FEB 765 Owner's manual

INSTALLATION, OPERATION, MAINTENANCE

IOM-F-765

Operation and Maintenance Manual

Pressure Vacuum Breaker

Model 765

Read and understand this

manual prior to installing,

operating or servicing this

equipment.

Model 765

Table of Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typical Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Vacuum Breaker – Model 765. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation

1. The Pressure Vacuum Breaker Assembly

must be installed where it is accessible

for periodic testing or repair.

2. The device must not be installed in a

pipe line until the line has been flushed

of foreign material. Failure to flush the

lines completely may cause the check

members to become fouled and require

disassembly and cleaning.

3. The device must be installed so that the Air Inlet operates in the verti-

cal position (see diagrams). Installation in any other manner will cause

the device to malfunction.

4. The device should be installed where some spillage is not objection-

able, as instantaneous siphon conditions and pressure surges will

cause “spitting.”

5. When threading the device in line, place wrench only on ball valve hex

ends. Keep pipe dope off interior surfaces of valve.

6. After installation, open inlet ball valve to pressurize device. Slowly open

outlet ball valve to fill down-stream line.

NOTE: The downstream pressure must be maintained above 5psi to

keep the spring loaded air inlet poppet closed. If check valve fails to

hold 10psi minimum, it has become fouled and must be cleaned. Close

both ball valves and bleed pressure from device before disassembly.

Refer to Maintenance Manual for proper service methods.

NOTE: All devices are factory tested for proper operation. Any damage

caused by pipe line debris or improper installation is not included in the

product warranty. In case of malfunction, or possible warranty claim,

DO NOT REMOVE DEVICE FROM LINE. Contact your local FEBCO

Representative.

7. THE DEVICE MUST BE PROTECTED FROM FREEZING. Thermal

water expansion and/or water hammer downstream of the backflow

preventer can cause excessive pressure increases. Excessive pressure

situations should be eliminated to avoid possible damage to the system

and device. See recommended freeze protection procedures. (Freeze

Protection 765—Technical Sheet FP765)

IOM-F-765.indd 1 8/11/08 2:56:40 PM

2

PRESSURE VACUUM BREAKER

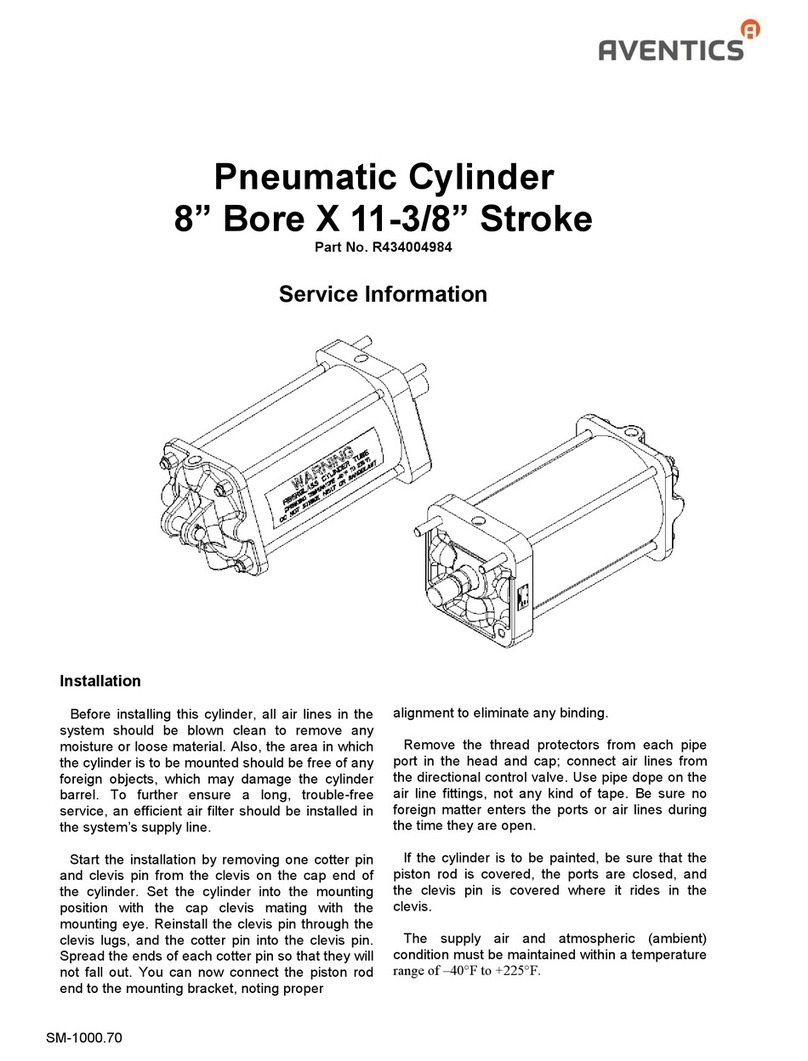

765 – Field Testing Procedure

Equipment Required For Test:

Sight Tube Test Kit (1" clear plastic Sight Tube about 40" long with appro-

priate fittings to attach to Testcocks of Vacuum Breaker.)

Purpose of Test: (see diagram)

To test the Air Inlet and the Check Valves for proper performance.

Test Air Inlet:

The Air Inlet should be

tested to verify opening

above 1psi.

1. Remove Canopy from

top of Vacuum Breaker to

expose Air Inlet.

2. Install Sight Tube at

Testcock #2.

3. Close Ball Valve B on

discharge side of Vacuum

Breaker.

4. Open Testcock #2 and fill

tube to about 30" above

poppet. Close Testcock

#2.

5. Close Ball Valve A on Inlet side of Vacuum Breaker.

6. Slowly open Testcock #2 watching poppet in Air Inlet. Poppet must

unseat. If the Air Inlet does not open, it is sticking and must be repaired.

Close Testcock #2 and remove sight tube.

Test Check Valve:

The Check Valve should be tested to hold against 1psi in the direction of

flow.

1. Install Sight Tube at Testcock #1.

2. Open Ball Valve A to allow unit to refill with water.

3. Open Testcock #1 and allow Sight Tube to fill about 30" above top of

unit, then close Testcock.

4. Close Ball Valve A. (Ball Valve B should already be closed.)

5. Open Testcock #1.

6. Open Testcock #2. Water may run from Testcock #2 initially, but should

not continue. The level of water in the Sight Tube may drop a little, but

should not drop below 28" above the Check Valve. (Centerline of the

Sight Tube

Testcock #2

T

estcock #1

Ball Valve B

Ball Valve A

Canopy

Discharge Ball Valve.) If the level in the Sight Tube continues to drop

and water continues to run out of Testcock #2, the Check Valve is leak-

ing and should be repaired.

7. Close Testcocks #1 and #2.

Restore Operation:

1. Restore all Valves and Testcocks to their original positions and replace

Canopy.

Service Procedure

General service instructions applicable to all

sizes.

a. Rinse all parts with clean water prior to assembly.

b. DO NOT USE ANY PIPE DOPE, OIL, GREASE OR SOLVENT ON

ANY PARTS unless instructed to do so.

c. Do not force parts. Parts should fit freely together. Excess force may

cause damage and render the device inoperable.

d. Carefully inspect seals, seating surfaces, etc. for damage or debris.

e. Test unit after servicing to ensure proper operation.

f. Tighten canopy nut only until canopy cannot turn freely.

g. Rapidly open inlet ball valve to minimize spillage through the air vent.

Slowly open outlet ball valve.

h. Test unit to ensure proper operation.

i. Test unit after servicing to ensure proper operation.

j. Refer to applicable parts list and figures for visual aid information.

A. Model 765 - 1/2" through 1 1/4" sizes

1. Disassembly Bonnet/Poppet

a. Close outlet ball valve then close inlet ball valve. Bleed residual pres-

sure by opening #2 testcock.

b. Remove canopy nut and canopy.

c. Unscrew bonnet assembly from valve body by hand. (If neces-

sary, use appropriate size wrench on outside diameter of bonnet.

However, this may cause damage and require replacement of the

bonnet assembly.)

d. Remove poppet/seal assembly from body.

2. Check Valve Removal

a. Evenly depress retaining bracket approximately 1/4", and rotate

bracket 90 degrees.

b. Remove the bracket, spring and check assembly.

3. Check Valve Seal Replacement

a. Remove screw holding the guide, and lift the seal from its holder.

CAUTION: Do not damage the guide legs or the guide pin of the

holder.

b. Insert seal disc into holder, position guide in center of seal and

thread the retaining screw through the guide into the holder.

c. Lightly tighten the screw to hold the guide from rotation.

CAUTION: Over-tightening may cause distortion of the guide legs.

4. Assembly

To reassemble the device use the reverse procedure described above

along with the following special instructions.

a. Position check assembly into valve body. Position spring into

recessed area on top side of check assembly. NOTE: In some cases

it may be easier to position the spring on the check assembly prior

to positioning in the valve body.

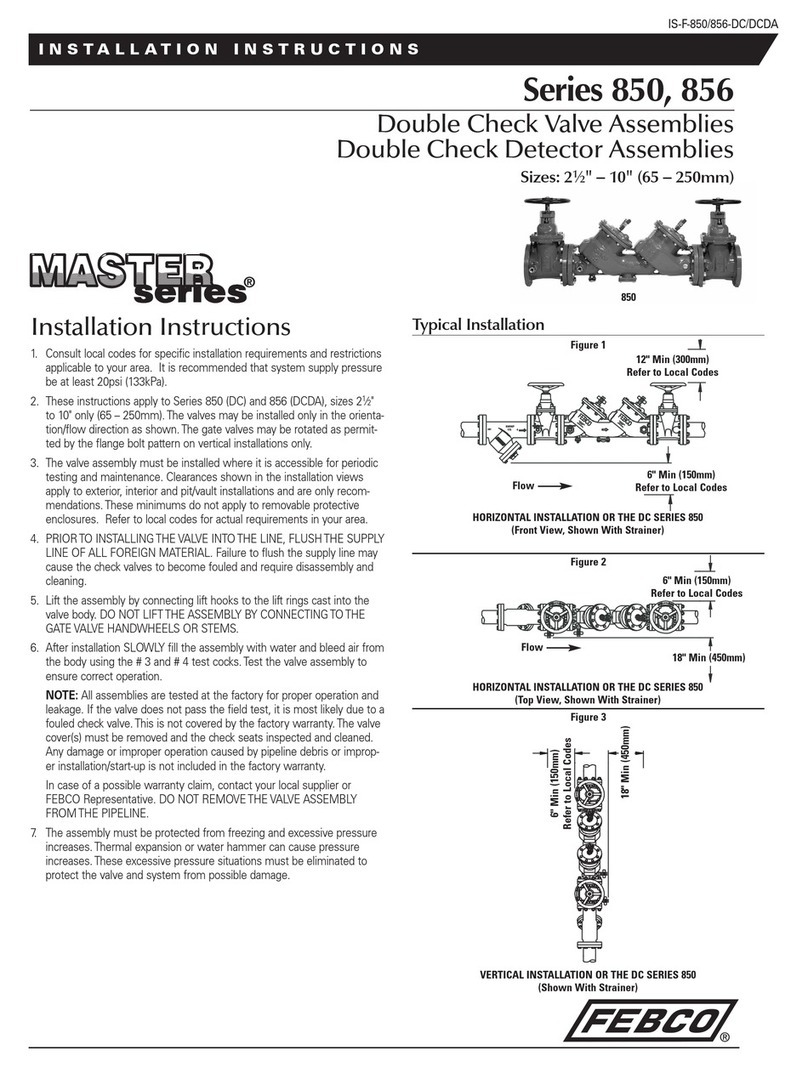

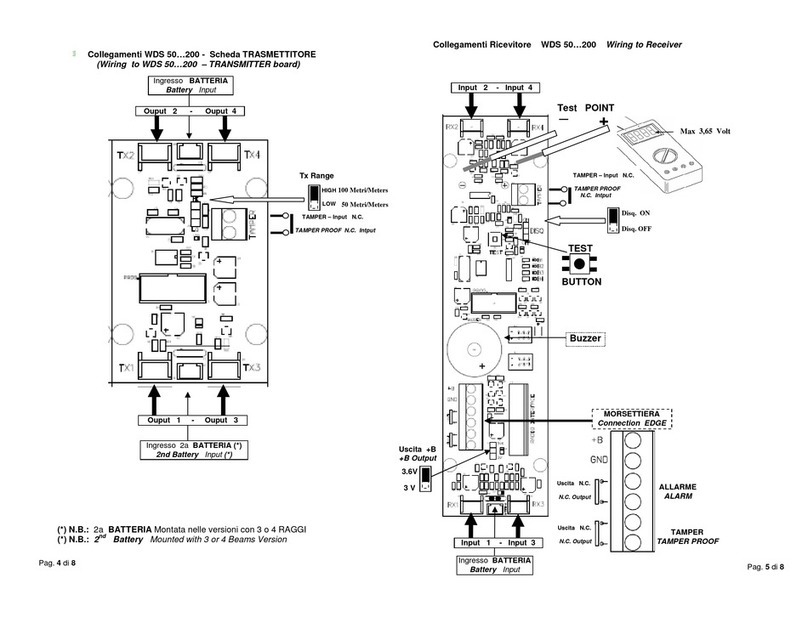

Typical Installations

Outside Installation (Side View)

IOM-F-765.indd 2 8/11/08 2:56:42 PM

3

PRESSURE VACUUM BREAKER

B. Model 765 – 1 1/2" through 2" sizes

1. Disassembly

a. Close outlet ball valve then close inlet ball valve. Bleed residual pres-

sure by opening #2 testcock.

b. Remove the six bonnet bolts and lift the bonnet from valve body.

Remove poppet and remove seat disc.

c. To replace poppet spring: unscrew nut, unscrew guide pin and

remove spring. Use caution to avoid damage to guide pin. Install

new spring and reassemble.

d. Remove the spring retaining web, spring and check assembly.

2. Check Valve Seal Replacement

a. Remove guide retaining nut and guide, lift seal from holder.

b. Insert new seal, position guide in center of holder/seal and thread

nut to retain guide. Lightly tighten nut to hold the guide from rotat-

ing.

3. Assembly

a. Position the check valve assembly, spring and retaining web into

valve body. Ensure the arms of the retaining web are aligned with

the guide and supports in the valve body.

b. Roll rubber disc into recess on poppet and position poppet assembly

in the retaining web. Place the bonnet on the valve body. Ensure the

retaining web is properly supported by the three case bosses inside

the bonnet.

c. Insert the bonnet bolts and tighten.

d. Rapidly open inlet ball valve to minimize spillage in the air vent.

Slowly open outlet ball valve.

e. Test unit to ensure proper operation.

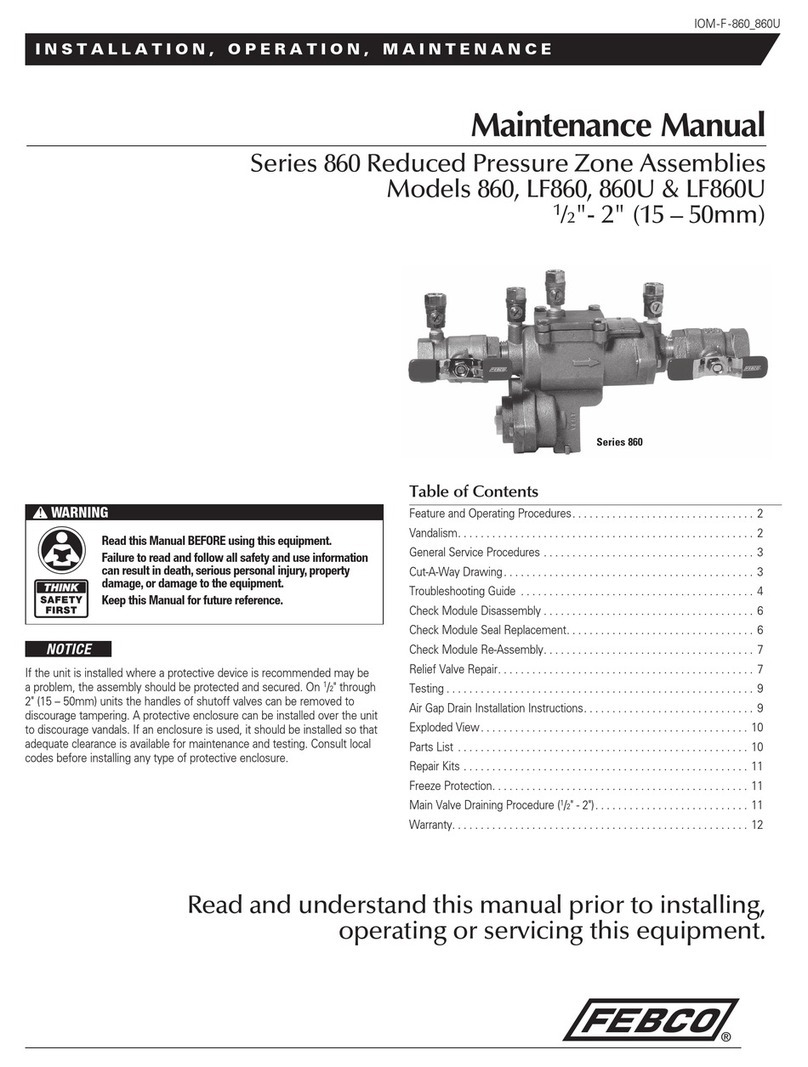

Pressure Vacuum Breaker – Model 765

"ONNET

!SSEMBLY

0OPPET

!SSEMBLY

/RING

3PRING

%RING

7ASHER

3TEM

(OLDER

$ISC

'UIDE

3CREW

2UBBER$ISC

0OPPET

2ETAINER

3PRING

#HECK

!SSEMBLY

#ANOPY

"ONNET "ALL6ALVE

)LLUSTRATIONSHOWNISFORSIZESTHROUGHONLY

"ONNETANDBOLTFORANDNOTSHOWN

#/--%2#)!,0!243

4EST#OCK

.UT

"OLT

.OTSHOWNUSEDFORn

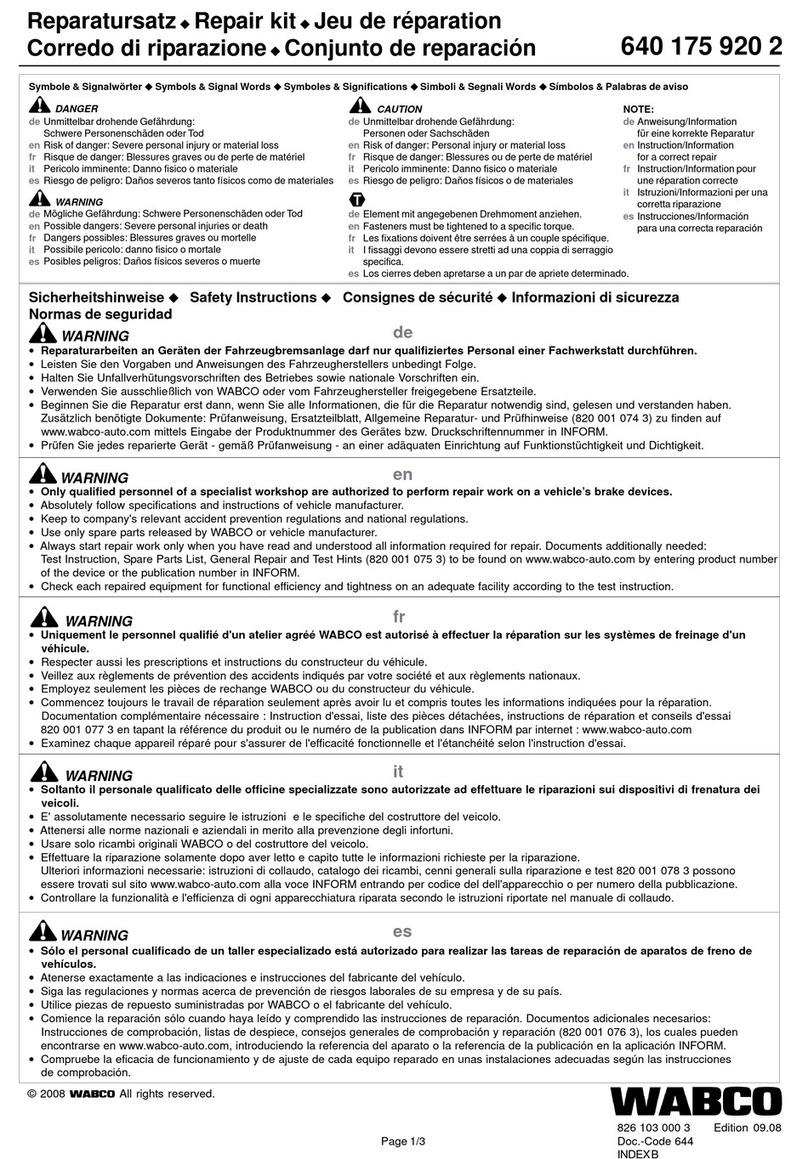

Fig. Description Quantity 765 765 765 765 765 765

No. 1

/

2" 3

/

4" 1" 11

/

4" 11

/

2" 2"

1 Nut 523-533-00 523-533-00 523-543-00 523-543-00 523-543-00 523-543-00

2 Canopy 300-092 300-093 300-089 300-089 300-083 300-083

4 Bolt 6 - - - - 1024564 1024564

6 O-Ring 1101068 1101068 398-140-72 398-140-72 398-247-72 398-247-72

7 Spring - - - - 630-096 630-096

10 Stem - - - - 200-767 200-767

13 Retainer 300-096 300-096 300-088 300-088 - -

14 Spring 630-108 630-108 630-106 630-106 630-063 630-063

20 Test Cock 2 781-074 781-074 781-075 781-075 781-075 781-075

22 Ball Valve 2 781-047 781-048 781-049 781-050 781-051 781-052

Part Kits

Rubber Parts Kit (6, 11, 16) 905-020 905-020 905-021 905-021 905-022 905-022

Bonnet Assembly (5-10) 905-047 905-047 905-048(2) 905-048(2) - -

Bonnet/Kit (3, 5-10) - - - - 901-857 901-857

Poppet Assembly (11,12) 905-049 905-049 905-050 905-050 901-860 901-860

Check Assembly (15-18) 905-051 905-051 905-052 905-052 - -

Check Repair Kit (6, 13, 15-18) - - - - 905-070 905-070

Bonnet/Poppet Kit (5-12) 905-211 905-211 905-212(2) 905-212(2) - -

(2) Kit includes parts to retrofit older style units

b. When installing the retaining bracket, ensure the spring is centered

around the base of the bracket.

c. Roll rubber disc into recess on poppet and position the poppet

assembly in the valve body.

d. To ease assembly of the bonnet into the valve body, apply a thin

coating of Vasoline on the o-ring. DO NOT USE ANY OTHER

LUBRICANT.

e. Ensure the guide pin of the bonnet correctly enters the hole in the

poppet.

f. Thread the bonnet into the valve body by hand until the bonnet

flange bottoms on top surface of valve body. DO NOT OVER-

TIGHTEN.

g. Tighten canopy nut only until canopy cannot turn freely.

h. Rapidly open inlet ball valve to minimize spillage through the air

vent. Slowly open outlet ball valve.

IOM-F-765.indd 3 8/11/08 2:56:42 PM

PRESSURE VACUUM BREAKER

Symptom: Cause: Solution:

1. Check value fails to hold 1.0 A. Debris on sealing surface or guide surfaces Disassemble and clean check

psid minimum valve surfaces

B. Damaged seat disc Disassemble and replace seal

C. Weak or broken spring Disassemble and replace spring

D. Poppet broken due to thermal expansion Replace broken poppet (see freeze protection)

2. Poppet fails to open at 1.0 A. Debris restricting free operation Disassemble and clean check valve surfaces

psig minimum B. Poppet seal adhering to bonnet Disassemble and clean and/or replace damaged parts

C. Weak spring load Replace bonnet assembly (1

/

2- 11

/

4)

Replace spring (11

/

2and larger)

3. Minor leakage through air vent A. Damaged poppet seal Disassemble and replace seal

B. Cracked or damaged poppet Disassemble and replace poppet seal

C. Cracked bonnet or damaged sealing edge Disassemble and replace bonnet assembly

D. Debris on sealing surface Disassemble and clean

4. Significant discharge through A. Poppet not properly guided Disassemble and replace damaged parts

air vent B. Major poppet or seal failure Disassemble and replace damaged parts

C. Low downstream pressure Check pressure at #2 testcock; should

be higher than 5 psig if low system

D. Insufficient inlet volume to operate device Pressure needs to be increased or partially

closed outlet ball valve to create higher

pressure on poppet.

E. Poppet and or bonnet broken Replace broken bonnet/poppet

due to thermal expansion (see freeze protection)

5. Chatter during flow conditions A. Worn, damaged or defective check valve guide Disassemble and repair or replace guide

Troubleshooting Guide

A Division of Watts Water Technologies, Inc. USA: 4381 N. Brawley • Ste. 102 • Fresno, CA • 93722 • Tel. (559) 441-5300 • Fax: (559) 441-5301 • www.FEBCOonline.com

Canada: 5435 North Service Rd. • Burlington, ONT. • L7L 5H7 • Tel. (905) 332-4090 • Fax: (905) 332-7068 • www.FEBCOonline.ca

IOM-F-765 0823 © FEBCO, 2008

IOM-F-765.indd 4 8/11/08 2:56:43 PM

Other FEB Industrial Equipment manuals