CONTENTS

PARAGRAPH

SAFETY 1

INTRODUCTION & PURPOSE - GENERAL 2

STORAGE & HANDLING 3

MECHANICAL INSTALLATION 4

- CONSTRUCTION 4.1

- INSTALLATION WITH ROOF CURB 4.2

- INSTALLATION ON A BASE FRAME USING INSTALLATION FRAME 4.3

- REPLACEMENT OF DSC AND DSM UNITS 4.4

ELECTRICAL INSTALLATION & OPERATION 5

MAINTENANCE 6

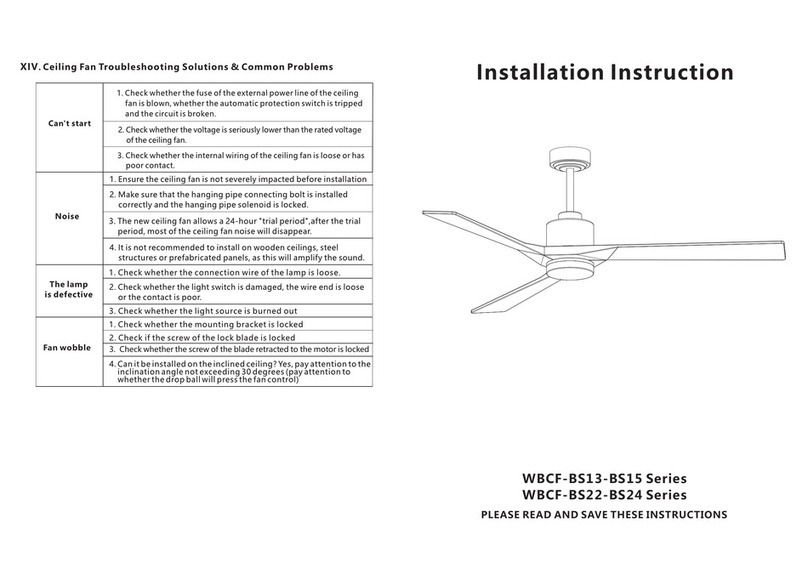

FAULT FINDING 7

- ELECTRICAL 7.1

- MECHANICAL 7.2

DISPOSAL 8

EUROPEAN MACHINERY DIRECTIVE 2006/42/EC 9

TABLE

ROUTINE MAINTENANCE PROCEDURES 1

MOTOR FIXING TORQUE VALUES 2

WIRING DIAGRAMS FIGURES

STOF AC 1ph 190, 225, 310, 355

6

STOF AC 1ph 400

7

STOF AC 3ph 355, 450, 500, 630

8

STOF EC 1ph 190, 225, 310, 355

9

STOF EC 1ph 400

10

STOF EC 3ph 450

11

STOF EC 3ph 500, 630 12

1. SAFETY

ATTENTION!

Only approved, qualified personnel familiar with the assessment of hazards and risks

associated with fans, and with the use of tools and test equipment required to service

such fans, should install, operate and maintain the product.

ATTENTION!

If the installer or user is unable to understand the information in this manual, or has

any doubt that a safe and reliable installation, operation and maintenance of the

equipment can be assured, Fläkt Woods Limited or their representative should be

contacted for advice.

ATTENTION!

Warnings and safety information relevant to specific operations are contained at the

start of each section to which they apply.

2. INTRODUCTION & PURPOSE - GENERAL

STOF roof fans are intended for use as exhaust fans in ventilation systems. The maximum

allowed rotational speed for fan-motor is shown within the technical catalogue. If the fan is not

used continuously, when operated in a cold climate, we recommend the use a back draught

shutter mounted within duct work. This is designed to prevent ambient humidity from freezing

within the fan construction, which could cause damage.

The fan assembly is manufactured and specifically designed to fulfil the requirement of a roof

mounted air extraction installation. No deviation from the original requirement should be

implemented without first referring to Fläkt Woods Limited head office in Colchester (UK). Any

queries regarding safety or operating problems should be referred to your nearest Fläkt Woods

office, sales centre or representative, together with full fan nameplate details. Should a fan

failure occur whilst the product is under warranty, then please contact our Fläkt Woods service

centre in Colchester (UK), before any repair work is undertaken.

If speed control is to be provided by means of a frequency inverter, then please seek drive

selection and compatibility advice from Fläkt Woods.

Motors are of the external rotor motor type and are integrated directly with the impeller

assembly. They are available to suit either single or three phase electrical supplies. EC motors

also have an integrated motor speed controller.

Fan size Motor type

190…400 1~230 VAC

355…630 3~400 VAC

3. STORAGE & HANDLING

If the fan assembly is to be stored; check immediately on receipt that it is as ordered and that

it has not been damaged in transit. Where the fan is delivered in a crate (or similar) the crate

should be considered as a protective device only. The crate must not have equipment stacked

on it and it must not be stacked on other equipment. The crate structure mush not be used a

lifting aid, unless otherwise indicated.

A fork-lift truck or similar should be used for moving the crate. The fan should be stored in a

safe, clean, dry, vibration free, location. The fan storage temperature must be between -20°C

and +40°C. When dismantling the crate to gain access to the fan assembly care should be

taken to avoid injury from sharp edges, nails, staples, splinters, etc.

If the fan is to be stored for 12 months or more, an inspection by Fläkt Woods Limited service

team before commissioning is advised.

1