CBDO3AEN.doc 18.03.2014 Rev. 3A 6 (8)

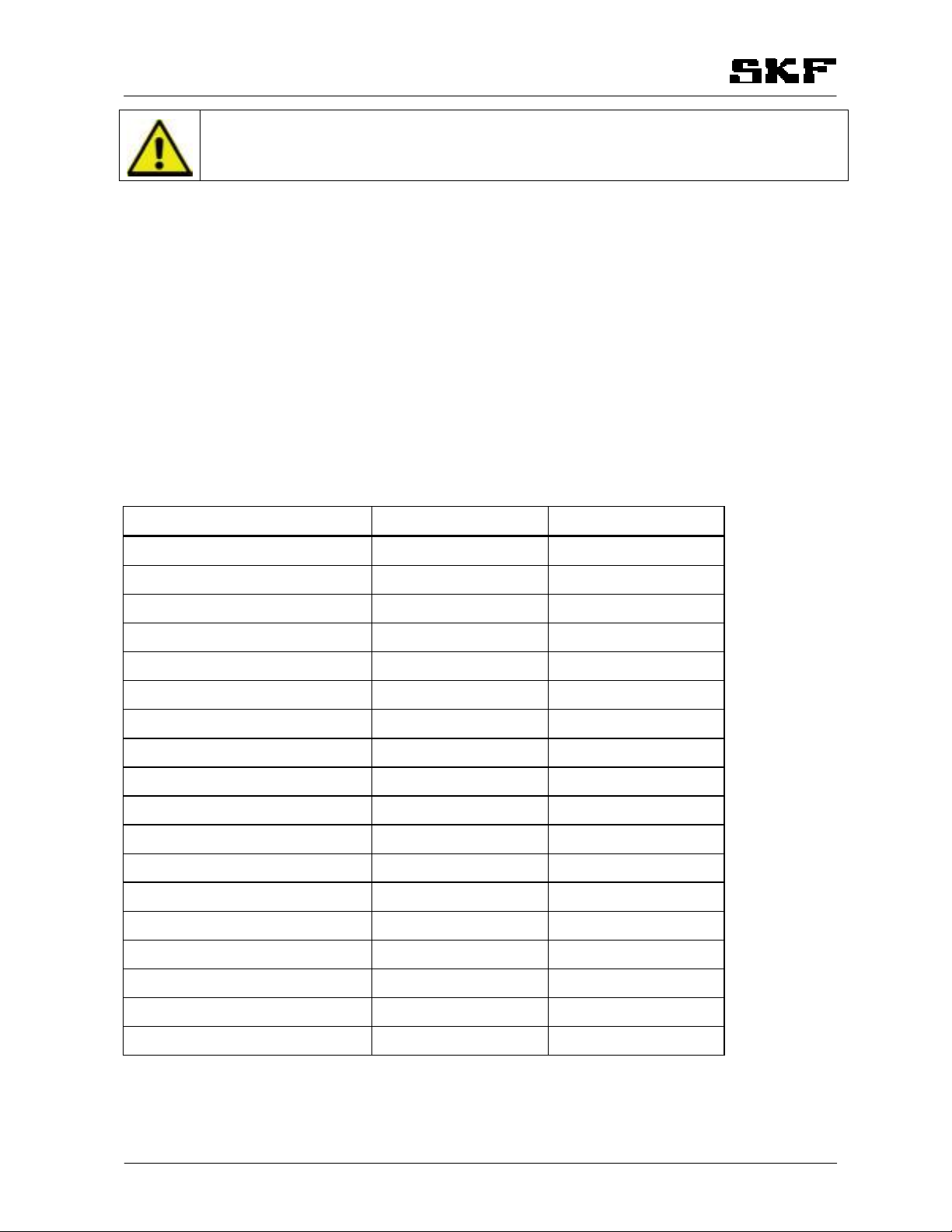

Table 6 Troubleshooting Table

Description of malfunction Cause of malfunction Solution

No lubrication spot receives lub-

ricant (line light A is flashing)

Dosers are leaking Replace the dosers

A lubrication point does not re-

ceive lubricant

Faulty doser Replace the doser

A lubrication point receives too

much lubricant

Leaking doser Replace the doser

7 Spare parts

Note! The spare parts for dosers and mounting rails are complete replaceable products.

Numbers in brackets are part numbers of drawings 461780 and 461803.

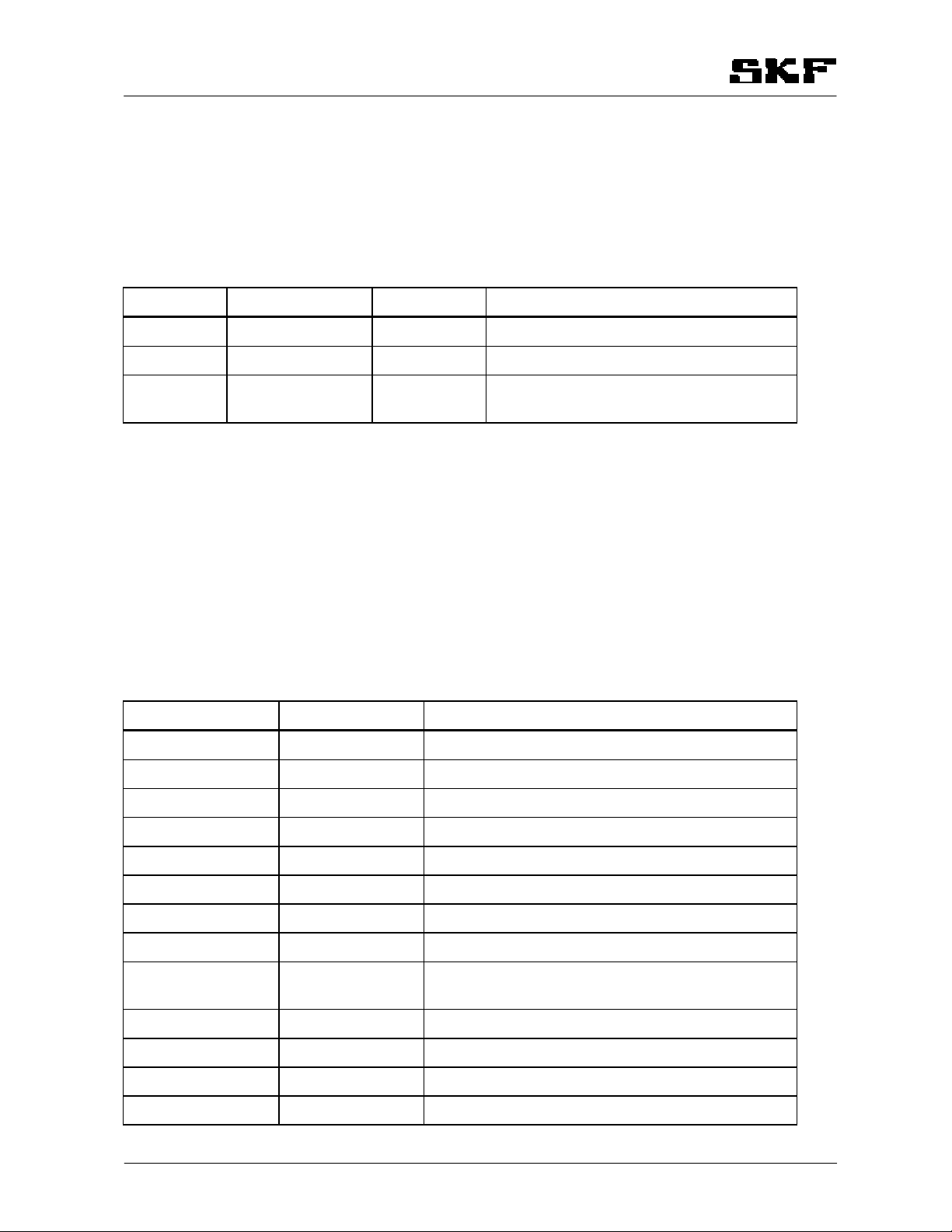

Table 7 Doser codes

Doser type Code Drawing number

B1-G1/8-ZN-4 11391000 461780

B2-G1/8-ZN-4 11391050 461780

B3-G1/8-ZN-4 11391100 461780

B4-G1/8-ZN-4 11391150 461780

B5-G1/8-ZN-4 11391200 461780

B6-G1/8-ZN-4 11391250 461780

B1-G1/8-ZN-6 11391300 461780

B2-G1/8-ZN-6 11391350 461780

B3-G1/8-ZN-6 11391400 461780

B4-G1/8-ZN-6 11391450 461780

B5-G1/8-ZN-6 11391500 461780

B6-G1/8-ZN-6 11391255 461780

B1-G1/8-ZN-6-U 12800250 461803

B2-G1/8-ZN-6-U 12800260 461803

B3-G1/8-ZN-6-U 12800270 461803

B4-G1/8-ZN-6-U 12800280 461803

B5-G1/8-ZN-6-U 12800290 461803

B6-G1/8-ZN-6-U 12800300 461803

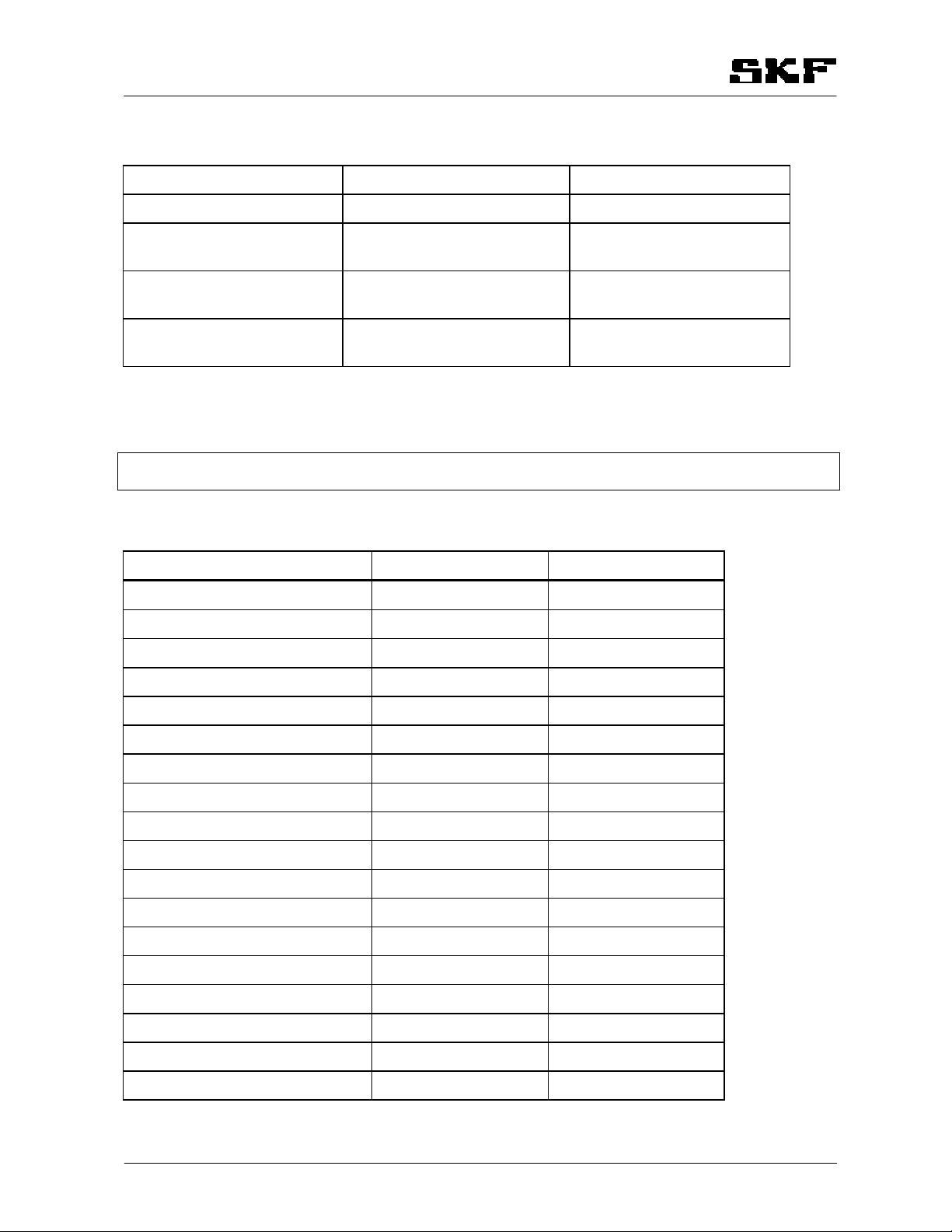

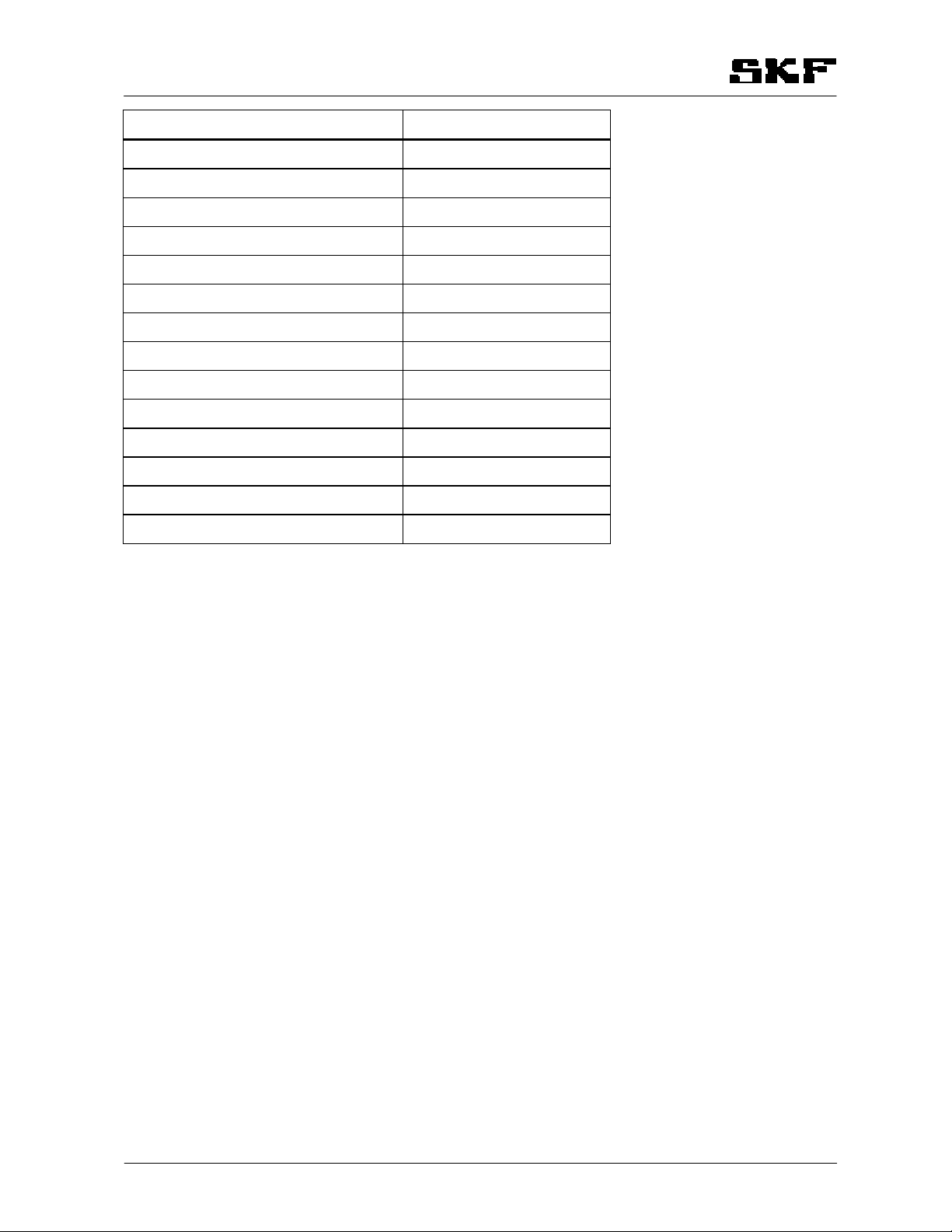

Table 8 Mounting rail codes