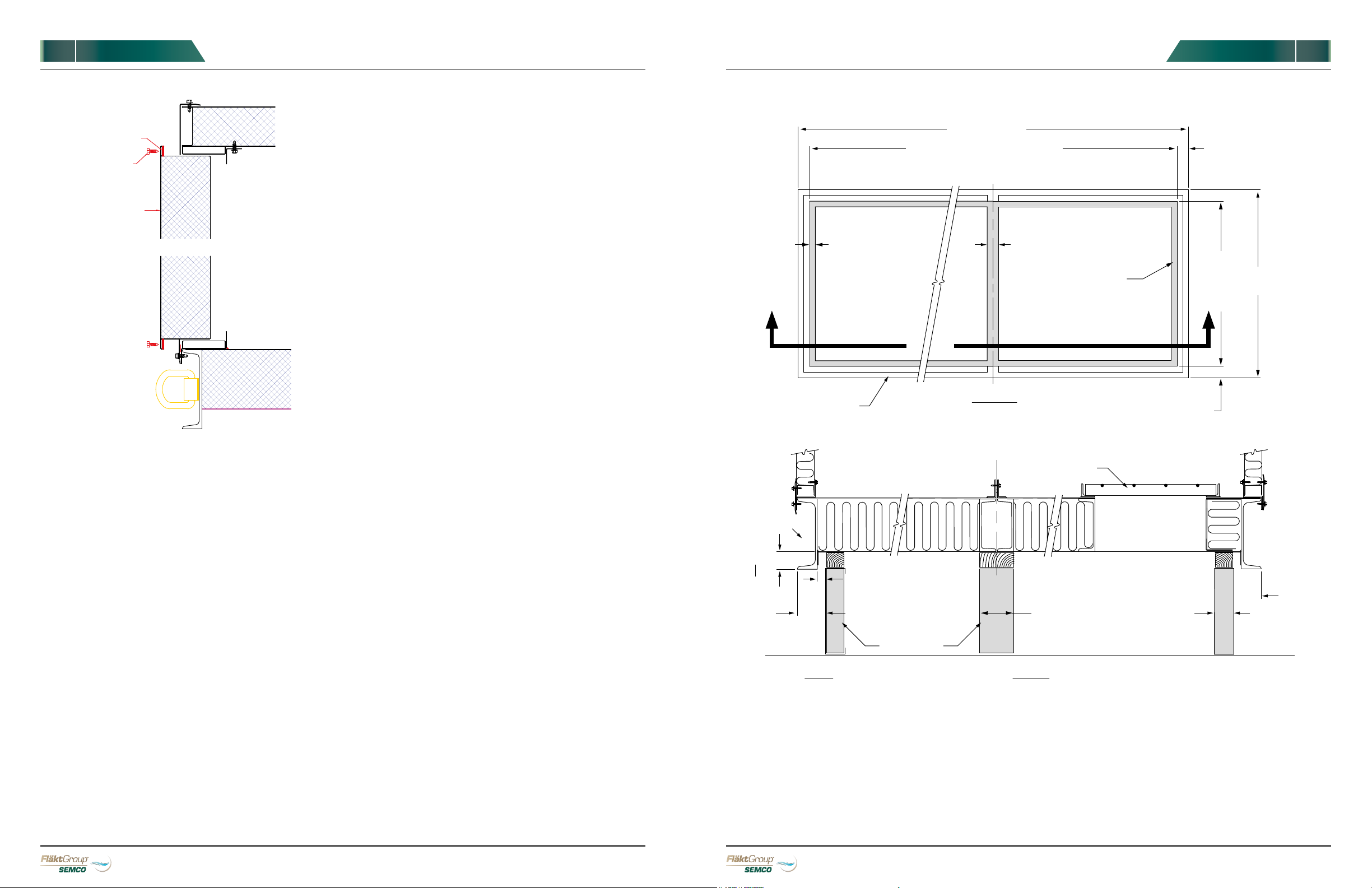

3) Adjoining ends of modules are covered with

plywood and/or plastic sheets during transport.

This must be removed prior to hoisting the

modules in place. (See FIGURE 6).If installation

FIGURE 5.

Module sides which are to be joined at time of installation are

covered with plywood and/or plastic sheets for protection

during transport.

Throughout the unit you will find instruction labels indicating

which steps MUST be performed for proper installation.

4) Remove shipping restraints at roof joint (not

shown).

5) Hoist the first module in place. Spreader bars and

hoisting lugs must be used on each module for

hoisting. Do not use forklifts. (See FIGURES 1 and 2

on PAGE 3).

6) After positioning the module correctly, install

continuous gasket material on field joint flange as

indicated in FIGURE 6.

INSTRUCTION

LABEL

REMOVE

BEFORE

INSTALLATION

BUTT STRAP TEK SCREW 12" O.C.

POLYURETHANE CAULK

POLYURETHANE CAULK

PANEL

GASKET BETWEEN JOINT

TEK SCREW 12" O.C.

POLYURETHANE CAULK

POLYURETHANE CAULK

POLYURETHANE CAULK

PANEL

GASKET

FIGURE 6. Detail of field joint located on side.

FIGURE 7. Field joint located on base. Use only these bolts to

pull the modules together!

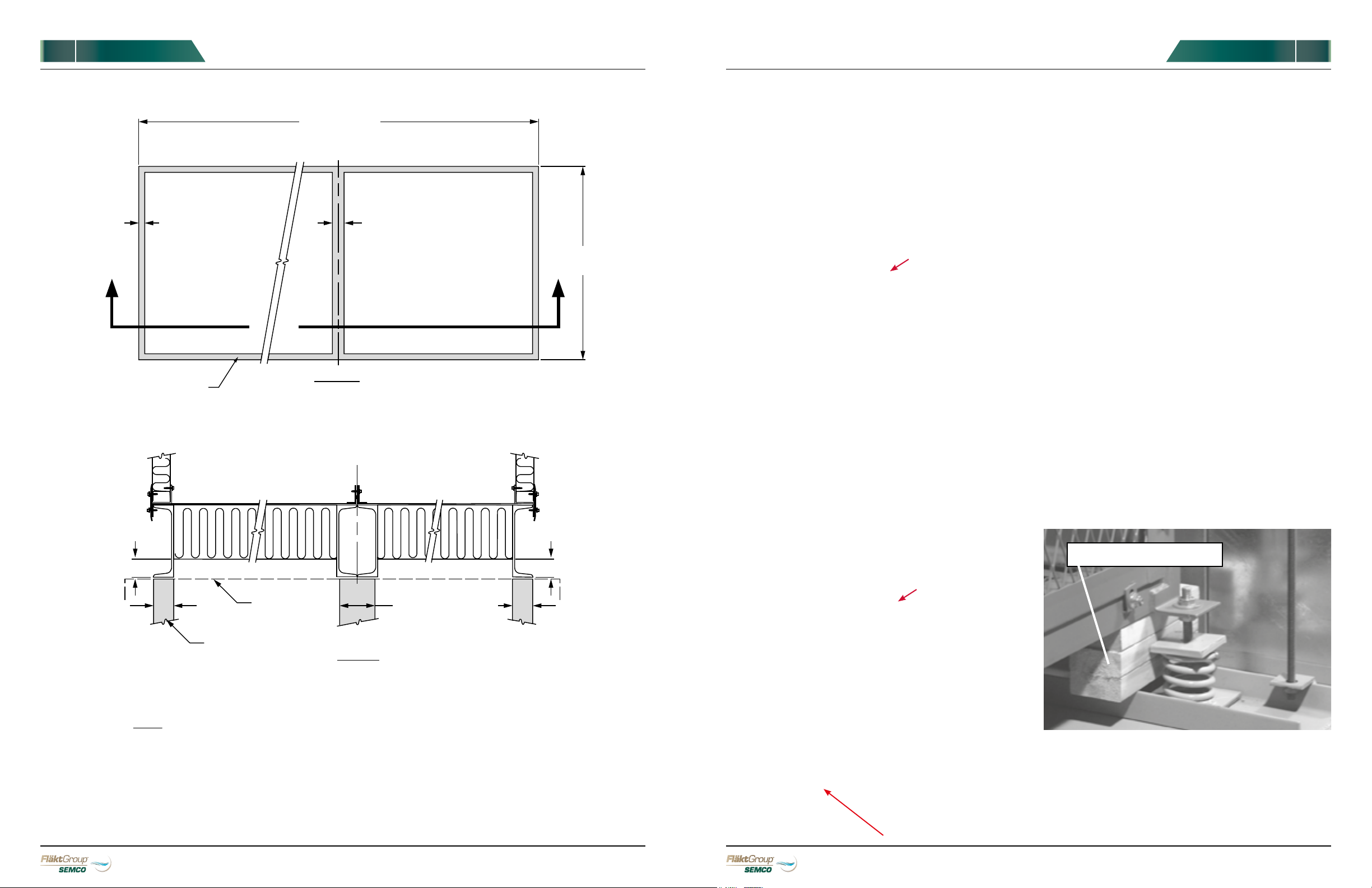

7) Hoist the second module by its lifting lugs

(continue to use spreader bars), and position it

close to the first module. After aligning with the

first module, move the second module against the

first module.

8) Insert bolts that join the first two modules in the

unit base and tighten. The large bolts in the unit

base may be used to help pull the two modules

against each other. Do not use any of the internal

field joints to pull the units together.

(See FIGURE 7).

9) Verify that the two modules are straight, square

and level. Use metal shims if necessary to level.

10) Hoist and set succeeding modules as described

in STEPS 5-7.

If moisture is found in any module, it must be removed

immediately. The source of the moisture must be

determined and corrected immediately.

During storage, modules should not be stacked on top

of each other.

Boxes containing bolts, gaskets and other items

should be stored inside the modules (See FIGURE 4).

11) If installation requires that some modules be

placed on top of base or bottom modules, be sure

to install continuous gaskets between upper

and lower modules as indicated in drawings and

submittals.

12) Do not torque connecting bolts until all upper

modules are installed. Experience suggests

installing bolts in the following manner. First,

attach bolts that join the centers of connecting

modules. Then work outward from the center

and attach remaining bolts, which will assure

proper alignment. Bolts should only be tightened

by hand until all upper modules are in place.

Then they should be torqued to 25 ft-lbs.