CMS-120

Coolant Management System

QUICK START

INSTRUCTIONS

Flo-Dynamics, Inc. • 3300 Reedy Drive • Elkhart, IN 46514 • 800-303-5874 Page 3of 8

When the coolant returns to the “cold” level on the

expansion tank, turn Assist Control to VENT.

When the cooling system stabilizes and both gauges show

zero, move the Flow Control to “OFF”.

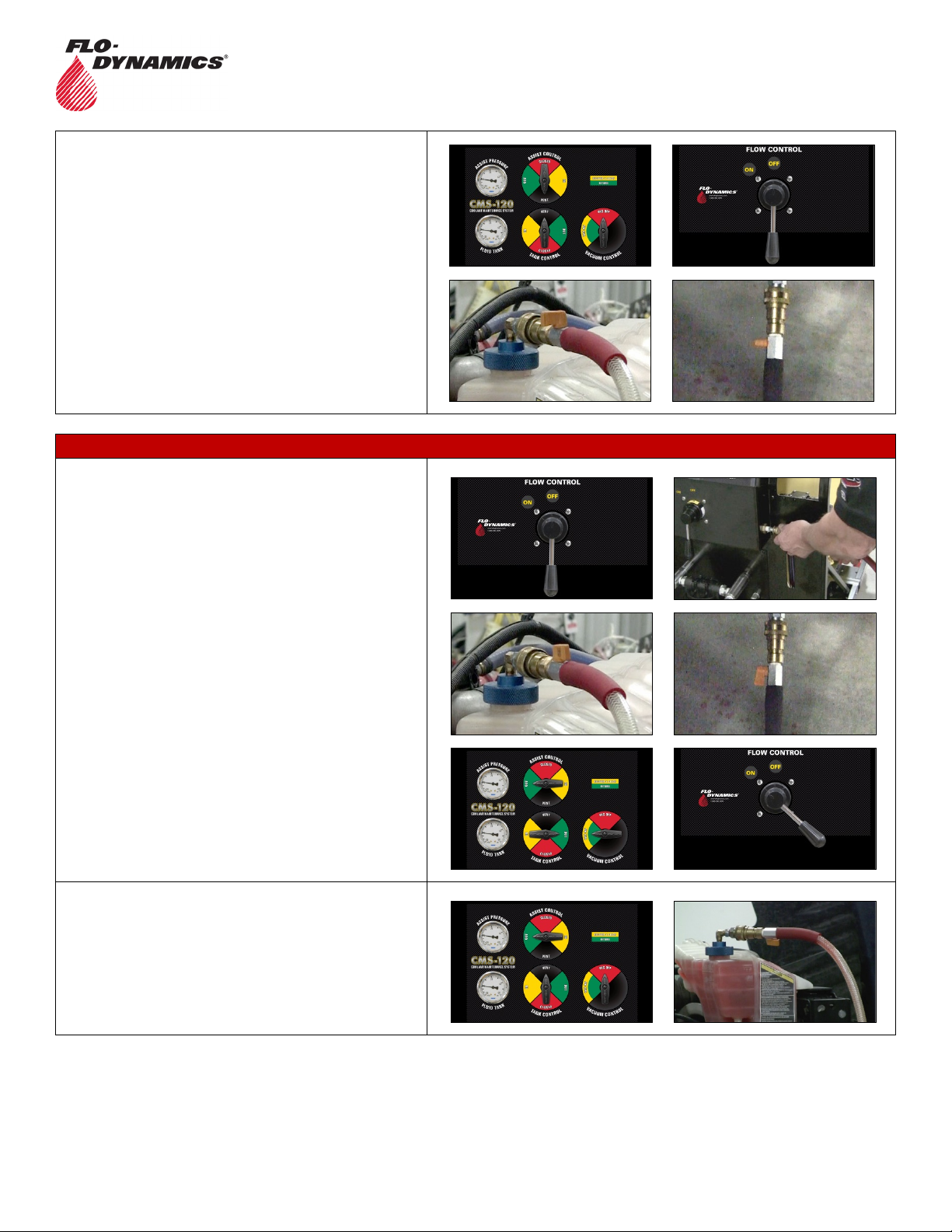

TO ADJUST COOLANT LEVEL IF IT’S TOO HIGH

Turn Tank Control and Vacuum Control to YELLOW and

Assist Control to VENT.

Move the Flow Control to “ON” until the desired coolant

level is reached.

Move the Flow Control to “OFF” and turn Vacuum

Control and Assist Control to VENT.

Close the ball valves and remove the service hoses.

NOTE: If cooling system overfills and coolant is seen in the

top service hose going into the vacuum generator overflow

filter, stop flow immediately by moving Flow Control to

“OFF”. See “VACUUM GENERATOR OVERFLOW FILTER

REPLACEMENT” procedure to empty overflow filter

assembly.

TOP-OFF PROCEDURE / COOLANT LEVEL TOO LOW

NOTE: The following procedure is performed with the red

and black service hoses still connected from filling the

cooling system in the above procedure.

Turn Tank Control to Green, Assist Control to VENT and

Vacuum Control to OFF.

Move the Flow Control to “ON”.

When coolant is at the correct level, move the Flow

Control to “OFF”, Tank Control to VENT.

When the cooling system stabilizes and both gauges show

zero, close the ball valves and remove the service hoses.