Biobase BK-DH2000 User manual

Hybridization System

BK-DH2000

User Manual

BIOBASE GROUP

Version 2019.10

1

Foreword

Thank you for purchasing our Products: Hybridization Instrument. This Manual for users contains

function and operation of the Instrument. In order to use the instrument properly, please read this

manual carefully before using the Instrument.

Opening Check

Please check the Instrument and Appendix with the packing list when you first open the instrument

packing case. If you find there is something wrong with the Instrument and the Appendix, do contact

the vendor or the producer.

2

Content

Foreword................................................................................................................................................ 1

Content................................................................................................................................................... 2

Safety Warnings and Guidelines............................................................................................................ 3

1. Important operation information of the security......................................................................... 3

2. Safety...........................................................................................................................................3

3. The maintenance of Instrument...................................................................................................4

Chapter 1 Introduction.........................................................................................................................5

1. Introduction................................................................................................................................. 5

2. Normal Operation Condition.......................................................................................................5

3. Parameters and performance....................................................................................................... 5

Chapter 2 Preparations........................................................................................................................ 7

1. Structure Description...................................................................................................................7

2. Humidity sponge installation.......................................................................................................8

Chapter 3 Operation Guide..................................................................................................................9

1. Starting up and system load.........................................................................................................9

2. Main menu...................................................................................................................................9

3. Program list menu..................................................................................................................... 10

4. Program Edit/Run Menu........................................................................................................... 10

5. Parameter setting menu............................................................................................................. 11

6. Program name edit menu...........................................................................................................12

7. System configuration menu.......................................................................................................13

8. Calibration menu....................................................................................................................... 13

Chapter 4 Considerations.................................................................................................................. 15

Chapter 5 Fault Analysis and Processing..........................................................................................16

3

Safety Warnings and Guidelines

1. Important operation information of the security

Before using the instrument, user need have a complete understanding how to operate it safety.

Before running the instrument, please read this manual carefully.

Forbid anyone to operate the instrument before reading the manual.

If operate not in accordance with the tips on the manual ,the heat generated by the instrument at

runtime may cause severe burns, and electric shock accident. Please read the following safety tips

and guidance, and implementation of all precautions.

2. Safety

When operation, maintenance and repair of this instrument, it must subject to the following basic

safety precautions. if you don't abide by the warnings pointed in the manual , may affect the

protection and intended use scope of the instrument.

The instrument is for indoor use.

Before operating this equipment please read this manual carefully, otherwise it may cause

personal injury.

Only in the aspect of how to use electrical equipment installation trained qualified inspection

personnel to operate the equipment.

Operators do not attempt to open or repair equipment, doing so will make you lose the

warranty qualification, also may be limited by electric shock. If you need repair, please contact our

company. In order to avoid electric shock accident, the instrument input power cord must be reliable

grounding. This instrument uses three core grounding plug, of which the third feet for grounding,

which should be used with grounding type power socket.

Before connecting the power supply, ensure the power supply voltage and the instrument

voltage required the same. And make sure that the power outlet rated load no less than the instrument

requirements.

If the power cord damaged, replace it according to the same type and specifications. Don’t

press anything on the power cord when it be used, don't put the power cord in place where people

often walk.

When insert the power cord plug, must hand-hold the plug and ensure that the plug is completely

inserted into the socket, when pull out the plug, must hand-hold the plug as well and don't pull the

power cord.

The instrument should be put in lower humidity and less dust and away from water and

avoid direct sunshine and strong light, indoor should be well ventilated, no corrosive gas or strong

magnetic field interference, away from heat, stoves and other heat sources. Don't take equipment in

4

wet or dusty places.

In order to avoid temperature overheating ,do not block or cover the holes on the instrument. when

several equipment be used at the same time, the more the distance between each instrument shall be

not less than 30 cm.

Shutting off the power when stop working. unplugging the plug and using soft cloth or

plastic cover to prevent dust from entering the instrument when long time no use.

When happened as following listed cases, it should be pulled the power socket immediately

and contact the supplier or trained maintenance personnel:

The instrument comes into contact with liquid;

The instrument gets soaked or burned;

The instrument emits an abnormal sound or smell;

The instrument is dropped or the outer shell damaged;

The instrument functions abnormally.

Instrument functions have obvious changes.

3. The maintenance of Instrument

The instrument shall be cleaned regularly use a soft cloth with a small amount of anhydrous alcohol

cleaning heating plate, ensure good heat conductivity and avoid pollution.

5

Chapter 1 Introduction

1. Introduction

BK-DH2000 can be setting constant temperature, time and etc. Instead of manual operation

experiment, the accuracy of experiment is higher and result is more reliable than traditional manual

experiment. Hybridization and degeneration can be operated at same time, which reduces

experimental procedure and improves efficiency and accuracy of operation.

Features:

This instrument is adopted FISH processing step, which can reduce a lot of manual operating

time and avoid the damage of reagent.

Full touch screen operation, simple interface.

Auto resume to run after power failure.

Auto cooling after running over.

Auto preheating.

High precise temperature control, low fluctuation.

Deal with 12 slides.

Support 105 custom programs stored functions.

Three operation modes: Integrated denaturation & hybridization, hybridization, multi-step

operation.

2. Normal Operation Condition

Ambient temperature:0C35C

Relative humidity:≤70%

Power supply:AC 220V (optional)

3. Parameters and performance

Project

Parameters

Temperature control range

RT+5℃~100℃

Temperature set range

0℃~100℃

Time range

1min~99h59min

Accuracy of temperature

≤±1℃

Uniformity temperature

≤±1℃

Heating time

≤2min(from 37℃ to 95℃)

Cooling time

≤6min(from 95℃ to 45℃)

Capacity

12

Power

350W

Input voltage

220V/50-60Hz

6

Fuse

250V 3A Ф5×20

Dimension(mm)

440x220x120

Weight(kg)

4.5

7

Chapter 2 Preparations

1. Structure Description

Slide heating plate

Power switch

Cooling fan

Humidity sponge

mounting groove

Touch screen

Power connector

Fuse

8

2. Humidity sponge installation

a) Before each experiment, need to add 30ml of purified water to each sponge.

b) Then install sponges into sponge mounting groove. Please make sure the humidity sponges place

flat.

9

Chapter 3 Operation Guide

1. Starting up and system load

Plug the instrument into a properly grounded outlet, and turn on the power switch on the rear of the

instrument. The touch screen shows system self-testing and loading menu. During the process, please

be patient, the system will automatically enter the operating menu.

2. Main menu

After system testing and loading, it enters into the main menu. Select a operation mode in the

program list menu.

Denat&Hyb:Press Denat&Hyb mode to choose the editing or running program.

Hyb Only:Press Hyb Only mode to choose the editing or running program.

Multi-Step:Press Multi-Step mode to choose the editing or running program.

OPTION:Press system set menu to set key sound, calibration, preheating function, auto resume to

run.

Beside the red thermometer, it displays the real-time temperature of heating platform.

10

3. Program list menu

A: Return button: Return to the upper menu

B: Edit/Load button: Selected program is loaded, run or edit the program

C: Delete button: Clear the selected program, and restore to default value.

D/E: Select program

F: Program list

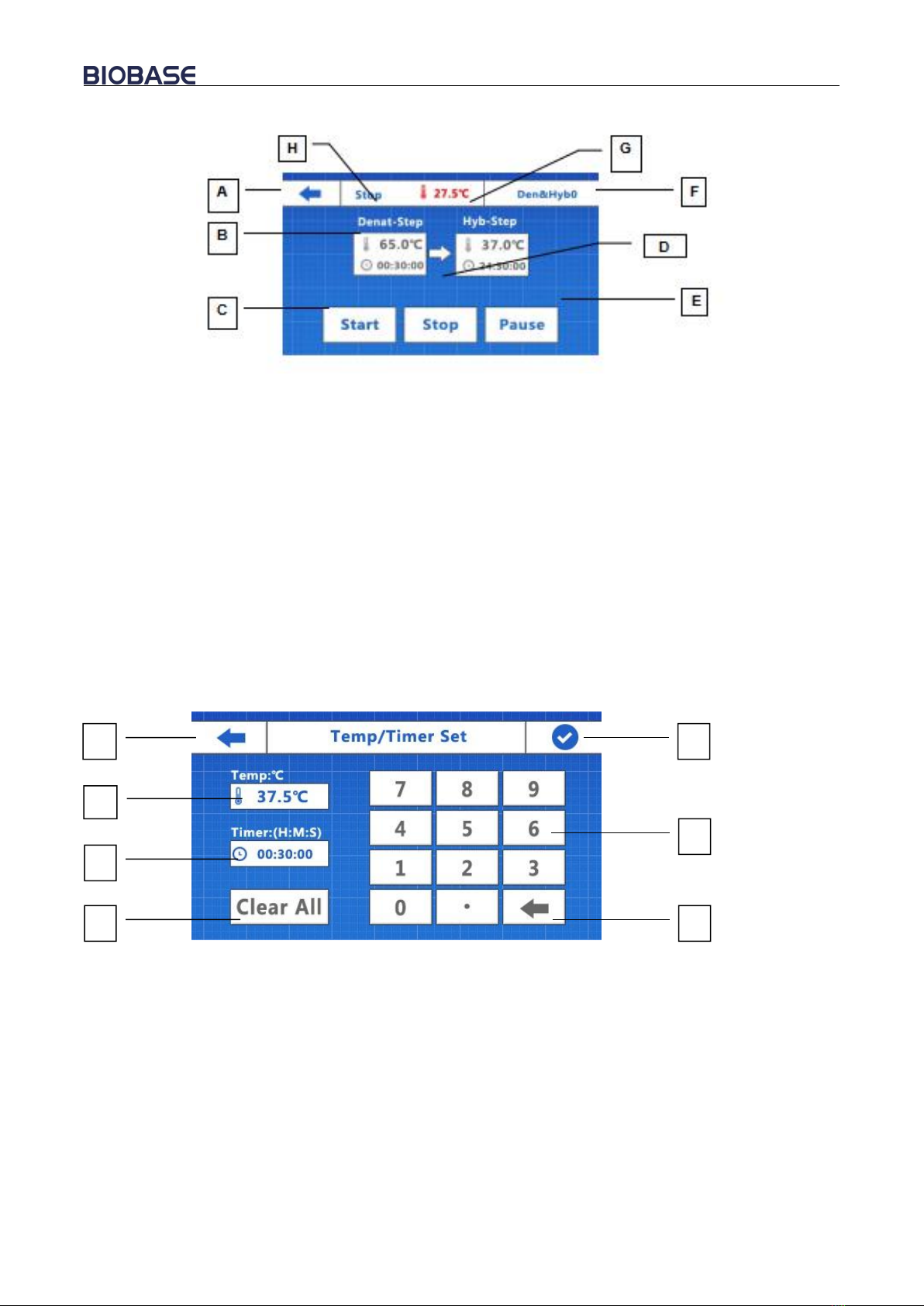

4. Program Edit/Run Menu

In this Menu user can edit or run selected program.

Hyb Only Mode

Multi-Step Mode

Den&Hyb mode

A

D

E

B

C

F

11

A: Return button: Return to the upper menu. No save the revised parameters.

B: Parameters display/edit button: Press this button to edit parameters (temperature and timing

value).

C: Start --Press this button to start program run.

D: Stop--Press this button to Stop running program(This button only valid in the status of programs

running)

E. Pause: If the program is running and starts the countdown, click this button, the program will

pause the countdown. However, the platform temperature will remain in current temperature.

F. Program name: Press this button to edit program name.

G. Platform temperature: It shows the real-time temperature of platform.

H. System Status: It shows the current status--Running, Stop, Pause.

5. Parameter setting menu

In this menu, the user set the temperature and timing of the program.

A: Return button--Return to the upper menu. No save the revised parameters.

B: Temperature--Click the button to enter temperature value through the keypad.

C: Timing--Click the button to enter timing value through the keypad. Time format (hour: minute:

second).

D: Clear ALL--Click Clear temperature value.

If the temperature value is blank, the program runs automatically skip this step.

E: Delete--Click to delete entered parameters.

F: Keypad--Used to enter temperature value and time value.

G: Save--Click to Save current parameters and automatically return to the previous menu.

A

B

C

D

G

E

F

12

6. Program name edit menu

In this menu, user can edit the program name.

A: Return button--Return to the upper menu. No save the revised parameters.

B: A/a—Upper/lower case letter switch key.

C: numeric keypad--Click it to switch to numeric keypad.

D: alphanumeric keyboard--Click it to switch to alphabetic keyboard.

E: delete button--Click it to delete input characters.

G: Save button--Click it to save current program name and return to the previous menu.

Alphabetic keyboard

A

B

C

F

E

numeric keyboard

D

13

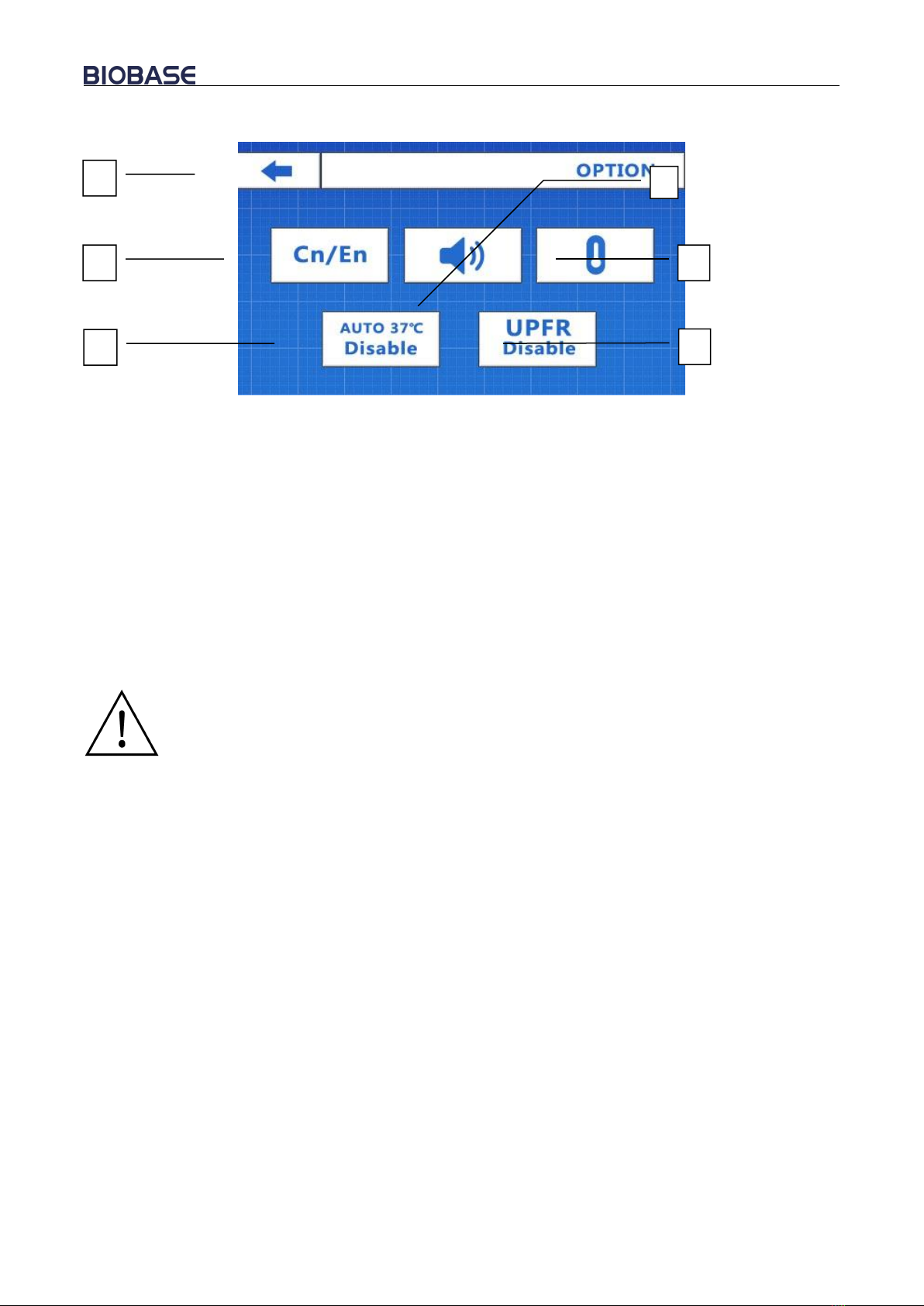

7. System configuration menu

A: Return button--Return to the upper menu.

B: Menu Language--Switching system menu language (Chinese/English).

C: Auto 37℃*-- Enable/Disable preheating function.

D: UPFR*--Enable/Disable UPFR(Auto resume to run after power failure).

E: Temperature calibration*--Click it to start temperature calibration.

F: Button sound—Enable/Disable the button sound.

Auto 37℃:

If enable, the platform temperature is constant at 37℃(except in the running state).

If disable, after finishing each program, the system will turn on the fan, cooling the heating platform.

* UPFR:

If enable, the instrument will auto resume to run the unfinished program after unexpected power

failure.

* Calibration:

If the temperature deviation is very big, the user can use this function to re-calibrate the

instrument.

8. Calibration menu

If the temperature deviation is very big, the user can use this function to re-calibrate the

instrument.

Preparations before calibration:

1. Thermometer accuracy:≤±0.2℃.

2. Room temperature:≤30℃.

3. Need to add 30ml of purified water to each sponge.

4. The thermometer attached to the surface of heating platform. (Note: Thermometer and heating

platform should contact completely, add the appropriate amount of paraffin oil between these two, to

ensure thermal efficiency). After installing a thermometer, close the cover.

5. The calibration process takes approximately one hour. During the process, to ensure that the

instrument can not be accidentally broken.

If unexpected power outages during the calibration process, all data of this calibration is invalid.

A

B

C

D

E

F

14

6. Go to System Option menu, click temperature calibration button to start temperature calibration.

A: Return button--Exit temperature calibration, all data of this calibration is invalid.

B: Temperature calibration point: It is calibrated temperature point (4 default calibration points:

40/60/80/100℃).

C: Real-time temperature value: real-time temperature value of heating platform.

In the heating process, please be patient. When the temperature is constant, the system will

automatically enter the calibration correction mode.

A: Starting next calibration point--confirm and save the current temperature correction value, and

then go to the next temperature calibration point.

B: Calibration correction-

C: Calibration correction+

D: Correction value--show the actual temperature value after correction.

In the subsequent calibration point repeats the above steps to complete the calibration. After

temperature calibration, system will exit the calibration mode automatically.

Calibration warming

A

C

A

D

C

B

B

Calibration correction

15

Chapter 4 Considerations

During running, do not move the instrument.

During use, stay away from an external heat source to ensure the accuracy of temperature

control,.

After use, turn the power off. After cooling for 30 minutes, erase the legacy of water vapor

around the heating platform with a dry clean soft cloth. Place the instrument in a dry and

ventilated place.

Humidity sponge is made of high-temperature sponge. No need to replace under normal

circumstances.

High voltage inside the instrument without permission is prohibited disassemble repair!

16

Chapter 5 Fault Analysis and Processing

Phenomenon

Processing Procedure

No response after power-on

No connection of power(a)

No response after power-on

Broken fuse(b)

No response after power-on

Broken switch(c)

The actual and displayed temperatures are quite different

Broken sensor(c)

No heating/Cooling

Broken temp control system(c)

Press invalid

Touch screen failure(c)

System error: Platform Temp Error!

Sensor failure(c)

System error: Platform ADC Lost!

Sensor initialize failure(c)

System error: Platform ADC Error

Error of sensor data(c)

a) Check connection of power.

b) Exchange fuse, then reboot instrument. If this problem is not solved, please contact supplier.

c) Reboot instrument. If this problem is not solved, please contact supplier.

BIOBASE GROUP

2# building, No.9 Gangxing Road, High-tech Zone, Jinan City, Shandong Province,

China

Tel: +86-531-81219803/01

Fax: +86-531-81219804

Inquiry: expo[email protected]

Complaints: custom[email protected]

Web: www.biobase.cc/www.meihuatrade.com / www.biobase.com

Table of contents

Other Biobase Laboratory Equipment manuals

Biobase

Biobase BSC-3FA2-NA User manual

Biobase

Biobase BSC-2FA2-HA User manual

Biobase

Biobase BKQ-B Series User manual

Biobase

Biobase BBS-V1300 User manual

Biobase

Biobase BSC-4FA2-HA User manual

Biobase

Biobase BSC-4FA2-GL User manual

Biobase

Biobase BFG Series User manual

Biobase

Biobase BCI-I User manual

Biobase

Biobase BBS-V800 User manual

Biobase

Biobase BK-HS32 User manual

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific CTS Xenon user guide

Koehler

Koehler KV4000 Operation and instruction manual

Insphero

Insphero GravityTRAP product manual

Macherey-Nagel

Macherey-Nagel NANOCOLOR Advance quick start guide

dental X

dental X dxp DOMINA PLUS B Operator's manual

Easypix

Easypix SteriBox SB1 user manual