FLETCHER Alfamacchine U200P User manual

1

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

PLEASE RETAIN FOR FUTURE REFERENCE

Name

Function

Model / Type

Serial number

Year of construction

Manual Revision

FRAME ASSEMBLING MACHINE

ASSEMBLY OF FRAMES BY INSERTION OF METAL V-NAILS

U200P

2016

EN INSTRUCTIONS MANUAL

2

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

1

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

EN

1. INTRODUCTION TO USE......................................................................................................................................................... 2

1.1. HOW TO CONSULT THIS MANUAL AND THE SYMBOLS ADOPTED ....................................................................... 2

1.2. WARNING-SAFETYALERTDECALS(seegure)..................................................................................................... 2

1.3. TYPE OF USE AND CONTRAINDICATIONS............................................................................................................... 3

1.4. TECHNICAL CHARACTERISTICS............................................................................................................................... 6

1.5. PRODUCTS PROCESSED - HANDLED OR GENERATED ........................................................................................ 7

1.6. EMISSION OF AIRBORNE NOISE............................................................................................................................... 7

1.7. RESIDUAL RISKS - GENERAL INFORMATION .......................................................................................................... 7

1.8. RESIDUAL RISKS ........................................................................................................................................................ 8

1.9. DESCRIPTION OF SAFETY FUNCTIONS................................................................................................................... 9

1.10. MACHINE DESCRIPTION.......................................................................................................................................... 10

1.11. MAIN MACHINE COMPONENTS ............................................................................................................................... 10

2. INSTALLATION ....................................................................................................................................................................... 14

2.1. STORING.................................................................................................................................................................... 14

2.2. CHECKS ON RECEPTION......................................................................................................................................... 14

2.3. TRANSPORT, LIFTING AND HANDLING................................................................................................................... 15

2.4. LIFTING AND HANDLING .......................................................................................................................................... 15

3. PRELIMINARY PREPARATION AND ADJUSTMENT PROCEDURES ................................................................................. 17

3.1. PUTTING THE MACHINE INTO SERVICE ................................................................................................................ 17

3.2. POSITIONING (IF OPTIONAL STAND HAS BEEN PURCHASED) ........................................................................... 17

LEVELLING THE MACHINE (MOUNTED ON STAND) ....................................................................................................... 18

3.3. ASSEMBLY OF SEPARATELY SHIPPED UNITS....................................................................................................... 22

4. INITIAL START-UP AND USE OF THE MACHINE................................................................................................................. 23

4.1. PNEUMATIC SUPPLY ................................................................................................................................................ 23

4.2. WORKSTATIONS AND OPERATORS' TASKS........................................................................................................... 25

4.3. CHECKS, ADJUSTMENTS AND START-UP .............................................................................................................. 26

4.4. START-UP................................................................................................................................................................... 26

4.5. WORK CYCLE............................................................................................................................................................ 38

5. MAINTENANCE, TROUBLESHOOTING AND CLEANING ................................................................................................... 40

5.1. MAINTENANCE TECHNICIAN REQUIREMENTS ..................................................................................................... 40

5.2. WORK STATIONS AND MAINTENANCE TECHNICIAN DUTIES.............................................................................. 40

5.3. MAINTENANCE PRESCRIPTIONS............................................................................................................................ 40

5.4. GENERAL WARNINGS .............................................................................................................................................. 41

5.5. ISOLATION FROM EXTERNAL ENERGY SOURCES............................................................................................... 41

5.6. ROUTINE MAINTENANCE......................................................................................................................................... 41

5.7. TASKS THAT CAN BE PERFORMED BY THE OPERATOR ..................................................................................... 42

5.8. TASKS THAT CAN BE PERFORMED ONLY BY MAINTENANCE TECHNICIANS ................................................... 43

5.9. CLEANING.................................................................................................................................................................. 46

6. TROUBLESHOOTING AND RELEASE OF MOVING PARTS ............................................................................................... 49

7. REINSTALLATION AND REUSE ............................................................................................................................................ 51

8. EXTINGUISHING MEDIA........................................................................................................................................................ 51

9. SCRAPPING AND DISPOSAL................................................................................................................................................ 51

9.1. SCRAPPING............................................................................................................................................................... 51

9.2. DISPOSAL .................................................................................................................................................................. 52

TABLE 1 - MACHINE UNIT .............................................................................................................................................................. 53

TABLE 2 - HEAD UNIT..................................................................................................................................................................... 54

TABLE 3 - CROSSBAR AND COLUMNS UNIT .............................................................................................................................. 55

TABLE 4 - FENCE UNIT................................................................................................................................................................... 56

TABLE 5 - V-NAIL PUSHER UNIT ................................................................................................................................................... 56

TABLE 6 - STAND UNIT................................................................................................................................................................... 57

2

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

DANGER - WARNING

BEFORE USING THE MACHINE PLEASE READ THIS MANUAL CAREFULLY SO THAT YOU BECOME FAMILIAR

WITH THE MACHINE, ITS ENVISAGED USE AND ANY RISKS ASSOCIATED WITH IT.

KeeptheUseandMaintenanceManualingoodcondition:Remember,itisanintegralpartofthemachine.Alwaysrefertothemanual

togetbestmachineperformanceinmaximumsafetywhileperformingtheoperationsdescribedtherein.

Thismanualmustbekeptinaneasilyaccessibleplace,nearthemachine,atalltimessothatitcanbeconsultedwhenevernecessary.

DANGER - WARNING

USE THE MACHINE SOLELY AND EXCLUSIVELY FOR THE USES INDICATED AND IN ACCORDANCE WITH THE

RECOMMENDATIONS PROVIDED IN THIS MANUAL. NEVER TAMPER WITH IT, FORCE IT OR USE IT IN ANY

INAPPROPRIATE MANNER.

1. INTRODUCTION TO USE

1.1. HOW TO CONSULT THIS MANUAL AND THE SYMBOLS ADOPTED

Pleasepayparticularattentiontothewords“DANGER–WARNING”,“DANGER–CAUTION"and“NOTE”asusedinthismanual.

To draw the user’s attention to certain information and provide warning messages, the operations described in this manual are

accompaniedbysymbolsandnotes tohighlight thepresenceofanyhazardsandindicate thesafe useoftheequipment.These

symbolsandnotesbelongtovariouscategoriesasindicatedbelow:

DANGER – WARNING: IMPORTANT INFORMATION CONCERNING GENERAL SAFETY.

DANGER-CAUTION: highlights situations where careful and sensible actions are essential.

NOTES: information of a technical nature.

1.2. WARNINGSTICKERS-INDICATIONS(seegure)

Sticker Description

Wearprotectivegoggles.

Wearprotectivegloves.

Wearsafetyfootwear

Wear ear defenders.

Riskofimpactagainstobstacles:afxedon

thecornersoftheguards.

3

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

1.3. TYPE OF USE AND CONTRAINDICATIONS.

GENERAL WARNINGS

Theoperatormustreadalltheinformationinthismanualcarefully,payingspecialattentiontothesafetyprecautionslistedinthischapter.

ItisalsoessentialfortheOperatortoabidebythefollowingwarnings:

· Alwayskeepthemachineandworkareacleanandtidy.

· Arrangesuitablecontainersforstoringtheworkpiecestobeprocessedandthosethathavealreadybeencompleted.

· NEVERusethemachinewhennotingoodpsycho-physiologicalcondition.

· Alwayswearsuitableworkweartoavoidanyhindrancesand/orhazardousentanglementinmachineparts.

· PersonnelmustbeauthorizedandtrainedbeforehandonmachineusebyAlfamacchinetechnicians.

· Wearallnecessarypersonalprotectiveequipment:safetyfootwear,glovesandprotectiveglasses

· TheoperatormustwearpersonalprotectiveequipmentindicatedintheInstructionManual,inaccordancewiththeoperationsto

carry out.

· NeverremoveoralterthedataplatesafxedtothemachinebytheManufacturer.

· Keepngerswellawayfromtheoperatingarea.

· Keepfeetawayfromthepedalduringmachineadjustmentoperations.

PERMITTED USE

Themachinedescribedhereinisdesignedtoberunby1operatorsuitablytrainedandinstructedwithregardtoresidualrisks.The

operatormusthavethesameskills,intermsofsafety,asthemaintenancetechniciansandadequateprofessionalcompetence.

DuringitsPERMITTEDANDREASONABLYPREDICTABLEUSE,themachinemaybeusedexclusively:

• toworkwithwoodenmouldingsofvarioushardness,withmultiplesurfacenishes,forthepurposeofmakingframesforpictures,

mirrors,displaycases,cupboarddoorsetc.)inaccordancewiththecharacteristicsdescribedintheheading“ProductsProcessed

-HandledorGenerated”.Useofthemachinetoperformprocessesotherthanthosedescribedinthismanualistobeconsidered

improper and therefore strictly prohibited.

• withtheproducts(andmaterials)describedandhavingthedimensionsspeciedintheheading“TECHNICALCHARACTERISTICS”

Itisalsocompulsory:

• forthemachinetobeusedbyoneoperatoronlywhohasreceivedadequatetraining/informationconcerningmachineoperations,

performanceandanyhazardsassociatedwithitsuse.

• toensurenoexposedpersonsarepresentinthemachine’soperatingareabeforeproceedingwithanyoperationswhatsoever.

• tochecktheperfectconditionofallthesafetydevicesbeforestartingtoworkwiththemachine.

• toensure,whenthemachineisplacedonthefactoryoorwhereitistobeused,thatitisinstalledonalevel,smoothandperfectly

horizontalsurface.Theoormusthaveanadequateloadbearingcapacitytosupporttheweightofthemachine.

• tocheck,priortostartingworkwiththemachine,theconditionsofambientlightingandensuretherearenoareasofshadow,glare,

orpotentiallyhazardousstrobeeffects.

• todisconnect,priortostartinganyworkonthemachine,themaincompressedairsupplies,tosafelydischargeanyresidualenergy

inthemachinecircuits,andwaitforallpartsathightemperaturestocooldownadequately.

UNINTENDED USE

DANGER - WARNING

THE MACHINE MUST NOT BE USED IN A PROHIBITED MANNER. SPECIFICALLY:

• itcannotbeoperatedwithparametersdifferenttothoseshowninthe“TECHNICALCHARACTERISTICS”tableorwithproducts

and/ormaterialswithdifferentcharacteristicstothosepreviouslydescribedintheheading“TECHNICALCHARACTERISTICS”.

• all uses of the machine other than those described in this manual are construed as improper and as such the manufacturer declines

all liability

• theuserisresponsibleforanydamageresultingfromfailuretoobservetheoperatingconditionsagreedatthetimeoftechnical

specicationandorderconrmation

4

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

FORBIDDEN USE

DANGER - WARNING

FURTHERMORE IT IS PROHIBITED TO USE THE MACHINE IN AN INCORRECT MANNER, IN PARTICULAR:

• never leave the loaded machine unattended

• neveruseammable,corrosiveortoxicsubstancestocleanthemachine

• neverallowunauthorizedpersonneltousethemachine

• neversmokeoruseopenameequipmentorhandleincandescentmaterial,unlessadequatesafetymeasureshavebeenadopted

• neveractivateoradjustthecontrolandlockingdevices,suchasknobsorsimilardevices,duringmachineoperationorwhennot

authorizedtodoso

• neverhangobjectsorweightsonthemachine

• neverusethemachinewiththesafetyguardsopen,incorrectlyfastened,orremoved

• neverusethemachinewiththesafetymicroswitchesandinterlockingsafetydevicesinhibitedand,ingeneral,withanysafetyand/

or protective device (mechanical) deactivated and/or non-functional

• neverpartiallyortotallyby-pass,remove,modifyorinanywayrenderineffectivetheguards,safetymicroswitchesandwarning

signs

• useofthemachineisforbiddenwhentheuserhasnotadoptedallthenecessarymeasurestoeliminatetheresidualrisksas

indicated in this instruction manual

• neverusethemachineforoperationsotherthanthoseexplicitlyindicatedinthisinstructionmanual.

• neverusethemachineinenvironmentsforwhichithasnotbeendesignedunlessallnecessarysafetymeasureshavebeenadopted

beforehand.

• the machine must not be used by untrained personnel

• foodstuffsmustnotbebroughtintocontactwiththemachine

• itisprohibitedtoactivatethecontroldevicesformachinemovementswithoutrstcheckingandascertainingtheabsenceofpersons

inthedangerareassubjecttomachinemovements

• itisprohibitedtoentertheoperating/dangerzoneofthemachineduringcontrolofthemachine’smovingparts

• itisprohibitedtoenterthemachineworkingareawithanypartofthebody,handsandarmsincluded,beforehazardousmoving

elements have come to a complete standstill.

• itisprohibitedforthemachineoperatorandmaintenancetechniciantoenterthedangerzonestoperformcleaning,lubrication,

maintenanceoperationsetc.withouthavingrstsetthepowercut-offswitchesto“ZERO”andpadlockedtheminthisposition.

• themachinemustnotbeusedincriticalconditionsofstability,i.e.:

• whenplacedonasupportsurfacewhichisnotperfectlyhorizontalandsmooth,ordoesnothaveaninadequateloadcapacity

as indicated in this manual;

- outdoorsorworksiteswithopenwindowsanddoors.

• thefollowingarestrictlyprohibited:

- processingofmaterialsandproductsthatarenotexpresslyindicatedinthismanual

- processingofmetalmaterialsmadeofaluminium,lightweightalloys,andsteelanditsalloys

DANGER – CAUTION

The manufacturer cannot be held liable for any faults caused by unreasonable, improper and/or incorrect use of the

machine.

Theuserisanywayresponsibleforalldamagederivingfromfailuretocomplywiththespeciedtermsofuse.Foranyfurtherinformation

alwaysconsultthemanufacturer’sengineeringdepartment.

Theuserisalwaysresponsibleforprovidingsuitablepersonalprotectiveequipmenttomachineoperatorsandforinformingthemon

the permissible uses of the machine

5

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

PERSONNEL AUTHORIZED TO USE THE MACHINE

Thismachinehasbeendesignedandmanufacturedtobeusedbyqualiedpersonnelwithadequatetraining,experienceandskills

inaccordancewiththecharacteristicsdescribedbelow:

Operators/Apprentices:

• may be male or female;

• mustbeaged14orover;

• must have full use of both hands;

• must have no physical or mental disabilities;

• mustknowandfullyunderstandthecontentsoftheusermanual.

PERMITTED AMBIENT CONDITIONS AND OPERATING LIMITS

DANGER - WARNING

THIS MACHINE IS NOT SUITABLE FOR USE IN POTENTIALLY EXPLOSIVE ENVIRONMENTS.

THEREFORE IT IS PROHIBITED TO INSTALL OR USE IT IN ANY SUCH ENVIRONMENT.

SERVICE CONDITIONS

SERVICE CONDITION USER LIMITS

Installation type Indoor

Floorconditions Horizontalandsmooth:irregularityandgradienttolerancewithin

2%

Supportingsurfacecharacteristics Flooringincompliancewithhealthandsafetyrequirementsinthe

workplaceinaccordancewithallapplicablelegislation

Maximumambientairtemperature +40°C/104°F

Minimumambientairtemperature 5°C/104°F(iftheelectricalequipmentasaprotectionratingofat

leastIP54)0°C/32°F(iftheelectricalequipmenthasaprotection

ratinglowerthanIP54)

Ambientworkingtemperature +5°C<T<+45°C/113°F

Transportandstoragetemperature between-25°C/-13°Fand+55°C/131°F(temperaturesofup

to+70°C/158°Fareadmissibleforperiodsoflessthan24h)

Maximumaltitudeabovesealevel 1000m

Minimumrequiredlightintensity 600lux

Relativehumidityof100%at+25°C/77°F(electricalequipmentprotectionratingofatleastIP54)

Relativehumidityshallnotexceed50%at+40°C/104°For90%at+20°C/68°F(electricalequipmentprotectionratingbelowIP54)

Equipmentformachinedesignedforindoorinstallations

Machine NOT suitable for operation in contaminated atmospheres: for example, dusts, acids, corrosive gases, salt or similar

contaminants.

Machine NOTsuitableforoperatinginpotentiallyexplosiveatmospheresclassiedaszone0,zone1orzone2.

Machine NOTsuitableforoperationinenvironmentssubjecttothepresenceofionizingandnon-ionizingradiation:forexample,

microwaves,UVrays,laser,X-rays,andsimilar.

ElectricalequipmentNOTsuitableforinstallationonmachinesorforoperationinplacessubjecttovibrationandimpact:otherwise,

installequipmentwellclearofsourceofvibrationandimpactandtantivibrationsupports.

Pollutionclassofelectricalequipmentequivalentto3(THREE)

Installationenvironmentequivalenttotwo(2)

Canbeutilisedinresidential,commercial,oflightindustrialzonesthankstocompliancewithstandardEN61000-6-1

Intendedfordirect/exclusiveserviceofindustrialprocessmachinery

6

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

SERVICE CONDITIONUSER LIMITS

Specialandadditionalprescriptions,notenvisaged,

mayberequestedformachinesintendedfor:

• outdoor use;

• handlingpotentiallyexplosivematerials;

• useinpotentiallyexplosiveand/orammableatmospheres;

• use involving specic risks in the processing of specic

materials;

• use in mines;

• useinrefrigerationplants;

• useathightemperatures;

• use in corrosive environments;

• useinstrongmagneticelds;

• use in radioactive conditions;

• usefor loadsthenature ofwhich couldleadto hazardous

situations(forexample,moltenmetal,acids/bases,particularly

fragileloads,explosives),

• useonshipsandareasaffectedbyearthquakes;

• food-contact use;

• use in public areas;

•useinaircraftgroundsupport.

1.4. TECHNICAL CHARACTERISTICS

Machinecharacteristics

Workingbenchdimensions(WxL)...................................................................................................................... 300x450mm-13”x18”

Maximummachineheight...................................................................................................................................................450mm-51”

Machineweight....................................................................................................................................................................32kg-83lbs

V-nailmagazinecapacity.............................................................................................................................................................220pcs

Max.quantityofV-nailsinsertedperposition..................................................................................................................................9pcs

V-Nail insertion positions ............................................................................................................................................................Multiple

Max.distancebetweennails ...................................................................................................................................................... 180mm

Minimum/maximumwidthofmoulding .............................................................................................................6/130mm-¼”–5”1/8

Minimum/maximumheightofmoulding...............................................................................................................6/80mm-¼”–3”1/4

V-nailcharacteristics

Height ................................................................................................................................................................................. 7-10-12 mm

Heightofoptionalheads........................................................................................................................................................3-5-15 mm

Compressedairsupply

Maximumpermittedinletpressure .................................................................................................................................................. 8bar

Operatingpressure.................................................................................................................................................................. 2 ... 8 bar

Specicairconsumption...................................................................................................................................................................3 Nl

V-nailcharacteristics

V-nailtype Heightmm

H3 3mm (optional)

H5 5mm

H7 7mm

H10 10mm

H12 12mm

H15 15mm

7

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

Material Recommendedsharpness

Softwoods

and plastic

SW

transparent stick

Mediumwood MW

brownstick

Hardwood HW

greenstick

Very Hard Wood

and MDF

HS

red stick

1.5. PRODUCTS PROCESSED - HANDLED OR GENERATED

Theproductshandledbythemachinedescribedhereinmustbemadeupofwoodenmouldingsofvarioushardness,withmultiple

surfacenishes,forthepurposeofmakingframesforpictures,mirrors,displaycases,cupboarddoorsetc..

Themaintechnicalcharacteristicsoftheproductshandledbythemachinedescribedhereinareprovidedbelow.

DESCRIPTION OF PRODUCTS HANDLED CHARACTERISTICS

Minimum/maximumproleheight 6-80mm

Minimum/maximumprolewidth 6-130mm

1.6. EMISSION OF AIRBORNE NOISE

NOTE – The manufacturer declares, under his own responsibility, that the machine produces a continuous equivalent A-weighted

sound pressure level of 72 dB.

DANGER – WARNING:

TO AVOID THE DANGER OF HEARING DAMAGE CAUSED BY SHRILL OR INSISTENT NOISE, THE MACHINE

OPERATOR AND MAINTENANCE TECHNICIAN MUST ALWAYS USE APPROPRIATE HEARING PROTECTION, SUCH

AS HEARING DEFENDERS OR EARPLUGS.

1.7. RESIDUAL RISKS - GENERAL INFORMATION

Thismanualcontainsalistanddescriptionoftheresidualrisksthatcouldnotbeeliminatedinthedesignstageandthattherefore

remain present on the machine.

Foreachrisk,suitableinstructionsorprescriptionsaregivenwhichtheusermustobserveinordertoavoidhazardsaffectingthe

machineoperator,maintenancetechnicians,anyexposedpersonsandthemachineitself.

8

A

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

1.8. RESIDUAL RISKS

Foreachrisk,suitableinstructionsorprescriptionsaregivenwhichtheusermustobserveinordertoavoidhazardsaffectingthe

machineoperator,maintenancetechnicians,anyexposedpersonsandthemachineitself.

Residualriskofngercrushing

Duringthenormaloperatingcycleandduringmaintenance,Operatorsareexposedtocertainresidualriskswhich,duetothenature

of the operations could not be completely eliminated.

-Fingercrushinghazardintheoperatingareaoftheverticalclamp(A).

Furthermore,itistobepointedoutthatsaidngercrushingrisksarepresentneareachmobileelementinstalledoverthemachine’s

workingbench.

Consequentlytheoperatorandmaintenancetechnician,aswellasobservingtheinstructionsprovidedinthismanual,mustnever

placetheirngersoranyotherpartofthebodyinthezoneindicated.

What’smore,workersmustneverwearrings,wristwatches,jewellery,tornclothing,scarves,tiesoranyotherlooseclothingorpersonal

accessoriesthatmayconstitutearisk.Makesuresleevestsnuglyaroundwristsandkeeplonghairtiedback.

Residualriskduetothecombustibilityofthesubstancesusedinthemachineandtheproductshandledbythesame

Toavoidthehazardsresultingfrom:

• theignitionofsubstancesusedinthemachine;

• residualrisksassociatedwithpossibleoutbreaksofre;

theemployer,inadditiontotrainingandadequatelyinformingthemachineoperatorandmaintenancetechnicianonsuchrisks,must

providepermanentreprotectionsystemsinthevicinityofthemachinecontrolstation.Saidsystemsmustbesuitableforthetypes

ofmaterialwhichcouldcatchre.

PPEtobeused:

Protectivegloves Safetyfootwear Safetyclothing Hearingprotection

Residualriskduetonoise

Asdemonstratedbyexperimentaltests,themachineproducesacontinuousequivalentA-weightedsoundpressurelevelof70dB.

Toavoidtheriskofhearingdamagecausedbyshrillorinsistentnoiseduringmachineuse,inadditiontobeingadequatelyinformed

andtrained,theoperatorandmaintenancetechnicianmustalwaysuseappropriatehearingprotection,suchashearingdefenders,

earplugsorsimilarpersonalprotectionequipmenttosafeguardhearing.

9

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

Residualriskcausedbypilotingthevalves

Thereisaresidualriskforthemaintenancetechnician,whenthesafetyguardsareopenandthevalvepilotsareactivated,inorder

tocheck(duringtroubleshootingprocedures)theoperationofthepneumaticallyoperatedmobileelements,whenenergy

remainsaccumulatedintheactuatorcylinders.

Consequently,whentheaforementionedactivitiesareperformed,themaintenancetechnicianmustmakesurethatnoexposedpersons

are found near the pneumatically controlled mobile elements and in any case said mobile elements must only be activated if strictly

necessaryforpinpointingoperatingfaults.

Residualriskduetothepresenceofaccumulatedenergyinsidethepneumaticactuatorcylinders

Thereisaresidualriskforthemaintenancetechnicianwhenthemachineisisolatedfromthecompressedairnetwork,duetothe

presenceofaccumulatedenergyinsidetheactuatorcylinders,whenmobileguardsareopencausedbythepresenceofclosed-

centrevalvesand/ortankswhichremainpressurized.

Pleasenotethatsaidpipingisdulyidentiedandindicatedtodistinguishitfromallotherpipinginstalledonthemachine.

Consequently,beforecarryingoutanyworkontheaforementionedcylinders,inaccordancewiththeinstructionsgivenintheactuator

manuals, the maintenance technician must neutralise the accumulated energy working in compliance with the safety regulations

applicable to maintenance personnel, such as, for example, manual activation of the special tool for the piloting valves used to

dischargestoredenergy.

Undernocircumstancesmustthepipingbedisconnectediftheystillholdresidualpressure.

1.9. DESCRIPTION OF SAFETY FUNCTIONS

Protectivedevicesinstalledonthemachine

DANGER - WARNING

IT IS STRICTLY PROHIBITED TO REMOVE THE PROTECTIONS AND SAFETY DEVICES EXCEPT WHEN STRICTLY

NECESSARY FOR THE PURPOSE OF CARRYING OUT MAINTENANCE WORK.

Whensuchprotectionsandsafetydevicesneedtoberemovedallnecessarymeasuresmustbeadoptedtohighlightthissituation

immediatelyandminimiseanypossibleassociatedhazards.

Theprotectionsandsafetydevicesmustberettedassoonasthereasonsfortheirtemporaryremovalarenolongerapplicable.

Eachoperatingunitofthemachineisprotectedbyaguard,whichmayalsobeaxedguarddesignedtopreventaccesstodangerous

parts,except:

• intheupperpartoftheworkingbenchtoperformadjustments,tooling,partsreplacement,etc.

• inthelowerpartoftheworkingbenchtoperformadjustments,tooling,partsreplacement,etc.

10

A

D

E

C

B

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

1.10. MACHINE DESCRIPTION

TheU200Pframeassemblingmachinehasbeendesignedtoassembleeverykindofframe.

TheU200P,withitssimpleandeasy-to-useconstruction,canexecuteprecisejoinsofanytypeofmouldingusingspecialsteelV-nails.

ItcanoperatewithnormalV-nails,reinforcedV-nailsforveryhardwoodandspecialALFAGRAFV-nailswith“pullingpower”ofvarious

heights.

1.11. MAIN MACHINE COMPONENTS

Theequipmentlistedbelowreferstostandardmachines.

Consequently,anyspecialsuppliesmayhavesomedifferentcomponentstothoselisted.

Afterremovingthemachinefromthepackaging,makesurethefollowingaccessoriesarepresent:

• 1 head for 7-mm V-nails;

• 1 head for 10-mm V-nails;

• 1 Head for 12-mm V-nails;

• 1 Mechanical stopper holder;

• 1Magneticsupport;

• 1interchangeablestopper-soft(lightblue);

• 1Interchangeablestopper-medium(yellow);

• 1Interchangeablestopper-hard(black);

• 1Roundmagneticfeltstopper;

• 1Wrench(5-mm)forchangingheads;

• 1 Wrench (6-mm) for machine assembly;

• 1Rodwithmagnets(pencilmagnet)forV-nailremoval;

• 1Fixed90°fence;

• Singleclamp;

• Stand (optional);

• Instruction Manual.

Themaincomponentsthatmakeupthemachineare:

•Workingbench

Theworking benchisthe surfaceonwhich manualoperations

take place to move, clamp and join the frame mouldings, also

incorporatingalltheoperatorcontrols.

Itismadeupofthefollowingmainparts:

(A)Verticalmouldingclampunit

(B) Alignmentguidesunit

(C) V-nailringunitandmagazine

(D) Clampingunitsairpressureadjustment

(E) Alignmentguidemovementtravelstopadjustmentunit

Verticalclampunit

Thisunitisdesignedtoimmobilizethemouldingsontheworking

benchandcounteracttheV-nailingforce.

Itspositionensuresthatthestopperisalignedwiththeringhead

andisthereforeinlinewiththedirectionofV-nailinsertion.

It is important that the air pressure applied to the vertical clamp

providesthrustwhichisalwayshigherthanthethrustoftheV-nails,

ifthisisnotthecase,V-nailinsertioncouldresultinthemouldings

beingliftedup,resultinginincompleteinsertionoftheV-nailand

apoorqualityjoin.

Theunitismadeupofamechanicalormagneticstopperholder

(P) to which the interchangeable rubber stoppers of varying

hardness are applied, located at the bottom of a punched column

(N)whichcanbepositionedatvariousheightsdependingonthe

sizeoftheframe.

Theassemblyisfastenedtotwosturdycolumns(S)themovement

ofwhichiscontrolledbypneumaticactuators.Thepunchedcolumn

isinstalledonasupport(R)whichmakesitpossibletocarryout

horizontaladjustmentofthestopperalongthelineofassembly.

11

F

E

G

I

H

N

Q

S

O

P

R

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

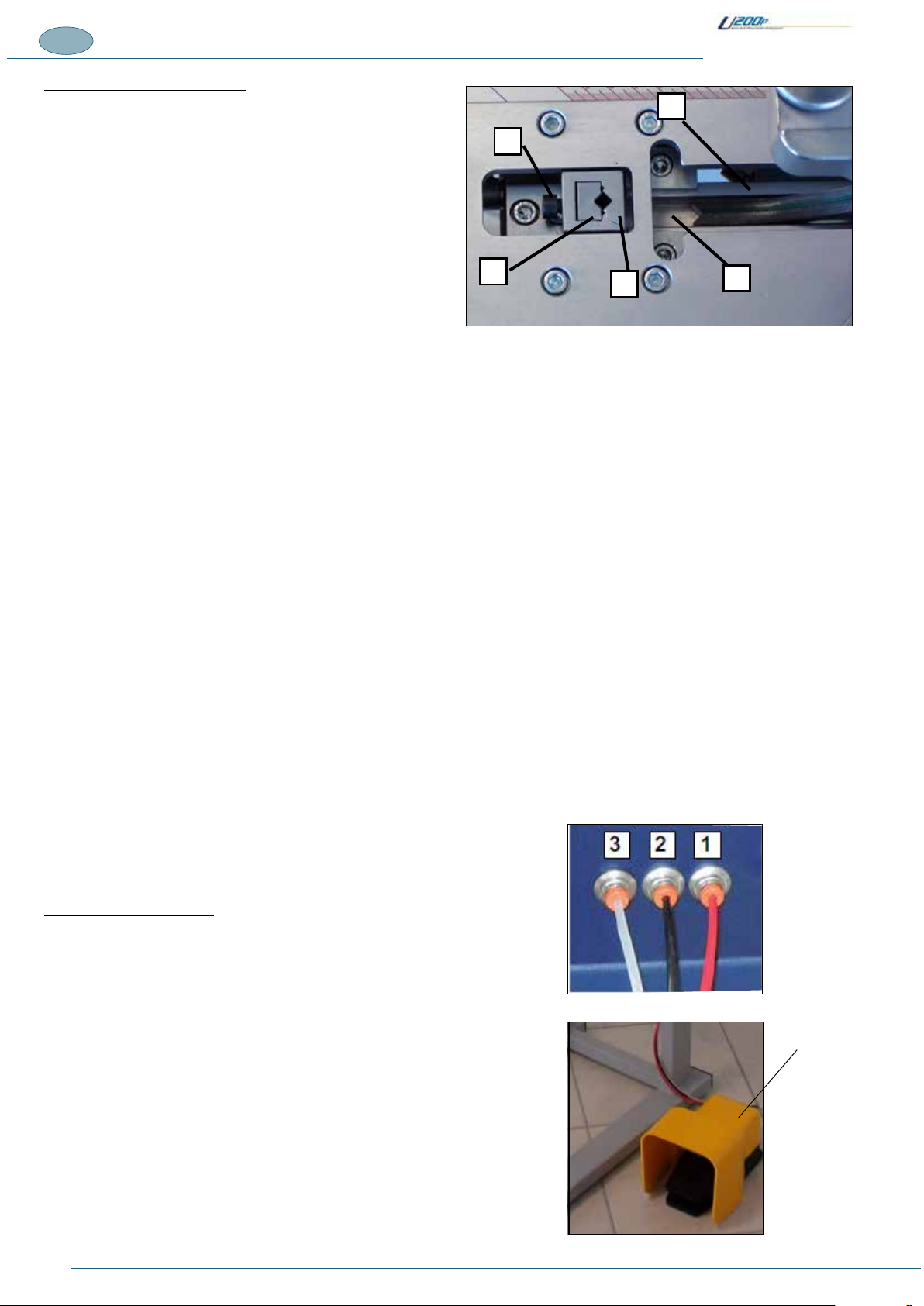

Theverticalstopperunitismadeupofthefollowingmainparts:

(N) Punchedrod-allowstheoperatortopositionthestopperat

variousheightsbasedonthevariousframeproles.

(O) Screw for fastening and for rapid changeover of the

mechanicalstopperholderorthemagneticsupport;

(P) Stopper holder, which may be mechanical or magnetic

dependingonthetypeofaccessoriesused.

(Q) Clickknobforblockingthecolumn.

(R) Drilled rod support arm.

(S) Piston stem vertically activated by the pneumatic actuator.

Stoppersavailableonrequest:

F) Mechanical stopper holder;

E)Interchangeablestopper-soft(blue);

E)Interchangeablestopper-medium(yellow);

E)Interchangeablestopper-hard(black);

I) Roundmagneticfeltstopper;

G)Cornermagneticstopperholder;

H)Magneticsupport

12

A

DCE

F

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

V-nailringunitandmagazine

In the U200P machine, the magazine (E) can hold V-nails of

differentheightsbutonlyoneV-nailheightcanbeusedatatime,

dependingonthenailingheadinstalled.

Whenthesizeofthe V-nailsischangedthe nailinghead must

alsobeswitchedovertomatchtheV-nailsused.

The V-nails are held in position by the V-nail pusher device (F).

Head and L-block support are designed to guide the V-nails

duringthethrustactionofthehammerandtheirinsertionintothe

overlyingmouldings.

ThemagazineisinturnbroughtupagainsttheL-blocksupport

andbymeansofaV-nailpushersuppliesandalignstheV-nails

againsttheguideeachtimethehammerisactivated.

The hammer is activated by a pneumatic cylinder which is

controlled by the pneumatic pedal.

Perfect mechanical alignment of these parts ensures precise

insertion,singleormultiple,oftheV-nailsinthemouldingstobe

joined,inthequantityandwiththespacingrequired.

(A) Screwforfasteningthehead.

(B) Headofdifferentheights.

(C) Hammer.

(D) L-block support

(E) V-nailpusherwhichkeepstheV-nailsataconstantpressure

upagainsttheringunit.

(F) V.nailmagazine

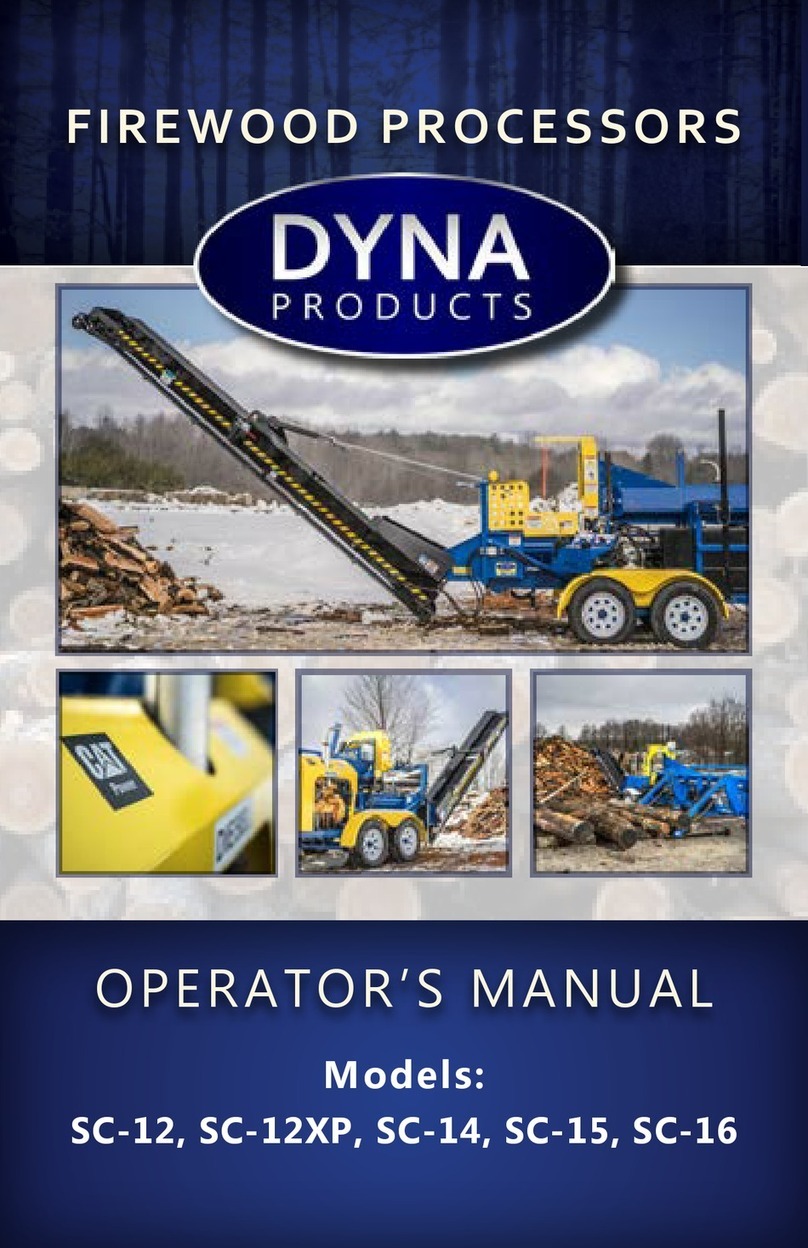

Pneumaticpedalhook-up

Beforeconnectingthemachinetothepneumaticsystem,youmust

rstconnectthecontrolpedal.

Thethreeairlineswhichareconnectedtothepedalassembly

mustbeinsertedinthethreeconnectorslocatedontheright-hand

sideofthemachineinthefollowingorder:

1) RED line in the connector on the outer side (1).

2) BLACK line in the intermediate connector (2).

3) TRANSPARENT line in operator side connector (3)

13

1

C

AB

A

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

Alignmentfencesunit

Thealignmentfencesunit,positionedontheworkingbench,can

slidealongtheassemblylineoftheringunitanditspositionis

adjustedbytheoperator.

Fixed fences for 120° and 135° corners may also be installed

inthe fence support (A) for making frames with 6 and 8 sides

respectively (available as optional accessories).

Two-knobfence(optional)

Thexedfencecanbereplacedwiththetwo-knobmodel(C)which

allowstheusertoadjustthetiltofthemouldingstopinrelation

totheworkbench.

Mouldingsmayhaveaslantingedgewhichwouldmaketheaction

ofthehorizontalclampineffective.Thetwo-knobfenceisdesigned

toincludetiltadjustmentofthesurfaceagainstwhichthemoulding

rests to improve stability.

The two-knob fence can be used to improve clamping of the

mouldingsduringassembly.

14

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

2. INSTALLATION

2.1. STORAGE

Themachine,intendedforindoorinstallationmustbestored,ifnecessary,inwellventilatedstoragefacilitiesandprotectedfromdust.

Thedeliveredelementsmustremainintheiroriginalpackinguntilthetimeofnalinstallation.

Allpartsofthemachinesubjecttotheriskofoxidationareprotectedwithgreaseandprotectivespraysatthetimeofdispatchtoprevent

oxidationcausedbyweatherconditions.

Inthecaseofprolongedinactivitythemachinemustbestoredwithallnecessaryprecautionstakenbasedonthelocationandexpected

storagetimes:

1. Store the machine in an enclosed place.

2. Protect the machine from impact and stress.

3. Protectthemachinefromhumidityandexcessivetemperaturedifferences(refertothetablebelow).

4. Donotallowcorrosivesubstancestocomeintocontactwiththemachine.

5. Checkthatthepackhasnotbeendamagedandthatitisperfectlydry.

6. Specically,ifthemachineisinsideashippingcontainer,thestoragearemustbecoveredandprotectedagainstdirectweather

includingrain,snowandhail,anditmustbeaccessibleexclusivelytoauthorizedpersonnel.

Themachineisprotectedinsuchawayastowithstandthetemperatures,humidityandvibrationlevelstypicallyassociatedwith

transportandstorage.

Ambient

temperature

Storing

temperature

Relative humidity

Vibrations

Atmospheric

pressure

-25/+40°C

-25/+55°C

0/+55°C

100%attemperatureof+25°C

Lowerthan50%attemperatureof+40°C

Lowerthan90%attemperatureof+20°C

5.9m/s2(0.6G)orhigher

900mbarorhigher

Avoidplaceswhere

there may be

unexpectedchangesin

temperature that could

lead to the formation

of condensate or

freezing.

Storagetemperatureisconstruedasashort-termvalue,e.g.duringtransportation.Condensationorfreezingnormallyoccursinsites

subjecttosignicanttemperatureexcursions.Evenifrelativehumidityinsuchconditionsfallswithinthevaluesshowninthetable,

locationssubjecttosignicanttemperaturechangesshouldbeavoided.

2.2. CHECKS ON RECEPTION

NOTES

It is essential to check the packs at the time of arrival and in the precise moment in which they are received. The check is performed

in two stages for each pack received to avoid misunderstandings with the shipping agent.

Administrativecheck

1. Crate number and number of packs.

2. Weightandsize

3. Correspondenceofinformationonshippingdocumentwiththematerialeffectivelydelivered(description,serialnumber,etc.).The

technicaldatagivenonthemachineidenticationplatemustcorrespondwiththedategiveninthetechnicaldatasupplied).

4. Checkcorrespondencebetweenshippingdocumentdataandtheorder.

Technicalcheck

1. Conditionandintactnessofpackaging.

2. Checkthatthepackagingshowsnosignsofvisibledamagecausedduringtransportandhandlingoperations.

Alltheabovechecksmustbeperformedbyinspectioninthepresenceoftheshippingagent’sdeliveryperson.Ifanydamageisnoted

orthesupplyisincompleteorincorrect,informthemanufacturer’ssalesdepartmentimmediately.

NOTES

In relation to the above prescriptions, the manufacturer informs the user that in compliance with current international and national

rulings, goods are always shipped at the risk and responsibility of the purchaser and, unless otherwise stated in writing at the

time of the order conrmation, freight travels without insurance cover.

15

A

B

C

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

2.3. TRANSPORT, LIFTING AND HANDLING

Dimensions,weightandhandlingofindividualmachineparts

BOX DIMENSIONS

Machineheight .............................................440mm-21⁄64in

Machine depth ............................................ 500mm-11⁄16in

Machinewidth.............................................660mm-63⁄64in

Weightofthemachine(includingthepackaging)approx.35kg-88lbs

DANGER – CAUTION

• Themachinemustbetransportedtoapositionasclosetotheintendedinstallationsiteaspossible.Saidsitemustbe

checkedbeforehandtoobtaininformationaboutthenecessaryclearancesanddimensions,includingtheessential

spacerequiredforinstallationprocedures.

• Itisstrictlyprohibitedtoliftloadsoverpeople.Ifpersonsarepresentinthearea,lowertheloadandensureeveryone

movesoutoftheway.

2.4. LIFTING AND HANDLING

The U200P machine is shipped ready for use.

Theboxdimensionsare:(660x440x500)mm.(seegure)

Transportmustbecarriedoutbyprofessionallyqualiedpersonnel.

Themachinemustbetransportedinsuchawayastoavoidany

damagetoitscomponents:

· The machine must be transported in its installation position.

· Beforetransportingthemachine,greaseallnon-paintedparts

to avoid the risk of deterioration.

· Based on the type of transport, take care to protect the machine

from all possible impact and stress.

NOTE – The machine must be lifted by TWO operators.

NOTE –It is advisable to keep the packaging in case it is

needed to store or transport the machine at a later date.

Themachineismovedonatwo-wheeltrolley.

MULTIPLE TRANSPORT AND HANDLING

Thetransportofmorethanonemachinecanbecarriedoutusing

aEUROPALLETwhichcancarryuptoamaximumof10boxes

(10 machines)

Overalldimensions=(80x120x180mm-AxBxC)

16

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

.2.5. REMOVING THE PACKAGING

Descriptionofthepackaging

The machine may be shipped in a container or on a lorry.

Inbothcasesthesametypeofpackingisenvisagedwhichissuitableforguaranteeingthegoodconditionandproperpreservation

ofthemachineduringtransportuptothetimeofdeliverytothecustomer.

Themachineisshippedpackedinaspecialboxandprotectedagainstdamagebypolystyreneinserts.

Maximumdimensions660x440x500(AxBxC).

NOTE –It is advisable to keep the packaging in case it is needed to store or transport the machine at a later date.

Whenstoringthemachine,neverstacktwomachinespackedonapalletwithshrinkwrap.

Thevariouspackingmaterialsmustbedisposedofincompliancewiththerelativelegislationinforce.Seekadvicefromthedelegated

authoritiesand/ortheassistanceofspecialistcompaniesauthorisedtodisposeofpollutantorrecyclablewasteproducts.

DANGER – CAUTION

Warning – pollution hazard: do not dispose of the packing material in the environment; retain it for future transport

uses or consign it to a recycling company.

Evaluation and management of the packing materials in terms of biological compatibility are the duty and responsibility

of the user.

17

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016 EN

3. PRELIMINARY PREPARATION AND ADJUSTMENT PROCEDURES

3.1. PUTTING THE MACHINE INTO SERVICE

1)POSITIONTHEMACHINEONTHETABLEORANOTHERHORIZONTALWORKSURFACE

2) CONNECT THE PEDAL BY INSERTING THE AIR LINES IN THEIR CONNECTORS ON THE SIDE OF THE MACHINE.

3) CONNECT THE COMPRESSED AIR SUPPLY LINE.

4) FIT THE VERTICAL CLAMP UNIT.

3.2. POSITIONING(IFOPTIONALSTANDHASBEENPURCHASED)

Suitabilityoftheoor–supportingsurface

The machine must be positioned on a solid, reinforced concrete foundation.

Theoormusthaveanadequateloadbearingcapacitytosupporttheweightofthemachine.Theoormustbedesignedandprepared

by the user.

Preparationonsite

Themachinelayoutisprovidedasanattachmenttothismanual.Itiscompletewiththenecessarydataforpositioningonthefactoryoor.

THEPLACEINWHICHTHEMACHINEISUSEDmustbecleanandfreeofobstacles(seegure).

TOALLOWFOREASYREMOVALOFTHEMACHINEFORMAINTENANCEitmustbepositionedinaplacehavingthesurface

dimensionsindicatedinthegure.

18

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U200P INSTRUCTIONS 01 30/06/2016 30/06/2016

EN

3.3. ASSEMBLY OF SEPARATELY SHIPPED UNITS

DANGER – CAUTION

All assembly activities concerning machine units supplied separately, include highly delicate operations which call

for signicant experience. Consequently they must be carried out exclusively by personnel appointed directly by the

manufacturer or authorised by the same and, in any case, under the manufacturer's responsibility. These activities are

therefore the sole responsibility of the machine manufacturer’s personnel.

Installationofworkingbenchextensions(optional)

Theworkingbenchextensionsareoptionalandmayberequestedfromthemanufacturer.

Theirinstallationrequiresprecisealignmentbetweentheworkingbenchandtheextensionssothatthelowersurfaceofthemouldings

restfullyontheentiresupportsurfacewhenthedoublestopperpressesdownontheendsofthemouldings.

Toinstalltheextensionsproceedasfollows:

1. Unscrewthegrubscrewslocatedontheleft-andright-handsidesofthemachine.

2. Placetherightandleftextensionsalongsidethemachineaccordingly.

3. Insertthexingscrewsandaligntheextensions.Finally,tightenthescrews.

Table of contents

Other FLETCHER Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT592862 Operation manual

Siemens

Siemens 3KC3424-2AA22-0AA3 operating instructions

SCHUNK

SCHUNK PSK 22/1 Assembly and operating manual

Sartorius stedim

Sartorius stedim Sartoclear Pilot Filter Holder operating instructions

RK Rose+Krieger

RK Rose+Krieger LZ60 S/P Assembly instructions

Jäger

Jäger Z33-M060.11 K02S1 manual

Wire wizard

Wire wizard TORCH WIZARD Installation & operation manual

Arcflash Labs

Arcflash Labs SGP-34 user manual

Jäger

Jäger Z33-D060.02 K0,9a manual

SKF

SKF MonoFlex B Series Translation from the Original Operating and Maintenance Instructions

Festo

Festo GRLZ operating instructions

Omec

Omec SBM1200 manual