Flomatic C501 Manual

15 Pruyn's Island Drive

Glens Falls, New York 12801

Phone: (800) 833-2040

High Quality Valves Built to Last…

WWW.FLOMATIC.COM

Automatic Control Valve

Operation & Maintenance Manual

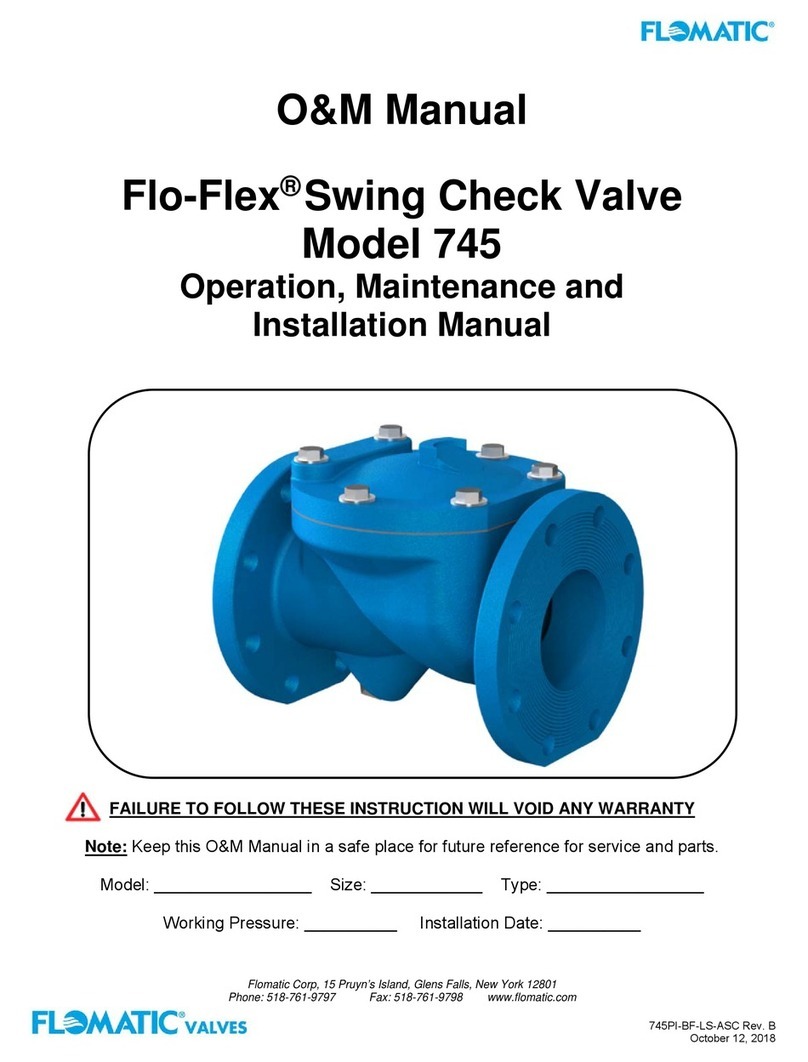

Model C501/CA501 Surge Arrestor Valve

MANUAL: C501 REV: 4

Note:

Place this Valve Product Manual in a safe place and with a person

responsible for the operation and maintenance of this valve.

Refer to Model and Serial Number above when ordering parts.

Serial Number: ___________________

Valve Model: ____________________

Size: ______

Serial Number: __________________

Low Pressure Pilot Setting : ______ PSI

Pressure Relief Pilot Setting: ______ PSI

System Pressure:_____ PSI

Installation Date: _________________

Name: __________________________

15 Pruyn's Island Drive

Glens Falls, New York 12801

Phone: (800) 833-2040

High Quality Valves Built to Last…

WWW.FLOMATIC.COM

Automatic Control Valve

Operation & Maintenance Manual

Model C501/CA501 Surge Arrestor Valve

MANUAL: C501 REV: 4

The Model 501 Surge Arrestor Valve controls over pressure and under pressure conditions. The pilot operated

control valve opens quickly to dissipate high surge pressure that exceeds a predetermined relief pressure setting

that can occur during pump start. The control valve also opens quickly for low surge pressure conditions that

can occur during normal pump shut down, electric power failure, and pump failure. The control valve will

continue to remain open following low surge pressure conditions to dissipate return pressure surges. The

control valve will close smoothly at an adjustable speed once system pressure has recovered within the normal

operating pressure zone above the low surge pilot setting or below the high surge pressure pilot setting.

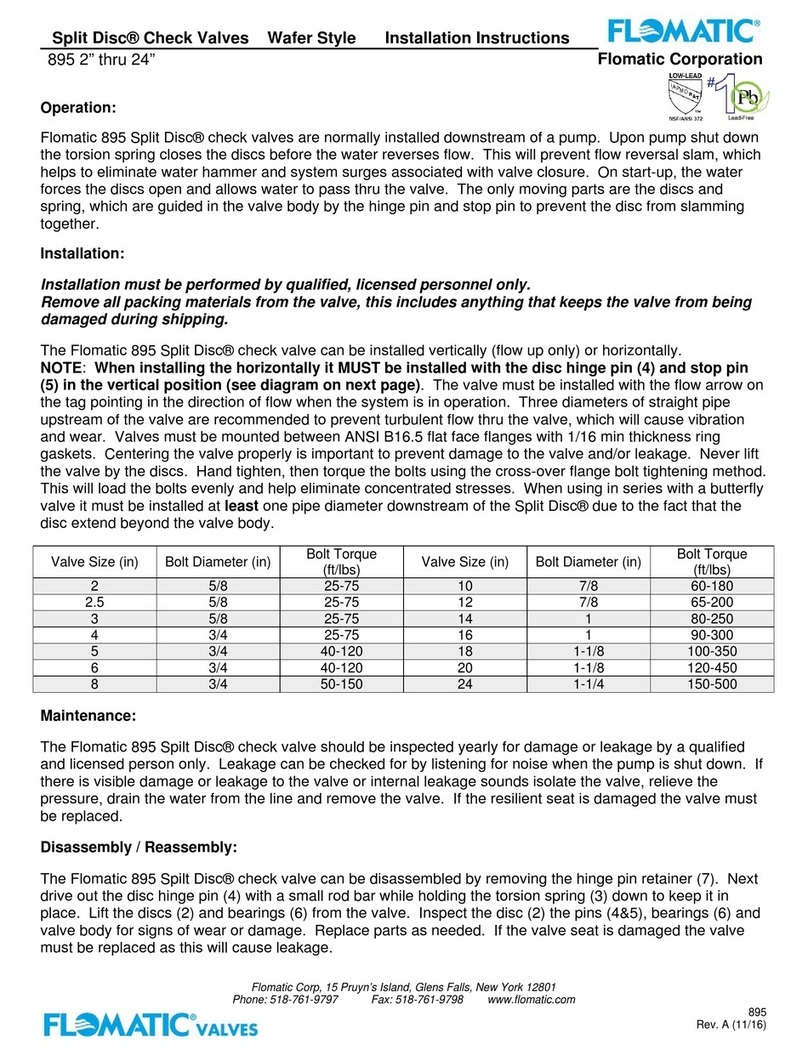

Part List

1. Shut-Off Valve (3)

2. Strainer

3. Orifice

4. Pilot Valve (Over Pressure)

5. Pilot Valve (Under Pressure)

6. Air/Vacuum Valve

7. Accumulator

8. Needle Valve or Flow Control

9. Testcock

SHIPMENT:

When shipped, controls are usually mounted

on the main valve. If control subassemblies

are shipped separately, all connections are

tagged to insure correct assembly.

INSTALLATION:

1. Model C501 is installed on a "Tee" from

the main line into atmosphere (waste).

2. Flush the pipeline before inserting the

valve.

3. Install the valve with the "arrow" on body

pointing in the direction of flow (waste).

4. Attach subassemblies to main valve if

necessary.

5. Allow enough clearance above valve for

removal of piston assembly.

STARTUP AND ADJUSTMENT:

1. Install pressure gauge to observe inlet pressure.

2. Model C501 requires manual closure to bring the valve on-line. Open Shut-Off Valve (1A) and close

Shut-Off Valve (1B). Re-open Shut-Off Valve (1B) after surge arrestor valve closes following step 4

or 5 to put the valve into automatic operation.

WARNING: Shut-Off Valve (1B) on downstream side must always be open for normal operation;

otherwise, main valve will not function.

3. Slowly open main line inlet side shut-off valve about 1/8 open and observe pressure gauge.

15 Pruyn's Island Drive

Glens Falls, New York 12801

Phone: (800) 833-2040

High Quality Valves Built to Last…

WWW.FLOMATIC.COM

Automatic Control Valve

Operation & Maintenance Manual

Model C501/CA501 Surge Arrestor Valve

MANUAL: C501 REV: 4

4. Open ¼” Test Cock (9) at top of valve. Re-close when water runs clear and absent of air bubbles. It

may take several cycles to bleed the Surge Arrestor power chamber properly.

5. Open the main line shut off valve (Gate or Butterfly valve) at the inlet (High Pressure) side of the

surge arrestor valve fully. If there is a main line shut-off valve at the outlet side of the surge arrestor

valve, open slowly. Water will flow through the open valve initially and decrease as the valve closes

gradually.

6. The controls of the Surge Arrestor Valve have been factory preset in accordance with the specified

operating conditions as provided on order placement. However, minor field adjustments may be

required as follows:

1. With pump running and developing the maximum pumping pressure:

a. If the Surge Arrestor Valve is open and passing water, turn the adjusting screw of

the Over Pressure Pilot (4) clockwise slowly until the main valve closes. Lock the

adjusting screw in this position.

b. If the Surge Arrestor Valve is closed, turn the adjusting screw of the Over Pressure

Pilot (4) counter-clockwise slowly until the valve opens and passes water; then

clockwise as noted in (a) above.

2. Shut down the pump and observe the pressure at which Under Pressure Pilot (5) starts to

open the Surge Arrestor Valve.To increase under pressure setting, turn the adjusting screw

of the Under Pressure Pilot (5) clockwise. To decrease under pressure setting, turn the

adjusting screw of the Under Pressure Pilot (5) counter-clockwise.

OPERATION:

The over pressure pilot is a Normally Closed Model BPP Back Pressure Sustaining Pilot that remains closed

when system pressure is below the pilot set point. The under pressure pilot is a Normally Open Model PRR

Pressure Reducing Pilot that remains closed when the system pressure is above the pilot set point.

When the Model PRR Pressure Reducing Pilot (under pressure pilot), senses a subnormal pressure created by

the low-pressure portion of the surge wave (immediately after pump shut down or power failure), it causes the

main valve to open rapidly by exhausting control water from above the diaphragm of the main valve to an

accumulator. This insures that the main valve is open in anticipation of the returning high-pressure portion of the

surge wave to eliminate potential shock or hammer. When system pressure recovers within the normal

operating pressure zone above the Model PRR under pressure pilot set point, the main valve closes slowly at a

rate controlled by an adjustable flow control valve to prevent valve closing surges, and the accumulator will drain

in preparation for the next cycle.

When the Model BPP Back Pressure Sustaining Pilot (over pressure pilot), senses high pressure equal to or

above it’s set point, it causes the main valve to open rapidly by exhausting control water from above the

diaphragm of the main valve. When system pressure recovers within the normal operating pressure zone below

the Model BPP over pressure pilot set point, the main valve closes slowly at a rate controlled by an adjustable

flow control valve to prevent valve closing surges.

15 Pruyn's Island Drive

Glens Falls, New York 12801

Phone: (800) 833-2040

High Quality Valves Built to Last…

WWW.FLOMATIC.COM

Automatic Control Valve

Operation & Maintenance Manual

Model C501/CA501 Surge Arrestor Valve

MANUAL: C501 REV: 4

TROUBLE SHOOTING GUIDE:

PROBLEM: Valve opens and will not close.

CAUSE

1. Main valve is air bound.

2. Isolation valve at the inlet side of controls is closed.

3. Indicator stuffing box or sight glass is leaking (if

equipped).

4. Fouled orifice (or needle valve).

5. Fouled Y-strainer.

6. Damaged under pressure or over pressure pilot valve

seat.

7. Ruptured diaphragm in main valve.

8. Debris lodged under seat of main valve.

9. Worn seat seal and/or seat ring in main valve.

10. Incorrect adjustment of Under Pressure Pilot (set too

high).

11. Incorrect adjustment of Over Pressure Pilot (set too

low).

12. Leakage from one or more fittings in the controls.

13. Damaged o-ring stem seal.

CORRECTION

1. Open ¼” air bleeder located on top cover of valve to

release air.

2. Open isolation valve.

3. Tighten packing nut or replace packing seals.

4. Remove and clean orifice if required. Open needle valve

wide (counter clockwise) to flush seat. Return to original

setting after 4 or 5 seconds.

5. Disassemble, clean or replace screen.

6. Disassemble, clean and replace damaged parts.

7. Disassemble and replace diaphragm.

8. Disassemble and remove. Replace damaged parts.

9. Disassemble and replace damaged parts.

10. Turn Under Pressure Pilot adjusting screw counter-

clockwise slowly until valve resumes control and closes;

(refer to Section 6.2 for Under Pressure Pilot set point

adjustment).

11. Turn Over Pressure Pilot adjusting screw clockwise

slowly until valve resumes control and closes; (refer to

Section 6.1.a & 6.1.b for Over Pressure Pilot set point

adjustment).

12. Tighten or replace fitting.

13. Disassemble and replace o-ring.

PROBLEM: Valve is closed and will not open.

1. Incorrect adjustment of Over Pressure Pilot (set too

high).

2. Needle Valve open too far

3. Isolation valve at the outlet side of the controls is closed.

4. Fouled pilot valve(s)

5. Worn or eroded orifice (or needle valve seat).

1. Turn the Over Pressure Pilot adjusting screw counter-

clockwise slowly until the valve opens, then turn clockwise

untill the valve closes at the desired set point; (refer to

Section 6.1.a & 6.1.b for Over Pressure Pilot set point

adjustment).

2. Turn adjusting cap clockwise slowly until vavle opens

and then clockwise until valve re-closes

3. Open isolation valve.

4. Disassemble and clean, rebuild as necessary.

5. Replace orifice (or needle valve).

This manual suits for next models

1

Table of contents

Other Flomatic Control Unit manuals

Popular Control Unit manuals by other brands

G&D

G&D DP-HR-U Installation and operations

ZIEHL-ABEGG

ZIEHL-ABEGG UNIcon CKG-3RVE operating instructions

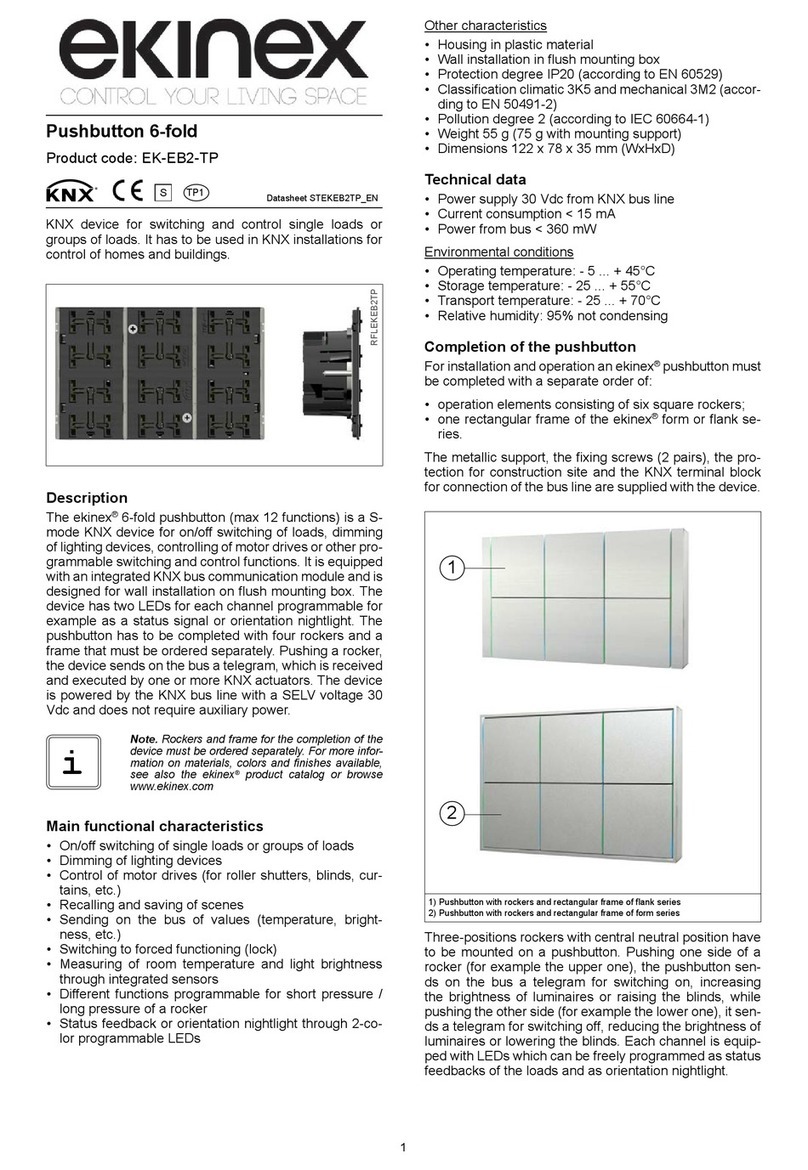

Ekinex

Ekinex EK-EB2-TP manual

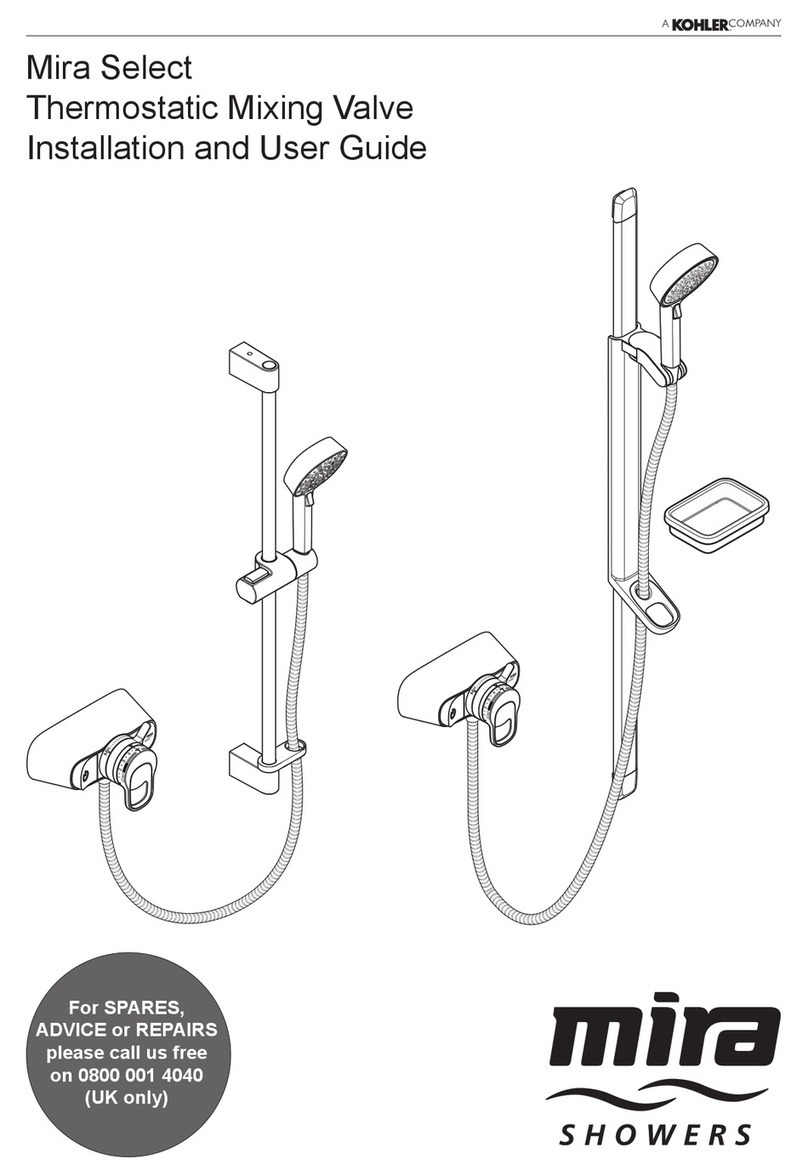

Kohler

Kohler Mira Select B14C Installation and user guide

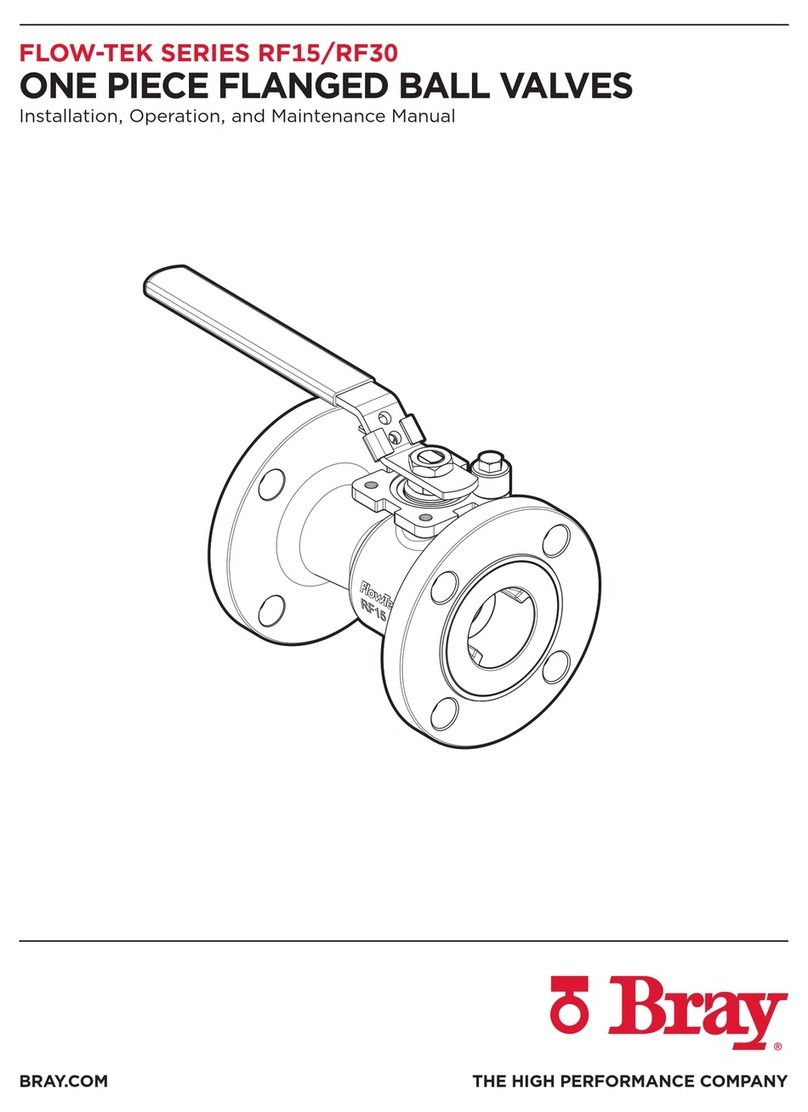

Bray

Bray FLOW-TEK Series Installation, operation and maintenance manual

Mitsubishi Electric

Mitsubishi Electric Q68AD-G user manual

Airwell

Airwell RCW-2 user manual

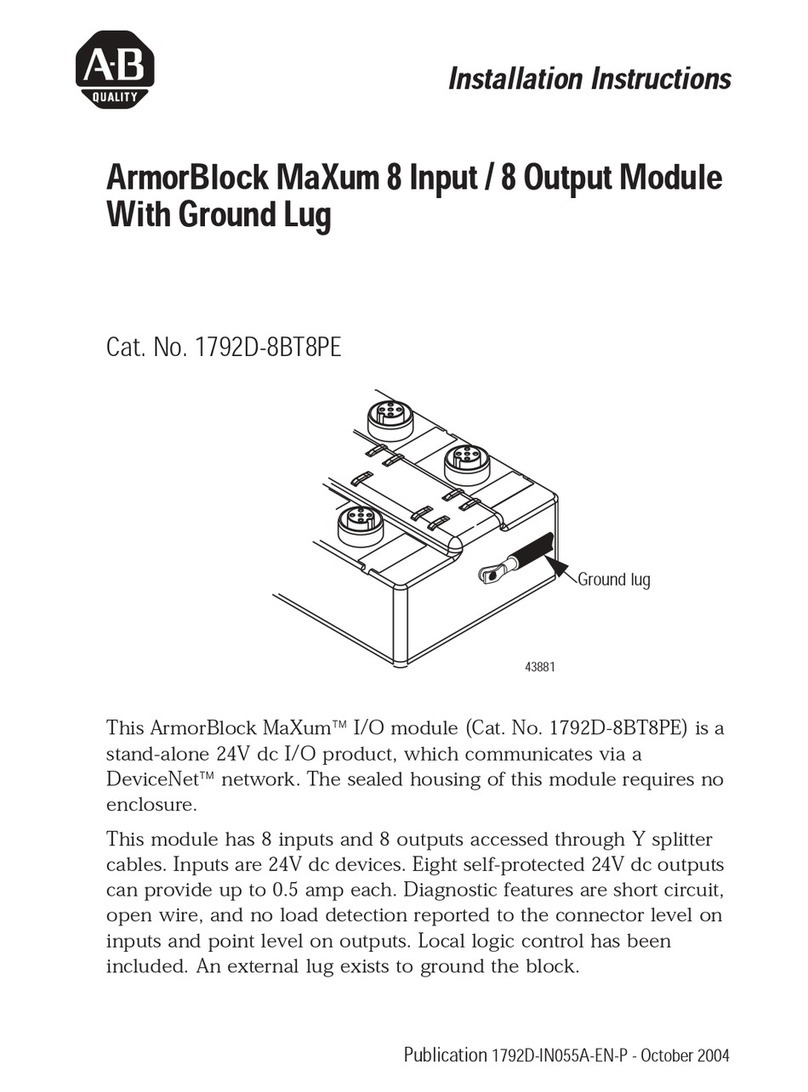

Allen-Bradley

Allen-Bradley 1771-OD Installation data

Beninca

Beninca BRAIN 24 operating instructions

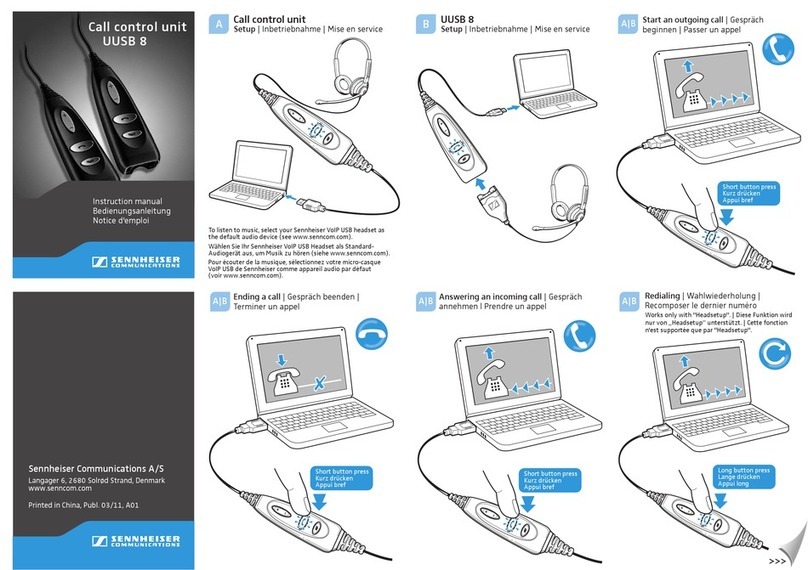

Sennheiser

Sennheiser UUSB 8 instruction manual

Access

Access Flow2 User's manual & installation instructions

Cyfral

Cyfral CC-4000 Operating, Installation and Programming Manual