TTCF-9A

Variable High Flow Heated

Hydraulic Component Flusher

QUICK START

INSTRUCTIONS

Flo-Dynamics, Inc. • 3300 Reedy Drive • Elkhart, IN 46514 • 800-303-5874 Page 2of 5

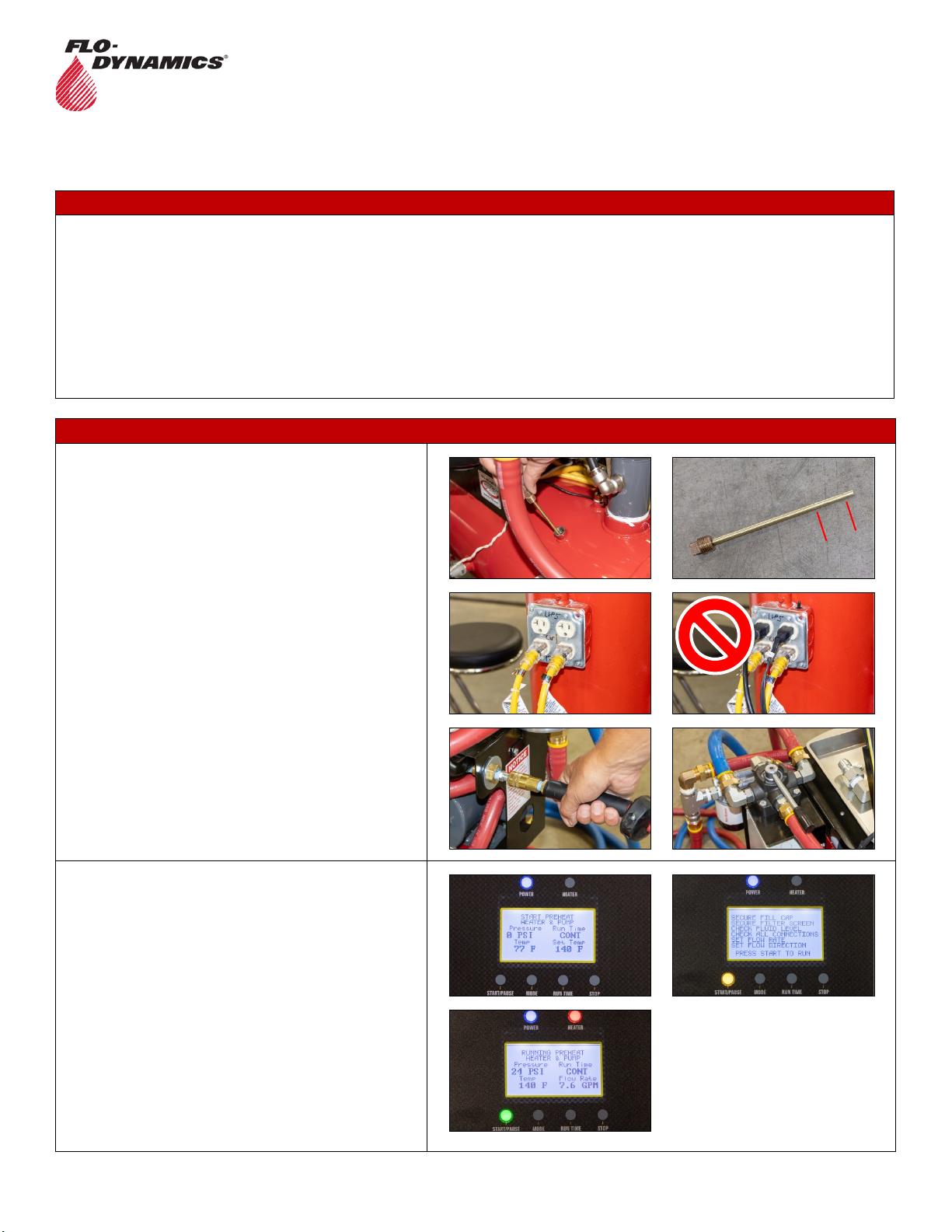

Connect the red service hose to the cooler inlet line and the

blue service hose to the return line of the cooling system.

Once the unit reaches 140 degrees, press the STOP

button.

Press the manual air purge button to clean out the lines.

Remove the top half of the filter housing and place the

screen filter into a waste bucket/container.

Move the Flow Control Valve to position 4.

Use the MODE button to select “START PURGE”. This will

run the initial purge for 7.5 seconds to purge the cooler and

line with clean fluid. Repeat until clean fluid is observed.

Clean the screen filter if needed, and reassemble the filter

housing.

Move the Reverser Valve toward the blue hose coming

from the cooling system’s return line. This will backflush the

cooling system.

Use the MODE button to select “START FLUSH”. Use the

RUN TIME button to select the flush cycle time. It is

suggested that the initial flush runs for 15 minutes to

capture initial contaminants within the cooler system.

Press START/PAUSE and check the following:

oSecure fill cap

oSecure filter screen

oCheck fluid level

oCheck all connections

oSet flow rate

oSet flow direction

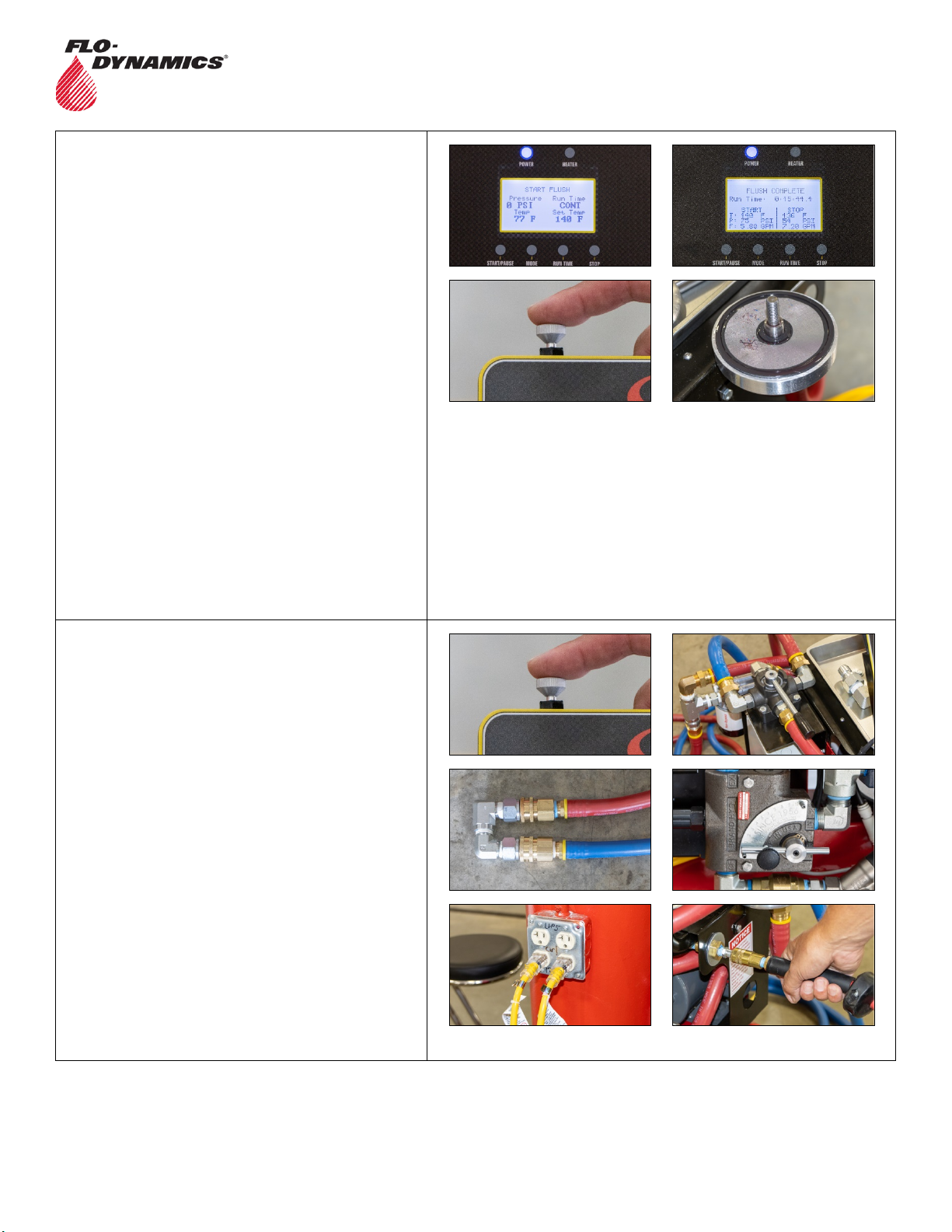

Press the START/PAUSE button to start the flush cycle.

At the end of a flush cycle, the flusher will stop and signal

with an audible sound. The display will show “FLUSH

COMPLETE” with before and after flush cycle results.

Press the manual air purge button to clean out the lines.

Remove the top half of the filter housing, note debris on

filter screen, clean the screen, and reassemble the filter

housing.

Repeat flush cycle selecting a desired time using the RUN

TIME button from 15-120 minutes.

NOTE: With an initial flush completed, you can now run

longer flush cycles along with switching the flow direction

using the reverser valve between flush cycles.

Move the Reverser Valve toward the red service hose.

Use the MODE button to select “START FLUSH”.