8

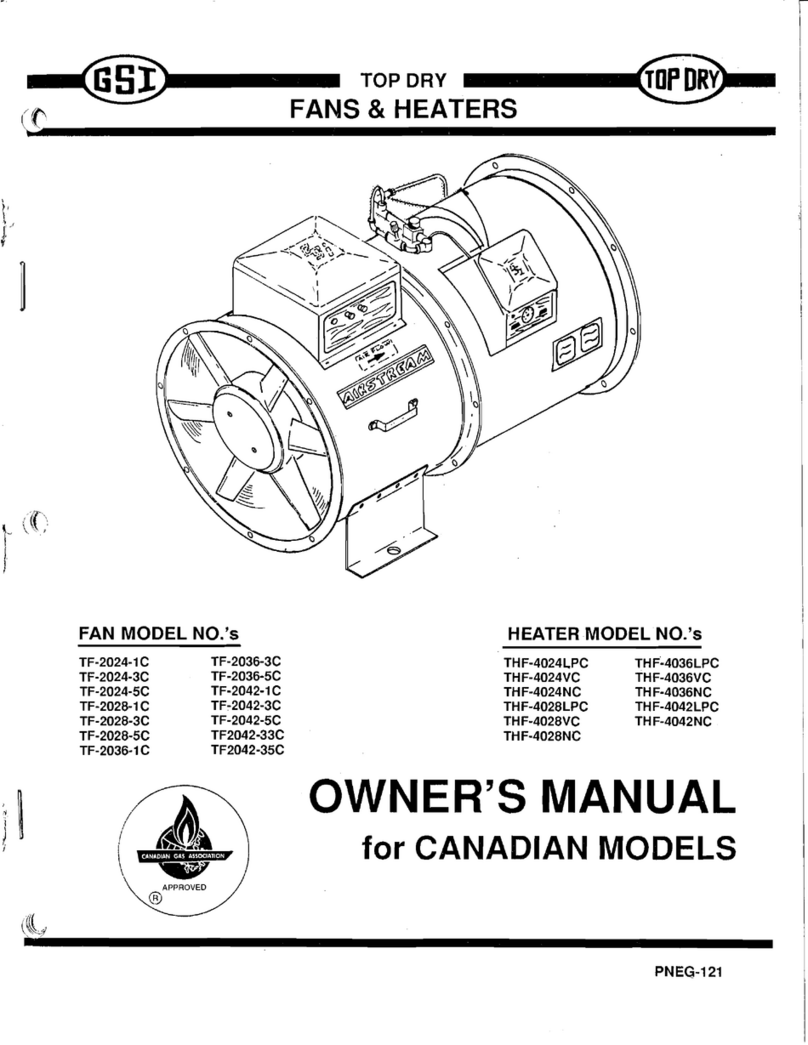

Fan and Heater

It is very important that a machine to earth ground

rod be installed at the fan. This is true even if

there is a ground at the pole 15 feet away. This

ground needs to be as close to the fan as possible,

but no more than 8 feet away. The ground rod

should be connected to the fan control panel with

at least a #6 solid bare copper ground wire, or in

accordance with local requirements. The machine

to earth ground provides additional safety if there

is a short. It also provides the grounding neces-

sary for long life and operation of the solid state

Machine to Earth Ground

Dig a hole large

enough to hold 1

or 2 gallons of

water. Work the

ground rod into

the earth until it

is completely in

the ground.

It is recommended that previ-

ously installed units be checked

to see that a machine to earth

ground has been installed by an

electrician.

(Ground rods and wires are not supplied by GSI

). It is recommended that the rod not be driven

into dry ground. The following steps ensure proper

ground rod installation:

1. Dig a hole large enough to hold 1 to 2 gal-

lons of water.

2. Fill hole with water.

Proper Installation of the Ground Rod

5. Connect the bare copper

ground wire to the rod with

the proper ground rod clamp.

6. Connect the bare ground wire

to the fan control boxes with

a grounding lug. See Figure

3

7. Ground wire must not have

any breaks or splices. Insu-

lated wire is not recom-

mended for grounding.

Figure 1: Use a #6 or approved size bare copper ground wire.

Install a 5/8" diameter 8' long copper-clad ground rod, 2' away

from the foundation and 1' below the surface of the ground or in

accordance with local requirements.

FAN INSTALLATION

Previously Installed

Units

3. Insert rod through water and jab it into the

ground.

4. Continue jabbing the rod up

and down, the water will work

its way down the hole, making

it possible to work the rod com-

pletely into the ground. This

method of installing the rod

gives a good conductive bond

with the surrounding soil.

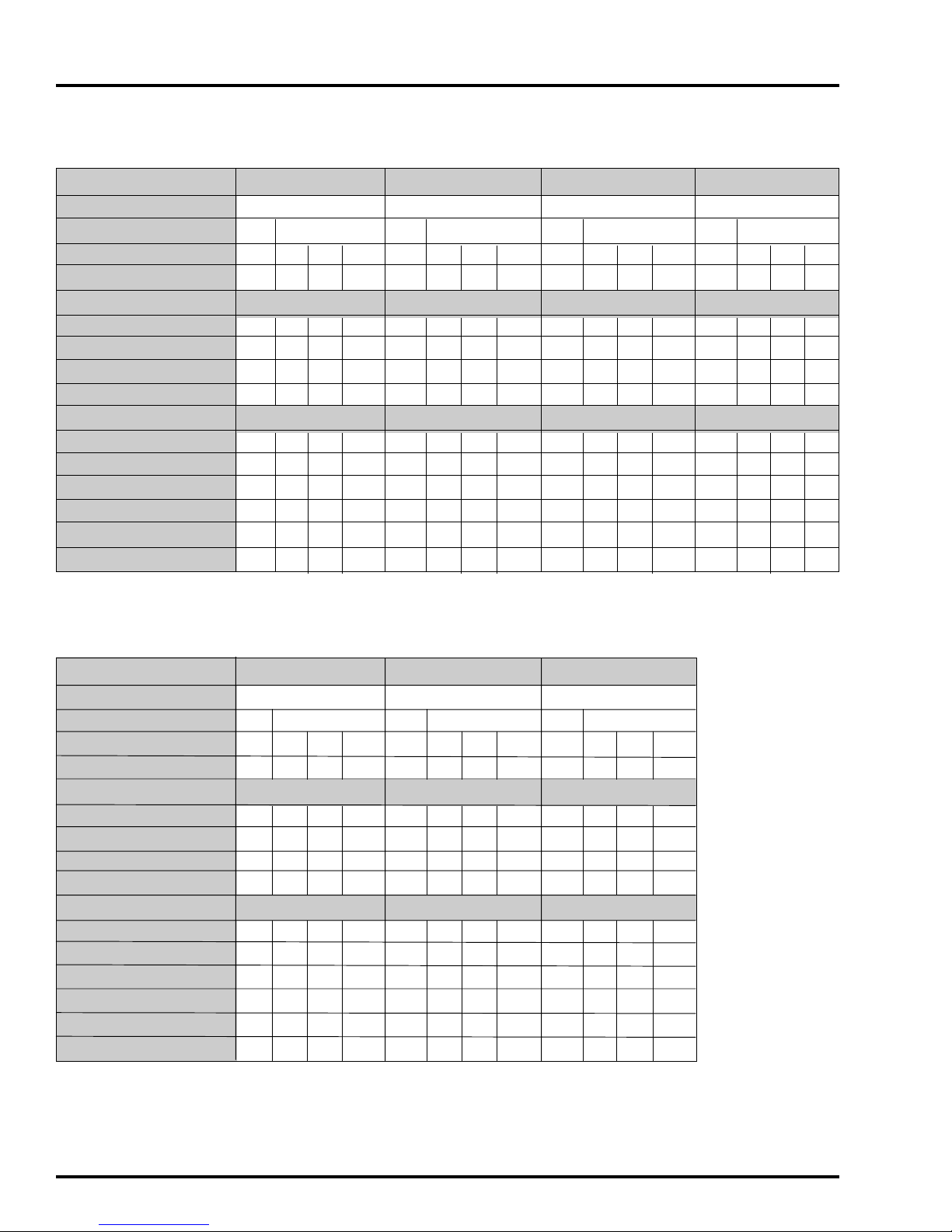

Cross-sectional area of phase

conductors supplying the

equipment S (mm²)

S<=16

16<=S<35

S=>35

Minimum cross-sectional area

of the external protective

conductor (mm²)

S

16

S÷2