INSTALLATION AND OPERATION INSTRUCTION

DIFFERENT PRESSURE CONTROL VALVEFlowCon DPCV

FlowCon International assumes no responsibility

for mistakes, if any, in any printed material.

Denmark Dubai USA Singapore www.owcon.com

1H95000 - 04/2016

- 1 -

FlowCon DPCV 15-50mm

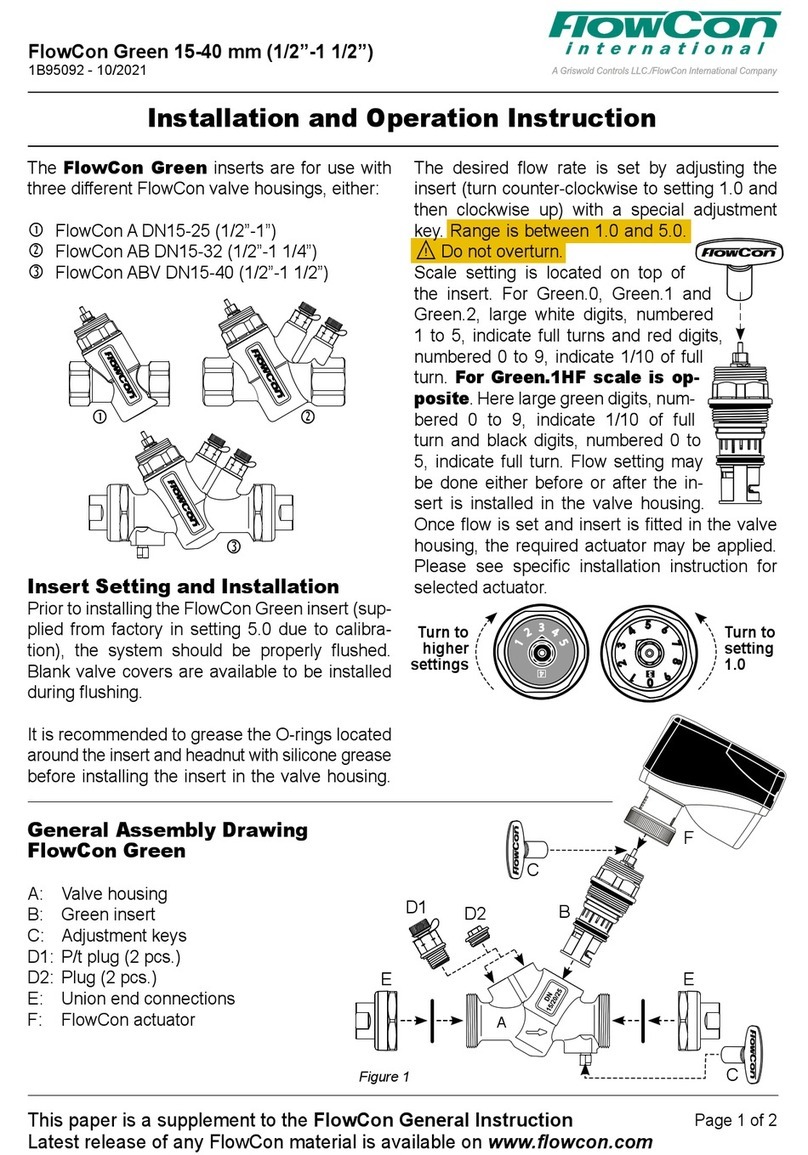

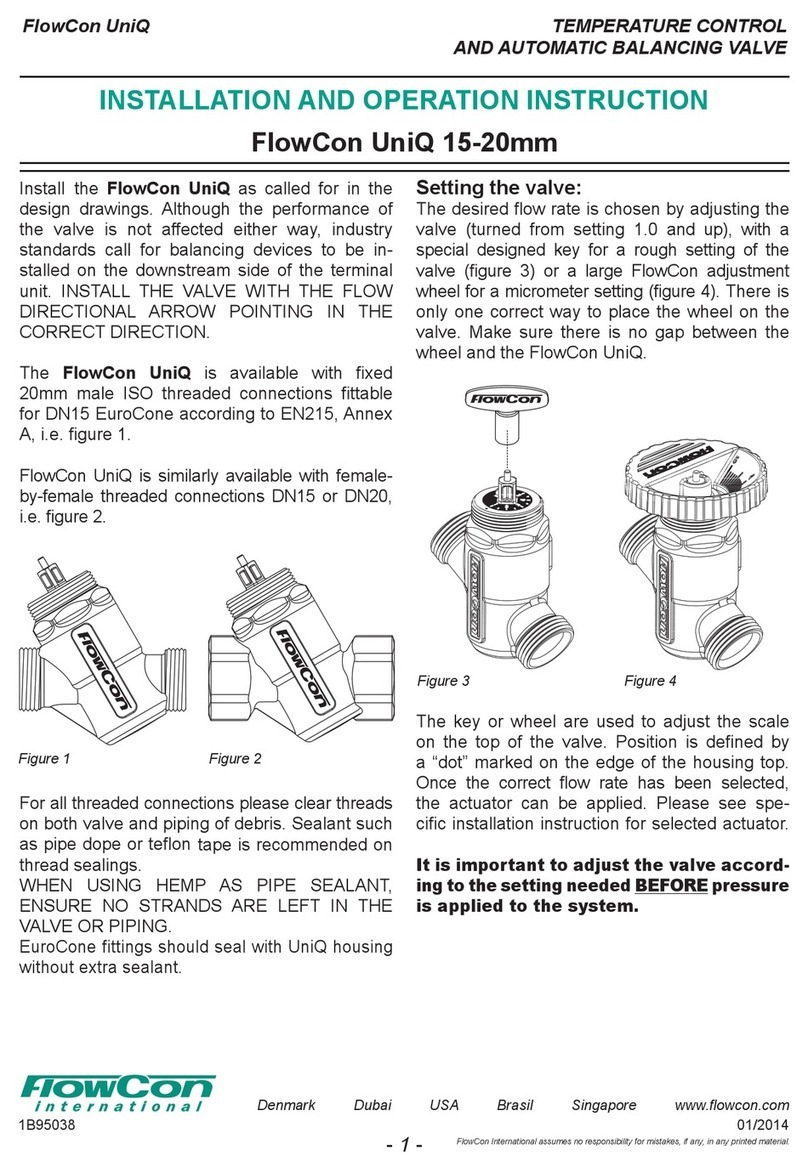

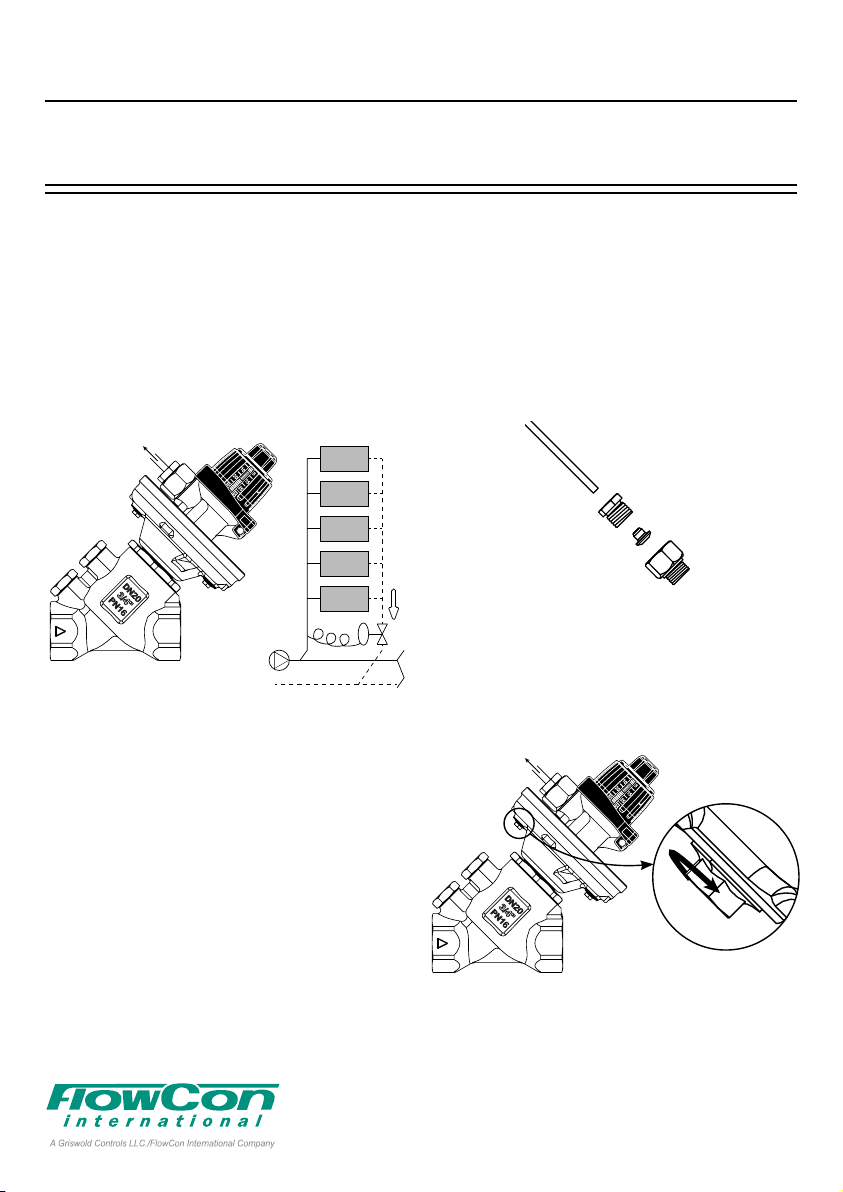

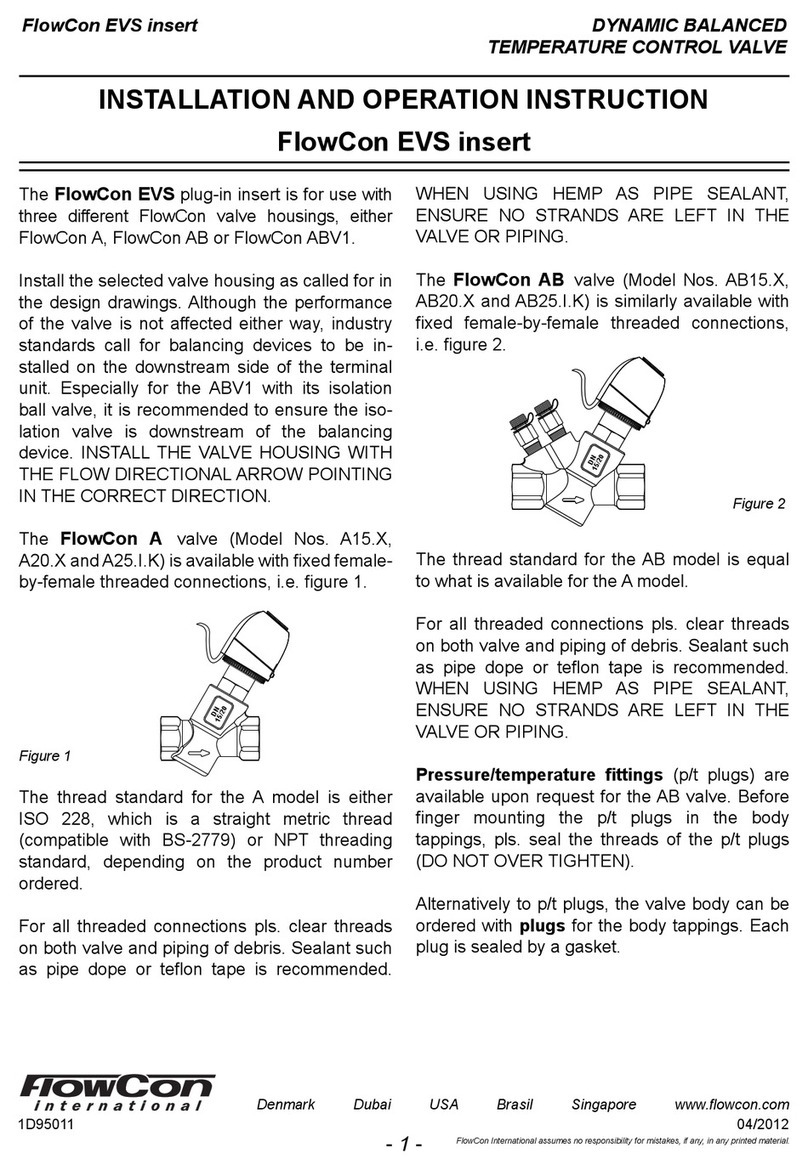

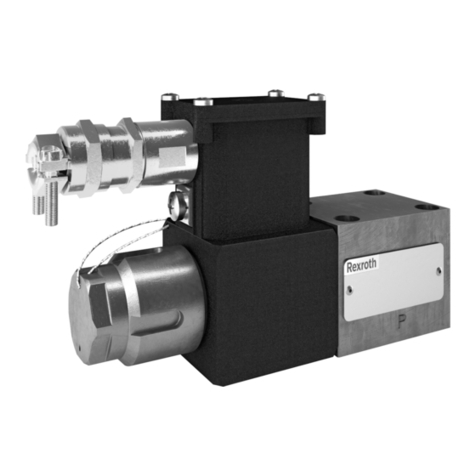

Figure 1

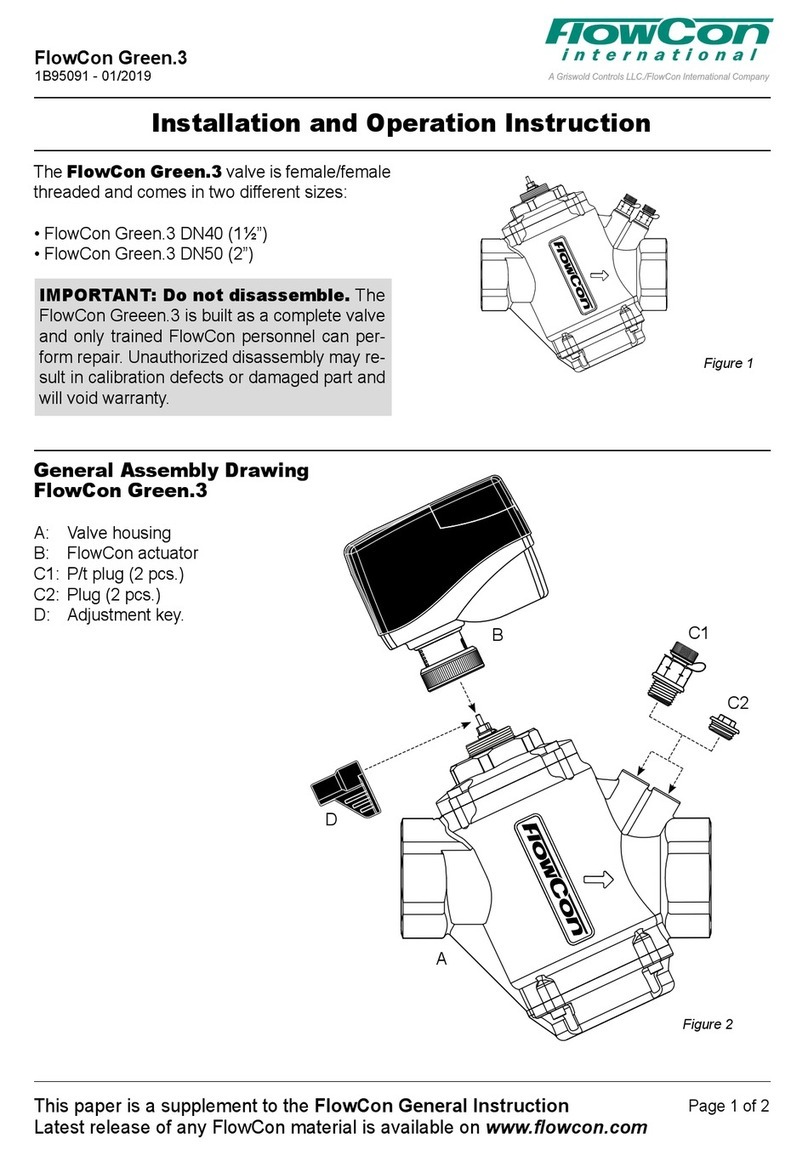

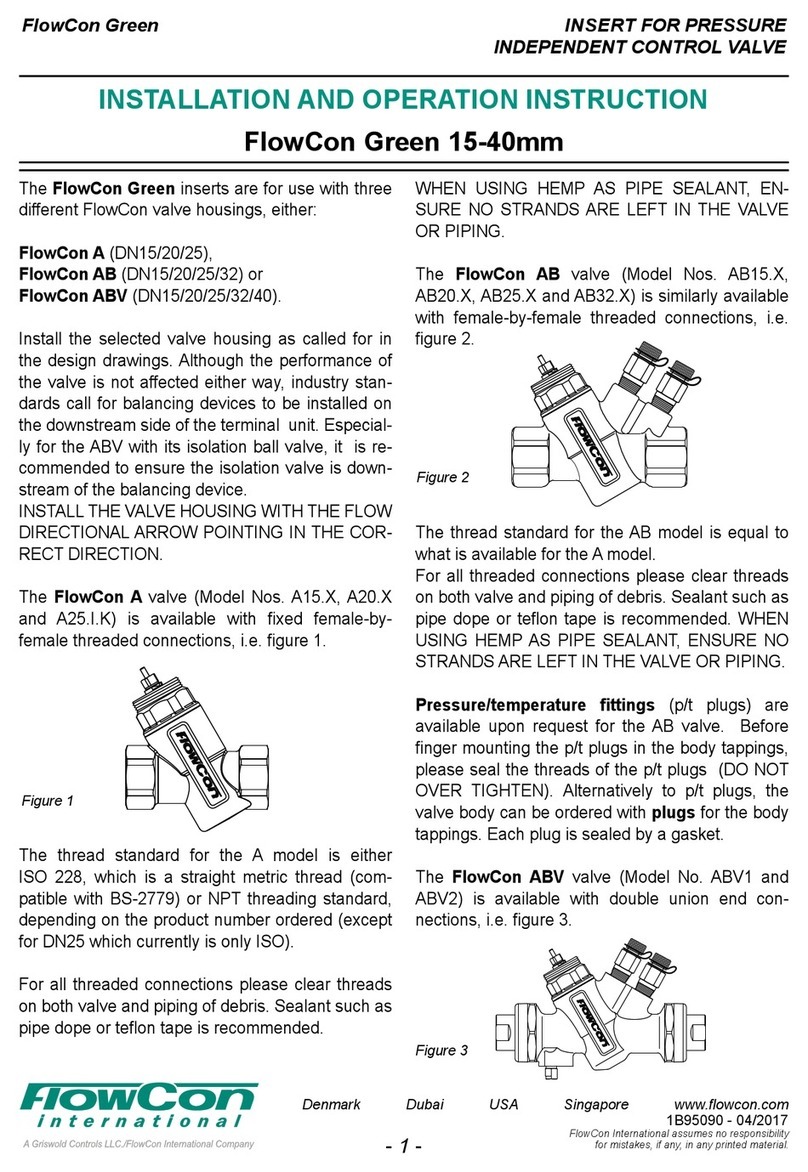

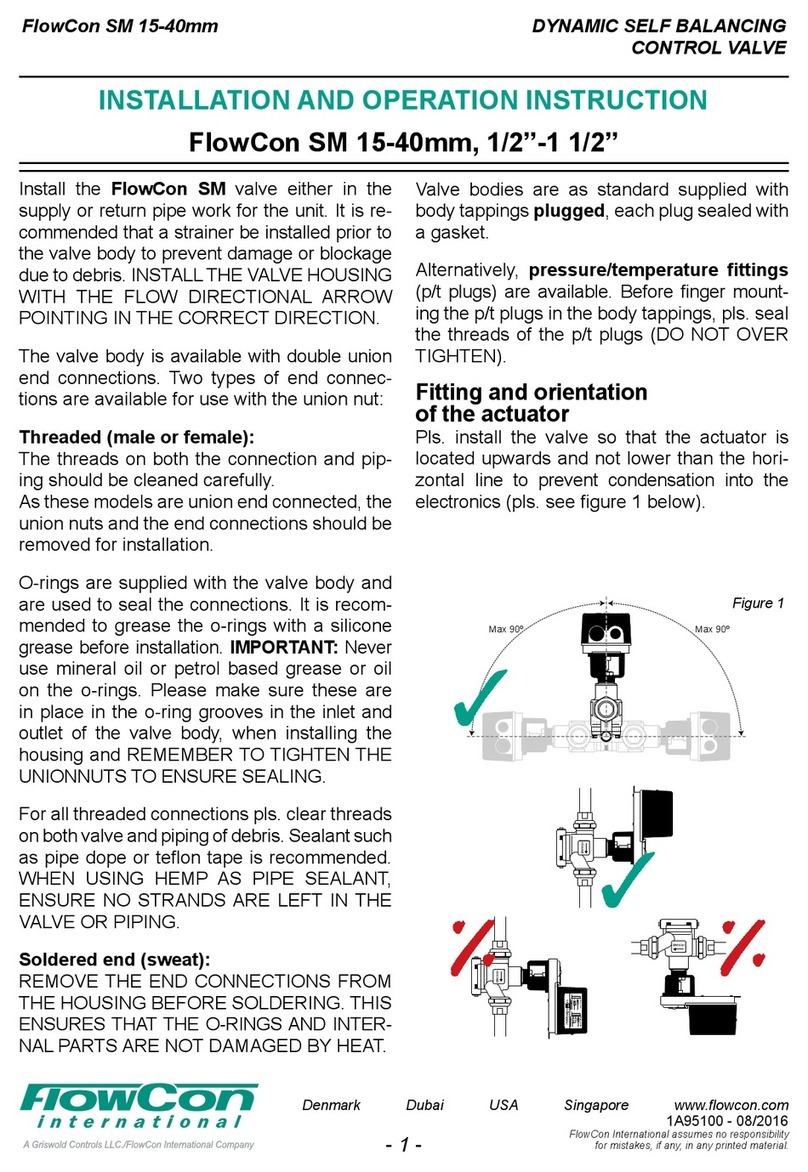

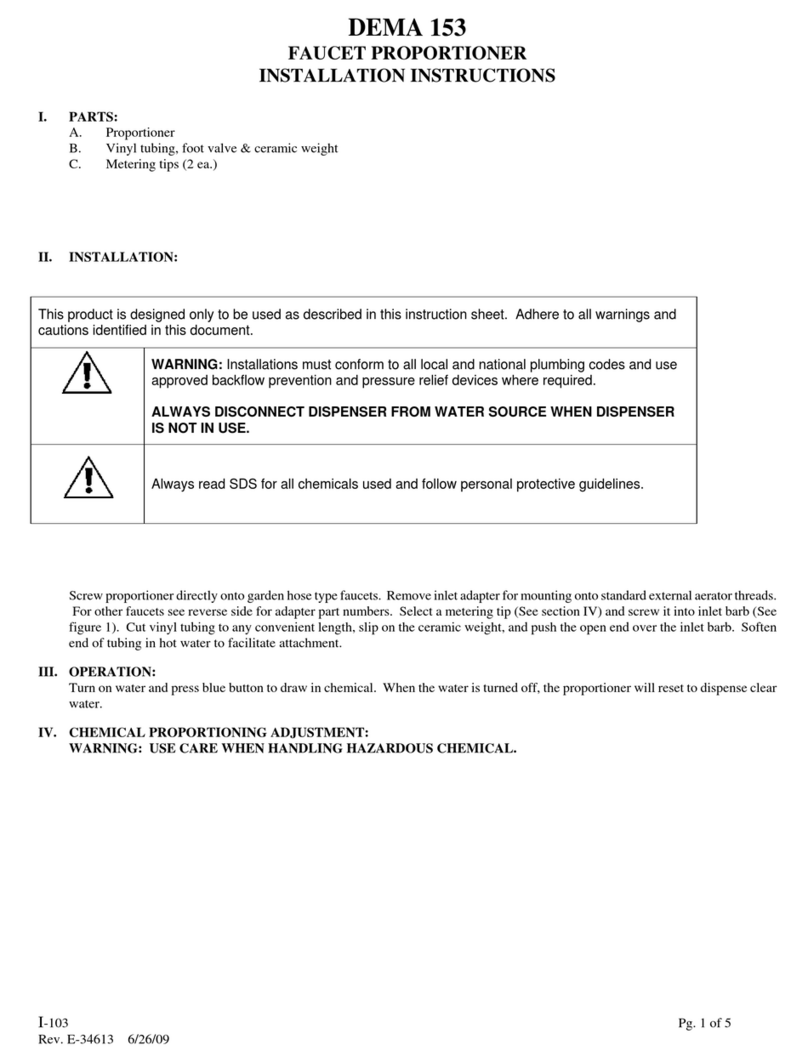

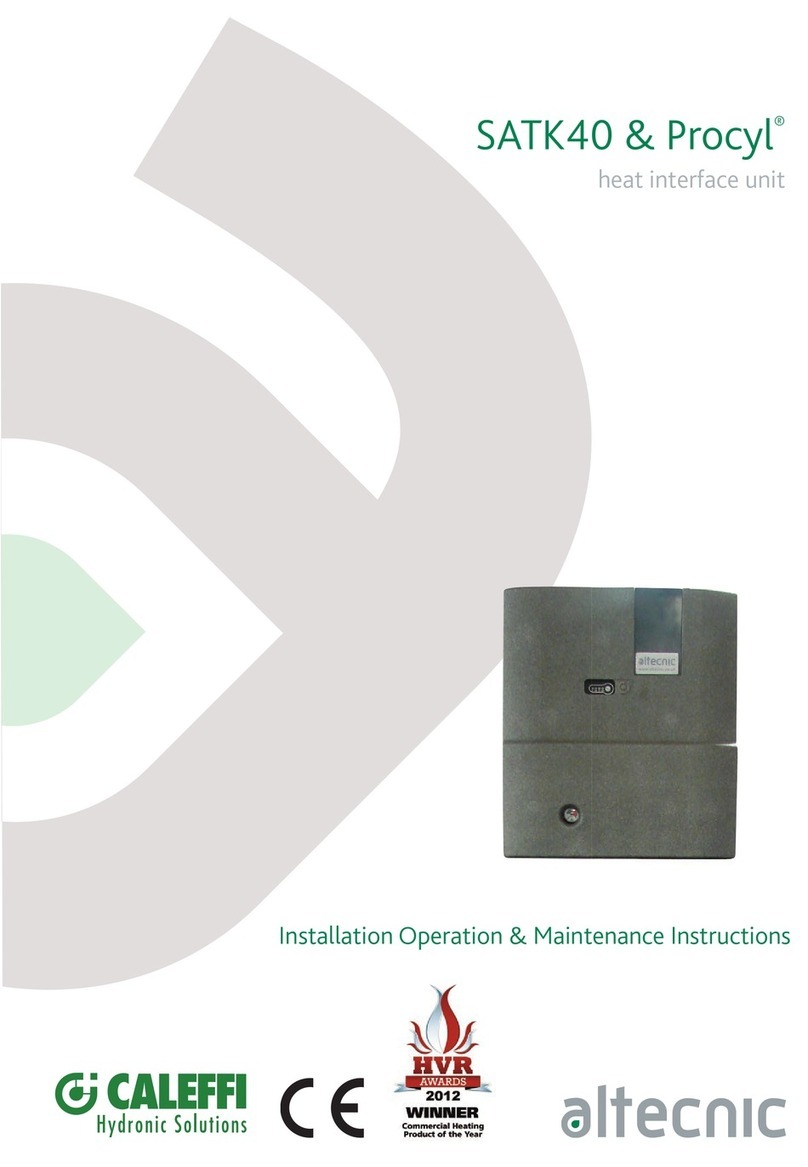

Figure 2

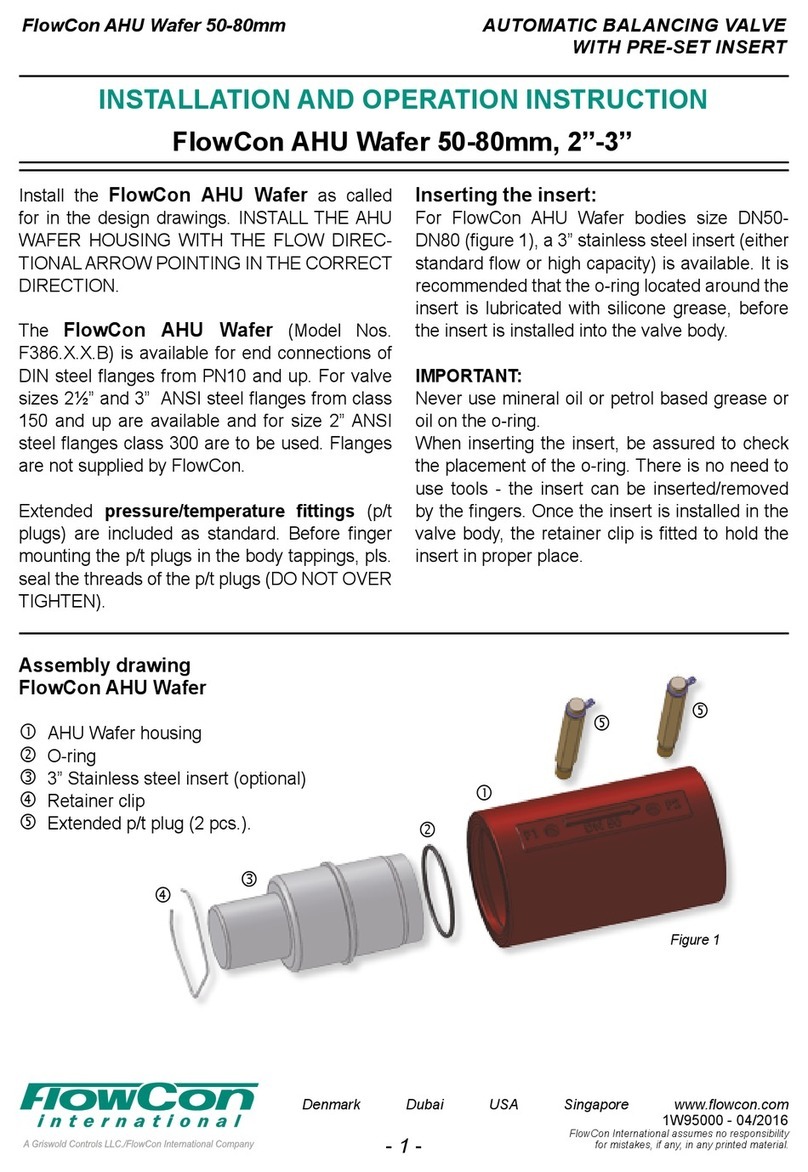

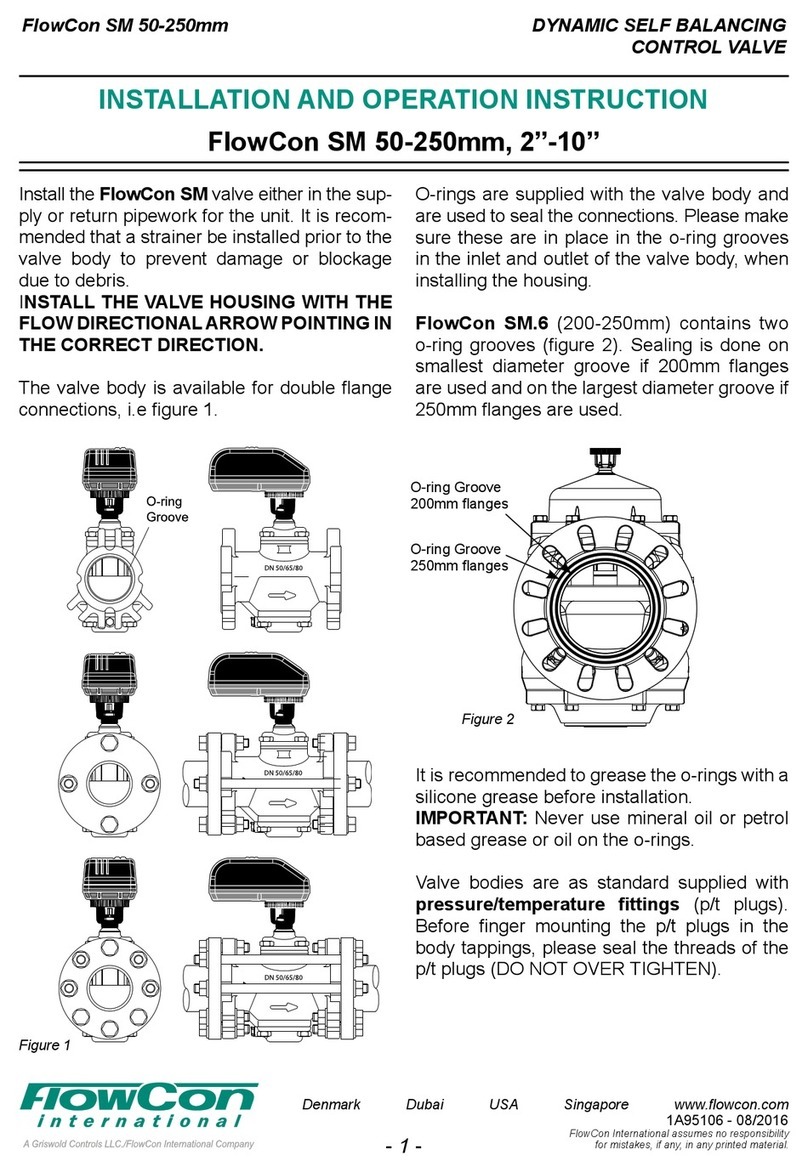

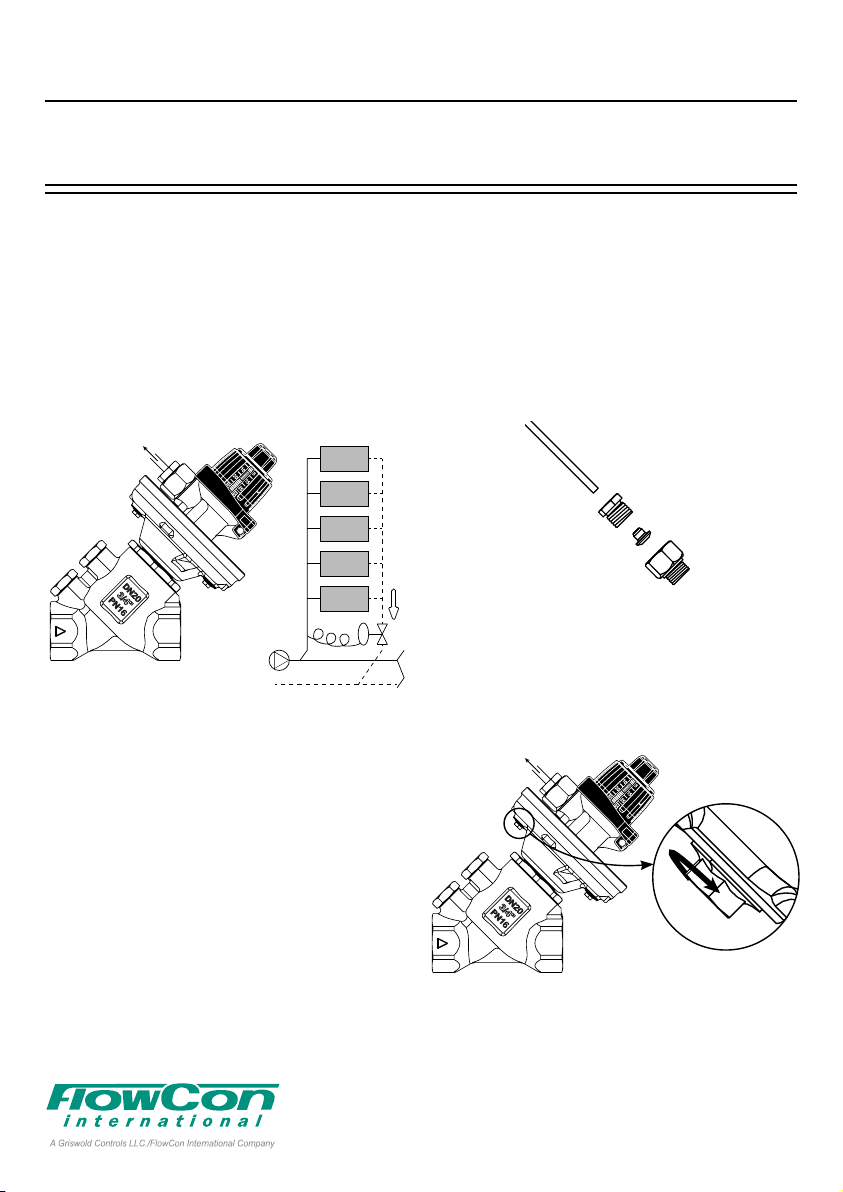

Figure 3

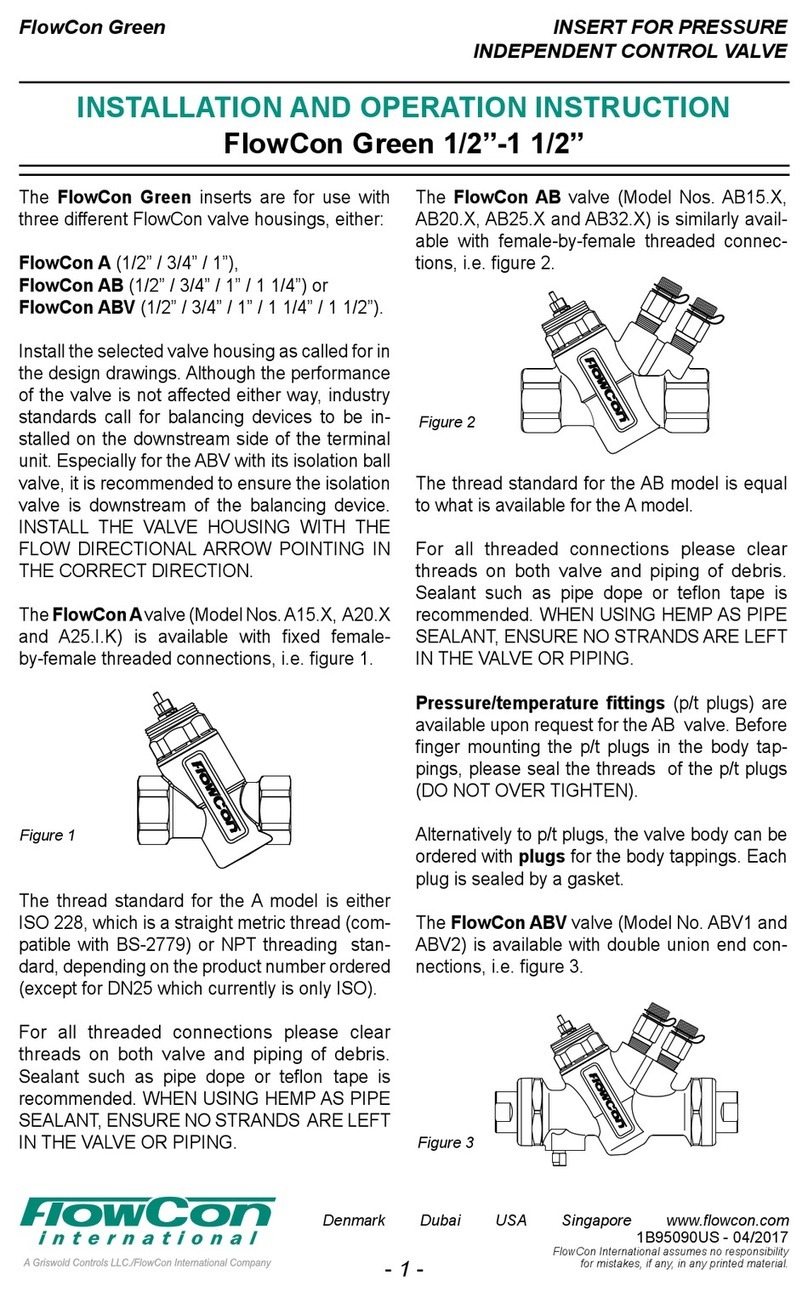

Install the FlowCon DPCV in the return pipe-

work of the riser with connection to the supply

pipework of the riser through the capillary tube

as called for in the design drawings. It is recom-

mended that a strainer be installed prior to the

inlet of the capillary tube to prevent damage or

blockage due to debris. INSTALL THE VALVE

HOUSING WITH THE FLOW DIRECTIONAL

TRIANGLE POINTING IN THE CORRECT DI-

RECTION.

The valve body is available with female threaded

end connections. The thread standard is EN

10226-1, which is a straight metric thread. Please

clear threads on both valve and piping of de-

bris. Sealant such as pipe dope or Teflon tape is

recommended. WHEN USING HEMP AS PIPE

SEALANT, ENSURE NO STRANDS ARE LEFT

IN THE VALVE OR PIPING.

The capillary tube is available with ¼” straight

male end connections with gaskets for sealing.

One end is mounted on the upper part of the

DPCV instead of the black plastic

plug. The other end is mounted at the inlet of the

riser fx. in a FlowCon ABS.

For each end of the capillary tube start by mount-

ing the big nut with the gasket () in the valve

and proceed as shown in figure 2. Pull the small

nut () onto the copper tube () with the thread

toward the end of the tube, and then push the

cutting ring () onto the tube as far as possible.

Push the copper tube into the hole of the big nut

and screw the small nut into the big nut with a

wrench using 12-15Nm.

When the DPCV is installed with the capillary

tube in place and the system is operational,

please vent the capillary tube as shown in figure

3. Open the highest elevated screw byturning it

counter-clockwise max. 2 rotations until water

runs constantly from it, and then close it again.

As standard, the valve body is supplied with

plugs in the body tappings. Each plug is sealed