flakt woods ECONOVENT - PUM Release Note

ECONOVENT®– PUM

Rotary heat exchanger

Technical Handbook

Fläkt Woods 3099 US 03.02 2 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

CONTENTS

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,4

Design – Description – Accessories . . . . . . . . . . . . . . . . . . .5,6

The process in the psychrometric chart . . . . . . . . . . . . .7,8,9

Rotor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Selection of heat exchanger type and size . . . . . . . . . . . . .11

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Design chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Project design advice . . . . . . . . . . . . . . . . . . . . . . . .14,15,16,17

Control Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17,18,19

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20,21

Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . .22,23

Ordering key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24,25

Sample specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26,27

Fläkt Woods 3099 US 03.02 3 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Design

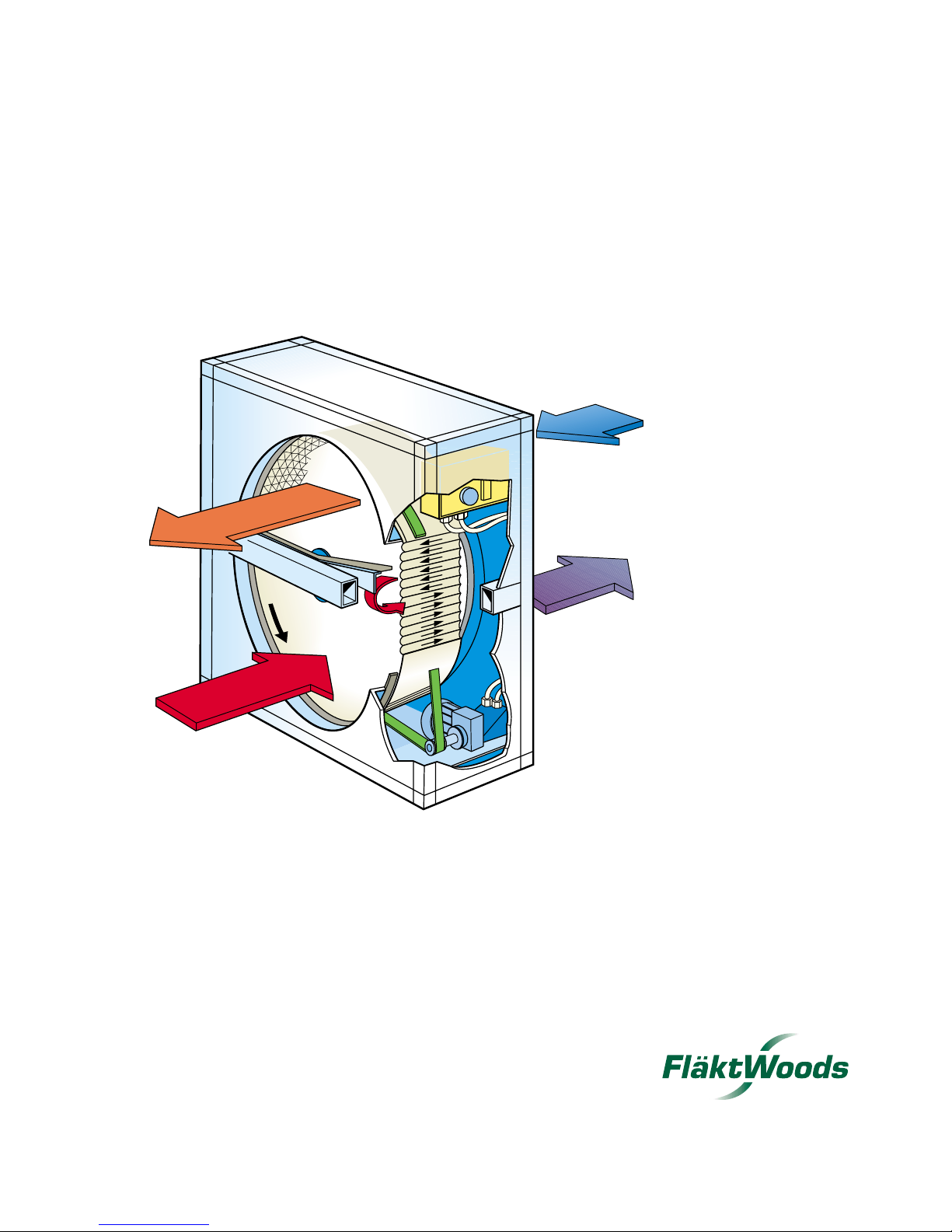

The ECONOVENT unit is a regenerative heat

exchanger comprising a rotor which transfers heat and

moisture from the exhaust air to the supply air as it

rotates.

The supply air flows through one half of the heat

exchanger, and the exhaust air flows in counterflow

through the other half. Supply air and exhaust air thus

flow alternately through small passages in the rotor in

opposite directions.

Most important benefits:

Reduced heat demand which, in turn, reduces the size

and thus also the investment cost for the boiler station

or the connection charge for tariff-linked heat, such as

electric power and heat from the district heating system.

In addition, the sizes and thus the investment costs for

air heaters, pipes and pumps are reduced.

Reduced heat energy demand, which reduces the

operating costs, i.e. the oil consumption or the con-

umption charge for electrical energy or heat from the

district heating system.

Reduced energy consumption for humidification

(hygroscopic rotors) of the air, since moisture is also

recovered.

Reduced cooling power demand (hygroscopic rotors)

which reduces the size and thus also the investment

cost for the refrigeration system (compressor, cooling

tower, etc.), air coolers, pumps and pipes.

Reduced energy consumption for refrigeration

(hygroscopic rotors).

General reduction in environmental pollutants.

ECONOVENT is a complete product range of rotary

heat exchangers for air handling systems in various types

of environments and plants. ECONOVENT is available

with six different materials for the rotor, and the right

material can therefore always be specified to suit most

environments.

2000 3000 4000 5000 10000 20000 30000 50000

Air flow, m3/h

Air flow, m3/s

100000 150000

0.4 0.5 1 2 3 4 5 10 20 30 40 500.30.2

Air flow, CFM

500 1000 2000 3000 4000 5000 10 000 20 000 30 000 50 000 100 000

060

080

095

110

135

150

170

190

200

215

240

265

290

320

350

380

420

460

500

120

Size

Air velocity 400 FTM

Air velocity 900 FTM

FPM

FPM

Fläkt Woods 3099 US 03.02 4 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Design

General

The heat exchanger consists of a casing, a rotor of hygro-

scopic or non-hygroscopic type, and a rotor drive unit.

Adjustable seals are fitted between the casing and the

rotor on both sides, in order to minimize the leakage of

air. The heat exchanger can be ordered either with or

without purging sector.

The purging sector is adjustable and prevents the carry-

over of exhaust air to the supply air.

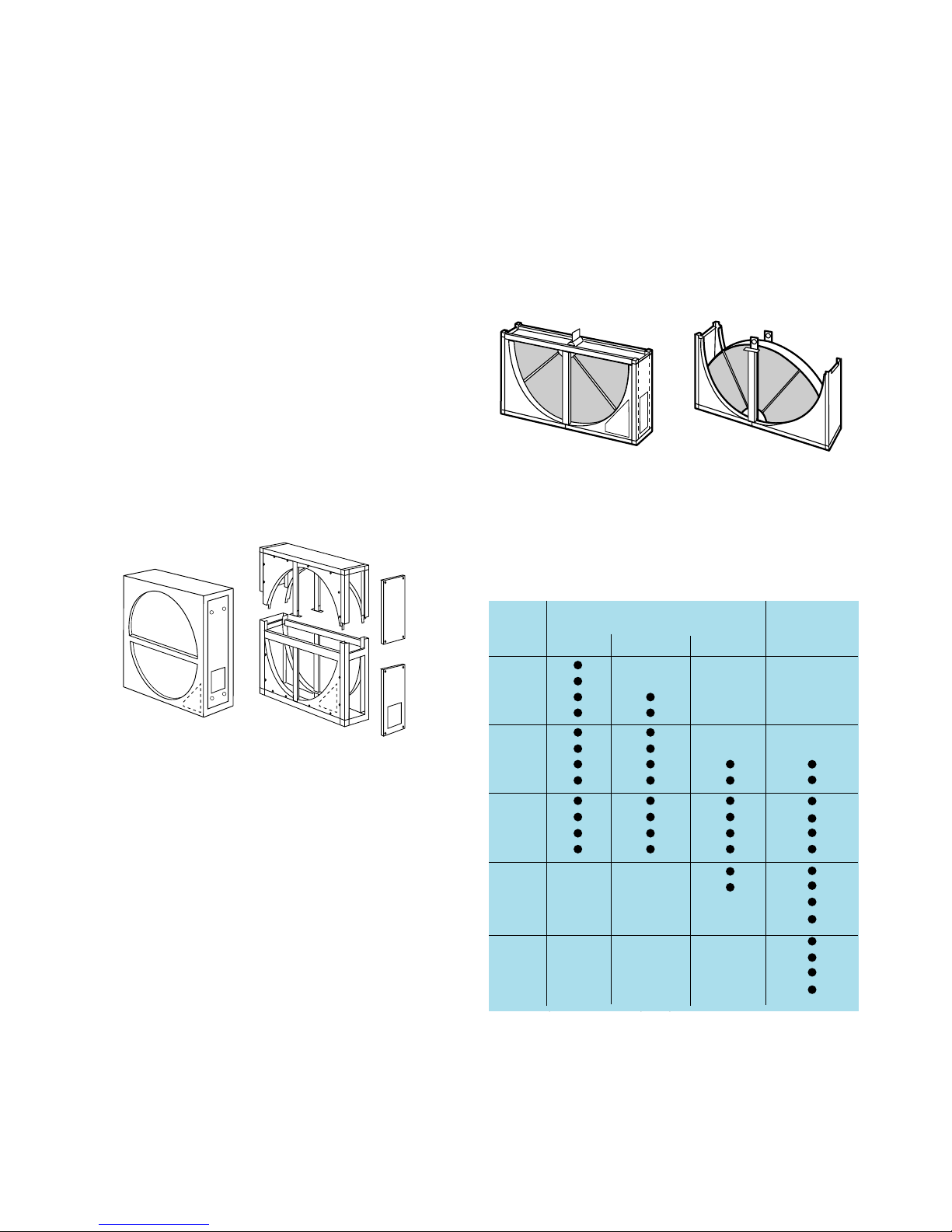

Casing for sizes 060–240

The casing is of single-skin design and is made as one

unit. An inspection panel (2 panels for size 190 and larg-

er sizes) is located on the end wall or front (optional) of

the casing as shown in Fig. 1. The drive motor and speed

controller (for a variable speed unit) are fitted and tested

at the factory. Note that a split casing as shown in Fig. 2

is available for size 150 and larger sizes.

Casing for sizes 265–500

The casing is of single-skin design and is delivered split,

as shown in Fig. 3. Size 265 and 290 units can also be

ordered assembled at the factory. Inspection panels are

located on the front or on the end wall (optional) of the

heat exchanger as shown in Fig. 3. The drive motor is

installed on the inside of the inspection panel. Access

panels are provided on the front of the casing for installa-

tion of the rotor sector.

Fig. 1 Fig. 2

Inspection panel

standard

Inspection panel, optional

Inspection panel

standard

Inspection panel, optional

Fig. 3.

Delivery

The ECONOVENT PUM(A-F) Heat exchanger is deliv-

ered as shown in Table 1.

●Standard. 1) A composite rotor (PUMF) is always sectorized.

One factory-assembled unit Split casing

Split casing ( 2 units)

Size One-piece Sectorized Sectorized Sectorized

bbb rotor 1) rotor rotor rotor

060

080

095 ●

110

120 ●

135

150

170

190

200

215

240 ●

265

290

320

350

380

420

460

500

Delivery form in split version.

Fläkt Woods 3099 US 03.02 5 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Design - Description - Accessories

Drive system

The drive system consists of an electric motor (constant

speed or variable speed) with reduction gear, driving the

rotor by means of a jointed V-belt. The V-belt is kept

automatically tensioned by the spring-mounted motor

bracket.

Temperature limit

The heat exchanger is suitable for use at temperatures up

to +165°F.

The temperature in the motor compartment must not

exceed +100°F. If the supply or exhaust air temperature

exceeds +100°F, see further under Temperature limit on

page 19.

Materials and finish

Frame Sizes 060–240: galvanized sheet metal

Sizes 265–500: rotor support steel beams

primed with anti-corrosion

paint.

Cover panels, inspection panels and purging sector: gal-

vanized sheet metal.

Hub (one-piece rotor): aluminum

Hub (sectorized rotor): steel, primed with anti-

corrosion paint.

Rotor material

ALUMINUM ROTORS (A, C and E rotors) are non-

hygroscopic, i.e. they recover only sensible heat, as long

as condensation does not occur.

ALUMINUM ROTORS (B and D rotors) are hygro-

scopic and recover both sensible heat and latent heat

(on changing moisture content).

COMPOSITE ROTORS (F) rotors are hygroscopic, i.e.

they recover both sensible heat and latent heat. The com-

posite material is incombustible and contains no metals,

which means that the material cannot corrode.

The material is treated with silica gel-based substances.

GENERAL SURVEY OF ROTORS

ECONOVENT Material Property Max temperature -

rotor designation range, °F

A Aluminum Non-hygroscopic 165

B Aluminum Hygroscopic 165

CEdge-reinforced aluminum Non-hygroscopic 165

DEdge-reinforced aluminum Hygroscopic 165

EEpoxy-coated aluminum Non-hygroscopic 165

FComposite Hygroscopic 165 1)

Heating and cooling energy recovery in air handling systems

- without moisture transfer.

Heating and cooling energy recovery in air handling systems

- with moisture transfer.

Heating and cooling energy recovery in air handling systems

- without moisture transfer in a corrosive environment.

Heating and cooling energy recovery in air handling systems

- with moisture transfer in a corrosive environment.

Heating and cooling energy recovery in air handling systems

- without moisture transfer in corrosive environment.

Heating and cooling energy recovery in air handling systems

- with moisture transfer in corrosive, city, marine and

coastal environments.

Application

1) Available for a max. temp. of 275°F. Get in touch with Munters International Inc.

Fläkt Woods 3099 US 03.02 6 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Design - Description - Accessories

Accessories

PUMZ-17 Duct connection frames

Slip joint connection, made of galvanized sheet metal and

fitted to the heat exchanger at the factory.

PUMZ-20 Speed detector

Used for continuous monitoring of the rotor speed, with

automatic alarm if the rotor should stop when heat recov-

ery is needed.

An alarm relay and sensor unit are needed for a constant-

speed exchanger. Only the sensor unit is needed for a

variable-speed exchanger.

PUMZ-21 Differential thermostat

In cooling energy recovery, used for switching the heat

exchanger to maximum speed when the outdoor temper-

ature is higher than the exhaust air temperature. Two sen-

sors are included for fitting in the outdoor air and

exhaust air ducts upstream of the heat exchanger.

PUMZ-27 Cleaning equipment

For automatic purging of the air passages in the rotor.

With compressed air nozzle which is moved by means of

a pneumatically actuated cylinder in a radial direction

along the face of the rotor. Nozzle, cylinder and control

unit are included.

For assistance in selecting the variant and locating the

equipment, please get in touch with Munters

International Inc. representative.

PUMZ-28 Condensate tray

For collecting and disposal of the condensate from the

rotor.

Fläkt Woods 3099 US 03.02 7 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

The process in the psychrometric chart

35

70

105

140

175

-20 -10 0 10 20 30 40 50 60 70 80 90 Dry Bulb Temperature°F

Humidity Ratio

grains/lb

100 110 120

0

5

10

15

20

25

30

35

40

45

50

20%

40%

60%

12.0 12.5 14.5

14.0

13.513.0

80%

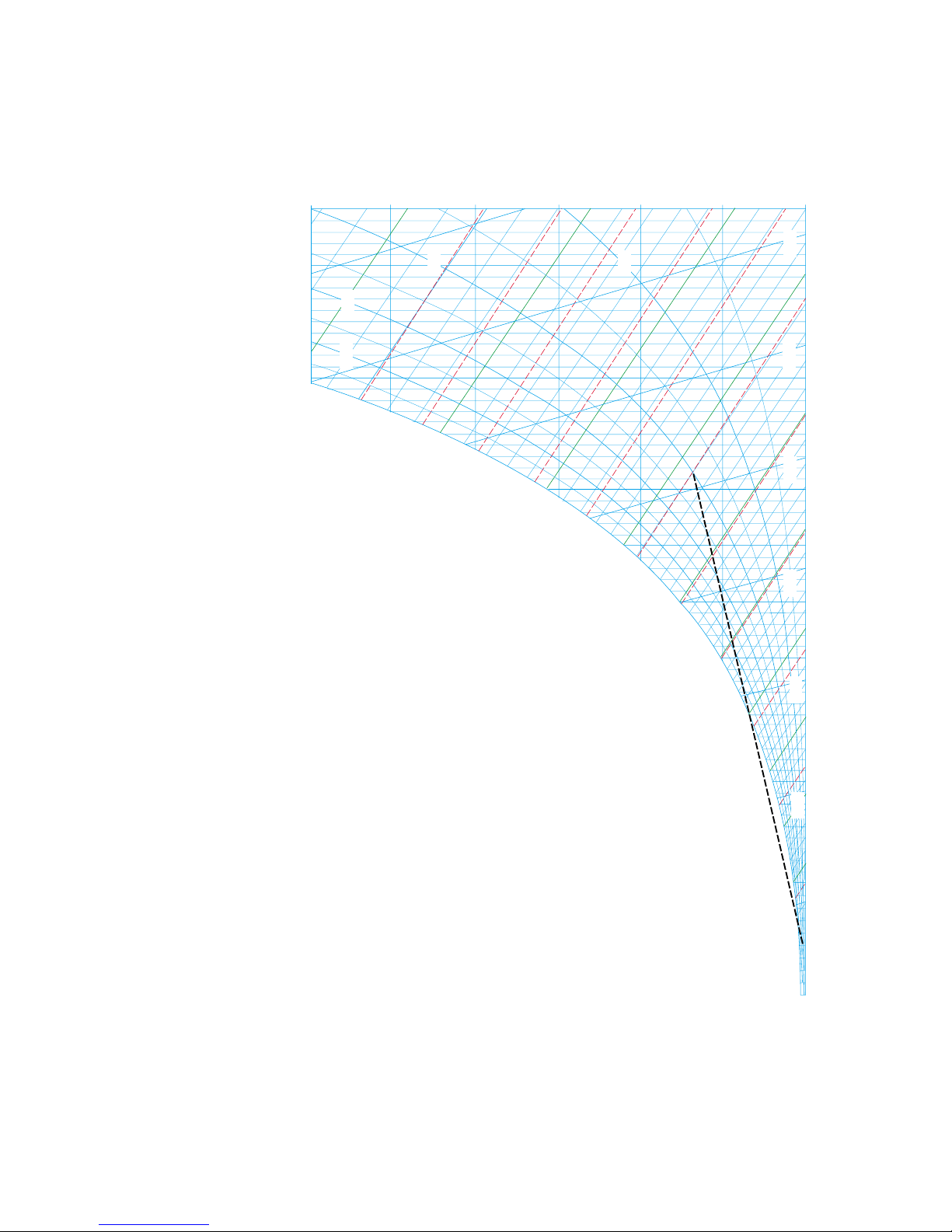

Chart 1

Non-hygroscopic rotors - type A, C and E

In type A, C and E NON-HYGROSCOPIC rotors, only

sensible heat exchange takes place as long as there is no

condensation in the rotor. As soon as condensation

occurs, the condensate will evaporate in the supply air.

The graphic presentation of the process in the psychro-

metric chart when condensation takes place varies with

the operating conditions and can therefore not be speci-

fied generally.

Outdoor air summer

Exhaust air summer

Exhaust air winter

Outdoor air winter

Fläkt Woods 3099 US 03.02 8 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

The Process in the psychrometric chart

35

70

105

140

175

-20 -10 0 10 20 30 40 50 60 70 80 90 Dry Bulb Temperature°F

Humidity Ratio

grains/lb

100 110 120

0

5

10

15

20

25

30

35

40

45

50

20%

40%

60%

12.0 12.5 14.5

14.0

13.513.0

80%

Chart 2

Hygroscopic rotors - type B, D and F

In type B, D and F HYGROSCOPIC ROTORS, the

moisture and temperature efficiencies at full speed are

equal. As a result, the process in the psychrometric chart

runs along the interconnecting line between the inlet

conditions for the supply and exhaust air

Outdoor air summer

Exhaust air summer

Exhaust air winter

Outdoor air winter

Fläkt Woods 3099 US 03.02 9 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

The Process in the psychrometric chart

Summer operation

Charts 1 and 2 show summer conditions in which the out-

door air is warmer and more humid than the exhaust air.

The hygroscopic rotor (Chart 2) lowers both the moisture

content and the temperature to the vicinity of the exhaust

air conditions, and gives an enthalpy efficiency of 75%. The

nonhygroscopic exchanger (Chart 1) lowers the temperature

by the same amount, but does not change the moisture con-

tent. In this case the supply air enthalpy efficiency will be

only about 25%. The example illustrates the significance of

the high moisture efficiency of the hygroscopic rotor, above

all in humid, warm climates.

Winter operation

Charts 1 and 2 show a winter case with moderately low

outdoor temperatures. No condensation takes place in the

nonhygroscopic rotor, (Chart 1) which therefore does not

contribute to the moisture content of the supply air. On

the other hand, the hygroscopic rotor (Chart 2) raises the

moisture content of the supply air by almost 11 Gr/lb of

air, which usually offers welcome humidification of the

supply air. The nonhygroscopic rotor can operate without

risk of freezing even when condensation takes place at

temperatures below 32°F.

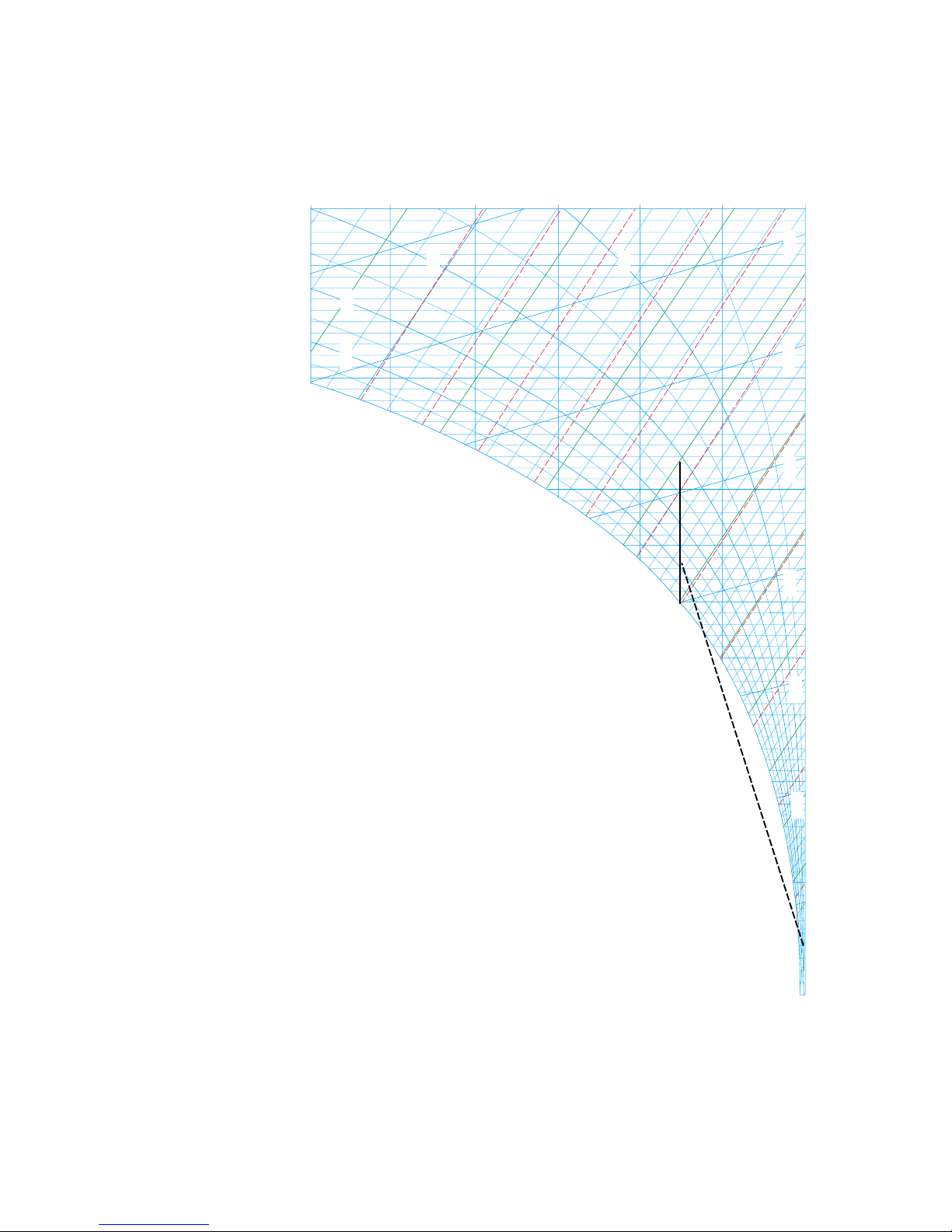

Frosting - Defrosting

Rotor temperatures below 32°F need not necessarily cause

frosting in the rotor. Moisture transfer then takes place by

the moisture, which has been deposited as frost on the

rotor surface, being evaporated on the supply air side. For

frosting to occur, there must also be excess water in the

rotor. This will take place if the supply air is not capable

of absorbing the moisture that has condensed out of the

exhaust air.

The frosting process, which causes an increase in pressure

drop across the rotor, normally takes many hours. The

frosting problem is therefore often relieved by the out-

door temperature varying over a 24 hour period, or

because the heat exchanger is in operation during only

part of the 24-hour period.

Frosting limit

Frosting will occur if excess water should occur, at the

same time as the supply air inlet temperature is below

14ºF. This temperature applies with relatively good accu-

racy at different airflow rates, full speed and typical

exhaust air temperatures occurring in comfort ventilation

systems.

Excess water will occur in the hygroscopic rotor as soon

as the interconnecting line between the inlet conditions

for the two air streams intersects the saturation line in the

psychometric chart (see Chart 3).

In the case of a nonhygroscopic rotor, excess water will

form when the interconnecting line between the supply

air condition and the exhaust air dewpoint plus approxi-

mately 7ºF, as shown in Chart 4, intersects the saturation

line in the psychometric chart.

Frosting time

As an example, it will take about 8 hours for the pressure

drop to increase by 50% if the saturation curve is inter-

sected as shown in Chart 3, and about 4 hours if the sat-

uration curve is intersected as shown in Chart 4.

Note that the frosting time will be as above if the temper-

ature and moisture conditions are constant throughout

the frosting time. But since the temperature often varies,

the frosting time may be appreciably longer. As a result of

factors such as operating time and supply air temperature

variations, experience shows that a minor intersection of

the saturation curve is permissible without significant

frosting occurring, even if the design outdoor tempera-

ture is below 14°F.

Defrosting - avoidance of frosting

Frosting can be totally avoided by preheating the outdoor

air to a temperature so that the line connecting indoor

and outdoor conditions in the psychometric chart falls

below the saturation line. Heating to 14ºF is normally

adequate. The rotor can be defrosted, normally within

5–10 minutes, in several ways.

– By reducing the rotor speed to around 0.5 r/min (see

example 5 page 22).

– By preheating the incoming outdoor air to around

23°F.

– By bypassing a sufficient amount of supply air across

the rotor so that the outlet temperature on the

exhaust air side will be at least around 41°F. As an

example, the supply air flow rate would have to be

reduced to around half for defrosting to take place at

the normal exhaust air temperature, at a 75%

temperature efficiency and an outdoor temperature

of about –4°F.

All three methods can be used for a variable speed rotor

drive, while the last two can be used with constant speed

drive.around half for defrosting to take place at the nor-

mal exhaust air temperature, around 75% temperature

efficiency and an outdoor temperature of about –4°F.

All three methods can be used for a variable-speed rotor,

while the last two can be used at constant speed.

Fläkt Woods 3099 US 03.02 10 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

The process in the psychrometric chart

35

70

105

140

175

-20 -10 0 10 20 30 40 50 60 70 80 90 Dry Bulb Temperature°F

Humidity Ratio

grains/lb

100 110 120

0

5

10

15

20

25

30

35

40

45

50

20%

40%

60%

12.0 12.5 14.5

14.0

13.513.0

80%

Chart 3

Frosting in a hygroscopic rotor

Fläkt Woods 3099 US 03.02 11 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

The process in the psychrometric chart

35

70

105

140

175

-20 -10 0 10 20 30 40 50 60 70 80 90 Dry Bulb Temperature°F

Humidity Ratio

grains/lb

100 110 120

0

5

10

15

20

25

30

35

40

45

50

20%

40%

60%

12.0 12.5 14.5

14.0

13.513.0

80%

Chart 4

Frosting in a non-hygroscopic rotor

Fläkt Woods 3099 US 03.02 12 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

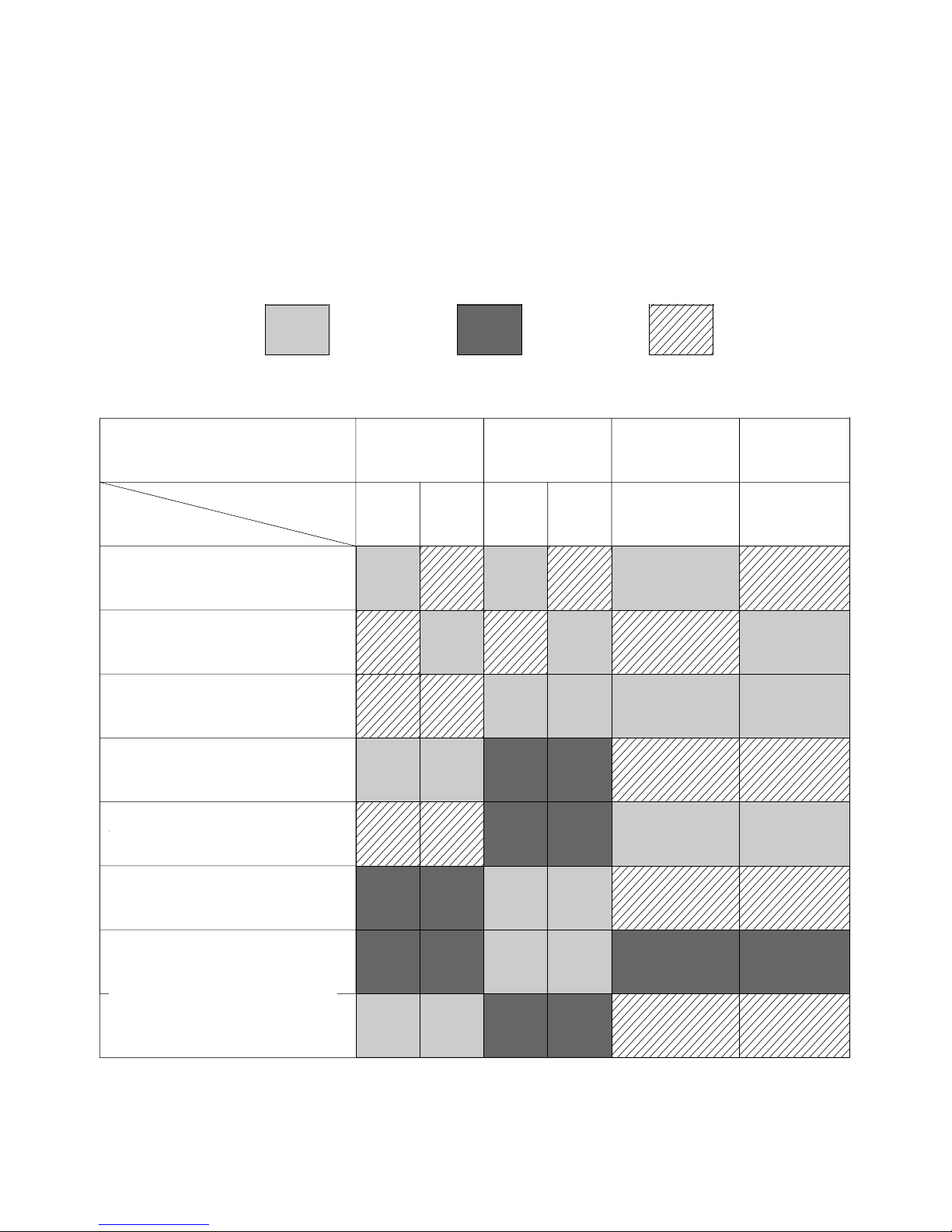

Rotor selection

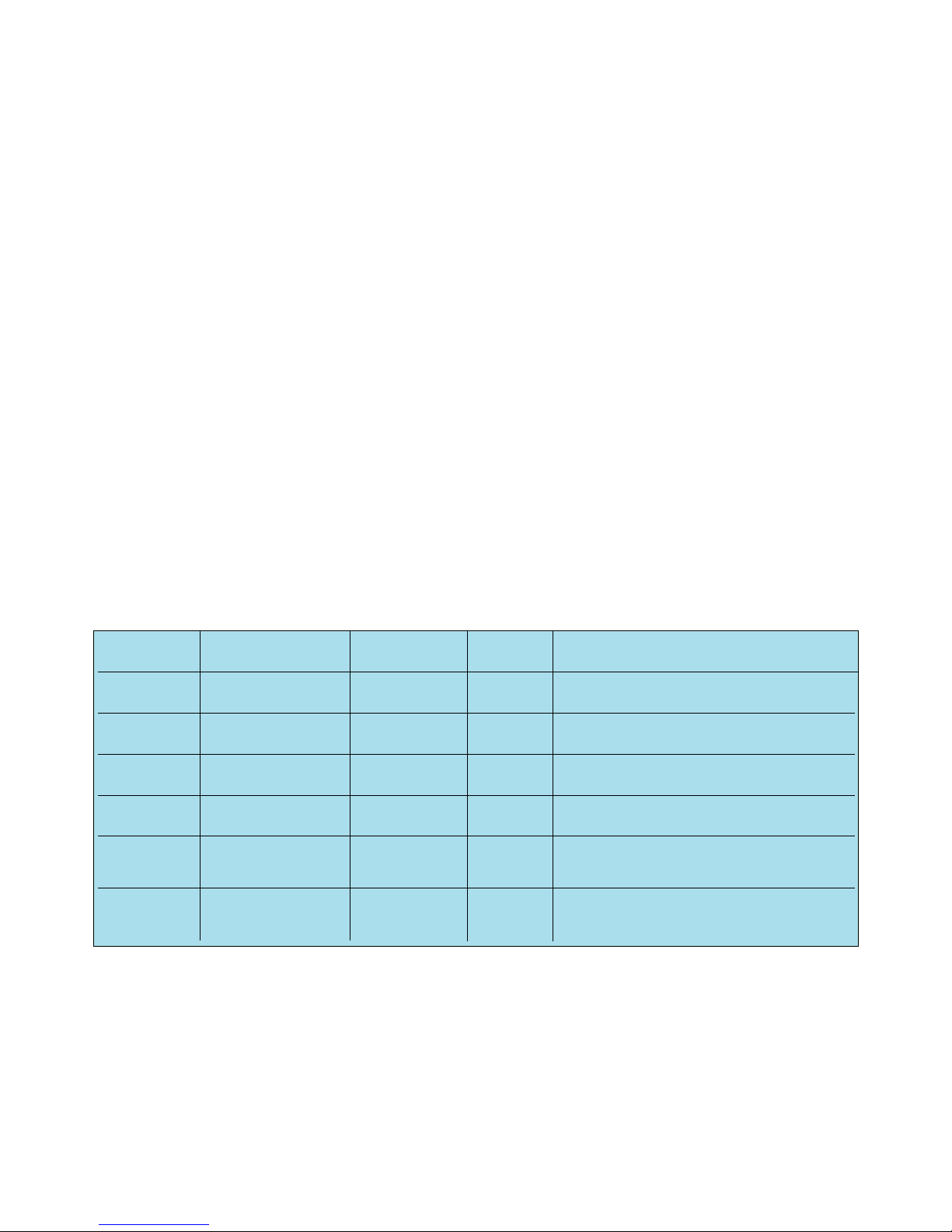

Selection of the rotor material to suit the application.

Take great care to select the right material for every envi-

ronment.

If in doubt, consult Munters International.

= Rätt val = Godkänd = Ej rekommenda

PUMA PUMB PUMC PUMD PUME PUMFRotorutförande

Rotormaterial

Användningsområde

Icke hygroskopisk

(återvinning av värme)

Hygroskopisk

(återvinning av värme + fukt)

Hav - kust

Inland

Tung industri

Lätt industri

Stad

Landsbygd

Aluminium Kantförstärkt

aluminium

Epoxibelagd

aluminium Komposit

y

Key to markings

Rotor material

Application

Non-hygroscopic

(recovery of heat)

Hygroscopic

(recovery of heat + moisture)

Marine - coastal

Inland

Heavy industry

Light industry

Urban

Rural

Rotor version

Composite

Edge-reinforced

aluminum Epoxy-coated

aluminum

Right choice = Satisfactory = Not recommended

Aluminum

Fläkt Woods 3099 US 03.02 13 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Selection of heat exchanger type and size

Selection of heat exchanger

No moisture transfer required

1.Systems intended for:

comfort air handling

exhaust air with solvents or

exhaust air with dry, granular dust.

Select the ECONOVENT with A rotor or possibly C

rotor.

2.Systems with risk of corrosion and intended for:

comfort air handling

exhaust air with corrosive solvents

exhaust air with corrosive dust.

Select the ECONOVENT with E rotor.

Moisture transfer required.

3.Systems with humidification or dehumidification of

the supply air and intended for:

comfort air handling,

light industry inland.

Select the ECONOVENT with B rotor or possibly D rotor.

4. Systems with humidification or dehumidification of

the supply air and intended for:

comfort air handling

heavy industry in a coastal environment or

corrosive urban environment.

Select the ECONOVENT with D rotor or possibly F rotor.

5. Systems with high risk of corrosion and intended for:

comfort air handling

heavy industry in a coastal environment or

corrosive urban environment

Select the ECONOVENT with F rotor

For a non-hygroscopic rotor (A, C and E rotor):

The temperature efficiency can be obtained from the de-

sign chart on page 16. At maximum speed and for equal

supply and exhaust air flow

rates

ηtt = ηtf

The procedure for calculating the temperature efficiency

at different air flow rates is given in the design chart on

page 16. If the rotor size and the supply and exhaust air

flows are given, the temperature efficiency is independent

of the conditions of the supply and exhaust air.

A non-hygroscopic rotor recovers only heat as long as

condensation does not occur in the rotor. There is no

generally applicable formula for calculating the moisture

content of the supply air downstream of the rotor when

condensation takes place. If the rotor speed is reduced,

the supply and exhaust air temperature efficiencies will

decrease. This phenomenon is used for controlling the

supply air temperature downstream of the heat exchanger.

The temperature efficiency is the same for all rotor

types at a given face velocity.

Definitions, see page 15

Fläkt Woods 3099 US 03.02 14 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

14

Efficiency

For a hygroscopic rotor (B, D and F rotor):

The temperature efficiency for a given rotor size and a

given supply air flow is obtained from the design chart

on page 16. At maximum speed and for equal supply and

exhaust air flow rates: ηtt = ηtf

where

ηtt = supply air temperature efficiency and

ηtf = exhaust air temperature efficiency.

At maximum speed and at different supply and exhaust

air flow rates, the supply air efficiencies are linked, and so

are those of the exhaust air.

ηtt ≈η

xt ηtf ≈η

xf

How the temperature efficiency changes at different flow

rates is shown in the design chart on page 16.

Chart 3

Temperature and moisture efficiencies at different rotor

speeds

Temperature and moisture recovery

The temperature efficiency ht and the moisture efficiency

hx at different rotor speeds are shown in Chart 3. The

chart is valid for normal changes in condition in climate

systems and at an air velocity v = 3 m/s through the

rotor.

Definitions:

Efficiency

Supply air temperature efficiency ηtt =t2-t1

t3-t1

Supply air moisture efficiency ηxt =x2-x1

x3-x1

Supply air enthalpy efficiency ηht =h2-h1

h3-h1

Exhaust air temperature efficiency ηtf =t3-t4

t3-t1

Exhaust air moisture efficiency ηxf =x3-x4

x3-x1

Exhaust air enthalpy efficiency ηhf =h3-h4

h3-h1

t = temperature (°F)

x = water content per lb of dry air (gr)

h = enthalpy (Btu/lb)

A common feature of all hygroscopic aluminium rotors is

that when the rotor speed is reduced, the moisture effi-

ciency also drops below the temperature efficiency.

However, with the ECONOVENT F rotor of composite

material, the difference between the two efficiencies on a

drop in speed is appreciably smaller.

0 102030405060 708090

0

20

40

60

80

100

Verkningsgrad η%

100

% av max. varvtal

ηt

ηx

Hygroskopisk rotor

Kompositrotor

t4, x4, h4t3, x3, h3

t1, x1, h1t

2, x2, h2

q1Tilluft q2

q4Frånluft q3

Rum

Composite rotor

Hygroscopic rotor

% of max. speed

Efficiency η%

Room

Fig. 4

Supply air q2

Exhaust air q3

Fläkt Woods 3099 US 03.02 15 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Design chart

Hygroscopic rotor with wider

foil spacing

600 800700 1 000 1 200300

0.2

0.3

0.4

0.5

1

2

3

4

5

10

20

30

40

50

200 000

150 000

100 000

50 000

40 000

30 000

20 000

15 000

10 000

8 000

6 000

5 000

4 000

3 000

2 000

1 500

500

1 000

2 000

3 000

4 000

5 000

10 000

20 000

30 000

40 000

50 000

100 000

1 000

800

Supply air flow, m3/h

Supply air flow, m3/s

Supply air flow, CFM

0.25

0.2

0.3

0.2

0.40.35 0.5 0.6 0.7 0.8 0.9 1 1.2 1.4 1.6 1.8

0.25 0.3 0.35 0.4 0.45 0.5 0.6

0.35 0.4 0.45 0.5 0.6 0.7 0.8

0.25 0.3 0.35 0.4 0.45 0.5

0.3 0.4 0.5 0.6 0.7 0.8

Air velocity, FTM

Pressure drop, IN. WG.

Pressure drop, IN. WG.

Pressure drop, IN. WG.

Pressure drop, IN. WG.

400 500

600 800700 1 000 1 200300 400 500

Pressure drop, IN. WG.

100

90

80

70

60

50

40

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.8

2.0

Air velocity, FTM

ηt= Supply air temperature efficiency, %

at maximum rotor speed

80

70

60

50

40

Composite rotor

Selected size

Non-hygroscopic rotor with

standard foil spacing

Non-hygroscopic rotor with

wider foil spacing

Hygroscopic rotor with stan-

dard foil spacing

The area marked

yellow is the normal

operating rane of

the heat exchanger

Wider foil spacing

Standard foil spacing

500 Size

Supply air/exhaust air flow ratio - q2/q3

460

420

380

290

350

320

265

240

215

190

200

170

150

135

120

110

095

080

060

Chart 4

The area marked

blue/grey is the normal

operating range of the

heat

exchanger

FPM

in.

in.

in.

in.

in.

FPM

Fläkt Woods 3099 US 03.02 16 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Project design advice

Angle, degrees 1°– 6°

123456

Pressure Standard foil spacing 4,8 2,0 1,3 0,9 0,7 0,6

differential, p1-p3, in WG Wider foil spacing 2,8 1,0 0,6 0,4 0,4 0,3

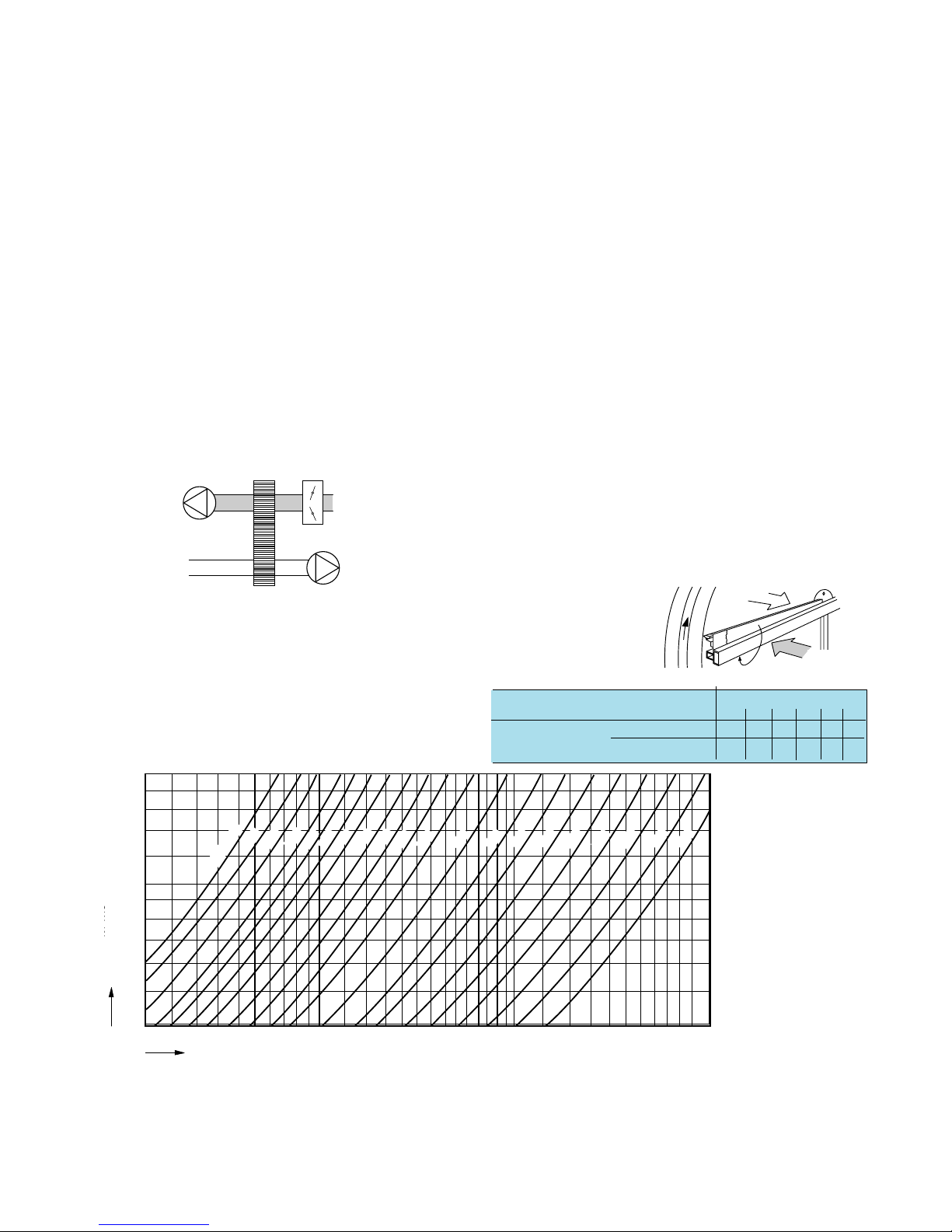

Leakage flow rates and fan sizing

Leakage between the supply and exhaust air sides cannot

be entirely eliminated in a rotary heat exchanger. But by

locating the fans as shown in Fig. 5, the carry-over of ex-

haust air to the supply air can be eliminated. The pres-

sure differential between the supply and exhaust air ducts

on both sides of the exchanger should be such that p1 >

p4 and p2 > p3. If necessary, an adjusting damper is

installed as shown in Fig. 5 to achieve this.

Leakage at the seals can be minimized by the pressure dif-

ferential between the supply and exhaust air ducts being

as small as possible. Chart 5 shows the leakage flow across

the seal as a function of pressure differential p1 - p3.

Purging sector – carry-over flow

The purging sector is located on the supply air outlet

side, at the point where the rotor passes from the exhaust

air flow path to the supply air flow path. The sector,

which is adjustable between 0 and 6°, should be set to

suit the pressure differential p1 - p3 in the system (see

table below).

If the purging sector of the heat exchanger is set to 0°, a

certain volume of exhaust air will always be transferred to

the supply air, and a certain volume of supply air will

always be transferred to the exhaust air by carry-over.

However, these volumes are equal and cancel one another

out. If the purging sector is correctly adjusted to suit the

prevailing pressure conditions (see the table), complete

purging of the rotor will take place without any air being

lost. However, a certain amount of supply air will be

transferred to the exhaust air by carry-over. This takes

place at the point where the rotor moves from the supply

air duct to the exhaust air duct as it rotates.

The volume carried over is approximately 3% of the

supply air flow at p1-p3 = 0.4 in. WG, and approximate-

ly 1.5% at p1-p3 = 0.8 in. WG, regardless of

the heat exchanger size (rotor speed = 10 RPM).

Tilluft

Frånluft

p3

p1

Frånluft

p4

Tilluft

p2

Fig. 6.

Purging sector

Chart 5

Leakage flow q1

Fig. 5. Heat exchanger on the suction side of both fans

110

120

135

150

190

200

215

240

265

290

320

350

380

420

300 400 500 1 000 2 000 3 000200

4.0

1.6

1.2

0.8

Leakage flow ql, CFM

p1–p3 , IN. WG.

2.0

2.4

3.2

Size 060

170

460

500

095

080

Supply air

Leakage flow ql,CFM

106 148 191 265 371 424 636 848 1272 1696 2120 2756 2968 3392

Size

Supply air

Exhaust air

Exhaust

air

inches WG.

Fläkt Woods 3099 US 03.02 17 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Project design advice

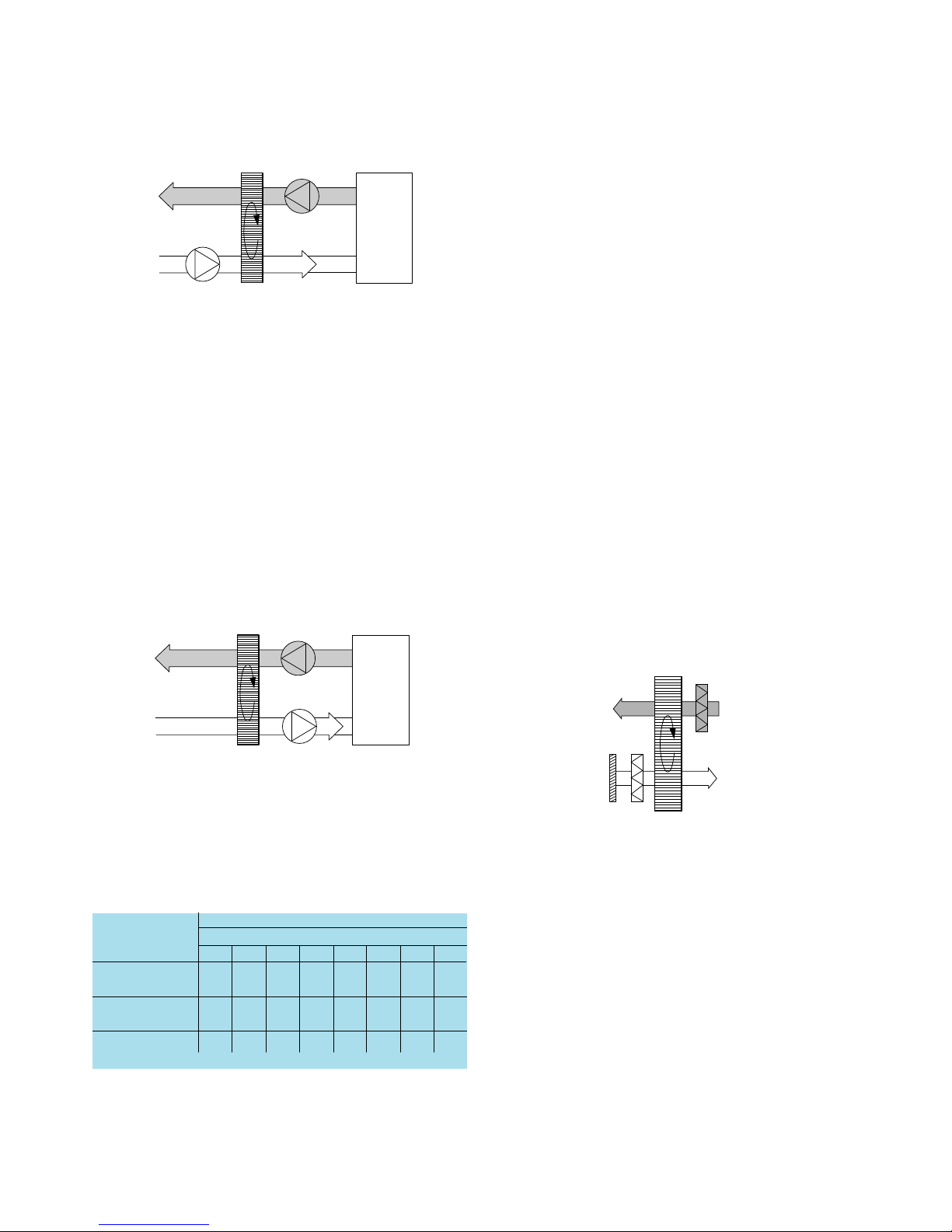

Location of the fan

Question: Is air recirculation permissible?

If air is recirculated, the fans can be located in any posi-

tion. If air recirculation is not permissible, the fans

should be installed as shown in Fig. 7 or Fig. 8 if particu-

larly high purging pressure is required.

Note that the installation shown in Fig. 7 may cause

negativ pressure in the building during the winter.

This is the most common location of the fans. The pres-

sure can be lowered by installing an adjusting damper in

the exhaust air duct upstream of the heat recovery unit.

Question: Is maximum cooling energy recovery desirable?

If the fans are installed as shown in Fig. 8, all of the losses

in the motor and the exhaust air fan and almost all of the

losses in the motor and the supply air fan will be dis-

charged with the exhaust air.

These locations give constant pressure conditions in the

building throughout the year.

Maximum cooling energy recovery will be achieved if the

fans are located so that the heat in the outdoor air and

the fan-generated heat are both transferred to the exhaust

air. This location is also suitable for premises in which

high air cleanliness is demanded.

p3

p1

p4

p2

Rum

p3

p1

p4

p2

Rum

Room

Room

Fig. 7

Fig. 8

Symbols used:

Rotor pressure drop on the supply air side,

∆p1-2, inches.WG

Pressure differential across the purging sector,

p1- p3, inches.WG

Supply air flow downstream of the heat exchanger,

q2, CFM

Exhaust air flow upstream of the heat exchanger,

q3, CFM

Exhaust fan air flow q4

Leakage flow, ql, CFM

Carry-over flow, qm, CFM

Rating factor for exhaust air =ƒ

Calculation example:

Given: PUMB-240 installed as shown in Fig. 5

q2= q3= 18 000 CFM

∆p = 0.66 in.WG

p1- p3= 1.6 in.WG

From Chart 5, ql= 540 CFM

From the previous page, the carry-over air flow

would amount to approximately 2% of the supply air

flow, q2 (3% at 0.4 inches WG; 1.5% at 0.8 inches WG.

The exhaust air fan thus operates at a flow which is

around 5% higher than the exhaust air flow rate from the

room (q3).

q4 =ƒ*q3

ƒ = 18000 + 540 + 0.02*18000 = 1.05

18000

q4 = 1.05 * 18000 = 18900 CFM

q3+q1+qm

ƒ= q3

Fläkt Woods 3099 US 03.02 18 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Project design advice

Filters

Experience has shown that the ECONOVENT rotor is

very insensitive to clogging during operation, in spite of

the dense structure of passages. This is due to the fact

that the direction of air flow through the rotor is contin-

ually reversing, which has an excellent self-cleaning

effect. The laminar flow through the rotor is also a con-

tributory factor to the very rare occurrence of clogging of

the rotor.

If either of the air streams has a high dust content, the

particles usually adhere to the rotor surface, and very

rarely settle inside the passages. As a result, the particles

are blown away from the rotor surface when the direction

of air flow reverses.

In many installations, the rotor is stationary during

parts of the year. To protect the rotor from deposits and

clogging, the supply air filter of the system should be

located upstream of the rotor.

If the rotor should become clogged, it can normally

easily be cleaned by vacuum cleaning. Compressed air,

low-pressure steam and certain types of grease solvents

can also be used.

Clogging problems may nevertheless occasionally

occur in practice. In the event of doubt, it is therefore

better to fit a filter rather than determine at a later date

that a filter is needed (see Fig. 11).

In order to prevent fouling and clogging of the rotor

during the construction period, the regular filters should

be in position, and the rotor should always be rotating

when the fans in the system are running.

Insertion loss ∆Lw, dB

Rotor version Octave band, mid-frequency, Hz

63 125 250 500 1000 2000 4000 8000

Non-hygroscopic

rotor, aluminium 344345 69

Hygroscopic

rotor, aluminium 323456 79

Composite rotor 3 3 3 4 5 6 10 14

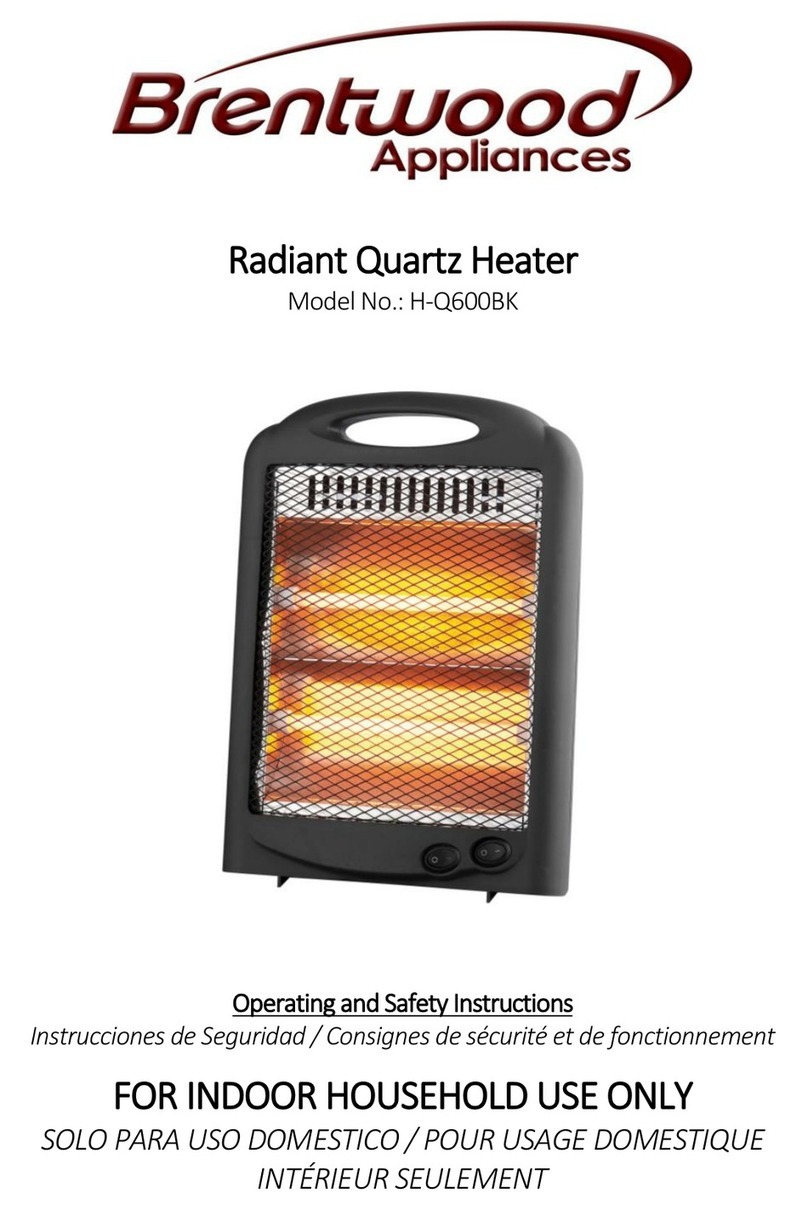

The fan locations shown in Fig. 9 may give rise to prob-

lems, since it may be difficult to achieve correct pressure

balance.

Question: Is maximum heat recovery desirable?

If the fans are installed as shown in Fig. 10, all of the

power supplied to the exhaust air fan motor and almost

all of the power supplied to the exhaust air fan motor will

be utilized.

The location provides constant pressure conditions in the

building throughout the year.

Maximum heat recovery will be obtained if the fans are

installed so that the heat from the exhaust air fan is

utilized (Fig. 10). This fan location can be used only in

systems in which air recirculation is permissible.

In cases where the exhaust air is polluted and return air

cannot be used, a correct pressure balance must be

obtained on both sides of the rotor.

Pressure conditions: p1> p4, p2> p3.

INSERTION LOSS ∆Lw, dB

Rum

Rum

Room

Room

Fig. 9

Fig. 10

Frånluft

TilluftUteluft

1)

2)

Outdoor air

Fig. 11 Supply air

Exhaust air

1) A basic filter should preferably be installed, particularly if the dust consists

of large particles, or of oily, tacky or adhering particles. If a filter is not

installed, space should be left for installing a filter at a later date.

2) The filter class should be selected to suit the requirements of the

premises.

Inspection facilities

An inspection section or a duct with inspection cover

should be connected to the heat recovery unit to enable

the rotor to be inspected and serviced. However, if unit

sections with good access facilities are connected directly

to the heat recovery unit, these may be used for inspection.

Fläkt Woods 3099 US 03.02 19 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Control of rotary heat exchangers

Either on/off or continuously variable control can be em-

ployed for controlling the rotor speed.

If on/off control is employed, the temperature effici-

ency will be either zero or a maximum.

In continuously variable control, the rotor speed is var-

ied from rest to maximum speed in a continuous manner.

The temperature and moisture efficiencies as a function

of the rotor speed are shown in Chart 6.

During periods when no heat recovery is required, the

rotor speed will be so low that the efficiency will be close

to zero, although the rotor will still be purged.

For particulars of selecting the drive equipment for

on/off or continuously variable speed, refer to separate

instructions from Munters International Inc.

Chart 6

Example. Heat recovery - Variable speed

The heat exchanger rotor speed is controlled steplessly by

temperature sensors for constant supply air temperature,

constant room temperature or constant exhaust air tem-

perature.

0 102030405060708090

0

20

40

60

80

100

Verkningsgrad η%

100

% av max. varvtal

ηt

ηx

Hygroskopisk rotor

Kompositrotor

Rum

RC-T

RC

RPM

DM

~

Ingår i PUM

Fig. 13

RC

RPM

DM

ST

SV

RC

T

DT

K

= Varvtalsregulator = Spjällreglermotor

= Reglercentral för temperatur

= Kontaktor

= Drivmotor för värmeväxlare

= Ventilreglermotor

= Temperaturgivare

= Differenstermostat

Room

Included in PUM

Efficiency η, %

% of max. speed

= Speed controller

= Temperature control unit

= Heat exchanger drive motor

= Damper motor

= Temperature sensor

= Proportional thermostat

= Differential thermostat

= Contactor

Composite rotor

Hygroscopic rotor

Fig. 12.

If the air is admitted at an angle to the rotor face

In systems in which the air impinges on the rotor face at

an angle as shown in Fig. 12, the rotor could start to turn

because of this inclined angle of flow. This may cause

undesirable heat recovery due to the rotor rotating even

when the heat exchanger is shut down.

In such installations, guide vanes should be fitted at

the rotor inlet in order to deflect the air so that it will

flow at right angles to the rotor face.

If the heat exchanger is located on the delivery side of

the fan, a space should always be provided between the

fan outlet and the rotor to enable the air leaving the fan

outlet to distribute itself evenly over the whole of the

rotor area.

Control Systems

Project design advice

Fläkt Woods 3099 US 03.02 20 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Control

Example 4. Speed detector

Variable speed: The speed detector monitors the rotor

speed. An alarm will be initiated if the rotor speed is

lower than that demanded by the speed controller. The

magnet, magnetic sensor and mounting bracket are

included in the supply.

Constant speed: The speed detector consists of a mag-

net, a magnetic sensor and an alarm relay. The alarm

relay is preset for an alarm delay time of 120 seconds.

This time corresponds to the lowest rotor speed of

approximately 0.25 rpm. In order to avoid an alarm

when the rotor is intended to be stationary, the alarm

relay should be wired so that an alarm can be initiated

only when the system requires heating or cooling energy

recovery (see the instructions).

Rotor

Magnet Impulsgivare

Larm, lampa e.dyl.

Larmrelä

Fig. 16b

Fig. 16a

Nät

220 V

RC

RPM Rotor

Fästplåt

Magnet

Impulsgivar

e

Magnetic

sensor

Mounting bracket

200 V

supply

Magnetic sensor

Alarm relay

Alarm, alarm lamp or the like

Magnet

Magnet

Example 2. Heating and cooling energy recovery

The temperature sensor 5 maintains the exhaust air

temperature or room temperature constant via the con-

trol unit 4 which, on a drop in outdoor air temperature,

begins by reducing the cooling output. If the sensor 2

senses a higher temperature than sensor 3 , the rotor will

run at maximum speed, which is known as summer case

control. If no cooling is carried out and the temperature

drops further, the rotor speed will increase. At maximum

speed and increased heat demand, the supply air temper-

ature is controlled by means of the reheater.

1 Speed controller

2 Temperature sensor

3 Temperature sensor

4 Control unit of a make available on the market

5 Temperature sensor

6 PUMZ - 21 or equivalent differential thermostat

Example 3. Cooling energy recovery - maximum speed

If the temperature sensors 2 and 3 of the differential

thermostat sense that the supply air temperature is higher

than the exhaust air temperature, the motor will run at

maximum speed for cooling energy recovery.

Rum

RC

RPM

DM

~

DT

1

3

2

~~

Rum

1

3

2

RC

RPM

DM

DT

6

5

4

RC

T

ST SV SV

+–

Fig. 14

Fig. 15

Room

Room

1 PUMZ - 21

differential thermostat

2 Temperature sensor

3 Temperature sensor

are included in 1

}are included in 6

}

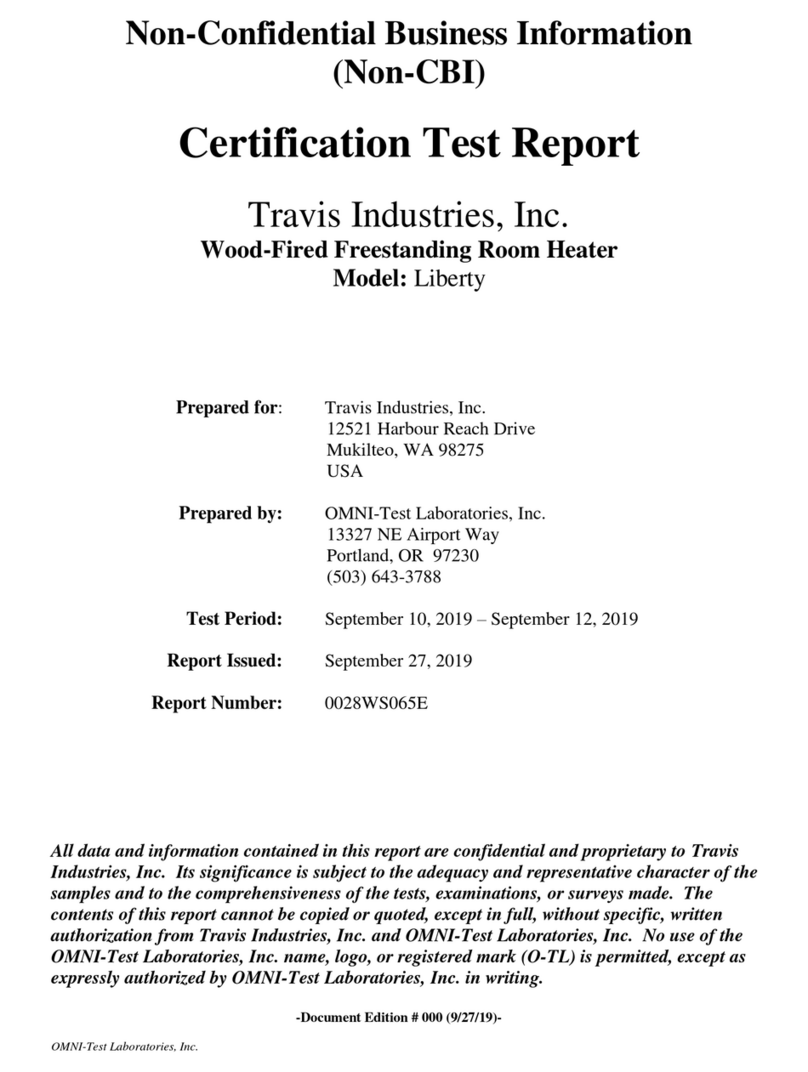

Table of contents

Popular Heater manuals by other brands

Rohnson

Rohnson R-8070 instruction manual

Greentouch

Greentouch DF1904-289 Assembly / care & use instructions

Brentwood Appliances

Brentwood Appliances H-Q600BK Operating and safety instructions

Frico

Frico Elztrip EZ300 Series Mounting and operating instructions

Travis Industries

Travis Industries Liberty manual

Goldair

Goldair GCT270 operating instructions

Rowi

Rowi HKH 2000/2/1 ODT Premium Original instruction manual

L.B. White

L.B. White Premier CS700 Owner's manual and instructions

Sears, Roebuck and Co.

Sears, Roebuck and Co. 583.409030 Assembly, operating instructions and parts list

BAWA

BAWA DBEPZMA00D Assembly and operating manual

Reece

Reece Kado Lussi installation instructions

Rinnai

Rinnai INFINITY 16 User instruction