427-0011-00-10 Revision 140 Copyright © FLIR Systems, Inc. 6

2.0 INTRODUCTION

The PTZ-35x140MS and SR-35x140MS are high-resolution multi-sensor (MS) camera systems

designed specifically for the security market for medium- to long-range security applications.

Each model includes a sophisticated thermal imaging system that provides excellent night

visibility and situational awareness, even in absolute darkness, as well as a standard high

resolution low-light video camera1, integrated into a compact weather enclosure.

Each system includes a versatile, dual field-of-view thermal imaging system called Foveus, a

FLIR-patented innovation, which provides a high-resolution thermal image with a 5° view nested

inside a wider 20° view. This image presentation concept, derived from the same principles as

human vision, offers excellent situational awareness and long range threat detection,

simultaneously. Each system has two thermal imagers: a 35mm camera for wide-angle

surveillance, and a long-range 140mm camera, and the ability to continuously zoom between

the two fields of view.

This thermal imaging system is complimented with a high-resolution daylight camera, providing

optimal surveillance regardless of the time of day or lighting conditions. With the touch of a

button you can switch between the thermal imager and the daylight / low light camera. The

daylight camera provides up to 26x optical zoom. Displaying both the thermal image and the

daylight image at the same time is also possible via Ethernet.

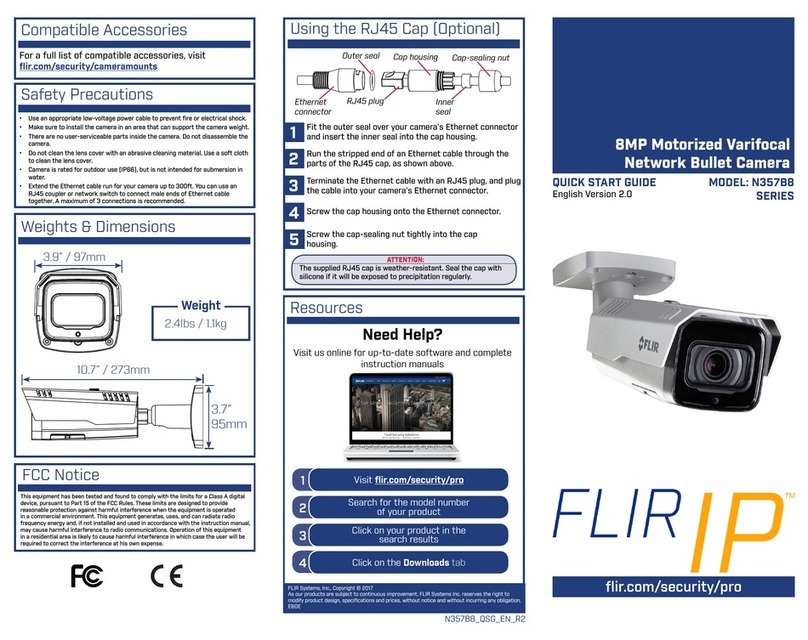

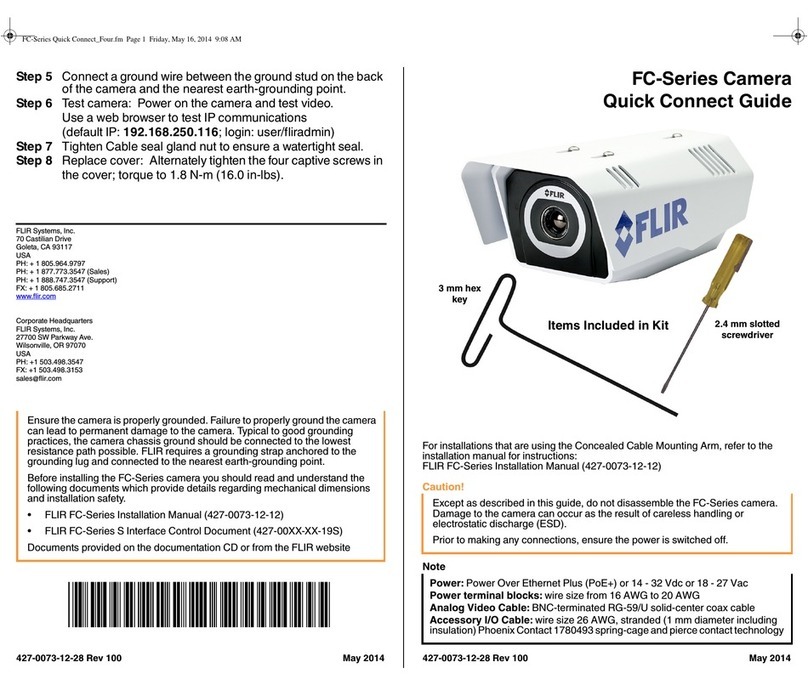

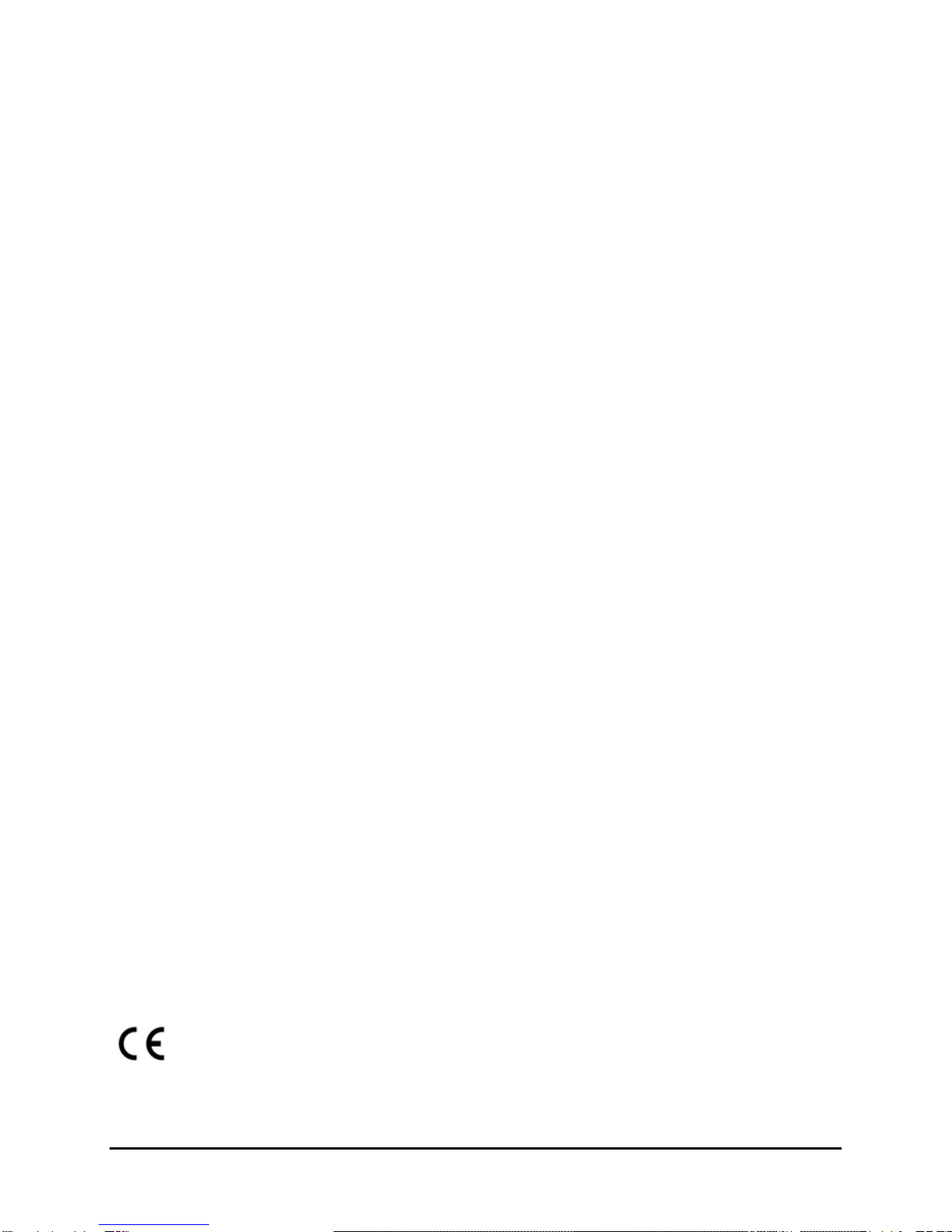

Figure 2-1: SR-35x140MS

The SR-35x140MS is used for fixed-mount applications, or it can be integrated with a pan/tilt

mechanism. The camera provides crisp, clear thermal imagery in total darkness, light fog or

smoke. On the PTZ-35x140MS, this advanced payload is packaged in a precision pan/tilt

enclosure that will slew up to 120° per second. Each system provides standard video output

(PAL or NTSC format) that works with digital video recording devices, video motion detection

software or off-the-shelf video encoders.

Both 35x140MS camera systems have the performance of military-grade camera systems at a

fraction of the cost. Security operators can field them as portable stand-alone cameras, or

integrate them into a camera network. The cameras provide serial and analog connectivity for

existing legacy infrastructures using widely-deployed interface standards. Either system can be

integrated into IP Video security infrastructures using TCP/IP standards. The cameras support

network operation and control through the Nexus ™ architecture using FLIR Sensors Manager

(FSM) software or a third-party VMS. Video can be streamed over TCP/IP using FSM or a third

party video player.

1The standard video camera is referred to in this manual generally as a daylight camera or

DLTV.

Daylight

camera

140mm lens

35mm lens