Flexit Spirit K2R User manual

Installation instructions

Air handling unit with kitchen hood

and control panel

Spirit K2

111140E-11

2016-11

A

2

Contents

1 Installation/Preliminaries 4

1.1 Inspection/Maintenance 4

1.2 Space Required 4

1.3 Location requirements 4

2 Installation of Flexit SPIRIT K2 R 6

2.1 Installing the volume hood 6

2.2 Encasing 7

3 Connection of unit and electrical work 8

3.1 Connection of unit 8

3.2 Electrical work 8

3.3 Automatic Control 8

3.4 External components 8

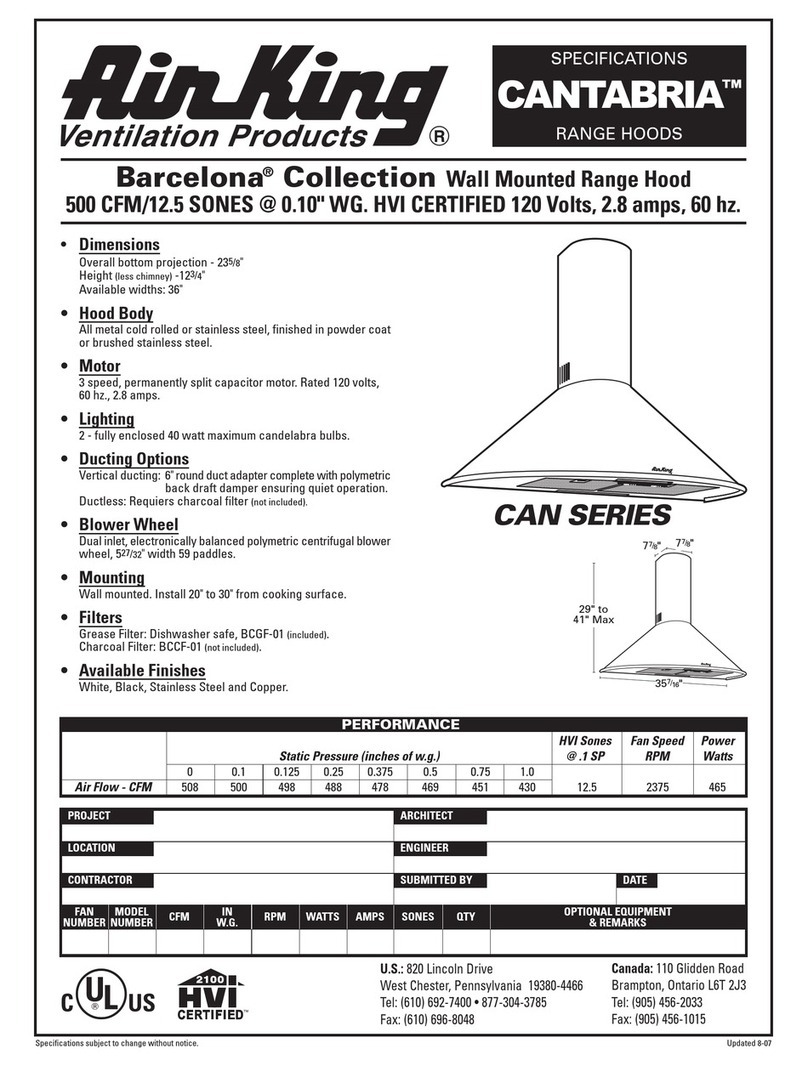

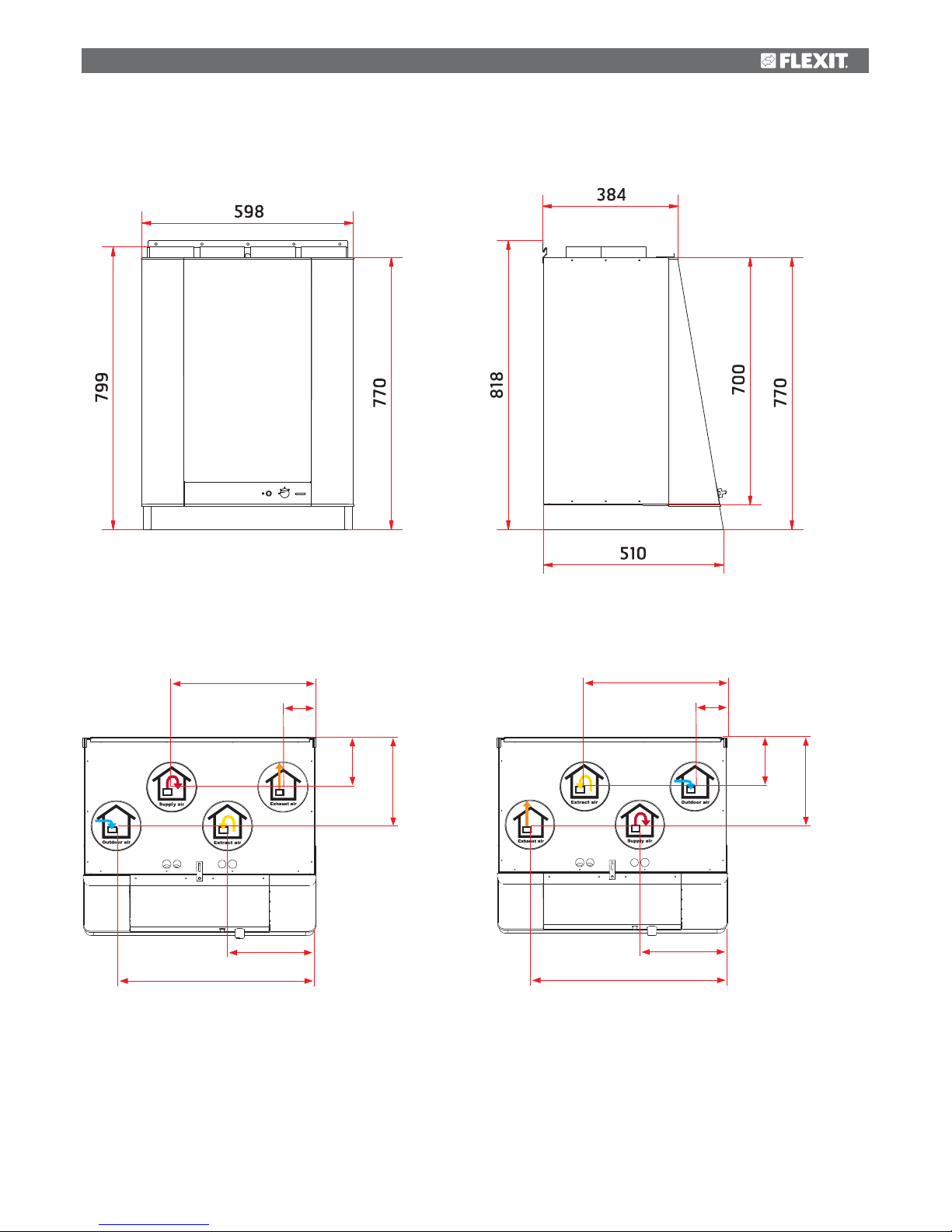

4 Sizes/Physical Dimensions 9

4.1 Dimensioned sketch Flexit SPIRIT K2 R 9

5 General Drawings and System Drawings 10

6 Capacity and sound data 11

6.1 Capacity diagram, sound data, specifications - K2 R EC 11

7 Technical data 12

7.1 Technical data Flexit SPIRIT K2 R 12

8 Installation of control panel CI 60/600 13

8.1 Content 13

8.2 Installation of CI60/600 13

8.3 Concealed installation 14

8.4 Surface installation 14

8.5 Finishing off – CI60 14

8.6 Finishing off – CI600 14

9 Adjusting EC units 15

9.1 Adjustment with CI60 15

9.2 Adjustment with CI600 16

9.2.2Temperature regulation 16

10 Adjusting the Kitchen Hood 17

10.1 Forced Ventilation 17

11 Adjustment Curves 17

11.1 Forced ventilation Flexit SPIRIT K2 R 17

12 Final checks/first use 18

13 EC Declaration of Conformity 19

Our products are subject to continuous development and we therefore reserve the right to make changes.

We also disclaim liability for any printing errors that may occur.

3

It is the installer's responsibility to carry out a full safety and

function assessment of the appliance

To reduce the risk of fire, electric shock or injury, read all the

safety instructions and warning texts before

using the appliance.

• This unit is only designed for ventilation air in buildings.

• Remove the power plug before commencing any service

and maintenance work.

• Before opening the door, current to the unit must be

turned off and the fans must have had time to stop (min. 3

mins.).

• The unit contains heating element which must not be

touched when it is hot.

• The unit must not be operated without the filters being in

place.

Important Safety Instructions:

!

Symbols Used

These products bear a number of symbols used for

labelling the actual product and in installation and user

documentation.

EXAMPLE OF NIPPLE LOCATION

(shown as right-hand model)

HIGH VOLTAGE

DANGER! DO NOT TOUCH

NB! When a text bears this symbol, damage to

equipment or a poor utilisation ratio may result if

instructions are not followed.

CAUTION When a text bears this symbol, it

means that personal injury or serious damage to

the equipment may result if the instructions are

not followed.

!

This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards

involved. Note that the product is not intended for use by children.

Children shall not play with the appliance. Cleaning and user maintenance

shall not be made by children without supervision.

Our products are subject to continuous development and we therefore

reserve the right to make changes.

We also disclaim liability for any printing errors that may occur.

Extract air

Outdoor air

Supply air

Exhaust air

• There shall be adequate ventilation of the room when the

range hood is used at the same time as appliances burning

gas or other fuels.

• The air must not be discharged into flue that is used for ex-

hausting fumes from appliances burning gas or other fuels.

• Accessible parts may become hot when used with cooking

appliances.

• There is risk of fire if cleaning is not carried out in accord-

ance with the instructions.

• Do not flambé under the range hood.

• Do not cook substances which could catch fire under the

ventilator.

• Do not leave a saucepan or frying pan containing oil or

grease unsupervised.

• Follow the instructions in the user manual.

To maintain good indoor air quality, comply with regulations

and to avoid condensation damage the unit must never be

stopped apart from during service/maintenance or in con-

nection with an accident.

4

1 Installation/Preliminaries

See separate documentation for installation of ducts, valves,

etc.

1.1 Inspection/Maintenance

The unit must be installed with space for service and

maintenance such as filter replacement and cleaning the

fans and recovery system.

The control cable with plug for automatic control on top of

the unit must be easily accessible.

1.2 Space Required

Type A B C

K2 R 335 mm 2 x 2 mm 215-380 mm

A: Space in front of unit

B: Space at side of unit

C: Space above unit

These are minimum requirements and only take service

needs into account. National statutory requirements for

electrical safety may deviate from this. Check which rules

apply in your country.

1.3 Location requirements

The unit has been designed for location in the kitchen over

the cooker as it contains an integrated kitchen hood. The

unit is available in left or right versions

(exhaust air nipple to the left or right), depending on what is

the most favourable in relation to the duct location.

The unit is designed for indoor installation.

596mm

B=2mm B=2mm

(filter)

C=215-380mm

A=335mm

Filter

Fig. 1

Cover on top of unit

(optional extra)

70mm

(volume hood) 700mm

(unit)

845mm

5

Fig. 2

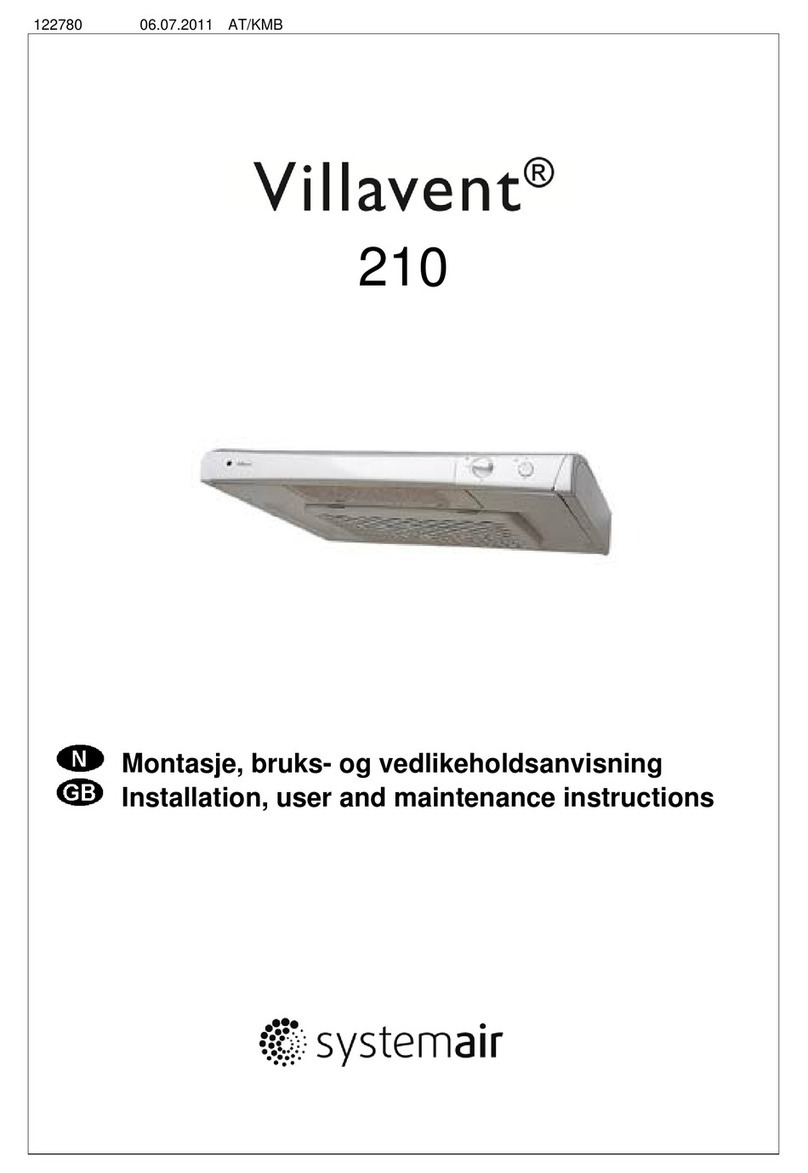

1.4 Recommended sound attenuation for

wall-mounting

For wall mounting, the (included) wall bracket fixed to the unit

is used.

The unit must not be placed on a wall with rooms on the

other side which are sensitive to noise. The wall must be

sound-insulated. If necessary, use double plasterboards on

the wall.

Interrupted studs must be used.

min 600 mm

min 500(650) mm

Recommended 500mm*

*min. req. 650mm for gas cookers

Min. req. 450mm

6

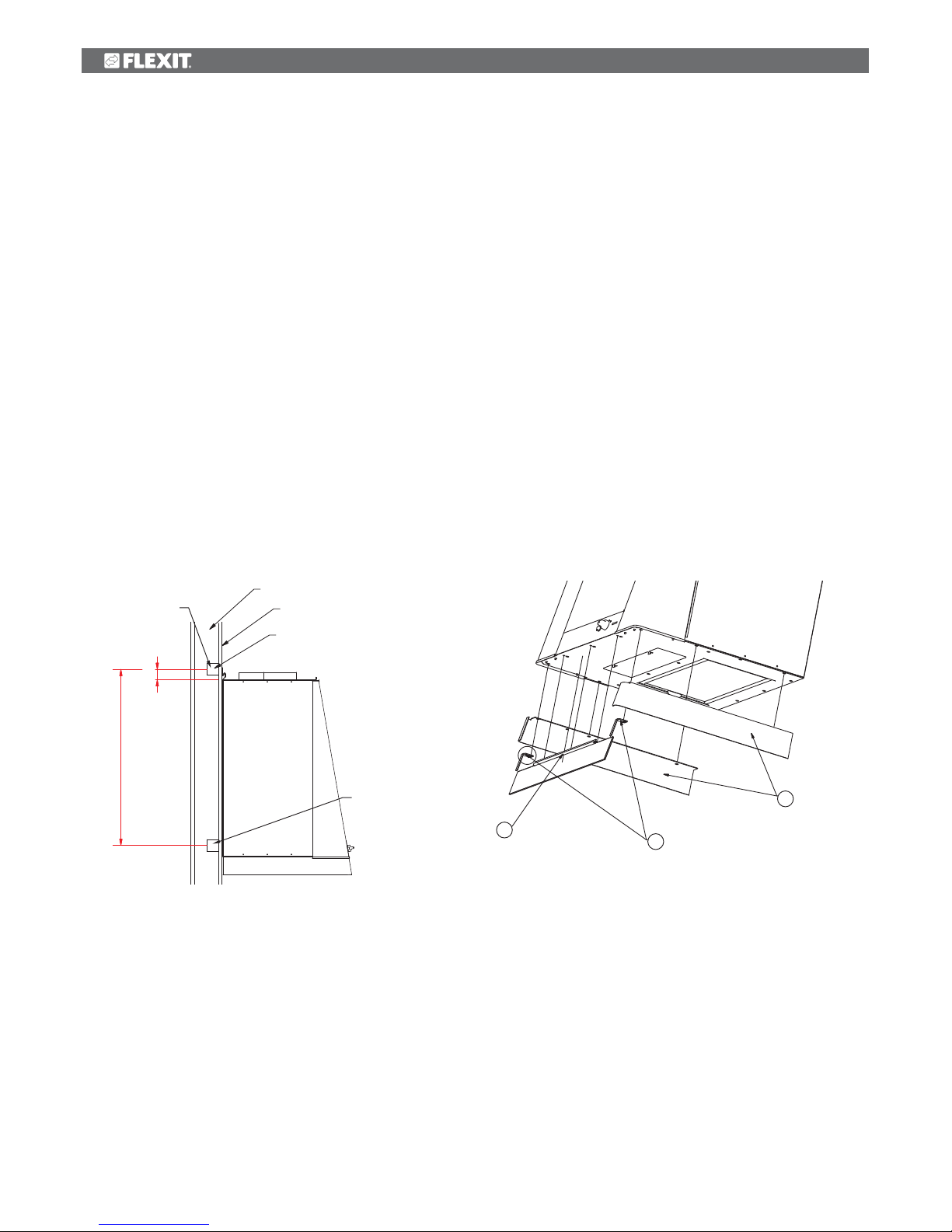

2 Installation of Flexit SPIRIT K2 R

Flexit SPIRIT K2 R is designed for installation in the kitchen

above the cooker, see Fig. 2. The unit is supplied in left and

right-hand versions depending on what suits duct locations

best (Chap. 4.1).

The unit must be wall-hung from a mounting bracket (Fig. 6)

at the top using the enclosed screws. It must also be screwed

to the wall at the bottom edge of the unit. Remove 2 plastic

plugs to access the mounting holes. For secure mounting, it is

necessary to use extra nailing strips (noggins). The location

of these is shown in Fig. 3.

NB! The wall must have good sound insulation, see Chap. 1.4.

The wall must be completely flat behind the ventilation unit.

If the kitchen hood area is tiled, a suitable liner plate must be

mounted behind the unit. The distance between the bottom

of the grease filter and the cooker should be at least 50 cm

for electric cookers and 65 cm for gas cookers. For the

external dimensions of the unit, see the dimensioned drawing

in Chap. 4.1.

2.1 Installing the volume hood

A

1

2

3

3

1

2

Fig. 4

1. Mount the two sides.

2. Attach the two angles.

3. Fix the glass profile.

fixing, top edge

40 mm

720 mm

spikerslag

gips

steinull

Fig. 3

fixing lower edge

gypsum

studs

rockwool

7

Fig. 5

Fig. 6

596 mm

B=2mm B=2mm

min 600 mm

min 500(650) mm

Recommended

500mm*

*min. req. 650mm for gas cookers

Min. req. 450mm

2.2 Encasing

The casing must not be deeper than dimension A.

Fig. 7

A

8

3.3 Automatic Control

The control pack is included in the unit package. The

low-voltage cable must be laid between the unit and the

switch unit. See separate manual for automatic control

included in pack.

3.4 External components

See wiring diagram enclosed with unit.

3 Connection of unit and electrical

work

3.1 Connection of unit

• Ensure that the ducts arrive at the right muff coupling. See

the marking on the unit (top/bottom and behind door).

The symbols are explained on page 3 and the location is

shown in the dimensioned drawing in Chap. 5.

• Pull the duct insulation well up to the unit.

• To avoid condensation, it is very important for the outdoor

air duct and the exhaust air duct to have insulation and a

plastic muff pulled right down to the unit.

NB! Use tape to seal the plastic sleeve to the unit

but do not compress the insulation.

• Lay the outdoor air duct with a slight incline towards the

outdoor air cap so that any water that enters drains out

again.

• If there is a short distance between the unit and the

exhaust point, sound insulation must be installed to ensure

that the requirements for the outdoor sound level are met.

• Ducts must have good sound insulation, particularly above

the unit.

3.2 Electrical work

The unit is suppied with a 1.8 m cable with plug.

The cable leaves the top of the unit and is connected to a

230V 50 Hz single-phase earthed power point located within

a convenient distance. The plug must be used as a service

switch.

NB! Make sure the power point for the unit is not boxed in.

See Chap. 13 for fuse sizes.

A low-voltage cable (with connector) leaves the unit for

use on the control panel. It is important to retain easy

access to this plug - in case of any fault or when replac-

ing the unit.

The unit must be installed with a separate earth

leakage circuit breaker.

The low-voltage cable must be laid minimum

30 cm from the 230 V cable and in the case of

chased mounting be laid in 20 mm electrical

piping. The cable length must not exceed 24

meters.

All electrical work must be carried out by author-

ised personnel.

9

4 Sizes/Physical Dimensions

4.1 Dimensioned sketch Flexit SPIRIT K2 R

(Shown as right-hand model)(Shown as left-hand model)

514

227

371

84

129

229

514

227

371

84

129

229

10

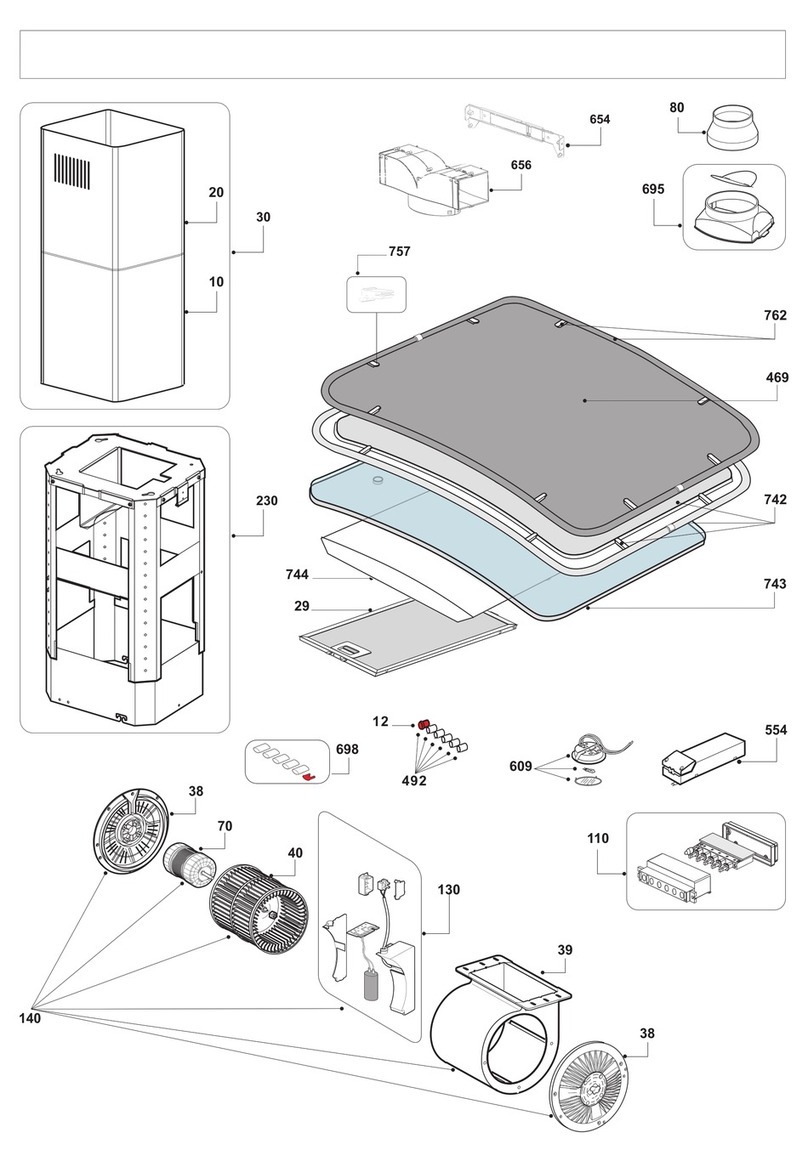

5 General Drawings and System

Drawings

General Diagram (Rotary Wheel-type Heat

Exchanger)

1(FI2) Extract filter F 7

2 (FI1) Supply air filter F 7

3 (EB1) Heating element

4 (F10-20) Overheating thermostat (heating) (Reset)

5 (M1) Supply air fan

6 (M2) Extract air fan

7 (HR-R) Rotary wheel-type heat exchanger

8 (M4) Rotor motor

9 Control unit

10 Kitchen hood

11 Damper adjustment

System drawing (electric battery)

B1 Supply air temperature sensor

EB1 Heating element

F10 Overheating thermostat, manual reset

F20 Overheating thermostat, automatic reset

FI1 Supply air filter

FI2 Extract air filter

M1 Supply air fan

M2 Extract air fan

HR-R Rotary wheel-type heat exchanger

M4 Rotor motor

K Kitchen hood

DA4 Damper

Outdoor Supply Extract Exhaust

air air air air

Outdoor Supply Extract Exhaust

air air air air

(Shown as left-hand model. The right-hand version is a mirror image.)

6

2

7

3

8

9

5

1

10

11

4

DA4

K

FI1

M1 M2

EB1

F10

F20

M4

FI2

B1

HR-R

11

6 Capacity and sound data

6.1 Capacity diagram, sound data, specifications - K2 R EC

Supply air side (with F7 filter)

Data for supply air is measured in accordance with ISO 5136,

"In-duct method".

Radiated noise is measured in accordance with ISO 9614-2.

Bruel & Kjær measuring equipment, type 2260.

Air capacity at various capacity settings in %

Supply air fan power consumption at various capacity settings.

Sound power level LwA, cf. correction table.

Radiated 1: K2 free hanging

Radiated 2: K2 built-in kitchen

Sound data is given at sound power level LwA in the capacity diagrams

and is corrected with the table below for the various octave bands.

Radiated noise produces Lw in the various octave bands and total

LwA. This is read directly from the supply air table.

Correction factor for Lw

Hz 63 125 250 500 1000 2000 4000 8000 LwA

Supply air 14 12 1 -6 -7 -15 -22 -26

Extract air 14 13 0 -5 -10 -16 -25 -28

Radiated 1 -4 -7 -12 -19 -27 -32 -32 -34 -16

Radiated

2

3 -5 -17 -23 -29 -32 -37 -35 -18

Extract air side (with F7 filter)

SFP

<

0,75

8060

4020

0

10

20

30

40

50

60

70

80

0

50

100

150

200

250

300

350

400

0 50 100 150 200 250 300 350

Power Consumption [W]

Air flow rate [l/s]

Contact resistance [Pa]

Air flow rate [m³/h]

80%

100%

60%

40%

55dB(A) 59dB(A)40dB(A) 50dB(A)45dB(A)

100%

80%

60%

40%

00

10

20

30

40

50

60

70

80

50

100

150

200

250

300

350

400

0 50 100 150 200 250 300 350

50dB(A) 55dB(A) 60dB(A) 63dB(A)45dB(A)40dB(A)

Power Consumption [W]

Air flow rate [l/s]

Contact resistance [Pa]

Air flow rate [m³/h]

100%

80%

60%

40%

100%

80%

60%

40%

SFP

<

0,75

20 40 60 80

12

7 Technical data

7.1 Technical data Flexit SPIRIT K2 R

EC EC

700W 350W

Rated voltage 230 V/50 Hz 230 V/50 Hz

Fuse size 10 A 10 A

Rated current, total 3,91 A 2,1 A

Rated power, total 870 W 495 W

Rated power, electric batteries 700 W 350 W

Output fans 2 x 74 W 2 x 74 W

Fan type F-wheel F-wheel

Fan motor control 0-10 V 0-10 V

Max. fan speed 1,970 RPM 1,970 RPM

Automatic control standard CS 50 CS 50

Filter type (SUP/EXTR) F7/F7 F7/F7

SUP filter dimensions (WxHxD) 130x335x50 mm 130x335x50 mm

EXTR filter dimensions (WxHxD) 130x335x50 mm 130x335x50 mm

Weight 56 kg 56 kg

Duct connection Dia. 125 mm (sleeve) Dia. 125 mm (sleeve)

Duct connection kitchen fan

Height 700 mm* 700 mm*

Width 598 mm 598 mm

Depth 510 mm** 510 mm**

* without volume hood and duct connection, see Chap. 5

** see Chap. 5

13

8 Installation of control panel CI 60/600

8.1 Content

1

2

3

4

5

1. Control panel

2. Back piece for concealed installation

3. Back piece for surface installation

4. Installation instructions

5. Cable for control panel

Fig. 8

ON OFF

Configuration Setting

CI 600 (MASTER)

CI60 1 (SLAVE)

CI60 2 (SLAVE)

Automatic

OFF

ON

CI60 1 (MASTER)

CI60 2 (SLAVE)

OFF

ON

CI 600 (MASTER)

CI60 (SLAVE)

Automatic

Irrelevant

8.2 Installation of CI60/600

CAUTION! The control panel must be connected

to the ventilation unit before the ventilation unit

is connected to mains.

!

Lay the cable for the control panel between the ventilation

unit and the control panel. The control panel is adapted for

concealed installation over a single connection box (use low

back piece, item no. 2) or surface installation on the wall (use

high back piece, item no. 3).

Click the cable into the contact at the back of the control

panel and into the contact on the top of the ventilation unit.

It is possible to connect two CI60 panels and one CI600

panel to each unit. If several CI60 panels are used, each

panel must have its own identity. This is selected with the

switch on the panel’s printed circuit board (se Fig. 27). Use

the appropriate table settings. The panels can be connected

serially, in arbitrary order.

OFF = MASTER

ON = SLAVE

OBS! The low-voltage cable must be at least 30

cm from cables carrying mains voltage or higher.

With concealed installation, the cable is laid in

20 mm conduit pipes. The cable length must not

exceed 24 meters.

14

8.3 Concealed installation

Lay the cable between the wall box and the ventilation unit in

the preinstalled conduit pipe. Fit the back piece (item no. 2),

over the wall box and click the cable in directly from behind

as in the illustration (se Fig. 9).

8.4 Surface installation

Lay the cable between the back piece (item no. 3), and the

ventilation unit. Cut out the perforation in the corner of the

back piece that is suitable for installation. Screw the back

piece to the wall with suitable screws. Click the cable into

the control panel from below, where there is a socket in the

printed circuit board (se Fig. 10).

Fig. 10

Fig. 9

8.5 Finishing off – CI60

Slide the panel off as shown by arrow no. 1 (see Fig. 11) and

fit the control panel straight into the back piece as shown

by arrow no. 2 (see Fig 12) until it clicks into place. Slide the

panel back on.

8.6 Finishing off – CI600

Fit the control panel over the hooks in the back piece as

shown by arrow no. 1 and then click the panel into place at

the bottom edge as shown by arrow no. 2 (see Fig. 13).

Fig. 11 Fig. 12

Fig. 13

1

1

2

2

15

Fig. 14

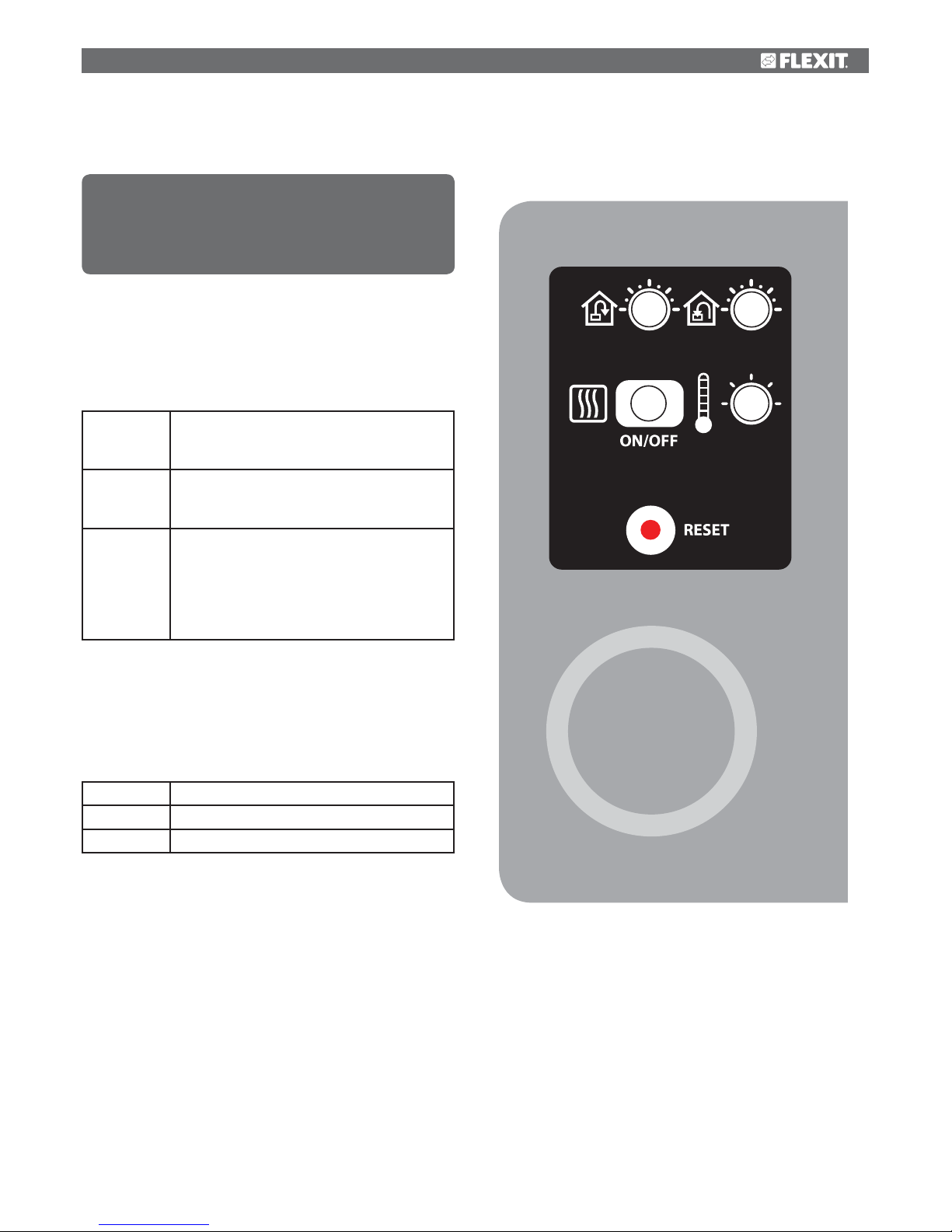

9 Adjusting EC units

9.1 Adjustment with CI60

9.1.1 Adjustment

Only stage 2 (NORMAL) needs to be adjusted. Stages 1

and 3 have fixed settings, while stage 2 has to be adjusted as

required in the individual home.

The function of the different stages:

MIN Must not be used when the home is in use.

Must not be used in the first two heating

seasons.

NORMAL Used under normal conditions. On this

setting the air supply must be adjusted

according to current regulations.

MAX Used if there is a need for increased air

supply on account of higher occupancy or

a raised humidity level, for example during

showering or when clothes are being dried.

This setting is normally used for limited

periods.

The ventilation unit's air supply is adjusted in speed level

NORMAL using the knobs on the back of the cover. Knob 9 is

used for supply air level and knob 8 for extract air level (see

Fig. 14). The adjustment range is 20-100% of the maximum

level according to the scale on the knob.

Factory settings for supply air/extract air:

MIN 50% (fixed)

NORMAL 75% (variable)

MAX 100% (fixed)

9.1.2. Adjusting the temperature

The temperature required for the supply air can be set

with knob 11. The adjustment range is 10 - 30°C. It should

normally be set to around 18°C. Use of the factory setting is

recommended.

If necessary, the ventilation unit's additional heating can

also be switched ON/OFF with switch 10. In this case only

the rotating heat exchanger is used as a source of heat. It is

best to leave it in ON position, as the unit will then respond

automatically when there is a need for additional heating.

8

9

10 11

The unit's air supply MUST be adjusted before the

unit is used for the first time. This should be done in

accordance with the projection documents. Adjust the

values based on the projected values.

16

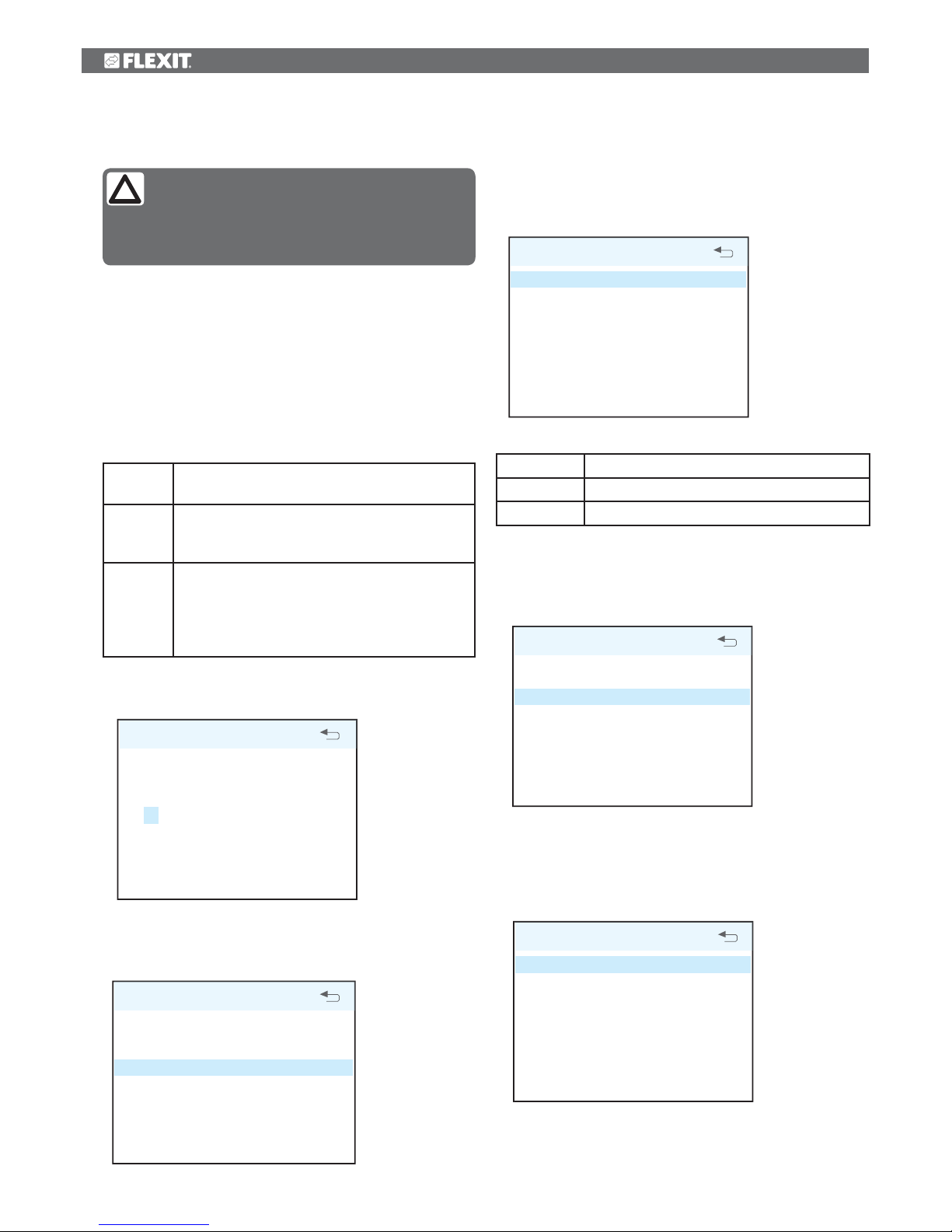

9.2 Adjustment with CI600

9.2.1 Adjustment

Only stage 2 (NORMAL) needs to be adjusted.

Note that it is also possible to adjusted stages 1 and 3

with a CI600 control panel. This should only be done if a

special need arises, however. This is because it is extremely

important to have adequate air flow rates.

The function of the different stages:

MIN Must not be used when the home is in use. Must

not be used in the first two heating seasons.

NORMAL Used under normal conditions. On this setting

the air supply must be adjusted according to

current regulations.

MAX Used if there is a need for increased air supply

on account of higher occupancy or a raised

humidity level, for example during showering

or when clothes are being dried. This setting is

normally used for limited periods.

First go to the "Advanced user" menu, enter the PIN and

press OK:

PIN CODE

OK?

1 0 0 0

Then go to the "Fan control" menu. The fans are selected and

configured in this menu screen. Then go to adjustment of

the extract air fan and supply air fan.

FAN REGULATION

SUPPLY AIR

EXTRACT AIR

TIMER

AIR VOLUME COMP

>

>

>

OK?

This dialog is identical for the supply air and extract air fans.

The fans are adjusted individually to the desired capacity for

the respective speed.

SUPPLY AIR

MIN SPEED

NORMAL SPEED

MAX SPEED

OK?50%

75%

100%

Factory settings for supply air/extract air:

MIN 50% (variable)

NORMAL 75% (variable)

MAX 100% (variable)

9.2.2 Temperature regulation

In this menu screen (located under "Advanced user") you

configure the temperature regulation and cooling functions.

TEMPERATURE REGULATION

REGULATION TYPE

COOLING

NEUTRAL ZONE

EXT. TEMP. CONTROL

>

>

OK?

>

Regulation type

If supply air regulation is selected, no further settings can

be set here. If extract air regulation is selected, the max. and

min. supply air temperatures can also be specified.

REGULATION TYPE

REGULATION

MAX SUPPLY AIR TEMP

MIN SUPPLY AIR TEMP

EXTR OK?

35°

15°

The unit's air supply MUST be adjusted before

the unit is used for the first time. This should

be done in accordance with the projection

documents. Adjust the values based on the projected

values.

17

11 Adjustment Curves

11.1 Forced ventilation Flexit SPIRIT K2 R

Max. air volume through kitchen hood in case of forced

air volume

Measurements have been taken at 2/3 pressure in the

extract air duct and 1/3 pressure in the exhaust air duct

before opening the damper.

10 Adjusting the Kitchen Hood

If basic ventilation is desired via the kitchen hood, the

damper from the factory must be replaced. Replace it with a

damper with adjustment options. This is not supplied with the

unit.

10.1 Forced Ventilation

The unit has 4 forced ventilation options:

1. (Switch on front of unit.) This gives a half-open damper

which will increase the air volume passing through the hood.

2. Turn the knob to position 2. This gives a fully open

damper which will allow even more air through the kitchen

hood.

3. Turn the knob to position 3. This will give a fully-open

damper which will allow even more air through the kitchen

hood, in that the fans go to speed 3.

4. The air volume through the unit can also be increased by

setting the fans to speed 3 via the control panel (external

panel). See separate instructions.

The damper needs closing again manually. There is no timer

in the damper. Closed in position O.

The air entering the unit through the kitchen hood does not

pass through the rotary heat exchanger (by-pass).

Fig. 16

18

12 Final checks/first use

12.1 Final Checks

Check that:

• The duct insulation is in accordance with the manual

and the technical documents. It is very important the

ducts from the unit are also effectively insulated so that

no condensation forms on or in the ducts. It is especially

important to check this if the ducts are to be boxed in.

• Ducts are connected to the right nipples – check against

the unit drawings below.

• Adjustments have been made in accordance with the

manual and project planning documents (documentation

of ventilation data).

• The unit operates normally at all stages.

• Heating switches in.

• The unit has filters for both outdoor air and extract air.

• Tumble dryers must not be connected to the unit.

The installer may be held liable for any incorrect

or defective installation.

Flexit SPIRIT K2 R, Right-hand modelFlexit SPIRIT K2 R, Left-hand model

12.2 First use

• Check that the control panel has been connected.

• Plug the unit into the mains supply.

• The unit will now start.

• The unit will automatically perform a start-up procedure

lasting approx. 2 min.

• After the start-up procedure the unit will follow the settings

entered on the control panel.

• If it is wished to check or alter the settings, this can be

done from the control panel.

(See separate documentation for automatic control.)

19

13 EC Declaration of Conformity

This declaration confirms that the products meet the

requirements in the following Council Directives and

standards:

2004/108/EF Electromagnetic Compatibility (EMC)

2006/95/EF Low-voltage Directive (LVD)

1253/2014 Ecodesign regulation

1254/2014 Energy labelling regulation

Our products have been tested in accordance with parts of:

2006/42/EC Machinery Directive (Safety)

Manufacturer: FLEXIT AS, Televeien 15, 1870 Ørje, Norway

Type: K2 R Ventilation unit

The right to give notice of lack of conformity applies to this product in

accordance with the existing terms of sale, provided that the product is used

and maintained correctly. Filters are consumables.

The symbol on the product shows that this product must not be

treated as household waste. It must be taken to a reception station

for recycling of electric and electronic equipment.

By ensuring the correct disposal of the equipment, you will contribute

to preventing the negative consequences for the environment and

health that incorrect handling may entail. For further information

on recycling of this product, please contact your local authority, your refuse

collection company or the company from which you purchased it.

Notice of lack of conformity as a result of incorrect or defective installation must

be submitted to the installation company responsible. The right to give notice of

lack of conformity may lapse if the system is used incorrectly or maintenance is

grossly neglected.

Conforms to following standards:

Safety standard EN 60335-1:2012 + A11

EMF standard: EN 62233: 2008

EMC standard: EN 55014-1.2006 + A1 + A2

EN 61000-3-2: 2006 + A1 + A2

EN 61000-3-3: 2013

EN 55014-2:1997 + A1 + A2

The product has been CE-marked: 2011

FLEXIT AS 16.02.2011

Frank Petersen

CEO

Flexit AS, Televeien 15, N-1870 Ørje www.flexit.no

Other manuals for Spirit K2R

1

This manual suits for next models

1

Table of contents

Other Flexit Ventilation Hood manuals