Page 4 of 4

Installation instructions

Please ensure a copy of the installation instuctions

is left with the end user for future reference.

Installation Instructions

Plumbers, please ensure a copy of the Installation

Instructions are left with the end user for future reference

Kado Aspect Swivel Heated Towel Rail 635mm x 400mm

Chrome

WARNING

This product must be installed by a qualified electrician in accordance with AS/NZS 3000 wiring rules. Switch off the electrical

supply at the mains before installation and maintenance. A means of disconnection must be incorporated in the fixed wiring

in accordance with the wiring rules. Suitable for bathroom and non-bathroom/dry areas. Not suitable for above baths, nor

for installation in saunas, steam rooms or shower cubicles. Please consult with a qualified electrician to confirm appropriate

compliant installation location.

Do not connect to a plug and socket outlet. Rated IPX5 and suitable for indoor use only. Do not fix to damp or conductive

surfaces. Site well away from curtains and fabrics. Switch off after use. Do not leave on for prolonged periods. This appliance is

not to be used by persons (including children) with reduced physical, sensory or mental capabilities.

Please consult with a qualified electrician to confirm appropriate compliant installation location.

HYDROTHERM

MILAN HEATED WALL MOUNT TOWEL RAILS

INSTALLATION

• Slide the WALL BRACKET1into the BRACKETARM2

and hold up tothe wall in position.

• With a pencil, outline the WALL BRACKET1in the desired

position and remove from the wall.

• Using apencil and the WALL BRACKET1, mark the centre

screw hole and cross it for accuracy.

• Drill ahole for the SCREW 4and insert nylon plug into tiled

wall (if applicable). Installer may choose to use alternative

screws tosuit the application.

• Position WALL BRACKET1sothat the GRUB SCREW hole

faces directly down towards the floor and place SCREW 4

into the wall.

DO NOT OVERTIGHTEN SCREW - LEAVE SLIGHT

ADJUSTMENT OF THE FLANGE (SLACK) TO ENABLE

MOVEMENT WHEN THE TOWEL RAIL IS POSITIONED.

• When all of the WALL BRACKETS 1are in place, slide

the TOWELRAIL 5into position towards the wall, until

BRACKETARM2reaches the WALL BRACKET1.

•Insert GRUB SCREW 3through BRACKETARM2and into

WALL BRACKET1.

• With the ALLEN KEY 6provided, tighten the GRUB SCREW

until tight toensure that towel rail stays in position.

Please ensure that the measurements are taken accurately and

that the screw is in astud or noggin toprovide support. Do not

overtighten screws.

WARNING

All rails are individually hand made.

Due to this fact some measurments may not be exact.

PLEASE READINSTRUCTIONS CAREFULLY and do

not force towel rail into bracket if position of wall flange is not

accurate.

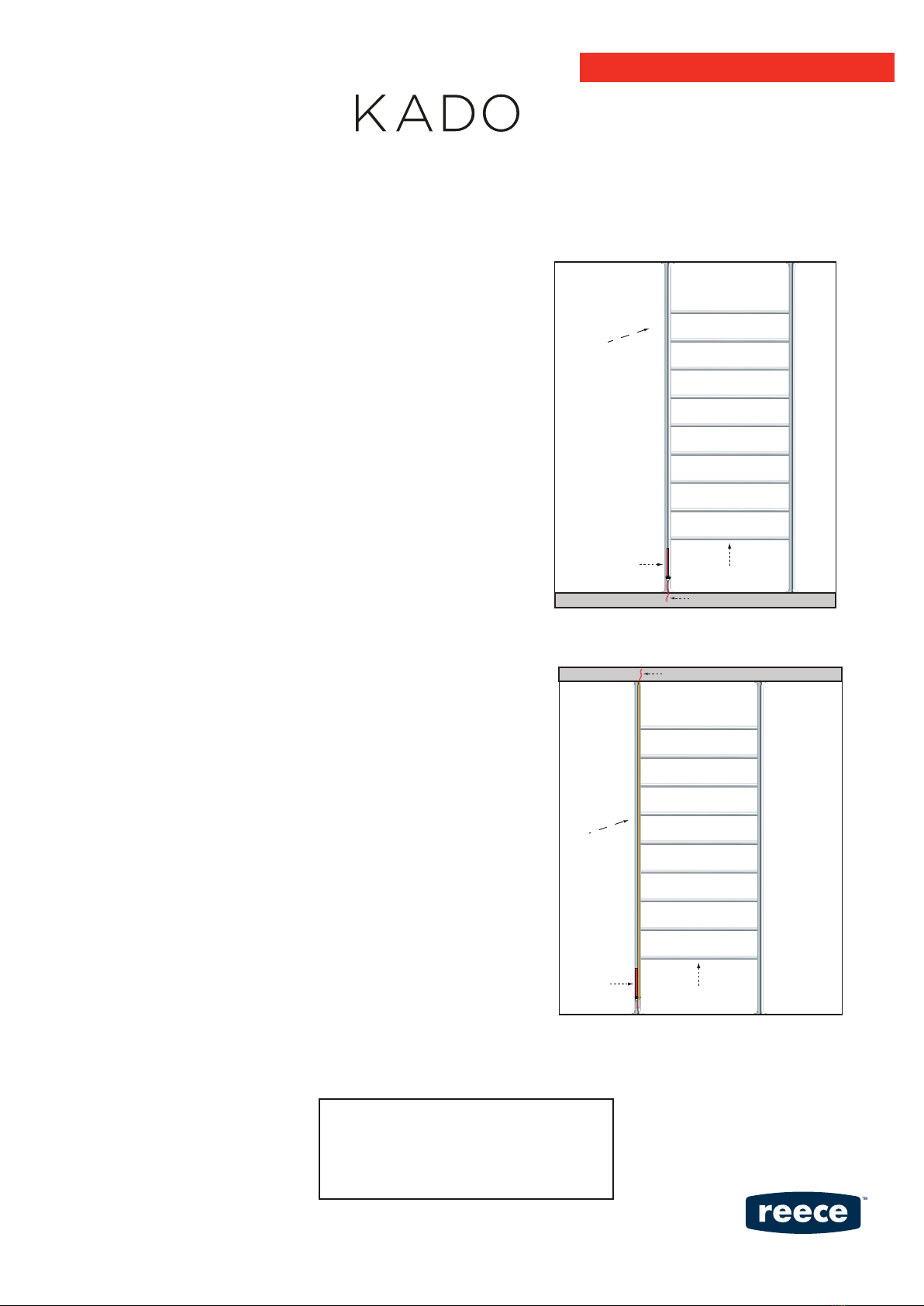

INSTALLINGBRACKETS

WARNING

Hydrotherm take pride in the fact that all rails are individually hand made. Due to this fact

some measurements may not be exact. PLEASE READ INSTRUCTIONS CAREFULLY and do not

force towel rail into bracket if position of wall flange is not accurate.

TOWEL RAILS MUSTALWAYS BE INSTALLEDWITHTHE ELEMENT

PLACEDATTHE BOTTOM FOR CORRECT HEATTRANSFER

•

Slide the WALL BRACKET

1

into the BRACKET ARM

2

and hold up to the wall in position.

•

With a pencil, outline the WALL BRACKET

1

in the

desired position and remove from the wall.

•

Using a pencil and the WALL BRACKET

1

, mark the

centre screw hole and cross it for accuracy.

•

Drill a hole for the SCREW

4

and insert nylon plug into

tiled wall (if applicable). Installer may choose to use

alternative screws to suit the application.

•

Position WALL BRACKET

1

so that the GRUB SCREW

hole faces directly down towards the floor and place

SCREW

4

into the wall.

DO NOT OVERTIGHTEN SCREW - LEAVE SLIGHT

ADJUSTMENT OF THE FLANGE (SLACK) TO ENABLE

MOVEMENT WHEN THE TOWEL RAIL IS POSITIONED.

•

When all of the WALL BRACKETS

1

are in place, slide

the TOWEL RAIL

5

into position towards the wall, until

BRACKET ARM

2

reaches the WALL BRACKET

1

.

•

Insert GRUB SCREW

3

through BRACKET ARM

2

and

into WALL BRACKET

1

.

•

With the ALLEN KEY

6

provided, tighten the GRUB

SCREW until tight to ensure that towel rail stays in position.

5

**INSTALLER MAY CHOOSE NOT TO USE SCREW IF NOT SUITABLE FOR APPLICATION

Wall Bracket Wall Screw**

Hydrotherm Towel Rail

Alen Key & Grub Screw

Bracket Arm

Grub Screw

Hydrotherm will not accept

responsibility for incorrectly

installed brackets.

Please read instructions carefully.

Please ensure that the measurements are taken accurately

and that the screw is in a stud or noggin to provide support.

Do not overtighten screws.

STUD OR

NOGGIN

WALL

INSTALLINGBRACKETS

TOWEL RAILS

LY and do not

force towel rail into bracket if position of wall flange is not accurate.

TOWEL RAILS MUSTALWAYS BE INSTALLEDWITHTHE ELEMENT

PLACEDATTHE BOTTOM FOR CORRECT HEATTRANSFER

•

Slide the WALL BRACKET

1

into the BRACKET ARM

2

and hold up to the wall in position.

•

With a pencil, outline the WALL BRACKET

1

in the

desired position and remove from the wall.

•

Using a pencil and the WALL BRACKET

1

, mark the

centre screw hole and cross it for accuracy.

•

Drill a hole for the SCREW

4

and insert nylon plug into

tiled wall (if applicable). Installer may choose to use

alternative screws to suit the application.

•

Position WALL BRACKET

1

so that the GRUB SCREW

hole faces directly down towards the floor and place

SCREW

4

into the wall.

DO NOT OVERTIGHTEN SCREW - LEAVE SLIGHT

ADJUSTMENT OF THE FLANGE (SLACK) TO ENABLE

MOVEMENT WHEN THE TOWEL RAIL IS POSITIONED.

•

When all of the WALL BRACKETS

1

are in place, slide

the TOWEL RAIL

5

into position towards the wall, until

BRACKET ARM

2

reaches the WALL BRACKET

1

.

•

Insert GRUB SCREW

3

through BRACKET ARM

2

and

into WALL BRACKET

1

.

•

With the ALLEN KEY

6

provided, tighten the GRUB

SCREW until tight to ensure that towel rail stays in position.

2

3

2

1

1

3

6

6

4

4

5

5

**INSTALLER MAY CHOOSE NOT TO USE SCREW IF NOT SUITABLE FOR APPLICATION

Wall Bracket Wall Screw**

Hydrotherm Towel Rail

Alen Key & Grub Screw

Bracket Arm

Grub Screw

Hydrotherm will not accept

responsibility for incorrectly

installed brackets.

Please read instructions carefully.

Please ensure that the measurements are taken accurately

and that the screw is in a stud or noggin to provide support.

Do not overtighten screws.

1Twin Hole Wall Bracket (BOTTOM) 4Wall Screw *

2Single Hole Wall Bracket (TOP)5HydrothermTowel Rail

3Grub Screw 6Alen Key & Grub Screw

page 2 of 5

Plumbers, please ensure a copy of the installation

instructions is left with the end user for future reference

* Installer may choose not to use screw if not suitable for application.

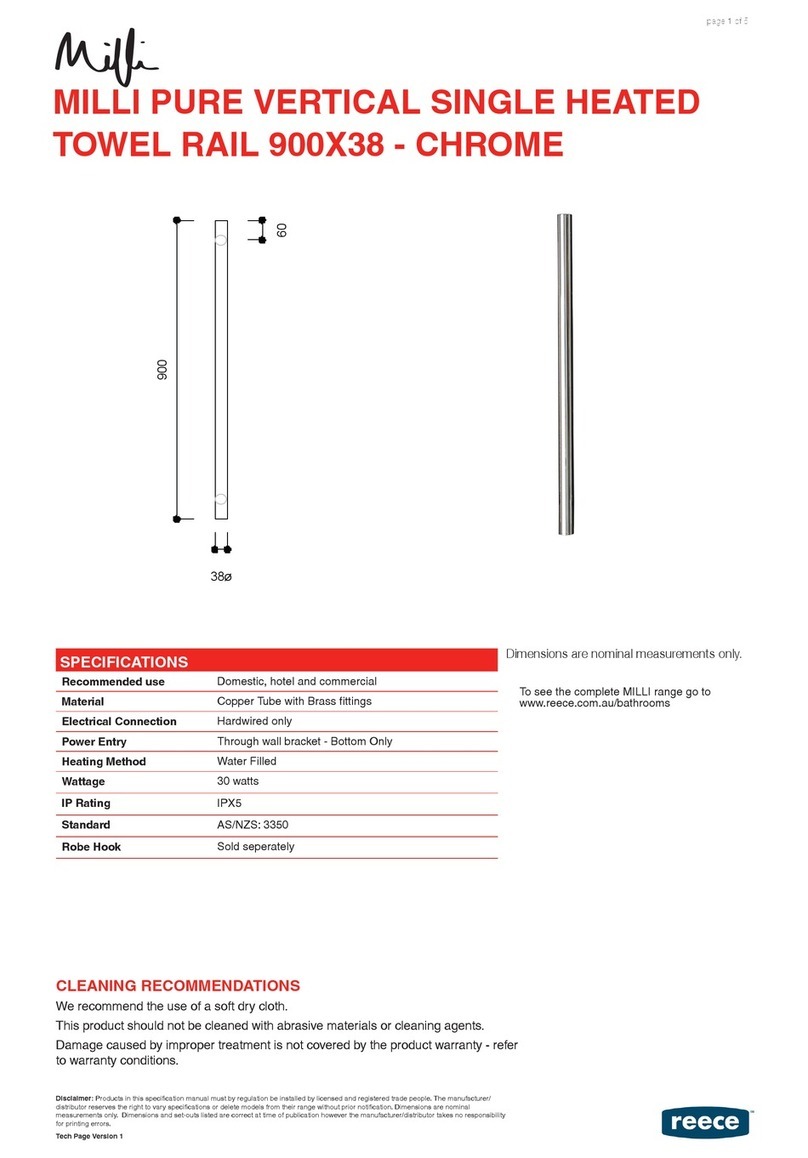

TOWEL RAILS MUST ALWAYS BE INSTALLED WITH THE ELEMENT

PLACED AT THE BOTTOM FOR CORRECT HEAT TRANSFER

CLEANING RECOMMENDATIONS

We recommend the use of soapy water or approved cleaners.

This product should not be cleaned with abrasive cleaners.

Damage caused by imporper treatment is not covered by the product warranty. Refer to Warranty Conditions.

WARNING:

This appliance is not intended for use by young children or infirm persons without supervision.

CAUTION:

The cord extension set must be positioned so that it is not subject to splashing or ingress of moisture.

The supply shall have means for disconnection with an air gap in all active conductors

incorporated in the fixed wiring according to the Wiring Rules in AS/NZS 3000:2000.

CAUTION

Kado Lussi Heated Towel Rail Floor to Ceiling Hardwired

(Floor Cable Entry) 550mm Chrome