Matest E094 User manual

Instruction Manual

“AUTOMATIC LABORATORY MORTAR MIXER”

Product Code

E094 / E094T / E095

Do not attempt to operate this equipment before reading

and comprehending the manual in all its parts

Users

MACHINE MANUFACTURERS |DRAUGHTSMEN |OPERATORS |MAINTENANCE WORKERS |ANY OTHERS

REV.

DESCRIPTION

MANAGED

APPROVED

PRODUCT CODE

PAGES

ISSUE DATE

02

User manual

Technical

Office

Chief

Technician

E094.M01.EN.02

15

01/2007

Matest S.p.a. Via delle Industrie 25, 24048 Treviolo (BG) Italy TEL. +39 035 2055011

GENERAL INDEX

GENERAL INDEX

CHAPTER 1

GENERAL INFORMATION

1.1

GENERAL FEATURES

1.2

IDENTIFICATION

1.3

APPLICATIONS

1.4

STRUCTURE AND OPERATING OF THE MACHINE

CHAPTER 2

SAFETY INFORMATION

2.1

GENER

AL SAFETY STANDARDS

2.2

SAFETY DEVICES

2.3

DANGEROUS PARTS AND RESIDUAL RISKS

2.4

NOISE

CHAPTER 3

INSTALLATION

3.1

LIFTING

3.2

UNPACKING

3.3

INSTALLATION

3.4

ELECTRIC CONNECTIONS

CHAPTER 4

MACHINE FEATURES

4.1

DIMENSIONS A

ND MASS

4.2

CALIBRATION

CHAPTER 5

OPERATOR INTERFACE

5.1

DESCRIPTION ENCLOSURE B/C

–

STANDARD CE MIXER

5.2

DESCRIPTION ENCLOSURE E

–

CONTROL PANEL

CHAPTER 6

APPLICATION

6.1

WARNING

6.2

SWITCHING ON THE APPLIANCE

6.3

TOOLING U

P

6.4

PREPARATION AND POSITIONING OF THE MORTARS

6.5

EMERGENCY STOP

6.6

STARTING AFTER EMERGENCY STOP

6.7

STOP CONTROLLED BY SAFETY CIRCUITS

6.8

APPLIANCE FUNCTIONING

6.9

SWITCHING OFF THE APPLIANCE

6.10

TRIAL STARTING

CHAPTER 7

MA

INTENANCE

7.1

ROUTINE MAINTENANCE

7.2

SPECIAL MAINTENANCE

7.3

CALIBRATION

7.4

PERIODICAL INSPECTIONS

CHAPTER 8

DIAGNOSIS

8.1

DIAGNOSIS

CHAPTER 9

SCRAPPING

9.1

SETTING ASIDE

9.2

SCRAPPING

2

LIST OF ENCLOSURES

A

COMPLETE

APPLIANCE

B

MIXER E095 (MODEL CE)

C

MIXER E094 (STANDARD)

D

TOOLING UP

-

MIXER (CE / STANDARD)

E

CONTROL PANEL

LIST OF ELECTRIC DIAGRAMS E095

S1

INTERNAL VIEW MIXER E095

S2

POWER DIAGRAM MIXER E095

S3

AUXILIARY CIRCUIT MIXER E095

S4

POWE

R DIAGRAM MIXER E095

S5

CLAMP BOARD MIXER E095

S6

LAY OUT OF PROTECTIONS FOR MIXER E095

LIST OF ELECTRIC DIAGRAMS E094

S7

INTERNAL VIEW

-

MIXER E094

S8

AUXILIARY CIRCUIT MIXER E094

EEC CONFORMITY DECLARATION (FOR EEC COUNTRIES ONLY)

3

CHAPTER 1

GENERAL INFORMATION

1.1

GENERAL FEATURES

THIS MANUAL IS ADDRESSED TO the carrier, the installer, the user, the maintenance operator, the

scrapping operator.

Please read it carefully because it informs you about the operating of the machine in safety conditions.

This manual has to be considered a part of the product and concerns only the machine it is delivered

with.

Keep the manual in order during the whole life of the appliance to consult it for any needs.

In case of sale, the manual and its enclosures should be given together with the machine.

The manufacturer assumes no liability for any damages caused by a misuse of the machine.

The manufacturer has the right to modify this technical literature as well as the machines this refers to

without any previous notice.

Messages meaning:

ATTENTION

This warning refers to all those procedures that have to be carefully followed to avoid

any damage to the machine.

DANGER

This warning refers to all those procedu

res that could present some risks for the

operator if not carefully followed.

1.2

IDENTIFICATION

MANUFACTURER IDENTIFICATION: See the cover page.

MACHINE IDENTIFICATION: See the plate on the machine where complete identification

data as well as electric features are to be found.

1.3

APPLICATIONS

The laboratory Mixer E094 and E095 has been developed for the automatic mixing of the cement pastes

and mortar. This process will result in the preparation of the specimens for flexure, compression tests in

perfect compliance with the EN 196/1 specifications.

This appliance has to be used only for the aim it has been projected and manufactured for.

Any other use of the machine is not permitted.

ATTENTION

The instructions given in this operating manual are

only made for the right use of the

appliance. To carry out the test in the right way, the user must refer to the specific

standards in force for the test itself.

1.4

STRUCTURE AND OPERATING OF THE MACHINE

The appliance is mainly formed by two parts (see enclosure Afor further details):

THE MIXER (B) is made by a metal sheet frame (B9/C9) and by a lower basement of aluminium; a

bowl (B14) is fixed at the bottom, while the electric disposals for the machine control as well as the

motor (B4/C4) are located at the top. A special lever (B7/C7) allows fixing the bowl to the frame. The

electric motor activates the beater (B1/C1), which mixes the mortar.

THE CONTROL PANEL (C) allows controlling the various mixer functions.

For further information please contact the Agent or the Manufacturer.

4

CHAPTER 2

SAFETY INFORMATION

2.1

GENERAL SAFETY STANDARDS

The use, lifting, installation, maintenance and scrapping of the machine are allowed only to

qualified staff. Qualified staffs are composed by people who are authorised by the safety responsible

to do any activities due to their experience and acknowledgement of the operating of the machine and

of the standards, rules and actions.

The user must be carefully taught about the operating of the machine to avoid any misuse of it and

about the safety devices, which the machine could be eventually equipped with. The safety devices

will have to be kept always assembled and to be daily checked.

The manufacturer offers training and assumes no liability for any damages due to a misuse of the

machine by an unskilled staff.

The manufacturer recommends following carefully the instructions and procedures of the operating

manual and the safety standards concerning the safety devices and the general rules of the work

environment.

Verify the accordance of the machine to the standards in force in the State where the machine has to

be installed.

The operating manual must be carefully read by the safety responsible, by the operators and

maintenance engineers. It must always be kept near the machine in order to be able to read it any

times it will be necessary.

Any tampering or modifications of the machine (electric, mechanical etc.) that are not allowed by a

written agreement of the manufacturer must be considered as not permitted and the manufacturer will

not accept to be charged for any damages.

The removal or the tampering of the safety devices will be an infringement to the EEC Safety

Standards. The manufacturer assumes no liability for any damages.

The machine has to be installed in places safe from fire and explosions.

We do recommend using only original spare parts and accessories; on the contrary the manufacturer

assumes no liability.

Be careful that any dangerous situations won’t happen during the working; stop immediately the

machine in the event that it will not work properly and ask the manufacturer or the Authorised Service

Staff of the dealer at once.

The manufacturer assumes no liability for any damages to people, things and animals caused by the

non-compliance of the above instructions.

2.2

SAFETY DEVICES

MEANING: Safety devices are all the safety measures, which consist of the use of specific technical

equipment (guards, cages etc.) to protect the operator from any danger that couldn’t be avoided during

the planning.

FIX AND MOVABLE SAFETY DEVICES

The Mixer is supplied in two versions:

CE VERSION: The mixer E095 has got a protection door (B16), which prevents the opening during the

test so that the operator cannot come in touch either with the internal mechanisms or with the beater

(B1/C1). The door opening causes an immediate interruption of the power feeding; in this way the motor

(B4/C4) and the beater stop moving. The rotation can start again only after the closing of the protection

door.

ATTENTION

It is suggested to open the protection door only when the mixer is not turning, the

opening of the safety door during the working of the appliance must be made only in

case of real and urgent need.

STANDARD VERSION: For the Mixer E094 no safety devices are foreseen.

ACTIVE SAFETY DEVICES

Active Safety Devices are all those disposals and devices, which cancel or greatly reduce the risks to the

operator. They require a conscious and active behaviour of the operator to be activated.

In every appliance there’s a main switch (B13/C13) acting also as emergency switch.

By activating it, the feeding to the mixer is disconnected and therefore also the beater (B1/C1) stops

moving.

5

2.3

DANGEROUS PARTS AND RESIDUAL RISK

The dangerous place is the space inside and around the machine where the operator could be wounded

or damaged.

During some procedures the operator could face some risks of danger.

The risks can be eliminated following carefully the procedures written in this manual and using suitable

safety devices.

ATTENTION

In case the manufacturer does not make the installation, use only people instructed on

the installation of the specific appliance.

GENERAL INFO

Before starting the standard use of the equipment, ensure that all the components are in

good working conditions, check there are no detective or damaged parts. If necessary repair

or replace any damaged part.

Pay attention to the possibility of electric shocks (both direct or indirect), which could be caused by

failures in the electric system.

Do not subject the appliance to impacts or shocks.

Do not expose the appliance to fire, extreme temperatures or weld splatter.

Avoid corrosive substances to come in touch with the appliance.

Do not wash the machine using water spray.

DURING THE USE

In order to grant the maximum-security level for the operator, do not touch any moving part

of the appliance during the test execution and wear the convenient protection devices.

Never wear large clothes, ties, watches, chains, and so on, which may entangle into the moving

parts of the machine.

DURING THE LIFTING

During the lifting take care that the machine is conveniently held and secured and that it cannot slide.

Do not stand in a direct line with the application of force. Do not allow people entrance under loads

that are no conveniently supported by mechanical means.

Never subject bars or cylinders to impacts or shocks.

RISK OR DANGER

PROTECTION DEVICES

FINGER SQUEEZE REINFORCED GLOVES

CUTS OR ABRASIONS REINFORCED GLOVES

The manufacturer a

ssumes no liability for any damages to people and things due to a lack of

observance of the instructions and the use of the safety devices.

2.4

NOISE

The indicated levels of noise are not necessarily safety levels for the operator.

The exposure levels of the operator are obviously related to the emission levels of the appliance, but

other factors influence the exposure levels as the time of exposure, the environment, other appliances

installed near to the appliance etc.

The exposure levels permit to value the damages that could be caused by the noise.

Acoustical pressure level equivalent

Laeq

at 1 m. distance

52

dB(A)

Acoustical power emitted by the appliance

LWA

57

dB(A)

Standard above data are referred

EN ISO 3746

DANGER

The continuous use of the

machine together with other noisy appliances could cause a

high level of exposure to the noise. If the daily exposure of the operator is equal or

higher than 85 dB(A), Safety Devices as headphone are suggested to be worn.

If the daily exposure is equal or higher than 90 dB(A), the use of the Safety Device is

compulsory.

For further information consult the standards of the country where the machine has

been installed.

6

CHAPTER 3

INSTALLATION

DANGER Consult chapter “DANGEROUS PARTS AND RESIDUAL RISKS” before proceeding.

3.1

LIFTING

The instructions of this section must be respected during the transport phases of the appliance in

following situations:

The lifting and the storing

The first installation

The further installations

The appliance is generally delivered in a wooden case movable by a forklift.

Pay attention during the lifting always follow the transport versus as labelled on the case. The use of

forklift or crane is recommended. Avoid the use of chains for the case lifting preferring whenever is

possible belts and hempen ropes.

ATTENTION

The moving of the packing with lifting systems must be made with caution and

respecting the indications given on the packing itself.

Pay attention to avoid impacts and turnovers of the packing.

ATTENTION

Protect the machine from the atmospheric agents. Water and humidity could oxidise it,

damaging it seriously.

3.2

UNPACKING

After removing the package, check that any parts of the machine are not damaged. In case of doubt, DO

NOT USE THE MACHINE and ask the manufacturer.

DANGER

The materials used for the package (plastic, polystyrene, screws, nails, wood etc.) have

to be kept far from children. They must be thrown away in a proper collection centre.

ATTENTION Pay attention to avoid impacts and turnover.

ATTENTION

Before throwing away the package, pay attention that any accessories, manuals,

documents, spare parts are not inside.

3.3

INSTALLATION

The machine has to be placed in an environment suitable for the aim it has been conceived for (in a

laboratory protected by the atmospheric agents). Skilled operator must do the installation.

ALLOWED TEMPERATURE

from +1°C to +40°C

ALLOWED HUMIDITY

from 30% to 100%

MAX HEIGHT OVER SEA LEVEL

No limits

As previously explained, this appliance has been projected for laboratory working, therefore it is

recommended to place it in an environment having a constant temperature.

The machine must be installed so that it is free from each side in order to be able to carry out easily

the maintenance operations.

No authorised people and no dangerous objects must be near the machine.

7

3.4

ELECTRIC CONNECTIONS

DANGER Skilled operators must arrange the electric connections.

DANGER

Before connecting, see the attached electric diagram and the pla

te on the machine for

the information about the voltage, the frequency, etc.

DANGER

Connect the ground by the terminal PE (yellow

-

green) before making any other

connection.

DANGER

Apply a knife switch at the top of the connecting cable of the machine t

o the power

system.

The knife switch must be combined with a safety device against the overload with a

differential switch (safety switch).

The technical features of the safety device must be in accordance with the standards in

force in the country where the machine has been installed.

ATTENTION

To grant an optimal working, the appliance needs a constant electric feeding with no

interruptions and no loss of tension. If the feeding net is not stable and trouble free, it

will be necessary to connect the appliance to a current equalizer with a 30 Watt power.

ELECTRIC TOLERANCES:

Real voltage 10 % of the nominal one.

Frequency: 1 % of the nominal one in a continuous way.

2 % of the nominal one for a short period.

The harmonic distortion of the sum from the second to the fifth harmonics not more than 10 % of the

total voltage as a real value between the conductors. A further distortion of 2% is accepted for the sum

from the sixth to the thirtieth harmonics of the real total value between the conductors.

With reference to the tension unbalance of the three-phase voltage, the inverted sequence component

and the zero sequence component must not be more than 2% of the direct sequence component of

the voltage.

The voltage pulses must not last more than 1,5 ms with an up/down time between 500 ms and 500 s

and a peak value not higher than 200 % of the real value of the nominal tension.

The electric feeding must not be interrupted or zeroed for more than 3 ms. Between two interruptions it

must not take more than 1 s.

The interruptions must not overcome 20 % of the tension peak for more than one cycle. Between two

interruptions it must not take more than 1 s.

The manufacturer assumes no liability for any damages to people, things and animals caused by the

non-compliance of the above instructions.

8

CHAPTER 4

MACHINE FEATURES

4.1

MACHINE DIMENSIONS AND MASS

E095 E094

LENGTH

475

475 mm

WIDTH

355

355 mm

HEIGHT

756

624 mm

MASS

38

35 Kg

BOWL CAPACITY

4.7 Litres

4.7 Litres

RPM FOR REVOLVING ACTION

140 / 285

140 / 285

RPM FOR PLANETARY ACTION

62 / 125

62 / 125

4.2

CALIBRATION

The machine is controlled and calibrated by the manufacturer, using sampling tools, which are

periodically checked by Official Institutions.

ATTENTION

Laws now in force foresee the calibration checking after every machine lifting.

Once the machine is installed and ready to work, Official Institutions must check the

calibration before this can be used for official tests.

9

CHAPTER 5

OPERATOR’S INTERFACE

5.1

DESCRIPTION OF PARTS

-

ENCLOSURE B

–

MIXER MODEL CE/STANDARD

CONTROL DESCRIPTION

B1 / C1 BEATER

It allows mixing water, cement and sand into the bowl (

B14

) in

order to get the desired quality of mortar. Its turning

movement achieves the mixing action.

B2 HOPPER

It allows collecting the sand. Going through the membrane

(B3) the sand falls into the bowl (B14).

B3 MEMBRANE It connects the hopper (B2) to the bowl (B14).

B4 / C4 ELECTRIC MOTOR It allows turning the beater (B1) inside the bowl (B14).

B5 / C5 FIXING SCREWS OF THE

UPPER CARTER

They allow securing the upper carter to the sheet frame (

B9

).

Removing it, the operator can easily inspect or maintain the

inside components of the mixer.

B6 / C6 ROTATION PIN

It allows the beater rotation (

B1

). The pin is assembled,

thanks to a reducer, directly to the electric motor (B4).

B7 / C7 LEVER

Using it the operator can free the bowl stop (

B14

). This allows

the removing of the bowl. To block it once again put the lever

back to its original position.

B8 / C8 SPRING

Together with the bayonet fitting on the tang (

B12

) it is used to

block the tang itself to the rotation pin (B6).

B9 / C9 SHEET FRAME It is the main structure of the whole appliance.

B10 / C10 BOWL STOP

It allows blocking the bowl (

B14

) in the position selected by

using the fixing device (

B11

).

B11 / C11 FIXING DEVICE

Together with the pin (

B10

) it blocks the bowl in the mixer

special housing. This fixing device is provided with notches to

regulate the bowl position. This is extremely important to keep

the minimum distance of 3 mm between the beater (B1) and

the inner walls of the bowl (B14) as required by the Specifics.

B12 / C12 TANG

It allows the hook

-

up of the beater to the rot

ation pin.

B13/ C13 MAIN SWITCH

It allows switching the appliance on and off. If necessary it

also acts as emergency switch.

B14 / C14 BOWL

It collects the sand making the mixture with water and cement

possible. A special grip grants an easy handling of the bowl.

B15 / C15 GREASING DEVICE

It helps the operator during the maintenance procedures

(greasing of the internal rotating components). To reach the

greasing device, just remove the upper carter undoing the

fixing screws (B5).

B16 PROTECTION CARTER

It protects the operator from the dangers coming from the

beater rotation and from the internal rotating components.

5.2

DESCRIPTION OF PARTS

–

ENCLOSURE E

–

CONTROL PANEL

CONTROL DESCRIPTION

E1 SPEED SELECTOR

Activating this switch, it is possible

to choose the desired

turning speed of the beater (B14). To start the turning, press

the button START (E2); furthermore it is possible to change

the speed without stopping the test.

E2 START PUSH BUTTON

Pressing this button, the appliance starts (only mot

or

rotation) in accordance to the pre-selected speed made

using the switch (

E1

).

E3 STOP PUSH BUTTON

Pressing this button, the beater turning is interrupted. To

continue the turning, press the button START (E2).

E4 FUNCTION SELECTOR

Turning this selecto

r, it is possible to choose between two

different turning modes (slow or fast). It is also possible to

stop the turning.

10

CHAPTER 6

USE

DANGER Consult the Chapter “DANGEROUS PARTS AND RESIDUAL RISKS” before

proceeding.

6.1

WARNING

Before proceeding with the ordinary use of the appliance, we recommend checking that the appliance is

in proper conditions to work and has no parts broken or used; eventually make all routine and special

maintenance operations listed in this manual.

ATTENTION

Nev

er start the beater rotation if the bowl isn’t at its place. The rotating

components of the Mixer could be seriously damaged.

6.2

SWITCHING ON THE APPLIANCE

ATTENTION

Before switching on the appliance, censure that the Mixer is connected to the electr

ic

feeding net (consult the Chapter “ELECTRIC CONNECTION” of this manual).

To switch on the appliance, follow hereunder instructions:

1. Put the Main Switch (B13 / C13) on the “I” position.

ATTENTION

Reminder valid for Mixer E094 only:

Before switching on the appliance, verify that the selector (E4) is on the middle position

of “STOP”. (See enclosure E for further details).

ATTENTION

Never start the beater rotation if the bowl isn’t at its place. The rotating

components of the Mixer could be seriously da

maged.

6.3

TOOLING UP

We describe here under a “standard procedure” which allows even to an operator without a wide

experience to carry out a procedure correctly:

BEATER POSITIONING

The automatic mortar mixer is furnished complete of tang for the beater attack. In order to place correctly

the beater proceed in the following way:

1. If this was not already opened, open the safety door (B16) and remove the bowl if it’s in the mixer

housing.

2. Unthread the tang (B12/C12) of the rotation pin (B6).

3. Fix the beater (B14/C14) to the tang (B12/C12), inserting two fins set on the beater in the special

joints present on the tang (see picture 1 of the enclosure D)

4. Screw the tang to the beater through the special screw.

5. Take the beater (B1 4/C14) and couple it with the pin (B6/C6) as shown in the picture 2.

6. Push the beater upwards till the small plug that is on the pin (B6/C6) touches its seat that is on the

beater connection (see detail 2 of picture 3).

7. At this step, turn the beater counter clockwise until the rotation stops, and then release the beater (see

detail 3 of picture 3); the spring (B8/C8) will automatically block it in the right position.

8. Fix the beater, the tang and the rotation pin through the fixing screw.

BOWL POSITIONING

Before placing the bowl (B14 /C14) inside the mixer housing, ensure to have correctly filled the same

with water and cement as foreseen by the Standards in force.

9. Open the safety door (B16) (only mixer E095).

10. Move the lever (B7 /C7) as described in the picture 4 of enclosure D.

11. Put the bowl (B14 /C14) so that it almost comes in touch with the tools housing (B11 /C11), then

move the lever (B7 /C7) according to picture 5. In this way the fixing device (B11 /C11) will block

the bowl in 3 points.

Now everything is ready for the test and you just have to close the safety door (only for mixer E095).

ATTENTION

Before starting with the standard use of the appliance, verify that all the components

have been correctly tooled up and are suitable for the test you are going to execute.

11

6.4

PREPARATION AND POSITIONING OF THE MORTAR

The preparation and the positioning of the material to be tested may be effected in several ways

depending on the nature of the tests. For a correct procedure in the specimen handling, refer to the

Standards ruling the test to be effected.

6.5

EMERGENCY STOP

In the event of an emergency, a sudden stop of the test is possible by positioning the Main Switch

(B13/C13) on “0”.

ATTENTION It’s always worth reminding that the test interruption causes its cancellation.

6.6

START AFTER AN EMERGENCY STOP

DANGER

Before starting the appliance again, find and eliminate the problem, which caused the

need for an emergency stop.

To start the machine again, put the Main Switch (B13/C13) on the “I” position. This will reset the appliance

normal functions.

6.7

STOP CONTROLLED BY SAFETY SYSTEMS

The test execution could be interrupted by the safety systems; in fact they are activated in case of

working problems. This Mixer is supplied with the following systems:

STOP CAUSED BY THE MICRO SWITCH FOR DOOR OPENING.

The Mixer E095 has got a safety door (B16), which is equipped with a security micro switch. In fact during

the test execution the operator cannot open the door since the micro is activated by the door opening and

automatically disconnects the feeding to the electric motor (B4 / C4).

6.8

APPLIANCE FUNCTIONING

DANGER Never try to use the appliance before reading and learning this manual in all its parts.

We describe hereunder the correct procedure for both models:

MIXER E095 – CE MODEL

1. Switch on the mixer (for further details, consult the Chapter “SWITCHING ON THE APPLIANCE” in this

manual).

2. Choose the slow or fast rotation according to your needs. Use the Selector (E1).

3. Push the START button (E2) to start the beater rotation (B1 /C1). During the mixer working, it is also

possible to change the selected speed acting on the special selector (E1) and without interrupting

the present turning.

To end the rotation cycle, push the STOP button (E3).

MIXER E094 – STANDARD MODEL

4. Switch on the mixer (for further details, consult the Chapter “SWITCHING ON THE APPLIANCE” in this

manual).

ATTENTION

Before switching on the appliance, ensure that:

-The bowl is correctly located in its housing (B11 /C11).

-The selector (E4) is on the middle position of “STOP” (see enclosure E for

further details).

5. Choose the slow or fast rotation according to your needs. Use the Selector (E4). The rotation starts

immediately after the selection. During the mixer working, it is also possible to change the selected

speed acting on the special selector (E4) and without interrupting the present turning.

To end the rotation cycle, turn the selector (E4) on the middle position “STOP”.

12

6.9

SWITCHING OFF THE APPLIANCE

After a test series, follow these instructions to switch off the appliance:

1. Verify that there are no residuals or dirty either in the bowl (B14/C14) or on the beater (B1/C1),if

necessary clean the components thoroughly.

2. Switch off the Mixer, by positioning the Main Switch (B13/C13) on the “0”.

6.10

TRIAL STARTING

Before beginning the standard use of this machine, check its perfect working conditions by carrying out at

least one complete empty cycle.

ATTENTION

Never start the beater rotation if the bowl isn’t at its

place. The rotating components of

the Mixer could be seriously damaged.

In case of problems during this test cycle, see Chapter “DIAGNOSIS“.

If neither the instructions given in this manual are not able to solve the problem, please contact our After

Sale Service or ask your local distributors for information about the repair procedures and diagnosis

service.

CHAPTER 7

MAINTENANCE

DANGER Consult “DANGEROUS PARTS AND RESIDUAL RISKS” before proceeding.

DANGER All the maintenance operations must be carried out with the machine turned off and

unplugged from the knife switch.

DANGER Skilled operators instructed about the purposes the machine is made for must carry any

kind of maintenance operations concerning the components of the machine and of the

electric components, even those that may seem very simple.

DANGER Only the use of original spare parts is allowed. The Manufacturer assumes no liability in

the event that non – original spare parts are used.

7.1

ROUTINE MAINTENANCE

In order to maintain good working of the machine for a long time, clean periodically all the parts and oil

the parts that are not painted.

Do not use solvents, which may damage the painting and the parts made of synthetic materials.

Ensure that all procedures described in the Chapter “PERIODICAL INSPECTIONS” are correctly and

punctually executed. This care will help preventing failures and dysfunctions.

7.2

SPECIAL MAINTENANCE

In case of special maintenance operations (repairs, replacement of parts and any other operation not

described in this manual) ask directly to the manufacturer.

7.3

CALIBRATION

Proceed with a check of the calibration by officially recognised institutes following the standards in force.

7.4

PERIODICAL INSPECTIONS

Ensure that all procedures described in this Chapter are correctly and punctually executed. This care will

help preventing failures and dysfunctions.

OPERATION CLEANING AND GREASING OF THE ROTATION PIN (B6 / C6)

PROCEDURE

The rotation pin must be cleaned from every dust residual and oil

ed every 100 working

hours.

FREQUENCY EVERY 100 WORKING HOURS

13

OPERATION CHECK OF THE SAFETY CAGE (B16)

PROCEDURE

Verify after 30 working hours the conditions of the safety disposals which form the

safety cage B16); in case of bad working conditions repair or replace the parts

immediately.

Clean the surfaces of the magnet plaques from any mortar dirty, in order to grant the

perfect closing of the door.

FREQUENCY EVERY 30 WORKING HOURS

OPERATION GREASING OF THE ROTATING COMPONENTS

PROCEDURE

Grea

se every 250 working hours the gears for beater rotation, which are placed inside

the frame sheet. Use complex lithium grease suitable for high temperatures. To remove

the upper carter, undo the special fixing screws (B5 /C5) on both mixer sides. Then

introduce the grease using the special fitting for greasing device (B15 /C15). You can

find it on the machine.

FREQUENCY EVERY 250 WORKING HOURS

OPERATION CHECKING THE MEMBRANE CONDITIONS (

B3

)

PROCEDURE

Periodically check the wear and tear conditions of

the membrane. In fact cuts or

abrasions could be provoked by the normal use and by the sand flowing. If necessary

immediately replace it.

FREQUENCY 6 MONTHS

OPERATION BOWL POSITIONING (B14 / C14)

PROCEDURE

The standard EN 196/1 states that a minimum di

stance of 3 mm ± 1 mm must be left

between the inside walls of the bowl (B14 /C14) and the beater. Since the beater (B1 /

C1) is made of material, which is subject to wear and tear, it is possible to modify the

bowl position by using the special notches of the fixing device. (

B11

/

C11

).

FREQUENCY EVERY 100 WORKING HOURS

CHAPTER 8

DIAGNOSIS

8.1

DIAGNOSIS

Some easy to solve and simple problem, which can happen during the working of the appliance, are

introduced in this chapter.

ATTENTION All maintenance, checking, control and repairing operations of each part of the

machine or of the electric system, must be carried out by skilled operators instructed

about the functions and working procedures of the appliance.

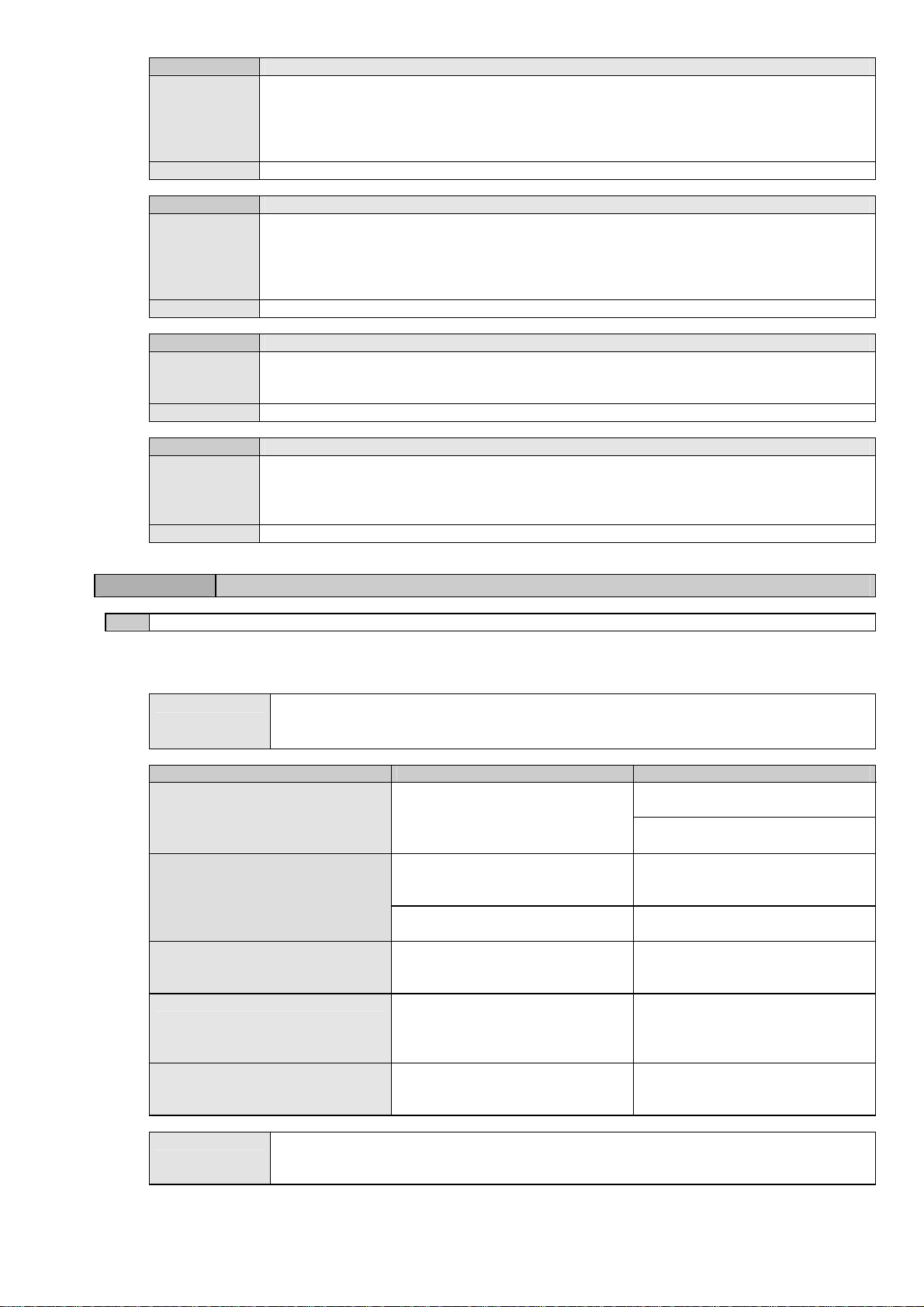

PROBLEM

POSSIBLE CAUSE

CURE

After the activation of the Main

switch, the appliance doesn’t

start.

No supply

Check the correct use of the

Main Switch

Verify the Main in the Panel

The beater (B1 / C1) doesn’t

turn

The inside mechanisms for the

beater movement are broken or

too worn out Contact the After Sale Service

Failure to the electric motor

(B4/C4)

Contact the After Sale Service

The lever (B7 / C7) doesn’t go

down or doesn’t come back to

the original position

The inside components for lever

movement are broken or too

worn out Contact the After Sale Service

The safety door (B16) doesn’t

close The magnet surfaces to close the

carter are dirty or damaged

Clean the blocking plates

carefully. In the event they are

too damaged or worn out Contact

our After Sale Service

When opening the safety door

(B16), the Mixer doesn’t stop Failure to the electric system

Check if the wires and the

connections of the electric circuit

are interrupted.

ATTENTION

Contact our After Sale Service for any other problem not listed or in the event the

problem remains even after the operator’s intervention according to the instructions

given above.

14

CHAPTER 9

SCRAPPING

9.1

SETTING ASIDE

In case of setting aside for a long time it is necessary to disconnect the electric feeding.

Execute all the maintenance operations.

It’s recommended to cover the machine against the dust.

9.2

SCRAPPING

When the machine is not used anymore, it is recommended:

Disconnect the feeding cable.

Cover/destroy all the parts which may be dangerous as cutting, projecting or sharpened ones.

Disassemble the machine and scrap it as per the actual laws.

Recycling notice for the disposal of electrical and electronical devices

This symbol, placed on the device or on the package and/or on the documentation, suggest that the

device shouldn’t be dispose together with other home garbage at the end of its life cycle.

To avoid further environment, or health-care damages, caused by the unsuitable disposal of

garbage, we kindly recommend the user to separate this device from other different types of

garbages and to recycle it in a responsible way to avoid the arguable reuse of material resources.

Indeed users must take care at the disposal of the equipment that have to be discarded, taking them away to

the next recycling site for the appropriate recycling treatment for electrical and electronical devices. Gathering

and Recycling deplete devices allow the preservation of natural resources and grant for them the adequate

treatment respecting health and environment.

For further information about your local recycling site please contact your local city hall or city waste treatment

department. The developer, as producer of electrical and electronical devices, will provide to finance the

recycling and treatment services for deplete devices that will come back through these recycling site,

accordingly the local statement.

This manual suits for next models

2

Table of contents