FLETCHER Alfamacchine U300 User manual

EN INSTRUCTIONS MANUAL

PLEASE RETAIN FOR FUTURE REFERENCE

Name

Function

Model / Type

Serial number

Year of construction

Manual Revision

FRAME ASSEMBLING MACHINE

ASSEMBLY OF FRAMES BY INSERTION OF METAL V-NAILS

U300 (previous version MINIGRAF 3)

01

2TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

Alfamacchine S.r.l.

Via Selva 23/25

47122 Forlì - Italy

CE DECLARATION OF CONFORMITY

CE CONFORMITY DECLARATION

Il Fabbricante / the Manufacturer Alfamacchine S.r.l.

con sede legale in / Address Via Selva, 23/25 47122 Forlì - Italy

DICHIARA, / Hereby DECLARES,

sotto la propria responsabilità, under its sole responsibility,

declares that the machine: that the machine:

Denominazione / Product Name : FRAME ASSEMBLING MACHINE

Funzione / Purpose : ASSEMBLY OF WOODEN AND SYNTHETIC MDF MOULDINGS USING METAL

V-NAILS

Modello/ Model Name : U300

Tipo / Type : PNEUMATIC

Numero di Serie / Serial Number :

E’ CONFORME ALLE DISPOSIZIONI PREVISTE DALLE DIRETTIVE:

COMPLIES WITH THE FOLLOWING STANDARDS AND DIRECTIVES:

- 2006/42/CE, Direttiva Macchine / Machinery Directive

poiché rispetta tutti i requisiti essenziali di sicurezza e sanitari che le concernono.

because it complies with all the relative essential safety requirements

Technical File drawn up by: ALFAMACCHINE S.R.L.

Technical File drawn up by: ALFAMACCHINE S.R.L.

Forlì ,

___________________________________

Data / Issued Date : Firma il Legale rappresentante / Signature of representative

1

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016 EN

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

INDEX

EN

1. INTRODUCTION TO USE ......................................................................................................................................................... 2

1.1. HOW TO CONSULT THIS MANUAL AND THE SYMBOLS ADOPTED ....................................................................... 2

.................................................................................................... 2

1.3. TYPE OF USE AND CONTRAINDICATIONS............................................................................................................... 2

1.4. TECHNICAL FEATURES.............................................................................................................................................. 6

1.5. PRODUCTS PROCESSED - HANDLED OR GENERATED ........................................................................................ 7

1.6. EMISSION OF AIRBORNE NOISE............................................................................................................................... 8

1.7. RESIDUAL RISKS - GENERAL INFORMATION .......................................................................................................... 8

1.8. RESIDUAL RISKS ........................................................................................................................................................ 8

1.9. DESCRIPTION OF SAFETY FUNCTIONS................................................................................................................... 9

1.10. DESCRIPTION OF THE MACHINE.............................................................................................................................11

1.11. MAIN MACHINE COMPONENTS .................................................................................................................................11

2. INSTALLATION ....................................................................................................................................................................... 16

2.1. STORAGE................................................................................................................................................................... 16

2.2. CHECKS ON RECEPTION......................................................................................................................................... 16

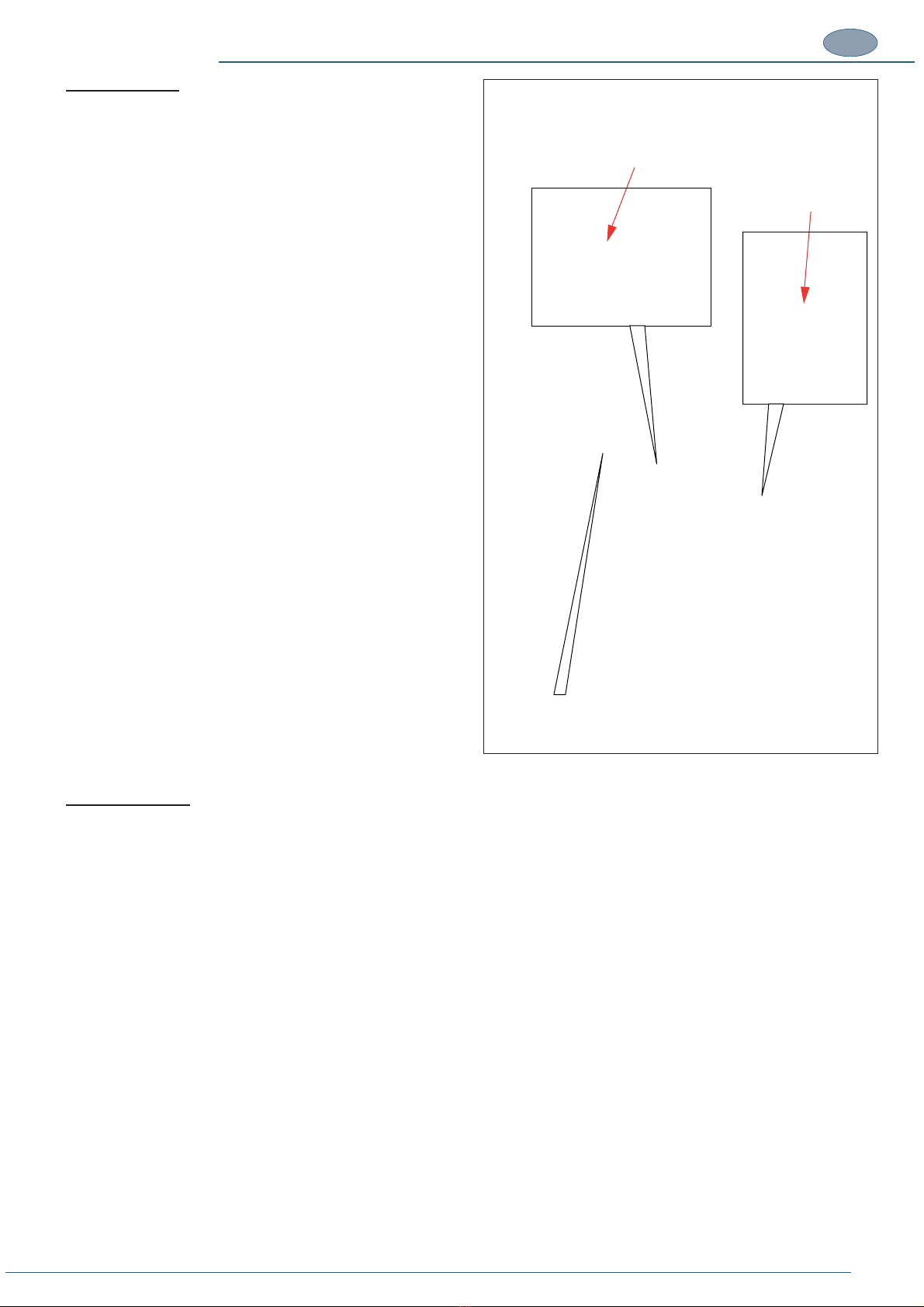

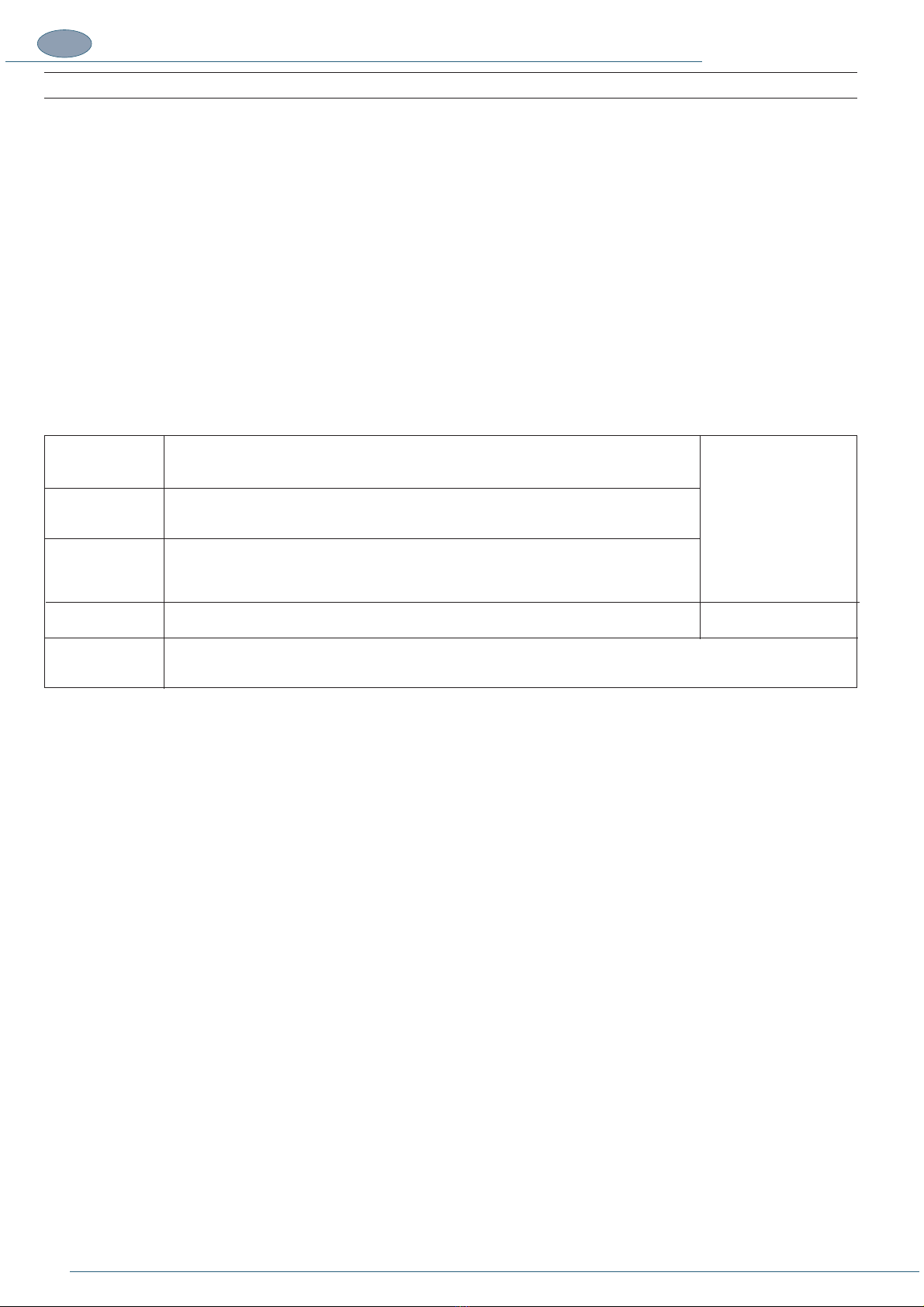

2.3. TRANSPORT, LIFTING AND HANDLING................................................................................................................... 17

2.4. LIFTING AND HANDLING .......................................................................................................................................... 17

2.4. LIFTING AND HANDLING .......................................................................................................................................... 17

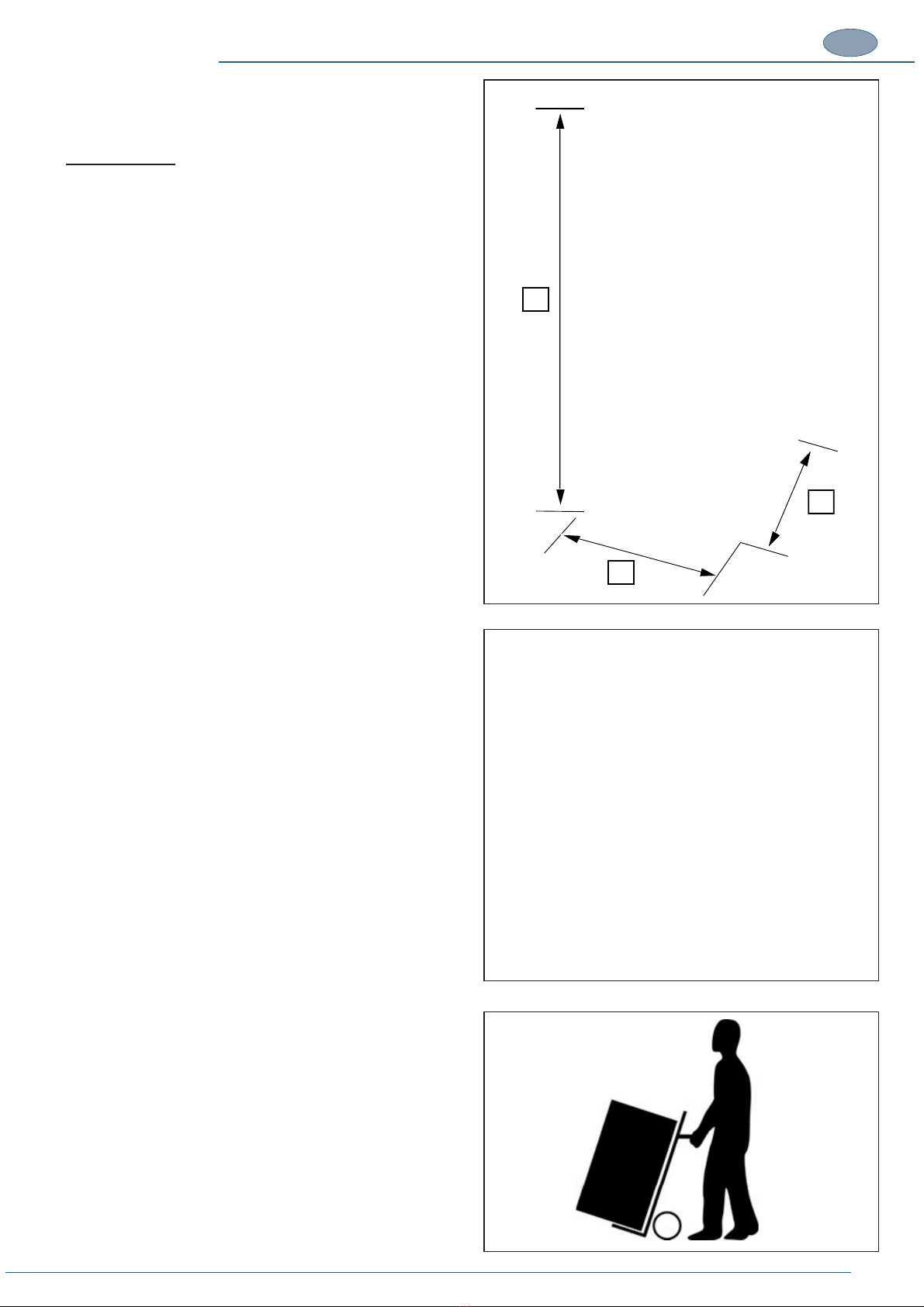

2.5. REMOVING THE PACKAGING .................................................................................................................................. 18

3. PRELIMINARY PREPARATION AND ADJUSTMENT PROCEDURES ................................................................................. 20

3.1. POSITIONING............................................................................................................................................................. 20

3.2. LEVELLING THE MACHINE....................................................................................................................................... 20

3.3. ASSEMBLY OF SEPARATELY SHIPPED UNITS ...................................................................................................... 21

4. INITIAL START-UP AND USE OF THE MACHINE................................................................................................................. 25

4.1. WORKSTATIONS AND OPERATORS’ TASKS........................................................................................................... 26

4.3. CHECKS, ADJUSTMENTS AND START-UP ............................................................................................................. 26

4.4. START-UP................................................................................................................................................................... 27

4.5. WORKING CYCLE...................................................................................................................................................... 38

4.5.1. CYCLE STOP ............................................................................................................................................................. 39

5. MAINTENANCE, TROUBLESHOOTING, AND CLEANING .................................................................................................. 40

5.1. MAINTENANCE TECHNICIAN REQUIREMENTS ..................................................................................................... 40

5.2. WORK STATIONS AND MAINTENANCE TECHNICIAN DUTIES.............................................................................. 40

5.3. MAINTENANCE PRESCRIPTIONS............................................................................................................................ 40

5.4. GENERAL WARNINGS .............................................................................................................................................. 41

5.5. ISOLATION FROM EXTERNAL ENERGY SOURCES............................................................................................... 41

5.6. ROUTINE MAINTENANCE......................................................................................................................................... 41

5.7. TASKS THAT CAN BE PERFORMED BY THE OPERATOR ..................................................................................... 42

5.8. TASKS THAT CAN BE PERFORMED ONLY BY MAINTENANCE TECHNICIANS ................................................... 43

5.9. CLEANING.................................................................................................................................................................. 46

6. TROUBLESHOOTING AND RELEASE OF MOVING PARTS ............................................................................................... 50

7. REINSTALLATION AND REUSE ............................................................................................................................................ 52

8. EXTINGUISHING MEDIA........................................................................................................................................................ 52

9. SCRAPPING AND DISPOSAL................................................................................................................................................ 52

9.1. SCRAPPING............................................................................................................................................................... 52

9.2. DISPOSAL .................................................................................................................................................................. 53

TABLE 0 - EXPLODED VIEW OF THE MACHINE........................................................................................................................... 54

TABLE 20 - HEAD UNIT INSTALLATION ........................................................................................................................................ 55

TABLE 21 - FENCE UNIT INSTALLATION ...................................................................................................................................... 56

TABLE 22A - AFC BRAKE ............................................................................................................................................................... 57

TABLE 22B - ROD CLAMP ............................................................................................................................................................. 57

TABLE 23 - VERTICAL CLAMP UNIT ............................................................................................................................................. 58

TABLE 24 - EC SAFEGUARD.......................................................................................................................................................... 59

2TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

DANGER - WARNING

BEFORE USING THE MACHINE PLEASE READ THIS MANUAL CAREFULLY SO THAT YOU BECOME FAMILIAR WITH THE

MACHINE, ITS ENVISAGED USE AND ANY RISKS ASSOCIATED WITH IT.

Keep the Use and Maintenance Manual in good condition: Remember, it is an integral part of the machine. Always refer to the manual

to get best machine performance in maximum safety while performing the operations described therein.

This manual must be kept in an easily accessible place, near the machine, at all times so that it can be consulted whenever necessary.

DANGER - WARNING

USE THE MACHINE SOLELY AND EXCLUSIVELY FOR THE USES INDICATED AND IN ACCORDANCE WITH THE

RECOMMENDATIONS PROVIDED IN THIS MANUAL. NEVER TAMPER WITH IT, FORCE IT OR USE IT IN ANY INAPPROPRIATE

MANNER.

1. INTRODUCTION TO USE

1.1. HOW TO CONSULT THIS MANUAL AND THE SYMBOLS ADOPTED

Please pay particular attention to the words “DANGER – WARNING”, “DANGER – CAUTION” and “NOTE” as used in this manual.

To draw the user’s attention to certain information and provide warning messages, the operations described in this manual are accompanied

by symbols and notes to highlight the presence of any hazards and indicate the safe use of the equipment. These symbols and notes

belong to various categories, as indicated below:

DANGER – WARNING: IMPORTANT INFORMATION CONCERNING GENERAL SAFETY.

DANGER-CAUTION: highlights situations where careful and sensible actions are essential.

NOTES: information of a technical nature.

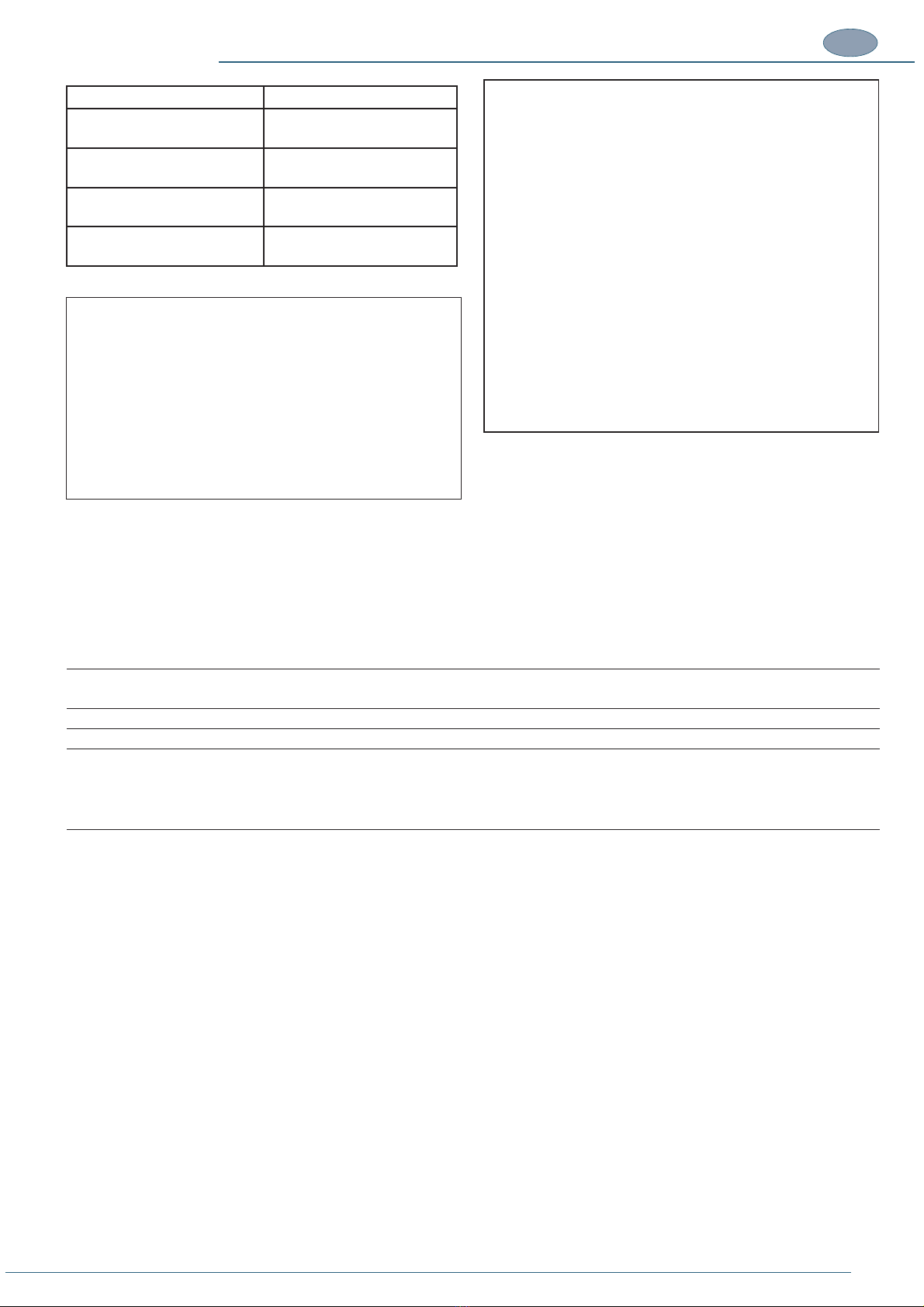

Sticker Description

Wear protective googles.

Wear protective gloves.

Wear safety footwear

Wear ear defenders.

the corners of the guards.

1.3. TYPE OF USE AND CONTRAINDICATIONS.

Safety warning on machine use

EC dataplate

3

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016 EN

PERMITTED USE

The machine described herein is designed to be run by 1 operator

suitably trained and instructed with regard to residual risks. The

operator must have the same skills, in terms of safety, as the

maintenance technicians and adequate professional competence.

During its PERMITTED AND REASONABLY PREDICTABLE USE,

the machine may be used exclusively:

for pictures, mirrors, display cases, cupboard doors etc.) in

accordance with the characteristics described in the heading

“Products Processed - Handled or Generated”. Use of the

machine to perform processes other than those described in

this manual is to be considered improper and therefore strictly

prohibited.

the dimensions specified in the heading “TECHNICAL

CHARACTERISTICS”.

It is also compulsory:

received adequate training/information concerning machine

operations, performance and any hazards associated with its

use.

operating area before proceeding with any operations

whatsoever.

starting to work with the machine.

where it is to be used, that it is installed on a level, smooth and

load bearing capacity to support the weight of the machine.

of ambient lighting and ensure there are no areas of shadow,

glare, or potentially hazardous strobe effects.

main compressed air supplies, to safely discharge any residual

energy in the machine circuits, and wait for all parts at high

temperatures to cool down adequately.

UNINTENDED USE

DANGER - WARNING

THE MACHINE MUST NOT BE USED IN A PROHIBITED MANNER. SPECIFICALLY:

or materials with different characteristics to those previously described in the heading “TECHNICAL CHARACTERISTICS”.

all liability.

4TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

FORBIDDEN USE

DANGER - WARNING

FURTHERMORE IT IS PROHIBITED TO USE THE MACHINE IN AN INCORRECT MANNER, IN PARTICULAR:

authorized to do so,

protective device (mechanical) deactivated and/or non-functional,

in this instruction manual,

beforehand,

elements have come to a complete standstill.

as indicated in this manual,

- outdoors or worksites with open windows and doors,

- processing of materials and products that are not expressly indicated in the present manual,

- processing of metal materials made of aluminium, lightweight alloys, and steel and its alloys.

DANGER – CAUTION

The manufacturer cannot be held liable for any faults caused by unreasonable, improper and/or incorrect use of the

machine.

always consult the manufacturer’s engineering department.

The user is always responsible for providing suitable personal protective equipment to machine operators and for informing them on the

permissible uses of the machine.

5

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016 EN

PERSONNEL AUTHORIZED TO USE THE MACHINE

accordance with the characteristics described below:

Operators / Apprentices:

PERMITTED AMBIENT CONDITIONS AND OPERATING LIMITS

DANGER - WARNING

THIS MACHINE IS NOT SUITABLE FOR USE IN POTENTIALLY EXPLOSIVE ENVIRONMENTS.

THEREFORE IT IS PROHIBITED TO INSTALL OR USE IT IN ANY SUCH ENVIRONMENT.

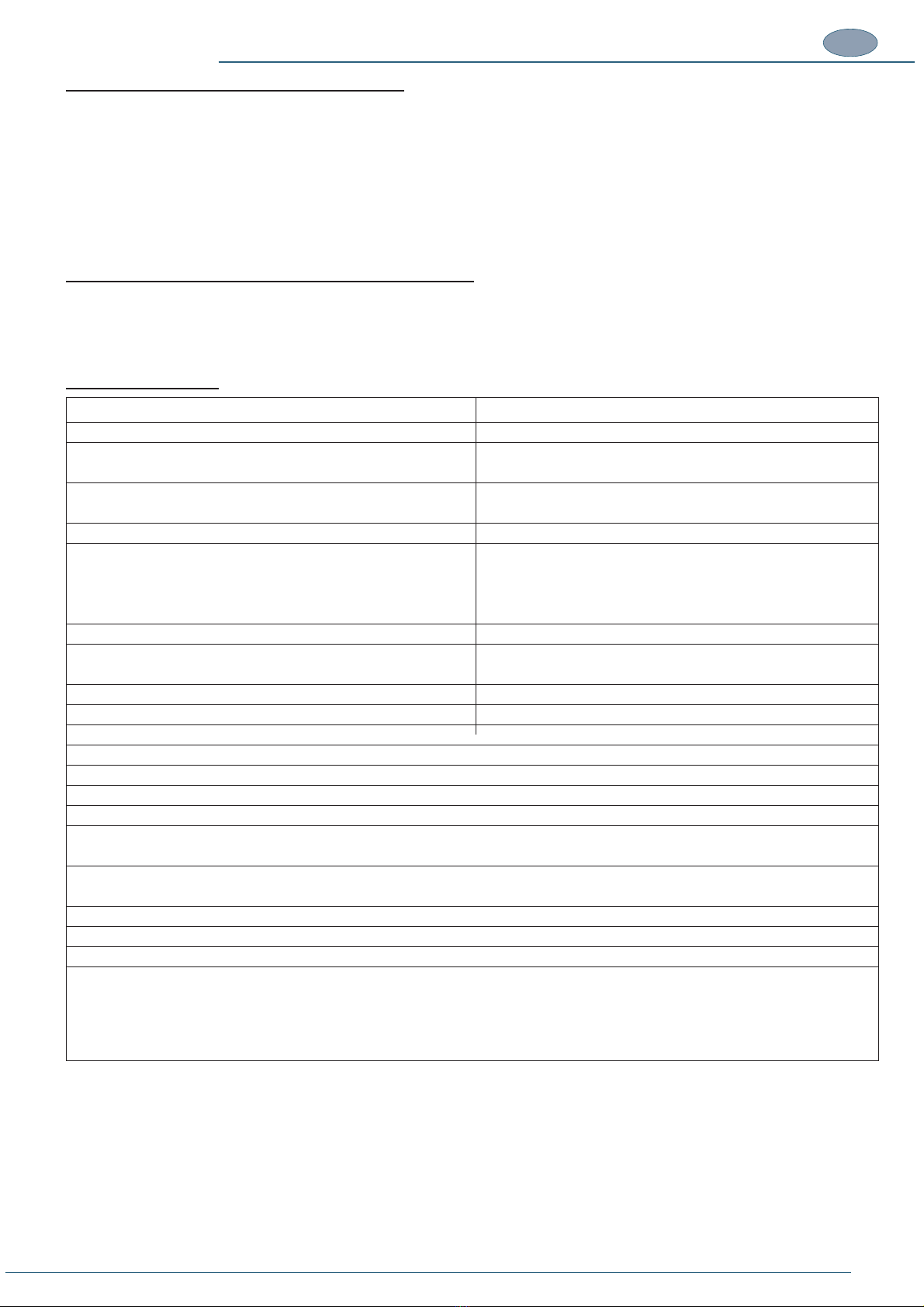

SERVICE CONDITIONS

SERVICE CONDITION USER LIMITS

Installation type Indoor

Floor conditions Horizontal and smooth: irregularity and gradient tolerance within

2%

Supporting surface characteristics Flooring in compliance with health and safety requirements in the

workplace in accordance with all applicable legislation

Maximum ambient air temperature +40°C / 104°F

Minimum ambient air temperature 5°C / 41 °F (with electrical equipment protection rating of at least

IP54)

0°C / 32 °F (with electrical equipment protection rating lower than

IP54)

Ambient working temperature +5°C / 41°F < T < +45°C / 113°F

Transport and storage temperature between -25°C / -13 °F and +55°C / 131°F (temperatures of up to

+70°C/158°F are admissible for periods of less than 24 h)

Maximum altitude above sea level 1000m

Minimum required light intensity 600 lux

Relative humidity of 100% at +25°C/ 77°F (electrical equipment protection rating of at least IP54)

Relative humidity shall not exceed 50% at +40°C / 104°F or 90% at +20°C / 68 °F (electrical equipment protection rating below IP54)

Equipment for machine designed for indoor installations

Machine NOT suitable for operation in contaminated atmospheres: for example, dusts, acids, corrosive gases, salt or similar contaminants.

Machine NOT

Machine NOT

microwaves, UV rays, laser, X-rays, and similar.

Pollution class of electrical equipment equivalent to 3 (THREE)

Installation environment equivalent to two (2)

Can be utilised in residential, commercial, of light industrial zones thanks to compliance with standard EN 61000-6-1

Intended for direct/exclusive service of industrial process machinery

6TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

SERVICE CONDITION USER LIMITS

Special and additional prescriptions, not envisaged,

may be requested for machines intended for:

situations (for example, molten metal, acids/bases, particularly

fragile loads, explosives),

1.4. TECHNICAL FEATURES

Machine characteristics

Work surface dimensions (W x L)............................................................................................................................... 300x485mm -12”x19”

Machine length.......................................................................................................................................................................... 485mm - 19”

Machine width ........................................................................................................................................................................... 300mm - 12”

............................................................................................................... 1020mm - 34”1/4

................................................................................................................... 1340mm - 53”

Maximum machine height......................................................................................................................................................... 450mm - 18”

Machine weight .......................................................................................................................................................................... 32kg - 70lbs

V-nail magazine capacity .................................................................................................................................................................. 220 pcs

Max. quantity of V-nails inserted per position ........................................................................................................................................ 9pcs

V-Nail insertion positions................................................................................................................................................................... Multiple

Max. distance between V-nails ................................................................................................................................................ 80mm - 3”1/4

Compressed air supply

Maximum permitted inlet pressure..........................................................................................................................................................8bar

..........................................................................................................................................................................3 Nl

V-nail characteristics

V-nail type

H3 3mm (optional)

H5 5mm

H7 7mm

H10 10mm

H12 12mm

H15 15mm

7

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016 EN

1.5. PRODUCTS PROCESSED - HANDLED OR GENERATED

The products handled by the machine described herein must be made up of wooden mouldings of various hardness, with multiple surface

The main technical characteristics of the products handled by the machine described herein are provided below.

DESCRIPTION OF PRODUCTS HANDLED

CHARACTERISTICS

Minimum/maximum width of moulding 6 / 60 mm - ¼” – 2”1/2

Minimum/maximum thickness of moulding 6 / 80 mm - ¼” – 3”1/4

Weight 10 Kg.

25 Kg.

Material Recommended sharpness

Soft woods

and plastic

SW

transparent stick

Medium wood MW

brown stick

Hard wood HW

green stick

Very Hard Wood

and MDF

HS

red stick

8TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

1.6. EMISSION OF AIRBORNE NOISE

NOTE – The manufacturer declares, under his own responsibility, that the machine produces a continuous equivalent A-weighted

sound pressure level of 72 dB.

DANGER – WARNING:

TO AVOID THE DANGER OF HEARING DAMAGE CAUSED BY SHRILL OR INSISTENT NOISE, THE MACHINE OPERATOR

AND MAINTENANCE TECHNICIAN MUST ALWAYS USE APPROPRIATE HEARING PROTECTION, SUCH AS HEARING

DEFENDERS OR EARPLUGS.

1.7. RESIDUAL RISKS - GENERAL INFORMATION

This manual contains a list and description of the residual risks that could not be eliminated in the design stage and that therefore remain

present on the machine.

For each risk, suitable instructions or prescriptions are given which the user must observe in order to avoid hazards affecting the machine

operator, maintenance technicians, any exposed persons and the machine itself.

1.8. RESIDUAL RISKS

Residual risk due to noise

As demonstrated by experimental tests, the machine produces a continuous equivalent A-weighted sound pressure level of 72 dB.

To avoid the risk of hearing damage caused by shrill or insistent noise during machine use, in addition to being adequately informed and

trained, the operator and maintenance technician must always use appropriate hearing protection, such as hearing defenders, earplugs

or similar personal protection equipment to safeguard hearing.

PPE to be used:

Hearing protection

Residual risk due to the combustibility of the substances used in the machine and the products handled by the same

To avoid the hazards resulting from:

the employer, in addition to training and adequately informing the machine operator and maintenance technician on such risks, must

PPE to be used:

Protective gloves Safety footwear Safety clothing

There is a residual risk for the maintenance technician, when the safety guards are open and valve piloting is activated using the special

tool, in order to check (during troubleshooting procedures) the operation of the pneumatically operated mobile elements, when energy

remains accumulated inside the actuator cylinders.

Consequently, when the aforementioned activities are performed, the maintenance technician must make sure that no exposed persons

are found near the pneumatically controlled mobile elements and in any case said mobile elements must only be activated if strictly

necessary for pinpointing operating faults.

There is a residual risk for the maintenance technician when the machine is isolated from the compressed air network, due to the presence

, when mobile guards are open caused by the presence of closed-centre valves

and/or tanks which remain pressurized.

Consequently, before carrying out any work on the aforementioned cylinders, in accordance with the instructions given in the actuator

manuals supplied with the machine, the maintenance technician must neutralise the accumulated energy working in compliance with

the safety regulations applicable to maintenance personnel, such as, for example, manual activation of the special tool for the piloting

valves used to discharge stored energy.

Under no circumstances must the piping be disconnected if they still hold residual pressure.

9

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016 EN

and maintenance technicians, inside the slot on the working bench

along the stroke of the V-nail shooting unit.

are present near each mobile element installed over the machine’s

working bench.

Consequently the operator and maintenance technician, as well as

observing the instructions provided in this manual, must never place

What’s more, workers must never wear rings, wrist watches,

personal accessories that may constitute a risk. Make sure sleeves

1.9. DESCRIPTION OF SAFETY FUNCTIONS

Protective devices installed on the machine

DANGER - WARNING

IT IS STRICTLY PROHIBITED TO REMOVE THE SAFEGUARDS AND SAFETY DEVICES EXCEPT WHEN STRICTLY

NECESSARY FOR THE PURPOSE OF CARRYING OUT MAINTENANCE WORK.

When such safeguards and safety devices need to be removed all necessary measures must be adopted to highlight this situation

immediately and minimise any possible associated hazards.

parts, except:

10 TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

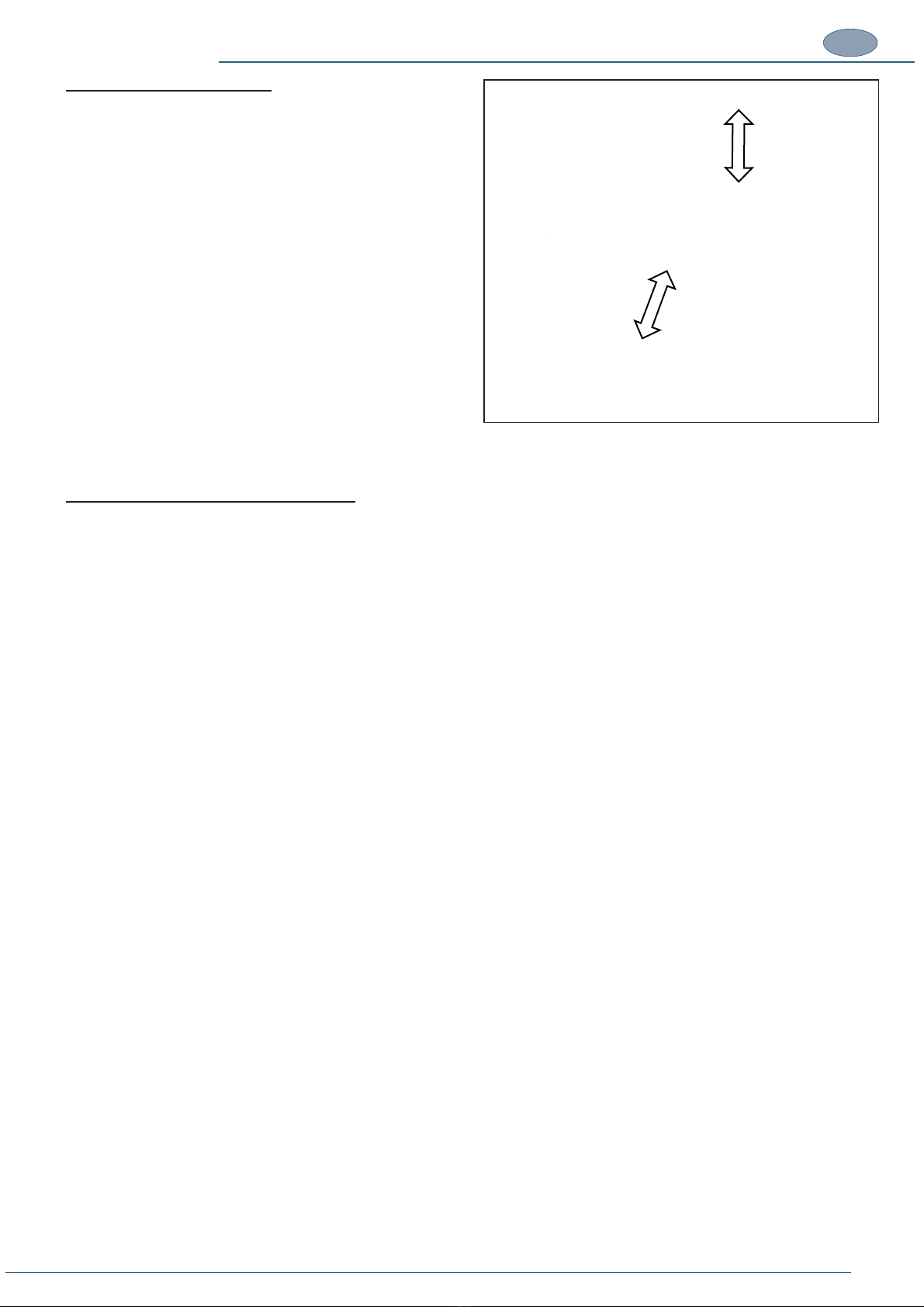

Ref.

A

B

GUARDS /

PROTECTIVE

DEVICES – POSITION

Fixed guard

TYPE OF SAFEGUARDED

HAZARD

Polycarbonate panel secured

to metal supports which can

relative knobs, to prevent

access to the stopper.

Casing in welded sheet metal

to support the working bench

and prevent access to the

pneumatic actuators housed

inside the machine.

openings to the protected dangerous work zone when the guards

are correctly secured in place.

secured in place by screws that call for the use of special tools

(Allen keys) and can only be removed, using the appropriate

tool, by authorized maintenance technicians.

maintenance technicians. Irrespective of the circumstances,

dangerous openings in the machine safeguards.

they will not remain lodged in their locations in the absence of

the fastening elements.

In sizing and selecting the guards and safety devices, the

possibility of access by persons aged 14 or over was used as

a reference condition.

DANGER - WARNING

ACCESS TO AREAS PROTECTED BY A MOVABLE GUARD IS ALLOWED FOR BOTH THE MACHINE OPERATOR AND

MAINTENANCE TECHNICIAN. IRRESPECTIVE OF THE CIRCUMSTANCES, THE MACHINE OPERATOR MUST NEVER

ATTEMPT TO VOLUNTARILY CIRCUMVENT A FIXED GUARD.

operator ever attempt to voluntarily circumvent a moveable guard.

meticulously and carefully to the indications provided in the installation, use and maintenance manuals accompanying said safety

devices (all of which are supplied with the machine) and this instruction manual.

area.

A

B

11

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016 EN

1.10. DESCRIPTION OF THE MACHINE

together the frame mouldings (which may be pre-glued or dry) using metal V-nails.

All operating phases such as: loading and unloading of the frame, clamping, head movement and nailing are completely manual.

The machine can use special Alfagraf V-nails with “Pulling Power” effect or universal V-nails.

1 stand

MACHINE FUNCTIONS are controlled manually by the operator

who directly activates the pneumatic actuators.

mounted on stand (optional), with mouldings clamping system,

mobile fence and pedal.

If purchased without the stand, the machine can be placed on a

sturdy, level and stable work bench.

The references and photos used in this manual refer to the machine

with stand so that all aspects are fully covered.

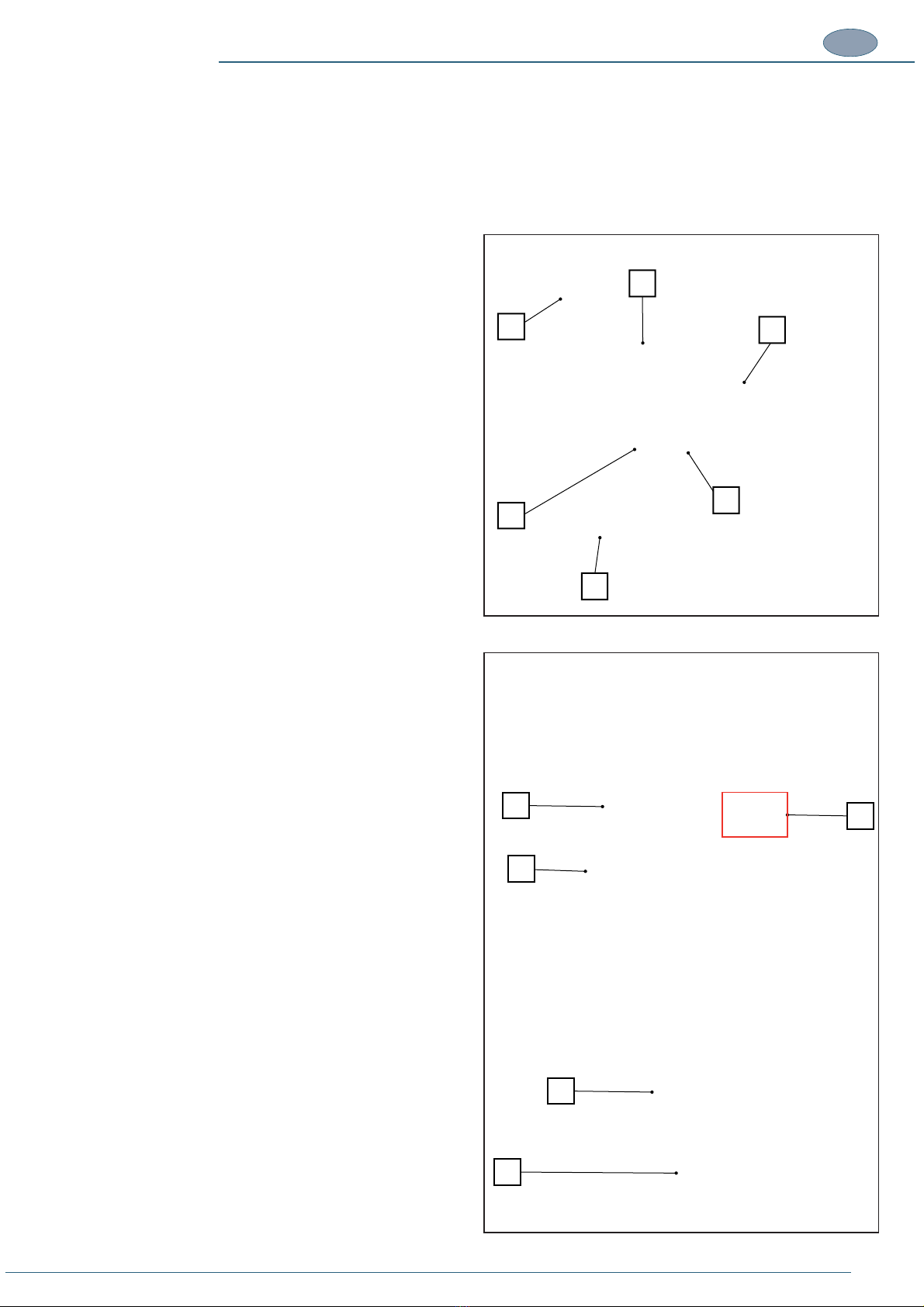

1.11. MAIN MACHINE COMPONENTS

operating units and zones, including:

(G) Working bench

(H) Stand (optional)

(I) Pneumatic pedal switch

(L) Machine casing

(M) External compressed air connections, pedal and power supply

M

G

H

I

L

A

C

E

D

B

F

12 TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

The working bench is the surface on which manual operations take

the operator controls.

It is made up of the following main parts:

(A) Vertical moulding clamp unit

(B) Alignment guides unit

(D) Front moulding clamp unit

(E) AFC brake

(H) EC safeguard

Vertical clamp unit

This unit is designed to immobilize the mouldings on the working

bench and counteract the V-nailing force.

and is therefore in line with the direction of V-nail insertion.

It is important that the air pressure applied to the vertical clamp

provides thrust which is always higher than the thrust of the V-nails,

if this is not the case, V-nail insertion could result in the mouldings

being lifted up, resulting in incomplete insertion of the V-nail and a

The unit is made up of a mechanical or magnetic stopper holder to

which the interchangeable rubber stoppers (P) of varying hardness

are applied, located at the bottom of a punched column (N) which

can be positioned at various heights depending on the size of the

frame.

The assembly is fastened to two sturdy columns (S) the movement

of which is controlled by pneumatic actuators. The punched column

is installed on a support (R) which makes it possible to carry out

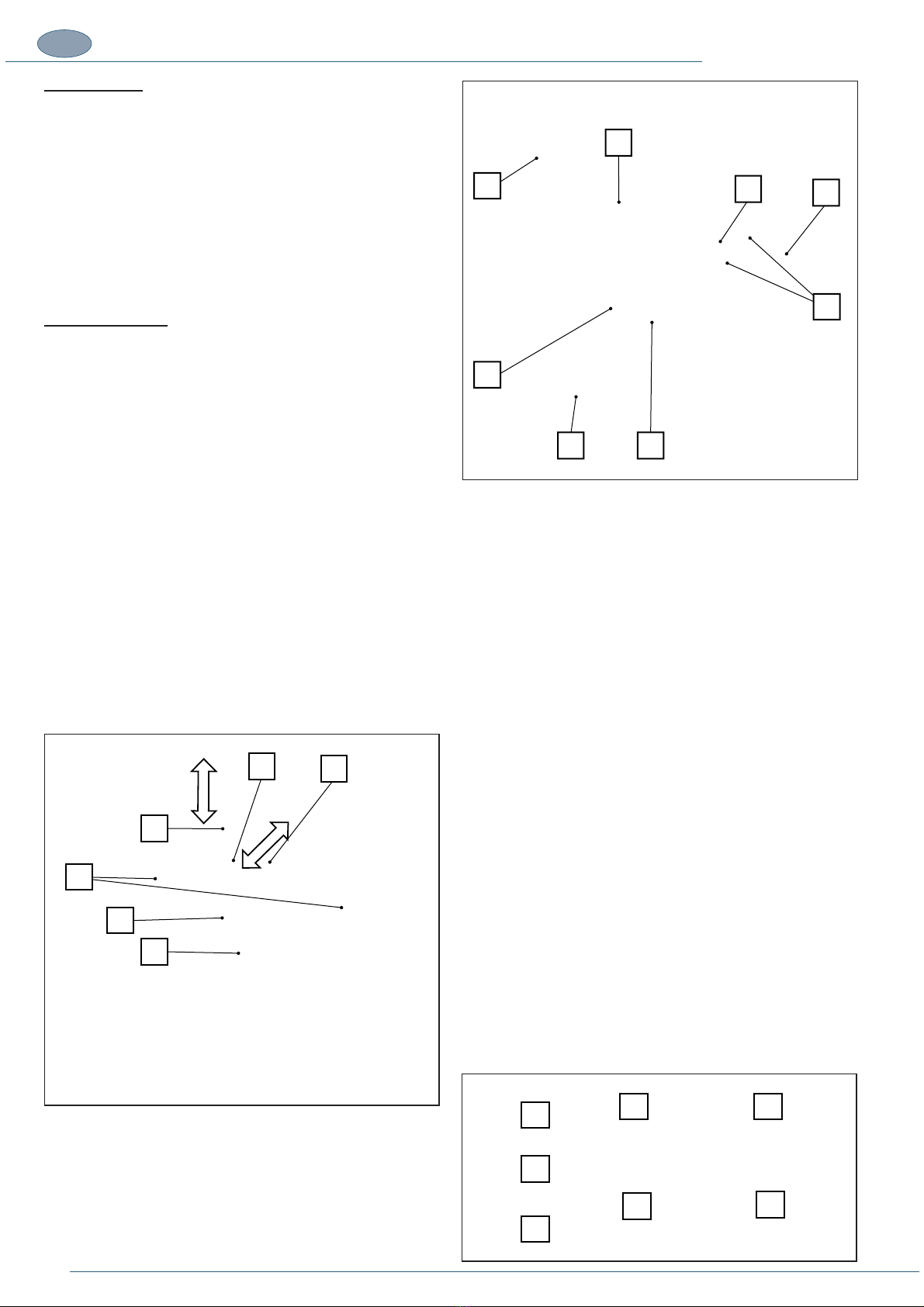

The vertical stopper unit is made up of the following main parts:

(N) Punched rod - allows the operator to position the stopper at

(O) Screw for fastening and for rapid changeover of the

(P) Stopper holder, which may be mechanical or magnetic

depending on the type of accessories used.

(Q) Click knob for blocking the column.

(R) Rod support arm.

(S) Piston stem vertically activated by the pneumatic actuator.

Stoppers available on request:

T) Mechanical stopper holder.

U) Interchangeable stopper - soft (blue).

V) Interchangeable stopper - medium (yellow).

W) Interchangeable stopper - hard (black).

X) Round magnetic felt stopper.

Y) Corner magnetic stopper holder.

Z) Magnetic support.

T

U

W

V

Z

YX

Q

S

O

P

N

R

A

C

B

F

E

G

D

H

13

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016 EN

In the U300 machine, the magazine (E) can hold V-nails of different

heights but only one V-nail height can be used at a time, depending

on the nailing head installed.

When the size of the V-nails is changed the nailing head must also

be switched over to match the V-nails used.

The V-nails are held in position by the V-nail pusher device (F).

Head and L-block support are designed to guide the V-nails during

the thrust action of the hammer and their insertion into the overlying

mouldings.

The magazine is in turn brought up against the L-block support and

by means of a V-nail pusher supplies and aligns the V-nails against

the guide each time the hammer is activated.

The hammer is activated by a pneumatic cylinder which is controlled

by the pneumatic pedal.

Perfect mechanical alignment of these parts ensures precise

insertion, single or multiple, of the V-nails in the mouldings to be

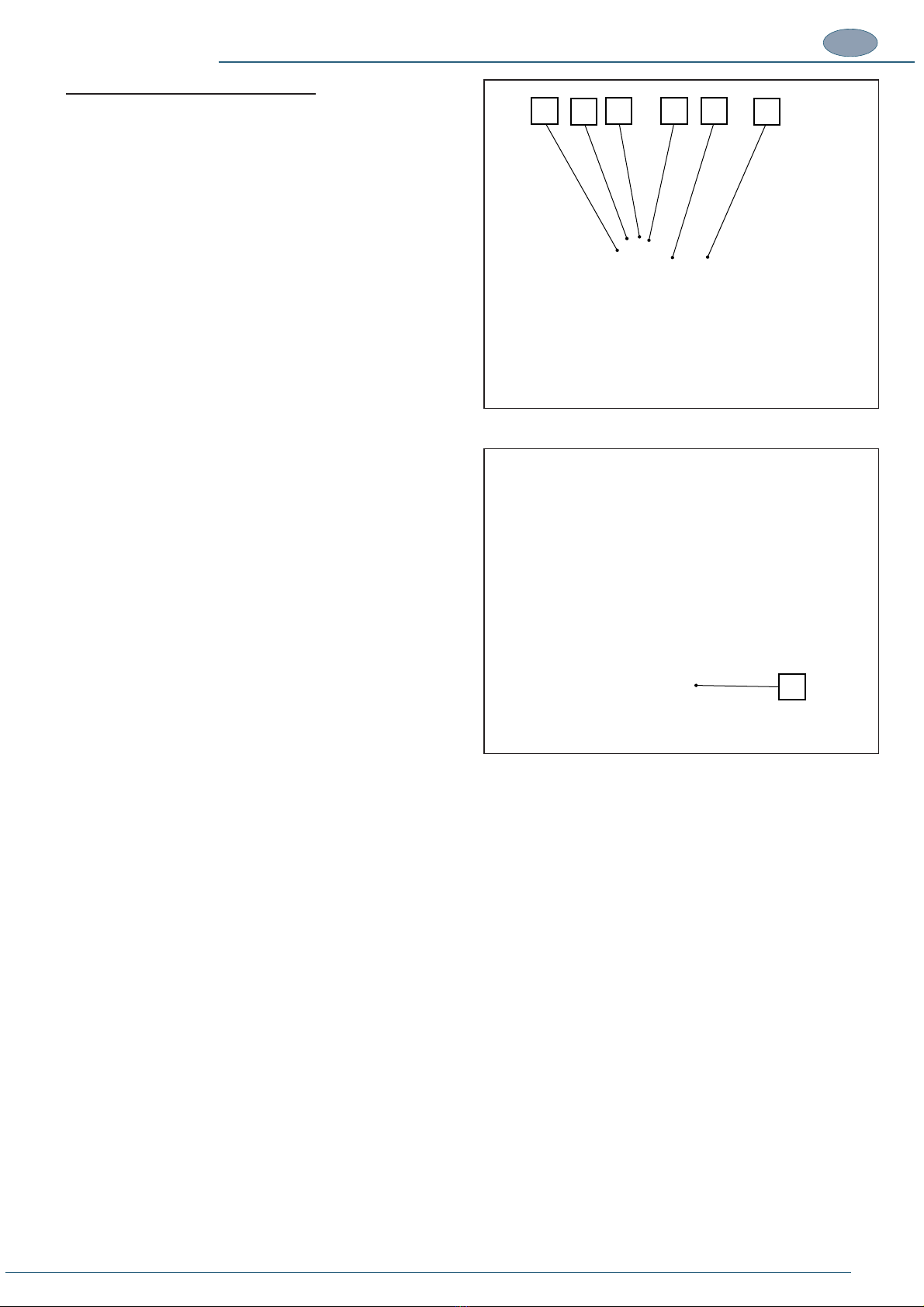

(A) Screw for fastening the head.

(B) Head of different heights.

(C) L-block support

(D) Hammer

(E) V-nail magazine

(F) V-nail pusher which keeps the V-nails at a constant pressure

(G) PLV selector lever:

in the OFF position (open) it draws the V-nail pusher back so

in the ON position (closed) the V-nail pusher pushes the

does not work.

G

ABCDE

F

14 TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

In the U300 machine, the magazine (E) can hold V-nails of different

heights but only one V-nail height can be used at a time, depending

on the nailing head installed.

When the size of the V-nails is changed the nailing head must also

be switched over to match the V-nails used.

The V-nails are held in position by the V-nail pusher device (F).

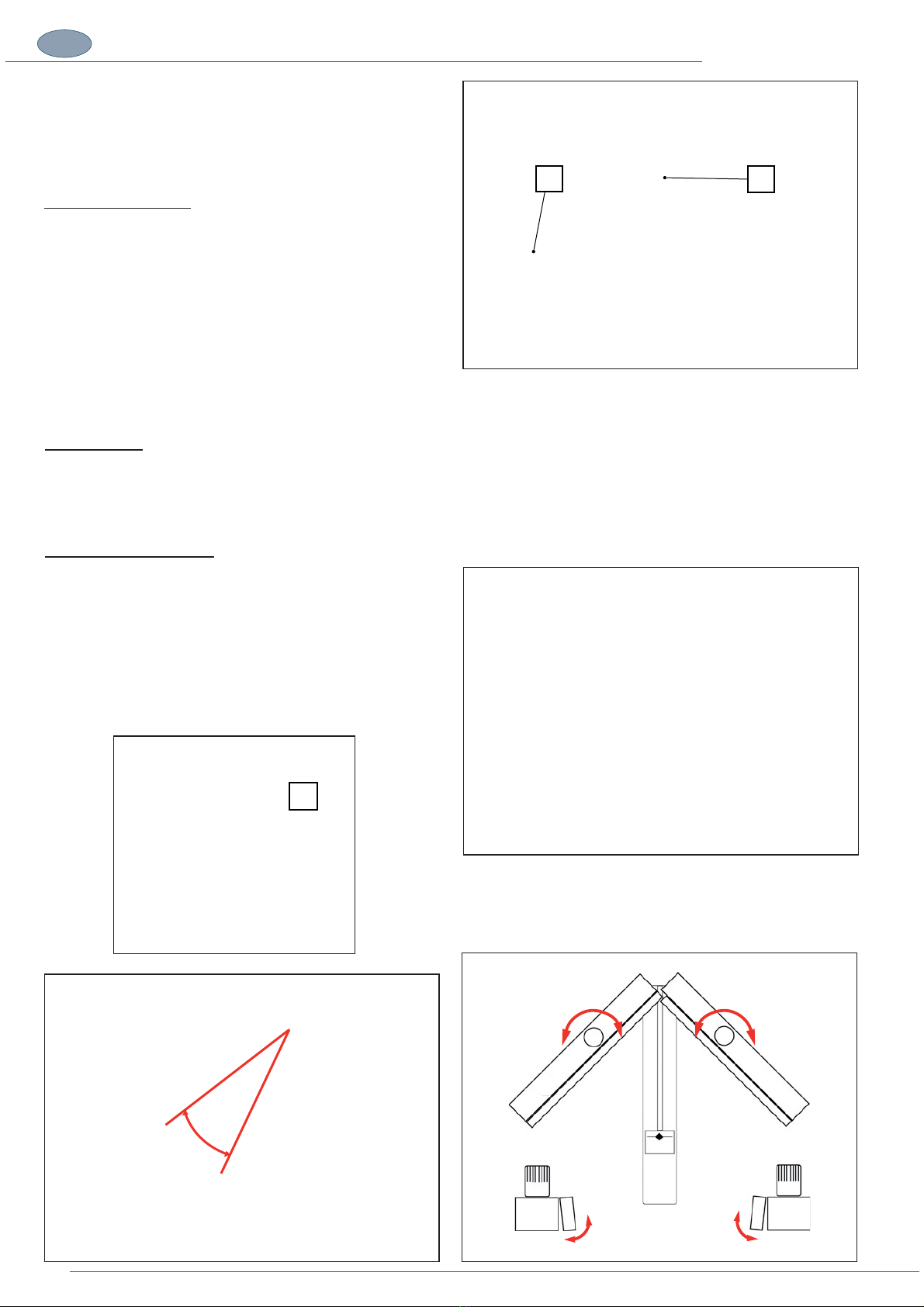

The alignment guide unit, positioned on the working bench, can slide

the operator based on the size of the moulding in relation to the

position of the front clamp (rod clamp).

Fixed fences for 120° and 135° corners may also be installed in the

fence support (A) for making frames with 6 and 8 sides respectively

(available as optional accessories).

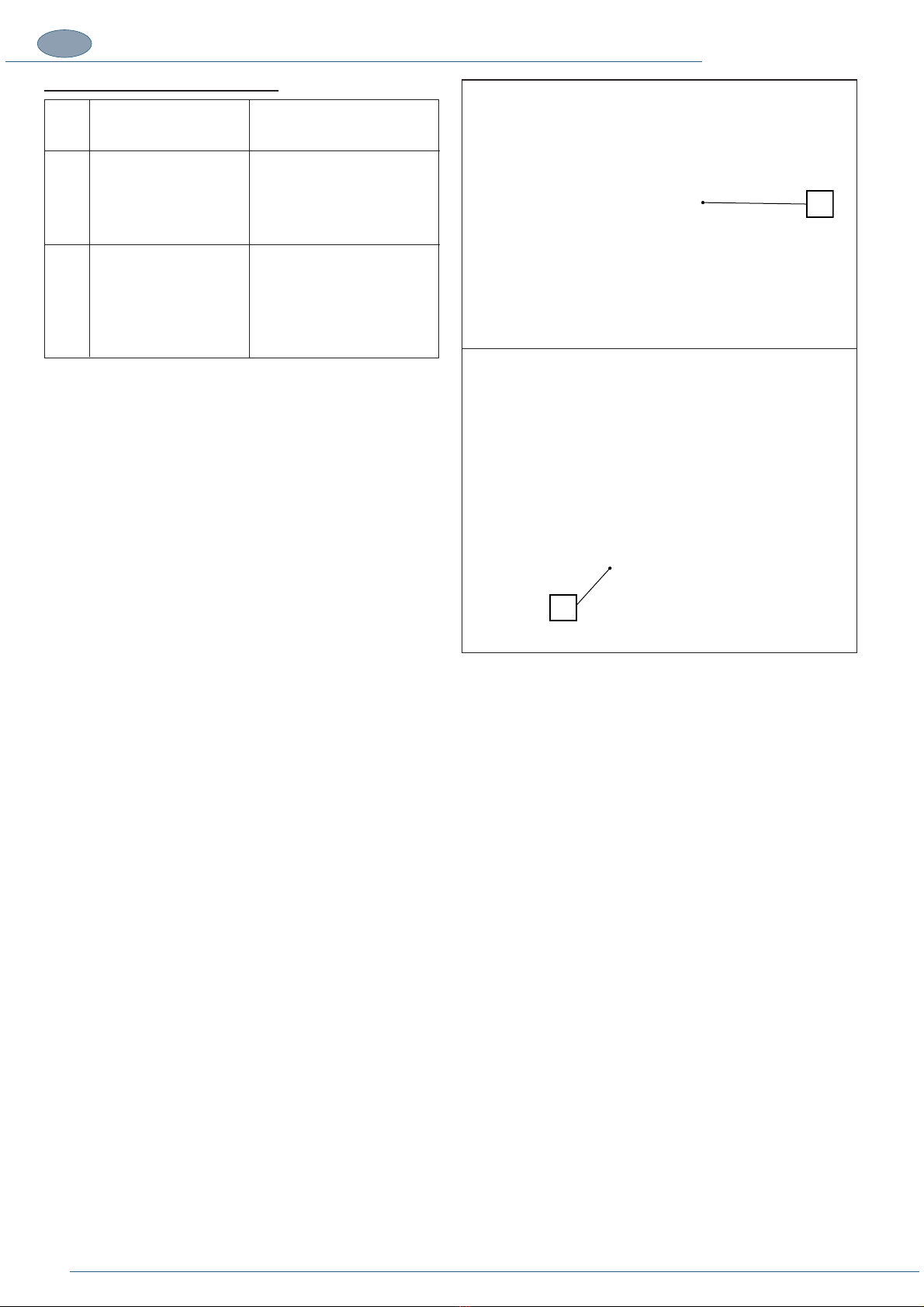

AFC brake unit

The AFC brake unit (B) is made up of a pneumatically activated

device which comes into operation during the nailing cycle.

The unit is designed to lock the position of the mobile fence and

oppose the horizontal thrust of the rod clamp.

the work bench.

Mouldings may have a slanting edge which would make the action

of the horizontal clamp ineffective. The two-knob fence is designed

rest to improve stability.

The two-knob fence can be used to improve clamping of the

mouldings during assembly.

B

A

C

15

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016 EN

the pedal thus clamping them against the fence unit.

Movement of the rod clamp occurs at the same time as vertical clamping and is activated by a pneumatic actuator when the pedal is

pressed. For as long as the pedal is pressed, it clamps the mouldings for the entire duration of the nailing cycle.

The front clamp is made up of:

(H) Knob for securing the rod to the pneumatic actuator of the front clamp.

(I) Holes for anchoring the cursor of the pneumatic actuator.

(L) Front locking rod clamp

bench needs to be increased by installing the two side extensions

(A) and (B) (optional).

perfectly aligned with the working bench, see heading ASSEMBLY

OF SEPARATELY SHIPPED UNITS.

(A) Right extension

(B) Left extension.

The machine is designed to be STATIC, i.e. it must be installed

structure so that it remains stationary during operation.

If detached from the stand, the machine can be used on a horizontal,

sturdy and stable table.

The machine is LOADED AND UNLOADED MANUALLY:

I. MANUAL POSITIONING OF THE MOULDINGS to be

and locked

ii. MANUAL REMOVAL OF THE ASSEMBLED MOULDINGS from

To extend the available work surface for the mouldings, it is possible

to install 6 brackets (C), 2 on each side, onto which a surface panel

in wood or other material (not supplied) is placed.

To install the brackets, please refer to the heading ASSEMBLY OF

SEPARATELY SHIPPED UNITS

(A) 90° bracket with slots and holes for fastening to the machine

and the wooden surface panel.

B

A

L

G

H

I

C

16 TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

2. INSTALLATION

2.1. STORAGE

The machine, intended for indoor installation must be stored, if necessary, in well ventilated storage facilities and protected from dust.

oxidation caused by weather conditions.

In the case of prolonged inactivity the machine must be stored with all necessary precautions taken based on the location and expected

storage times:

1. Store the machine in an enclosed place.

2. Protect the machine from impact and stress.

3. Protect the machine from humidity and excessive temperature differences (refer to the table below).

4. Do not allow corrosive substances to come into contact with the machine.

5. Check that the pack has not been damaged and that it is perfectly dry.

including rain, snow and hail, and it must be accessible exclusively to authorized personnel.

The machine is protected in such a way as to withstand the temperatures, humidity and vibration levels typically associated with transport

and storage.

Ambient

temperature

Storing

temperature

Relative humidity

Vibrations

Atmospheric

pressure

-25 ÷ +40°C - 13 ÷ 104°F

-25 ÷ +55°C - 13 ÷ 131°F

0 ÷ +55 °C / 32 ÷ 131°F

100% at a temperature of +25°C / 77°F

Lower than 50% at a temperature of +40°C / 104°F

Lower than 90% at a temperature of +20°C / 68°F

5.9 m/s2 (0.6G) or higher 900 mbar or more

Avoid places where

there may be

unexpected changes

in temperature

which could lead

to the formation of

condensate or freezing.

Storage temperature is construed as a short-term value, e.g. during transportation. Condensation or freezing normally occurs in sites

2.2. CHECKS ON RECEPTION

NOTES

It is essential to check the packs at the time of arrival and in the precise moment in which they are received. The check is performed

in two stages for each pack received to avoid misunderstandings with the shipping agent.

Administrative check

1. Crate number and number of packs.

2. Weight and size

3. Correspondence of information on shipping document with the material effectively delivered (description, serial number, etc). The

4. Check correspondence between shipping document data and the order.

Technical check

1. Condition and intactness of packaging.

2. Check that the packaging shows no signs of visible damage caused during transport and handling operations.

All the above checks must be performed by inspection in the presence of the shipping agent’s delivery person. If any damage is noted

or the supply is incomplete or incorrect, inform the manufacturer’s sales department immediately.

NOTES

In relation to the above prescriptions, the manufacturer informs the user that in compliance with current international and national

rulings, goods are always shipped at the risk and responsibility of the purchaser and, unless otherwise stated in writing at the time

17

TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016 EN

2.3. TRANSPORT, LIFTING AND HANDLING

Dimensions, weight and handling of individual machine parts

MACHINE BODY

Machine height .................................................A = 1340mm - 53’’

Machine length ................................................. B = 600mm - 24’’

Machine width .................................................. B = 500mm - 20’’

Weight of the machine ............................................. 35kg - 77 lbs

Weight of the stand ................................................. 30 kg - 66 lbs

Size of the packaging............................................... 600x440x500

2.4. LIFTING AND HANDLING

DANGER – CAUTION

to the intended installation site as possible. Said site

must be checked beforehand to obtain information

about the necessary clearances and dimensions,

procedures.

2.4. LIFTING AND HANDLING

The U300 is divided up and delivered as an assembly kit.

The machine must be transported in such a way as to avoid any

damage to its components:

· The machine must be transported in its installation position.

· Before transporting the machine, grease all non-painted parts

to avoid the risk of deterioration.

· Based on the type of transport, take care to protect the machine

from all possible impact and stress.

NOTE – The machine must be lifted by TWO operators.

NOTE –It is advisable to keep the packaging in case it is

needed to store or transport the machine at a later date.

The machine is moved on a two-wheel trolley.

A

B

C

660

500

440

18 TRANSLATION OF THE ORIGINAL INSTRUCTIONS (Keep for future reference)

Document Code Rev. Date saved Date printed

U300 INSTRUCTIONS 01 09/02/2016 09/02/2016

EN

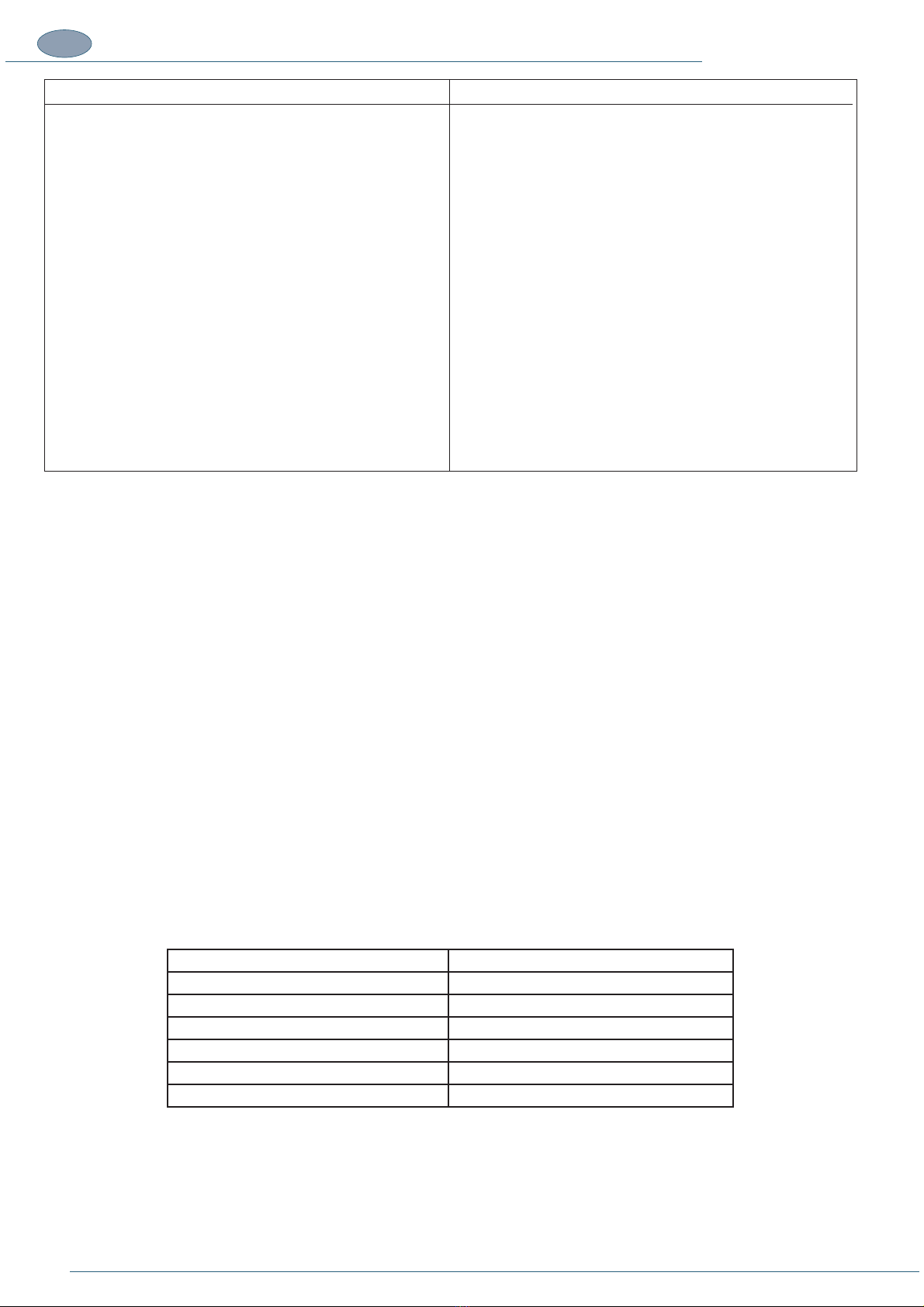

2.5. REMOVING THE PACKAGING

The machine may be shipped in a container or on a lorry.

In both cases the same type of packing is envisaged which is suitable for guaranteeing the good condition and proper preservation of

the machine during transport up to the time of delivery to the customer.

The machine is shipped packed in a special box and protected against damage by polystyrene inserts.

Maximum dimensions 660x440x500 (AxBxC).

NOTE –It is advisable to keep the packaging in case it is needed to store or transport the machine at a later date.

When storing the machine, never stack two machines packed on a pallet with shrink wrap.

MULTIPLE TRANSPORT AND HANDLING

The transport of more than one machine can be carried out using a Europallet which can carry up to a maximum of 12 boxes (12 machines).

Overall dimensions = (80x1200x1800mm - AxBxC).

A

B

C

A

C

B

Table of contents

Other FLETCHER Industrial Equipment manuals