flexcell Streamer System STR-4000 User manual

USER MANUAL

Streamer®System

STR-4000

05-12-17

Rev 6.0

Culturing Cells in a Mechanically Active Environment

™

Flexcell International Corporation 2730 Tucker Street, Suite 200 Burlington, NC 27215

800-728-3714 (919) 732-1591 FAX: (919) 732-5196 www.flexcellint.com

COPYRIGHT © 2003 FLEXCELL

INTERNATIONAL CORPORATION

FLEXCELL®INTERNATIONAL CORPORATION

i

TABLE OF CONTENTS

1. Getting Started ..............................................................................................................1

Introduction ........................................................................................................................................ 1

Streamer

®

Components...................................................................................................................... 1

Streamer

®

Setup and Assembly......................................................................................................... 1

Sterilizing the Streamer®................................................................................................................... 2

Streamer

®

Placement in the Incubator .............................................................................................. 3

Using the Pump .................................................................................................................................. 3

Quickstart Instructions ....................................................................................................................... 3

2. StreamSoft

™

V4.2 Software.........................................................................................5

Installation Instructions...................................................................................................................... 5

Setting up Parameters in StreamSoft

™

V4.2..................................................................................... 5

Main Panel.......................................................................................................................................... 6

General Information Tab ............................................................................................................. 6

System Tab................................................................................................................................... 7

Pre-Test Configuration ................................................................................................................ 8

Pull-down Menus......................................................................................................................... 9

Operate Menu................................................................................................................................... 10

Manual Mode............................................................................................................................. 10

View Data .................................................................................................................................. 11

Configure Users ......................................................................................................................... 12

Configure Regimes: Setup Parameters..................................................................................... 13

Configure Testing Apparatus .................................................................................................... 15

How to enter the proper values for your device ....................................................................... 16

Configure System Variables ..................................................................................................... 17

Reinitialize Hardware ................................................................................................................ 18

StreamSoft

™

V4.2 Notes.................................................................................................................. 18

3. Doing an Experiment .................................................................................................19

Overview .......................................................................................................................................... 19

Creating a Regime............................................................................................................................ 19

Setting up an Experiment................................................................................................................. 20

Filling the System to Eliminate Air Bubbles .................................................................................. 21

Post-Experimental Analysis............................................................................................................. 21

Application Notes ...........................................................................................................22

Culturing Cells on Culture Slips

®

.................................................................................................... 22

Appendix: Parallel Streamer

®

Shear Stress Numbers...................................................23

Warranty Information.....................................................................................................24

Contacting Flexcell.........................................................................................................25

FLEXCELL®INTERNATIONAL CORPORATION

1

1. GETTING STARTED

I

NTRODUCTION

Fluid-induced shear stress occurs in every tissue

in the body as a result of interstitial fluid

movement. Tissue deformation by

compression, tension or shear forces results in

the movement of interstitial fluid around cells.

Fluid movement acts as a transport vehicle for

ions, proteins, carbohydrates and other

molecules capable of movement within the

matrix. As the fluid moves past cell membranes,

a shear stress () is generated. If one assumes

that laminar flow occurs through a parallel-plate

flow chamber, fluid-induced shear stress values

can be determined with the following formula:

= 6Q/bh

2

where is the shear stress in dyne/cm

2

, is the

viscosity of the fluid in dynes/cm

2

, Q is the flow

rate in ml/s, b is the width of the flow channel

in cm, and h is the height of the flow channel in

cm. Shear stress in the vascular system may

vary from less than 1 to more than 35 dyne/cm

2

.

Fluid shear stress in canaliculi of bone may vary

from 1 to 20 dyne/cm

2

, while in cartilage it may

be in the range of 1 to 5 dyne/cm

2

.

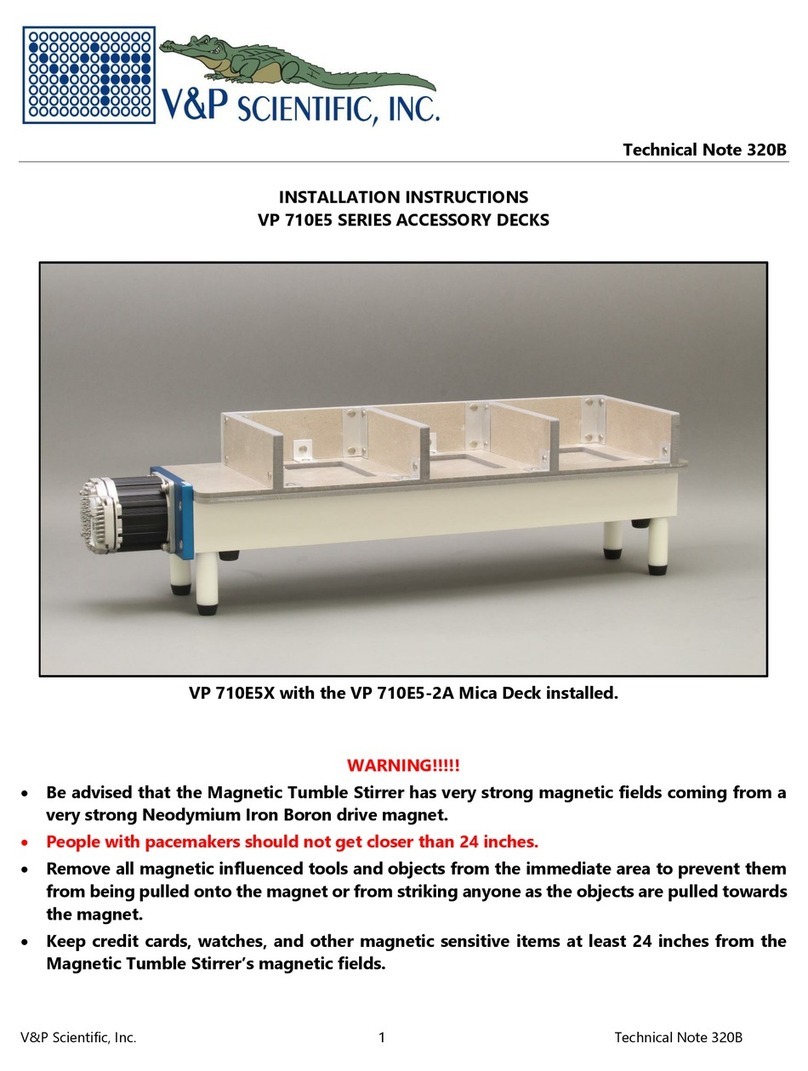

The Streamer

®

is a parallel-plate flow system

that is used to apply fluid-induced shear stress

to cells grown in a monolayer. The system

includes a six-chamber laminar flow device

designed to hold 75 x 25 x 1 mm Culture Slips

®

(Fig. 1). Cells are cultured on these matrix-

coated glass slides. StreamSoft

software

controls a peristaltic pump, thereby regulating

the flow rate into the chamber and the

magnitude of shear stress applied to the cells.

Shear stress values from 0 to 35 dyne/cm

2

can

be achieved depending on the tubing size used.

This six place flow chamber can be used to

assess RNA and protein expression by cells in

response to fluid-induced shear stress, and

production of secreted molecules into the

perfusate.

Figure 1. Image and schematic of Streamer

®

device with cells cultured in monolayer on Culture

Slips

®

.

S

TREAMER

®

C

OMPONENTS

Streamer

®

Device

Streamer

®

Tubing (includes quick

disconnect fittings)

Masterflex

L/S Peristaltic Pump

RS232 to USB Connector Cable

Pulse Dampeners (2)

12 Culture Slips

®

StreamSoft

Software V4.2

500 ml Culture Medium Collection

Reservoir (includes quick disconnects and

filter)

Dell Inspiron Notebook Computer

(optional)

S

TREAMER

®

S

ETUP AND

A

SSEMBLY

The following instructions are for the full

Streamer

®

system. Once fully assembled in the

incubator, the system should resemble the one

pictured in Figure 2. Always check the tubing

for cracks or leaks prior to use.

FLEXCELL®INTERNATIONAL CORPORATION

2

Figure 2. A) Streamer

®

system setup on the shelf

in a standard incubator. B) Schematic of Streamer

®

system setup.

1. Connect the medium collection reservoir to

the first pulse dampener with the 3’ (0.9 m)

long piece of beige Phar-Med

®

tubing. On

the medium reservoir, the quick disconnect

connected to the long tubing extending to

the bottom of the bottle should be used. Do

not use the quick disconnect leading to

the bent tubing in the bottle for this

connection.

2. Move the clamp mounted onto the Phar-

Med

®

tubing to the end closest to the pulse

dampener. Place the middle of this tubing

segment into the pump head. Rotate the

lever to the left to open the pump head for

tubing placement, then rotate the lever to

the right to secure the tubing into the pump

head. When not doing an experiment, the

pump head lever should be rotated to the

left to eliminate pressure on the tubing.

3. Connect the first pulse dampener to the

second pulse dampener with the 3” (7.6 cm)

long segment of silicone tubing.

4. Connect the second pulse dampener to the

inlet port (bottom) of the Streamer

®

with

one of the 2’ (0.6 m) pieces of silicone

tubing.

5. Connect the outlet port (top) of the

Streamer

®

to the quick disconnect on the

medium bottle that is connected to the short,

bent tubing in the bottle, using the other 2’

(0.6 m ) long piece of silicone tubing.

6. Before the first use, run deionized water

through the entire system to make sure there

are no leaks.

Note: Any of the tubing lengths above can be shorted

or extended according to your setup needs.

S

TERILIZING THE

S

TREAMER

®

All components of the flow system (except the

pump and computer) can be effectively and

safely sterilized in an autoclave at standard

autoclave temperature, pressure and time period

(120 °C, 15 psi, 15-20 minutes). When

autoclaving, leave all system components

connected together. Release the clamp on the

Phar-Med

®

tubing used between the medium

collection reservoir and the first pulse

dampener. Open the top of the Streamer

®

slightly so that steam can reach the inside of the

device. Also, do not place any system

component on top of the pulse dampeners, as

the pulse dampeners may deform under load at

high temperatures. The pulse dampeners should

be placed on top of all system components in

the autoclave.

Note: After autoclaving, check the threaded quick

disconnect fittings on the Streamer

®

inlet and outlet

and on the pulse dampeners for tightness. If any of

the fittings have become loose, turn them until they

are ¼ turn past finger tight.

If you do not have access to an autoclave you

can use ethylene oxide gas treatment with

subsequent vacuum treatment. 70% ethyl

A

B

FLEXCELL®INTERNATIONAL CORPORATION

3

alcohol can also be pumped through the system

for cleaning, however, this will not completely

sterilize the system.

S

TREAMER

®

P

LACEMENT IN THE

I

NCUBATOR

The Streamer

®

system should be placed into a

temperature-controlled, CO

2

incubator for

experiments. We recommend that the

Streamer

®

be kept in the incubator for at least

20 minutes before starting an experiment to

assure that the device is at a stable temperature

for cell culture. The pump is placed into the

incubator with the rest of the system. A

containment tray is placed underneath the

system to provide a means to transport the

system to the cell culture hood, and to catch any

fluid should a leak occur. The computer must

not be placed into the incubator.

U

SING THE

P

UMP

1. Plug the pump into a power outlet (110 V

for North America, 220 V for Europe and

Japan).

2. If using the flow system manually (i.e.

without computer control), ensure that the

correct tubing size is selected on the pump

and the clockwise flow direction. The

standard tubing included with the

Streamer

®

system is MasterFlex

L/S 17.

Therefore, you will want to press the “size”

button on the bottom right of the pump face

until the green light is beside the number

“17”.

NOTE: Once you reach the tubing size “25”, the

green light will remain on the same level for two

depressions and the second one will cause the “HP”

LED (near the bottom of the indicator light column)

to light up. The “HP” button specifies the tubing

numbers on the right column of the size listings.

Therefore, when the green light is beside the number

“17” you will want the “HP” light to be off.

Once this is set, the display on the pump

will read the flow rate for that particular

tubing as the pump is running. Consult the

appendix or the data following this manual

to find which flow rate corresponds to the

desired level of shear stress. Use the arrow

keys on the top left of the pump face to

select the required flow rate. Press the blue

start/stop button to initiate and stop flow.

3. If using the system with computer

control, connect the male end of the RS-

232 cable into the back of the pump and the

USB end into a USB port of the computer.

Turn on the power and start the software.

When the software controller is functional,

“PO1” will appear on the pump display.

Use the software to create a regime with

your desired flowrate(s). See pages 5-18 for

further instructions on using the

StreamSoft

™

software.

Q

UICKSTART

I

NSTRUCTIONS

1. Set up the entire system in an incubator. See

page 1 for the system setup.

2. Sterilize the Streamer

®

and system

components. See page 2 for sterilization

instructions.

3. Connect the cable from the pump to the

serial port of the computer. Turn on the

computer and pump and open up the

StreamSoft

™

software program.

4. Select the Operate menu, then select Users.

Add your name as a user by clicking Add

User, then click the Return button.

5. Select the Operate menu again, then select

Configure Regimes. Type a new name in

the Regime Name field and click on Insert

Step to insert a step into the regime. Create

a regime by entering values in one or more

steps. Once complete, click on Save

Regime. Click Return to exit.

6. On the main screen, click on Configure; this

will open the Pre-Test Configuration

window. Select the appropriate User,

FLEXCELL®INTERNATIONAL CORPORATION

4

Regime and Hardware, then click Update.

The regimen is now ready to start.

7. Culture cells on six Culture Slips

®

. Be sure

that you culture on the side with the Teflon

®

rim printed around the borders. Be careful

to plate cells only within this rim. We

recommend allowing cells at least 48 hours

to attach to slides before beginning your

flow experiment.

After cells have attached to slides:

8. Be sure that the Streamer

®

is closed (the top

lid should be flush with the body of the

device).

9. Place 500 ml of PBS into the medium

container and pump through the system to

flush out impurities. This can be done by

starting your regime or using the manual

mode under the Operate menu in the

software. If you are not using the software,

set the pump to the appropriate tubing size,

set the flowrate at 300 ml/min and press the

start button.

10. After pumping for several minutes, remove

the PBS from the medium container and

replace with 500 ml of sterile tissue culture

medium.

11. Pump the culture medium through the

system to flush out remaining PBS.

Remove the medium and replace with 500

ml of fresh sterile tissue culture medium.

12. Pump the tissue culture medium through

the entire system. Once the system is full,

tilt the pulse dampeners, one at a time, at an

angle of approximately 20 degrees, such

that the direction of the flow is going from

the vertex of the angle to the open end of the

angle. Leave the pulse dampener in this

position until the fluid comes through the

outlet fitting again, then lay the pulse

dampener down horizontally. This process

will allow the pulse dampener to fill to a

level slightly higher than the fittings,

thereby creating a bubble trap for any air

bubbles that may accidentally enter the

system. Do the same with the second pulse

dampener. Once this process is complete,

allow flow to continue and go to the next

step.

13. As the flow continues, check for any air

bubbles visibly trapped within the tubing.

Also check the walls of the medium

container to be sure that no air bubbles have

formed on the sides. If so, swirl the medium

around to release air bubbles from the side

walls.

14. Once the tubing and flow device are filled

with medium and all air bubbles are

eliminated, reverse the flow direction on the

pump to draw the medium level back to the

flow chamber and down past the head of the

chamber, then stop the pump. The fluid

level will have to be estimated once the

fluid can no longer be seen in the tubing

coming from the head of the Streamer

®

.

15. Tighten the small clamp on the Phar-Med

®

tubing just to the right of the pump head so

that the flow path in the tubing is

completely closed off.

16. Turn the lever arm on the MasterFlex

pump all the way to the left to release the

tubing and remove the tubing from the

pump head. Carefully move the tray

containing the Streamer

®

device, tubing,

pulse dampeners, and fluid collection

reservoir to the tissue culture hood.

17. Remove the Streamer

®

screws and open the

hinged top.

18. Transfer your cells from the incubator to the

tissue culture hood.

19. Using forceps and/or your fingers with

sterile gloves, pick up each Culture Slip

®

and place it into each one of the slots in the

flow device. Be sure that the side of the

slide with cells attached is facing the flow

area adjacent to the slot, not the closed

wall of the slot. Gently slide each Culture

Slip

®

downward until it reaches the bottom

of its chamber. Be careful that the Culture

Slip

®

glass is not chipped against the

stainless steel surface during this process.

FLEXCELL®INTERNATIONAL CORPORATION

5

All six slots must be filled to ensure proper

flow rate readings. If you do not wish to

use all six Culture Slips

®

with cells, use

blank Culture Slips

®

for the remaining

slots.

20. Close the top of the device, turn the bolts by

hand, then tighten them with the hex

wrench provided with the system.

21. Move the tray with the system components

back to the incubator. Put the Phar-Med

®

tubing back into the MasterFlex

®

pump

head and clamp the head down.

22. Unscrew the small clamp on the Phar-Med

®

tubing to open the flow path to full capacity.

23. Click the Start button in the software (or set

the pump to the desired flowrate and

depress the start button). Your regimen will

start and a green light will go on at the top

right corner of the screen.

24. The expected shear stress and actual value

will be displayed on the graph in real time.

Periodically monitor the flow system for

leaks during the protocol.

25. When the flow regimen is over and the

pump has stopped, remove the Streamer

®

system from the incubator as before. Open

the top and remove the slides for

processing.

26. Clean the Streamer

®

and system with

deionized water. Never leave culture media

in the Streamer

®

device after an

experiment, as this will corrode the

stainless steel finish over time.

See the instructional video, Streamer®

Assembly, on Flexcell

®

’s website

(http://www.flexcellint.com/videos-

instruct.htm) for a demonstration of how to

assemble the Flexcell

®

Streamer

®

and

associated tubing to run with a MasterFlex

Peristaltic Pump.

2. STREAMSOFT

™

V4.2 SOFTWARE

I

NSTALLATION

I

NSTRUCTIONS

1. Insert the StreamSoft

™

V4.2 DVD into the

DVD-ROM drive on the computer.

2. Double click My Computer (Windows

XP) or Computer (Windows

Vista/Windows 7).

3. Double click the DVD-ROM drive.

4. Double click the Setup installer.

5. The installer will now open and run.

6. On the Product Notification screen, click

Next.

7. On the Destination Directory screen, click

Next.

8. On the License Agreement screen, click I

accept the License Agreement and then

click Next.

9. On the next License Agreement screen,

click I accept the above 2 License

Agreement(s) and then click Next.

10. On the Start Installation screen, click Next.

11. Installation of the required National

Instruments and StreamSoft

™

software

will now begin.

12. Once the installation is complete click

Finish and restart the computer.

13. Installation of StreamSoft

™

V4.2 is now

complete.

NOTE: When the Select Pump to Use window

appears when opening the StreamSoft

™

V4.2

software, select the pump named MasterFlex

Peristaltic Pump to ensure correct function of the

equipment.

S

ETTING UP

P

ARAMETERS IN

S

TREAM

S

OFT

™

V4.2

Specific parameters will need to be set up in

StreamSoft

™

V4.2 to customize it for your

particular device and system. Setting up

these parameters is extremely important to

FLEXCELL®INTERNATIONAL CORPORATION

6

ensure accurate flow results for your

system. For instructions on setting up these

parameters, see Configure Testing Apparatus

and Configure System Variables, pages 15-

17. Complete this setup before proceeding

with any experiments.

MAIN PANEL

G

ENERAL

I

NFORMATION

T

AB

Function: The default main panel allows the user to verify that the system is running and to stop the

tests at any time.

Buttons and Fields

Status Number is bright green when an experiment is running

System 1,2,3,4 These tabs will automatically become highlighted according to the

number of pumps connected to the computer (1 - 4).

General Information Current date and time

FLEXCELL®INTERNATIONAL CORPORATION

7

S

YSTEM

T

AB

Function: This panel is used to run the experiments. Each System tab is identical.

Buttons and Fields

User Current user in currently configured regime

Regime Regime currently configured

Apparatus Device being used with the software (Streamer

®

or FlexFlow

™

)

Data File Name of file to which data is being saved (if appropriate)

Configure Configure (load) the experiment. The Pre-Test Configuration window will

appear.

Start Start the experiment.

Stop Terminate the experiment. This button is only active when an experiment is

running.

Pause Suspend the experiment. The pump will stop, but the test regimen is kept in

memory.

Resume Resume a paused experiment.

Graph This graph shows the expected and actual shear stresses during the experiment.

Elapsed Time (h:m:s) Elapsed time in the current experiment

Loop Current loop in the current step or series of steps

Pulse # Total number of pulsations (square wave) or oscillations (FWD/REV)

produced by the valves in this regime

Step Current (active) step in regime

Direction Current flow direction (FWD/REV)

FLEXCELL®INTERNATIONAL CORPORATION

8

P

RE

-T

EST

C

ONFIGURATION

Function: This panel allows the user to configure the parameters of an experiment. It appears when the

user presses the Configure button on the System panel. The information selected here is transferred to

the User, Regime and Apparatus fields on the System panel.

Buttons and Fields

Users List of all users. Select users with the mouse.

Regimes List of regimes created by the previously selected user. Select from list by using

the mouse to highlight the desired regime.

Apparatus

List of configured flow devices. Select the device that will be used for the

experiment. Important: Be sure that all parameters have been properly set for

your device in the Configure Testing Apparatus window (see page 15).

Print Print the current panel to a printer or HTML file.

Update Use the current selections to run the experiment.

Cancel Cancel any new selections and use the previously configured setup for the

experiment.

Help Online help (not currently available)

FLEXCELL®INTERNATIONAL CORPORATION

9

P

ULL

-D

OWN

M

ENUS

This section summarizes the function of each item in the three pull-down menus.

File Operate Help

-Print -Manual Mode -Help

-Exit -View Data -About LabVIEW

-Users

-Configure Regime

-Configure Apparatus

-Configure System

-Reinitialize Hardware

File

Print Allows user to print a copy of the current panel. This system is configured such that printing

sends a copy of the panel being viewed to a printer or to an html file. If there is no printer

connected to the computer, an error message from the Windows default printer queue will

appear when the user tries to print.

Exit Allows user to close the program. If the pump is operating at the time of exit, it will continue

running. The keyboard short-cut is Ctrl-Q.

Operate

Manual Mode Manually control the pump without setting up an experimental regimen.

View Data View shear stress data from a previous experiment.

Users Add and remove user names.

Configure Regime Create an experimental protocol.

Configure Apparatus Configure parameters of the flow device so that the software can assign the

flow rates corresponding to the desired shear stress. These parameters

must be set correctly to ensure that the proper shear stress values are

shown. See the manual of your device for the appropriate values.

Configure System Configure the system parameters such as data saving, the Com port used and

the presence or absence of valves in the system (Osci-Flow

®

).

Reinitialize Hardware This will reinitialize the software to connect the pump and Osci-Flow

®

(if

present) in the event that a cable is disconnected or the pump is turned off.

Help

Help Online help (not currently available)

About LabVIEW Software version information

FLEXCELL®INTERNATIONAL CORPORATION

10

OPERATE MENU

M

ANUAL

M

ODE

Function: This panel allows the user to manually control the pump. The actual flow rate and speed of

the pump (RPM) are shown on the graph when the pump is working. Manual mode may be used to

troubleshoot the pump operation. The shear stress value is not shown on this panel since it will depend

on the tubing size and flow chamber used.

Instructions

1. Enter the flow set point (pump speed) either by entering a number in the box or using the mouse to

drag the dial to the desired level.

2. Adjust the seconds between readings to a number between 0 and 5. This is the time between each

update of the pump data on the graph.

3. Click on Press to Start.

4. Click on Press to Stop when ready to stop.

5. Click on Return when done.

FLEXCELL®INTERNATIONAL CORPORATION

11

V

IEW

D

ATA

Function: This panel allows the user to view previously collected experimental data in a table format.

Buttons and Fields

File The complete file path to the data file being viewed

Table Contents of the experimental data log file

Export File Export data to a spreadsheet-compatible format

Print Print a copy of this panel to the Windows default printer or write a copy

to an HTML file.

Open Open a data file.

Return Close this panel and return to the Main panel.

Help Online help (not currently available)

FLEXCELL®INTERNATIONAL CORPORATION

12

C

ONFIGURE

U

SERS

Function: This panel allows the user to create or delete users.

Buttons and Fields

Existing Users Lists all current users of the system

User Name Field used to enter new users

Add User Add new users to the system.

Delete User Delete users from the system.

Help Online help (not currently available)

Return Exit this panel and return to the Main panel.

Instructions

To add a user:

1) Type the name into the User Name field.

2) Press the Add User button.

To delete a user:

1) Using the mouse, select the user from the list of Existing Users.

2) Press the Delete User button. If the user has any stored regimes and data sets, the operator will

be prompted to confirm the deletion.

FLEXCELL®INTERNATIONAL CORPORATION

13

C

ONFIGURE

R

EGIMES

:

S

ETUP

P

ARAMETERS

Function: This panel allows the user to configure (create) a regime.

Buttons and Fields

Existing Users List of all users; select a user from the list using the mouse.

Regimes for

Selected Users

List of regimens created by the current user. Selecting from this list will

load that regimen and allow the user to view and/or modify that regime.

Regime Name Name of the current regimen; if creating a new regimen, enter a name in

this field.

Time Between

Pump Updates

Time elapsed between computer updates of the pump parameters; default

is 1 second.

Time Between

Data Log to File

Time interval between each computer sampling of the experimental flow

data. Default value is 10 seconds. For an extremely long test, increase

this interval to reduce the size of the data file.

NOTE: this function only applies when the data saving option is selected in the

Configure System Variables window (see page 17).

Estimated file

size

This is an estimate of how large the data file would be given the total test

length and the time between data.

NOTE: this function only applies when the data saving option is selected in the

Configure System Variables window (see page 17).

Step Current step number selected or being modified

Step Name Name of the currently selected step

FLEXCELL®INTERNATIONAL CORPORATION

14

Flow Type Specifies the direction or type of flow for this step (forward, reverse,

pulsed (square wave), oscillation)

ON/HI (s)

When using pulsed (square wave) or oscillatory flow, specifies how long

the valves remain in a position to allow the fluid flow to continue

unhindered or flow in the forward direction, respectively. For normal

forward or reverse (unidirectional) flow, this value remains at 1.00.

OFF/LO (s)

When using pulsed (square wave) or oscillatory flow, specifies how long

the valves remain in a position to stop the fluid flow to the device or

cause it to flow in the reverse direction, respectively. For normal forward

or reverse (unidirectional) flow, this value remains at 1.00.

Shear

(dyne/cm^2) The value of shear stress to be applied to the cells in this step.

Duration

(h:m:s.ss) Time to spend in this step (hours:minutes:seconds.milliseconds)

GoTo To create a loop, indicate which step to go back to. The GoTo step must

always be a step number before the current step.

Loop Indicates how many times to loop between the GoTo step and the current

step.

Summary Table

This table is a listing of the current steps in the regimen. Selecting a row

from this table will allow the parameters of the step to be viewed and

modified.

Insert Step Insert a step into the regimen before or after the current step.

Delete Step Delete the currently selected step.

New Regime Clear all parameters and start a new regime. Type in a new name under

Regime Name and select Insert Step.

Delete Regime Delete the currently selected regime.

Save Regime Save a new or modified regime.

Return Exit this panel and return to the Main Panel

Check Shear Check the shear stresses entered in your regime to see if they are

achievable with the apparatus, pump and tubing size that you are using.

Print Print the current panel to a printer or an HTML file.

Help Online help (not currently available)

Instructions on how to set all the parameters for an experiment are included in the Doing an Experiment

section of this manual.

FLEXCELL®INTERNATIONAL CORPORATION

15

C

ONFIGURE

T

ESTING

A

PPARATUS

Function: This panel allows the user to create, modify or delete a testing apparatus (Streamer

®

or

FlexFlow

flow chamber).

As each Streamer

®

and FlexFlow

device is manufactured to strict dimensional specifications,

the values for the height and width of the chambers must be entered into the software for each

individual device.

These values are measured for your specific device and must be correct for accurate shear stress

measurement. The values can be found in the appendix of the manual for your device.

Buttons and Fields

Testing Apparatus List of all flow devices available

Name When a testing apparatus is selected, this field (and the parameters)

will be updated.

Flow Factor A factor that accounts for any parallel paths in the flow stream. This

number is 6 for the Streamer

®

and 1 for the FlexFlow

.

Hose Size

Hose size determines how fast the pump must move to achieve the

desired flow rate and shear stress level. The sizes listed are standard

for Masterflex

tubing. Select the hose size that you are using with

your system.

b

Width of the flow area (cm) in a single chamber of the Streamer

®

or

FlexFlow

device. This number is found in the back of the manual

for your device listed as Flow Area Width (cm).

FLEXCELL®INTERNATIONAL CORPORATION

16

h

Height of the flow area (cm) in a single chamber of the Streamer

®

or

FlexFlow

device. This number is found in the back of the manual

for your device listed as Flow Area Height (cm).

Viscosity Viscosity of the perfusate/media used in the experiment. The

standard value is 0.01.

Print Print the current panel to a printer or an HTML file.

Save Apparatus Save changes to the apparatus listed in Name.

Delete Apparatus Deletes apparatus listed in Name.

Help Online help (not yet available)

Return Exit this panel and return to the Main panel. Any changes that have

not been saved will be discarded.

H

OW TO ENTER THE PROPER VALUES FOR YOUR DEVICE

Please check the Appendix of the manual for your device for the proper band hvalues.

1. Select the Testing Apparatus being used for the experiment or enter a name for a new apparatus in

the Name box.

2. Enter the correct flow factor for your device. This specifies the number of parallel flow chambers

in your device.

3. Select the correct Hose Size for the type of Masterflex

tubing being used in the experiment.

4. Enter the proper band hvalues for your device.

5. Enter the Viscosity of the perfusate fluid used in the experiment. The default value is 0.01

dynes*s/cm

2

.

6. Click Save Apparatus button, then click Return to exit this screen.

FLEXCELL®INTERNATIONAL CORPORATION

17

C

ONFIGURE

S

YSTEM

V

ARIABLES

Function: This panel is used to select three system parameters – Communications port, data saving,

and the presence of valves in the flow system.

Buttons and Fields

Pump Serial Port Com 1 is the default port. This should be changed only if there is a

conflict with this port on your computer.

Save Data? Select this option if you want to save regime data files.

Valves in System? Select this option if you are using the Osci-Flow

®

Flow Controller.

FLEXCELL®INTERNATIONAL CORPORATION

18

R

EINITIALIZE

H

ARDWARE

Function: This panel will appear when the computer program is first started. It will also appear when

the Reinitialize Hardware item is selected in the Operate menu. When the system is properly initiated,

the pump will display PO1. If power to the pump is cycled during experimentation, or communication

is lost, the user should reinitialize the hardware before turning off the program and starting it again.

STREAMSOFT™ V4.2 NOTES

When running a regime in StreamSoft

™

V4.2, do not run other applications on the same computer.

The communication timing to the pump and Osci-Flow

®

requires full CPU availability. If another

program or operation is running that requires CPU power, it is possible that the pump or valve

timing could be interrupted. This effect may be noticeable when using the Osci-Flow

®

at a higher

frequency than 2 seconds on, 2 seconds off, or when oscillating the pump speed to create pulsatile

flow.

When the Select Pump to Use window appears when opening the StreamSoft

™

V4.2 software,

select the pump named MasterFlex Peristaltic Pump to ensure correct function of the

equipment.

Table of contents

Other flexcell Laboratory Equipment manuals