3

Addional Informaon

CE Marking

FloPlast has taken the responsibility of CE marking the products in accordance with harmonised European standard BS

EN 12380: 2002 and data is given in FloPlast’s Declaraon of Performance as applicable to the range.

1.0 Technical Specicaon

1.1 AF32/AFE32: The AF32 and AFE32 have been designed for installaon directly onto 32mm UK designated Solvent

Waste Pipe. with the use of the universal adaptor (provided with the product), the AF32 can also to be installed onto

40mm and 50mm UK designated pipe. The valve is also available designated as AFE32, which has been designed for use

with Eurpoean designated 32mm/40mm and 50mm Solvent Waste Pipe.

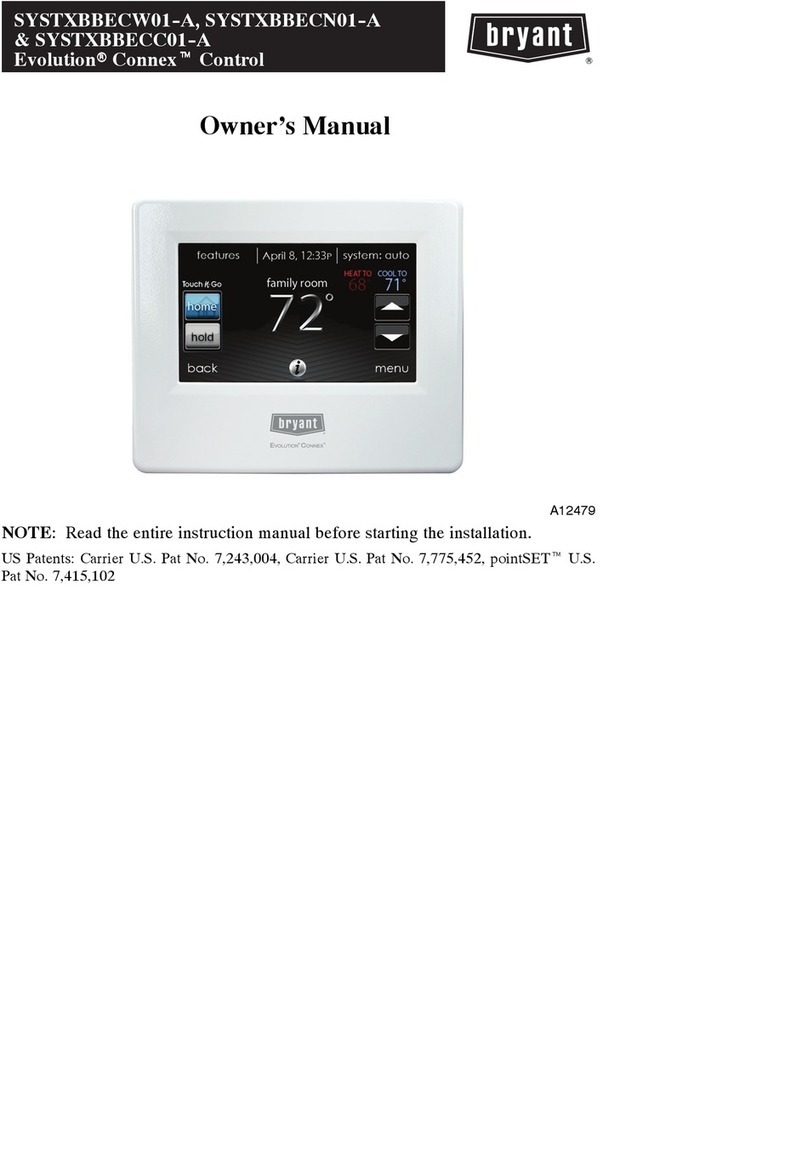

FloPlast’s AF32 Air Admiance Valve, (as seen on the front cover) comprises of an injecon-moulded, two-part acry-

lonite butadine styrene (ABS) body, screwed together incorporang an EPDM sealing ring. The valve incorporates a slid-

ing ABS injecon moulded disc and EPDM (ethylene propylene diene monomer) seal (poppet), this acts as the opening

and closing seal.

1.2 AV110/AVE100: The AV110 has been designed for installaon directly onto 110mm UK designated pipe. The

AVE100 has been designed for use with European designated 100mm Pipe.

FloPlast’s AVE100/AV110 Air Admiance Valve, (as seen on the front cover) comprises an injecon-moulded, two-part

poly vinyl-chloride (PVC-U) body, screwed together incorporang an EPDM sealing ring. The valve incorporates a sliding

ABS injecon moulded disc and EPDM sealing ring (poppet) which acts as the opening and closing seal.

1.3 AF110: The AF110 has been designed for installaon directly into 110mm UK designated pipe with the use of

and EPDM nned seal. Addionally the AF110 can be installed solvent welded directly onto 82mm UK designated pipe

by removing the nned seal and using the socket on the body. The valve can also be installed directly into 100mm or

110mm European designated pipe with the use of an EPDM nned seal, this product is designated AFE110.

FloPlast’s AF110 Air Admiance Valve, (as seen on the front cover) comprises of an injecon-moulded, two-part poly

vinyl-chloride (PVC-U) body, screwed together incorporang an EPDM sealing ring. The valve incorporates a sliding ABS

injecon moulded disc and EPDM seal (poppet) which acts as the opening and closing seal.

1.4 AX110: The AX110 incorporates the same features as the AF110, with the excepon of the inclusion of an insect/

debris grill manufactured from Polypropylene.

Document H of the Building Regulaons Clause 1.33 states that AAV’s should not be used externally or in dust laden at-

mospheres, however due to the design criteria requirements of the terminaon of SVP’s within 3 metres of an opening

window, and the use of the roof as habital space and also the upturn in lo/roof area conversions, and as a means of

overcoming unsightly SVP installaons, Building Control Ocers are accepng their use.

FloPlast strongly advise that conrmaon of acceptance of the use of the AX110 is gained from Building Control prior to

installaon.

1.5 These valves incorporate spigots detailed in Table 1. They incorporate a nned seal for installaon into 110mm and

100mm pipes or ABS and PVC-U solvent sockets.

1.6 The valves incorporate spigots with diameters that are in accordance with the standards for waste pipe, including:

BS EN 1329-1, BS EN 1455-1, BS EN 1565-1, BS EN 1566-1, BS4514 and BS5255.

1.7 Connuous quality control is exercised during the manufacture and assembly , including visual checks, checks on

dimensional accuracy and 100% funconal tesng of each product. The raw materials and bought-in goods are subject

to quality controls as dened within our ISO9001 Quality Mangement System (FM 501414).

1.8 FloPlast AAV’s are designated A1 in accordance with BS EN 12380: 2002 and can be ed below the ood level of

connected appliances, in air temperatures between -20°C and 60°C.