FlowCon SM 50-250mm Owner's manual

INSTALLATION AND OPERATION INSTRUCTION

DYNAMIC SELF BALANCING

CONTROL VALVE

FlowCon SM 50-250mm

FlowCon International assumes no responsibility

for mistakes, if any, in any printed material.

Denmark Dubai USA Singapore www.owcon.com

1A95106 - 08/2016

- 1 -

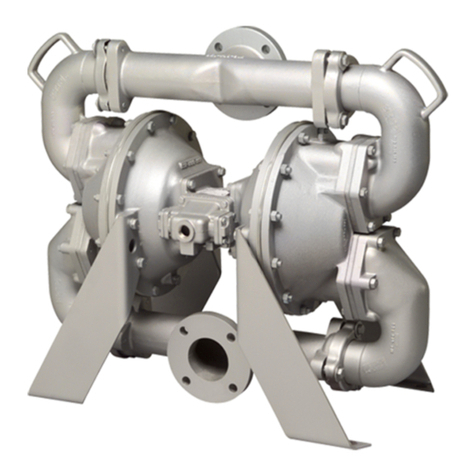

FlowCon SM 50-250mm, 2”-10”

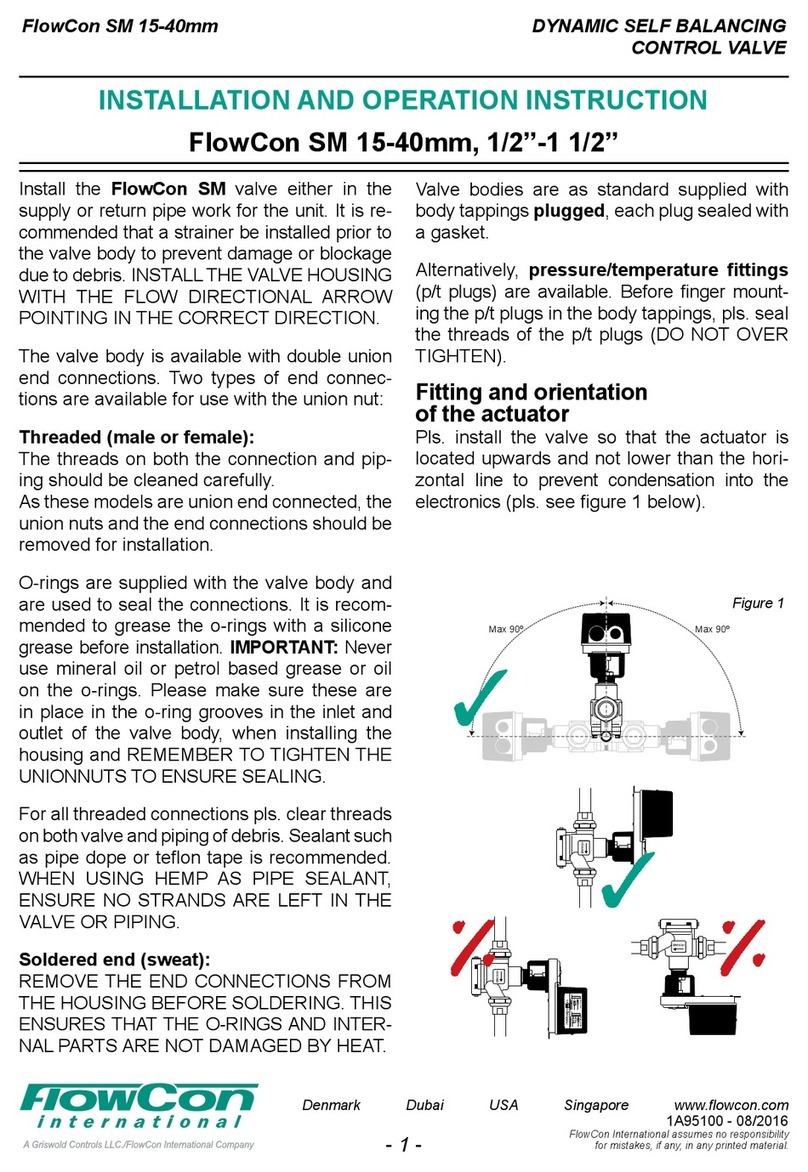

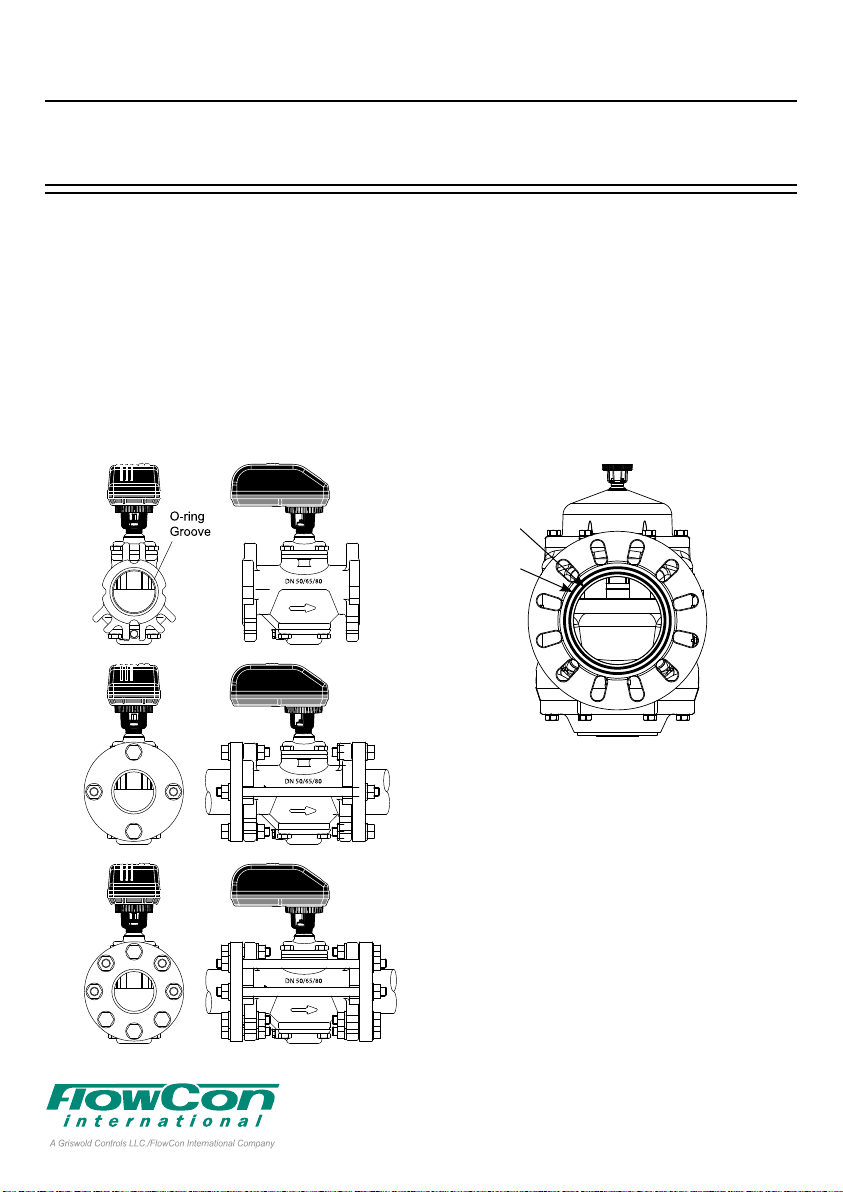

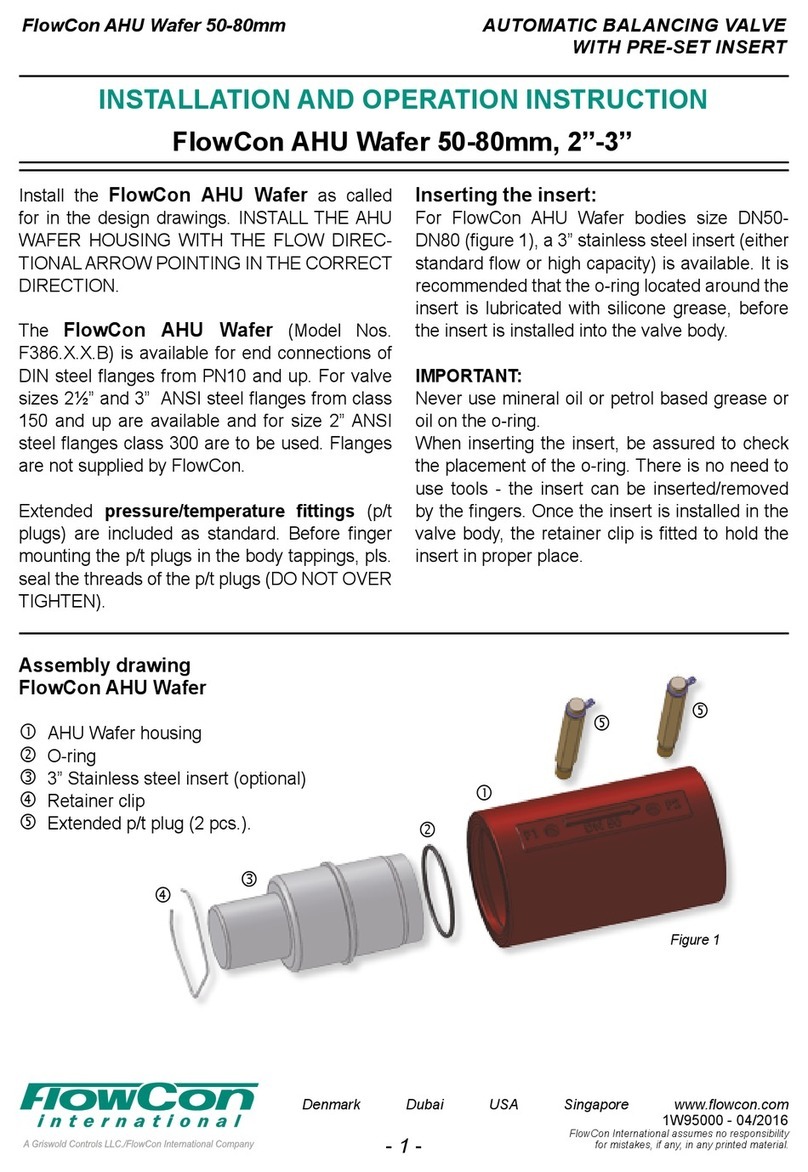

Figure 1

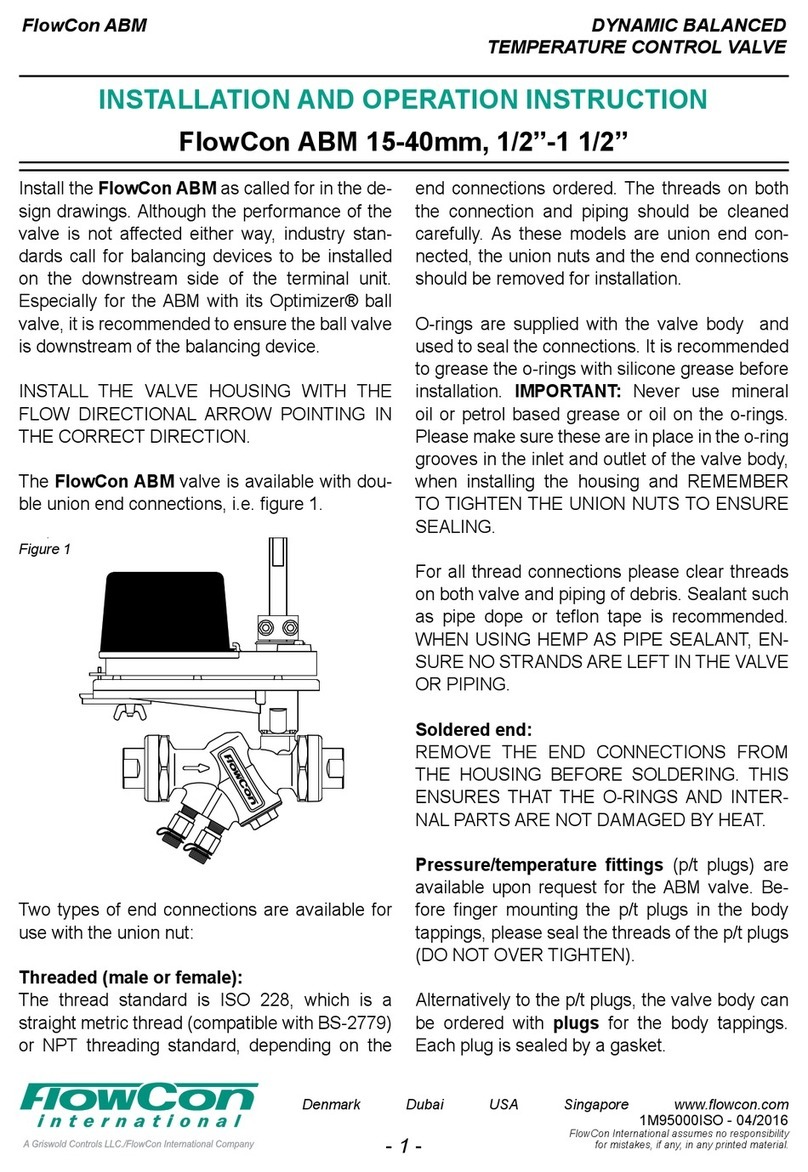

Figure 2

O-ring Groove

200mm anges

O-ring Groove

250mm anges

Install the FlowCon SM valve either in the sup-

ply or return pipework for the unit. It is recom-

mended that a strainer be installed prior to the

valve body to prevent damage or blockage

due to debris.

INSTALL THE VALVE HOUSING WITH THE

FLOW DIRECTIONAL ARROW POINTING IN

THE CORRECT DIRECTION.

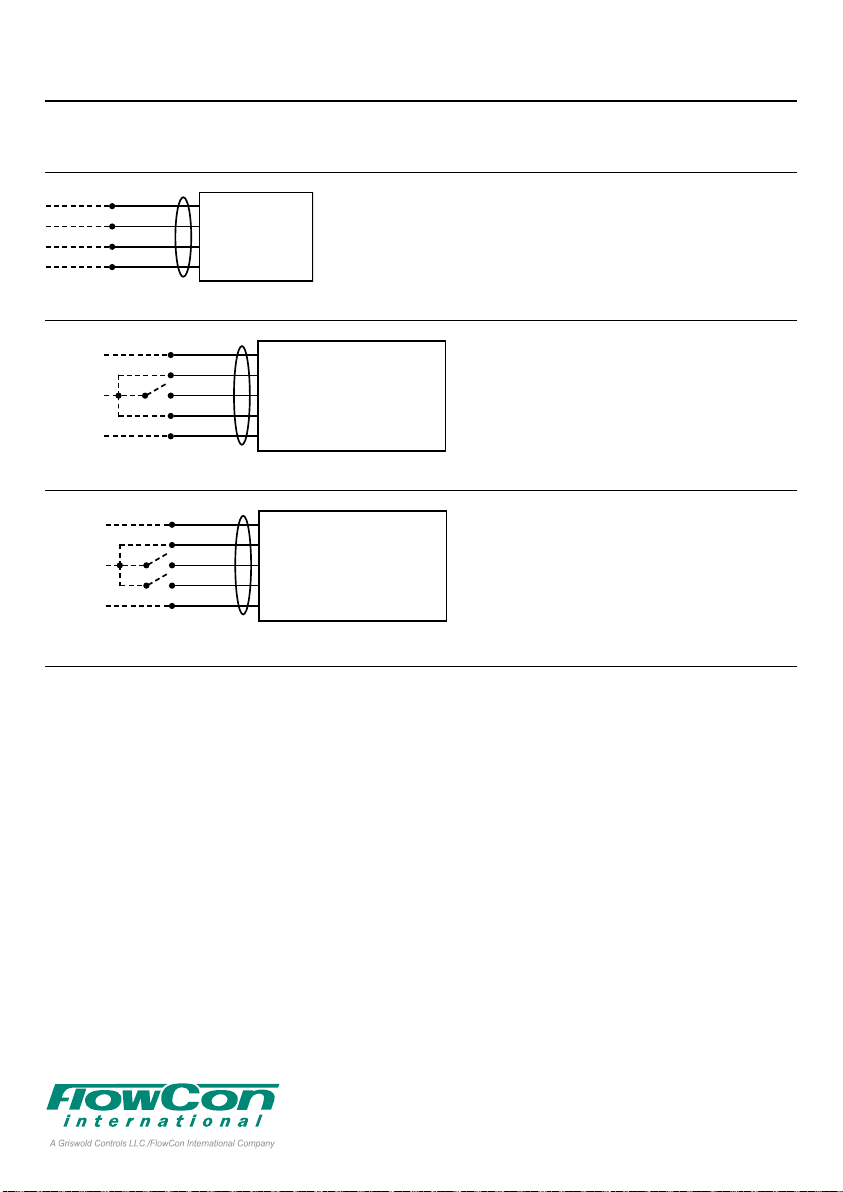

The valve body is available for double flange

connections, i.e figure 1.

O-rings are supplied with the valve body and

are used to seal the connections. Please make

sure these are in place in the o-ring grooves

in the inlet and outlet of the valve body, when

installing the housing.

FlowCon SM.6 (200-250mm) contains two

o-ring grooves (figure 2). Sealing is done on

smallest diameter groove if 200mm flanges

are used and on the largest diameter groove if

250mm flanges are used.

It is recommended to grease the o-rings with a

silicone grease before installation.

IMPORTANT: Never use mineral oil or petrol

based grease or oil on the o-rings.

Valve bodies are as standard supplied with

pressure/temperature fittings (p/t plugs).

Before finger mounting the p/t plugs in the

body tappings, please seal the threads of the

p/t plugs (DO NOT OVER TIGHTEN).

DYNAMIC SELF BALANCING

CONTROL VALVE

FlowCon SM 50-250mm

FlowCon International assumes no responsibility

for mistakes, if any, in any printed material.

Denmark Dubai USA Singapore www.owcon.com

1A95106 - 08/2016

- 2 -

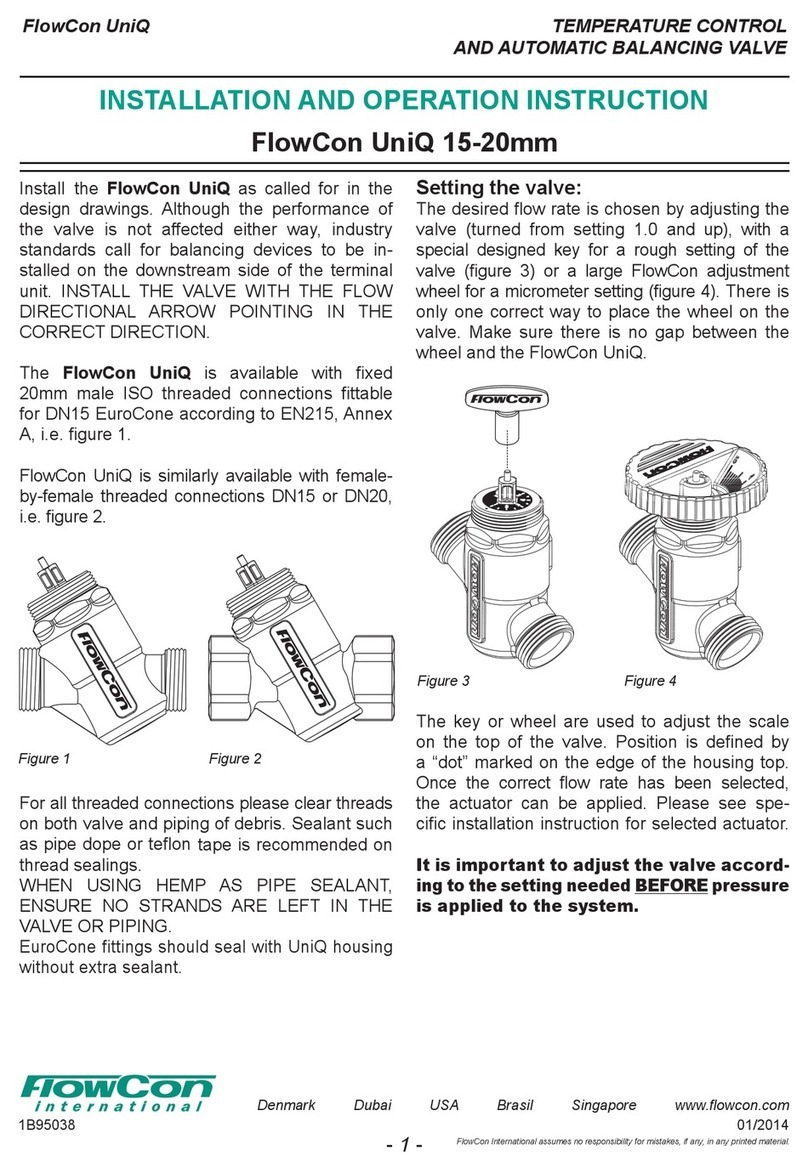

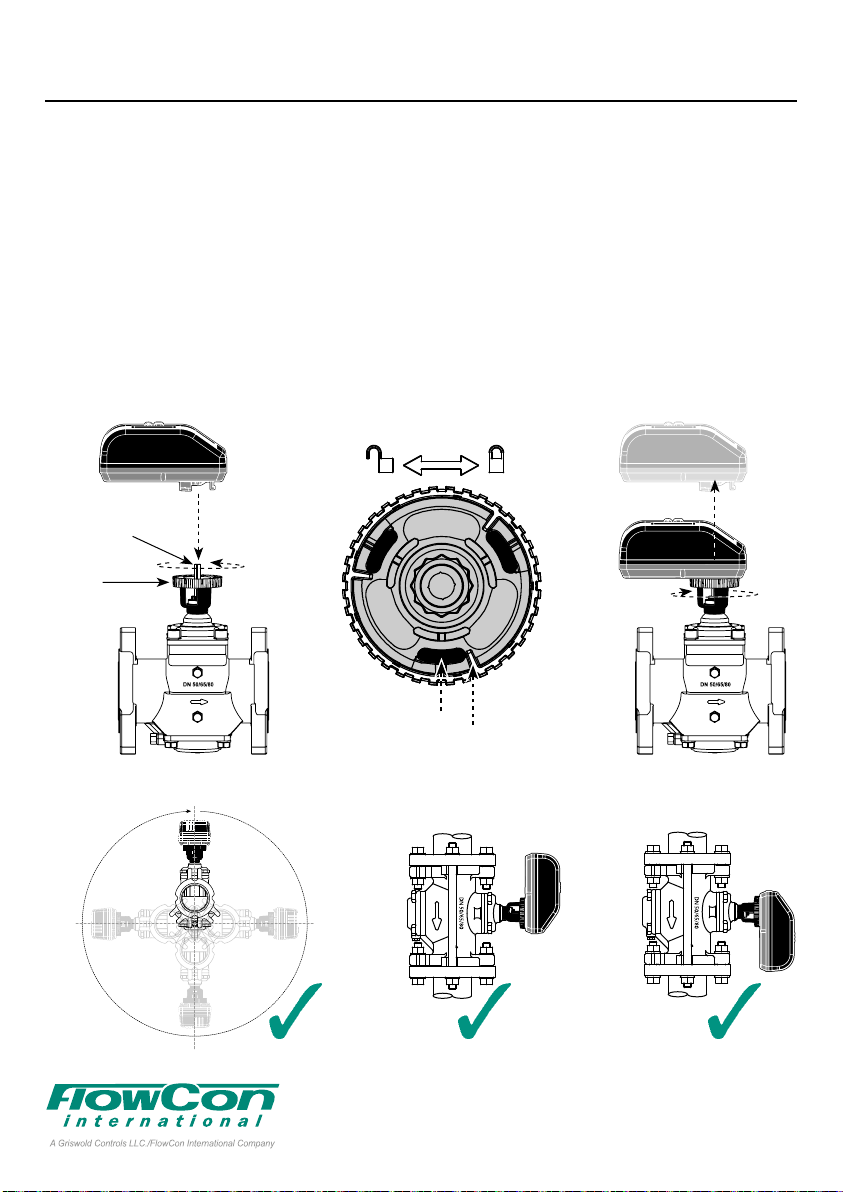

Figure 5Figure 4

The bottom side of the actuator

“Actuator legs”

Snap ring:

Stop points

360º

360º

Figure 6

360º

Figure 3

Spindle adaptor

Snap ring

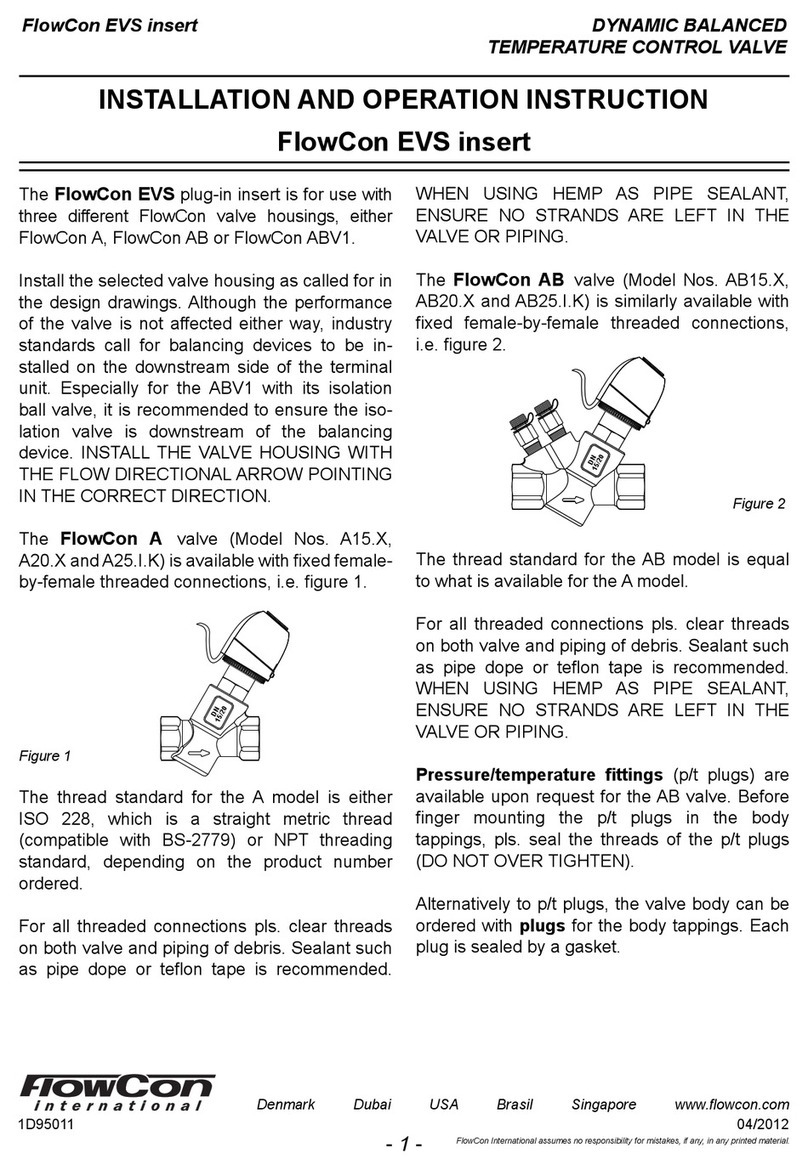

To fit the actuator on the valve body, please

grease the o-ring on the spindle adaptor and

place the spindle adaptor on the valve spindle.

Place the actuator on the spindle adaptor and

place the three actuator “legs” into the three

holes in the mounting bracket. Make sure

that the snap ring is clicked onto the mount-

ing bracket, so that the snap ring is locked at

the top of the mounting bracket, but is able

to rotate. Then turn the snap ring counter

clockwise (upside view) approximately 1/6 of

a turn until its stop points touch the actua-

tor “legs” and the mounting is locked with

a (small) click (please see figure 3 and 4).

To remove the actuator, please reverse the

procedure, i.e. turn the snap ring clockwise

until the actuator is loosened and lift the ac-

tuator up (fig. 5). To ease removal of actuator,

make sure that the valve is not fully closed.

Symbols at the bottom side of the actuator

also indicate how to lock and unlock the actu-

ator with the snap ring.

Fitting and orientation of the actuator

DYNAMIC SELF BALANCING

CONTROL VALVE

FlowCon SM 50-250mm

FlowCon International assumes no responsibility

for mistakes, if any, in any printed material.

Denmark Dubai USA Singapore www.owcon.com

1A95106 - 08/2016

- 3 -

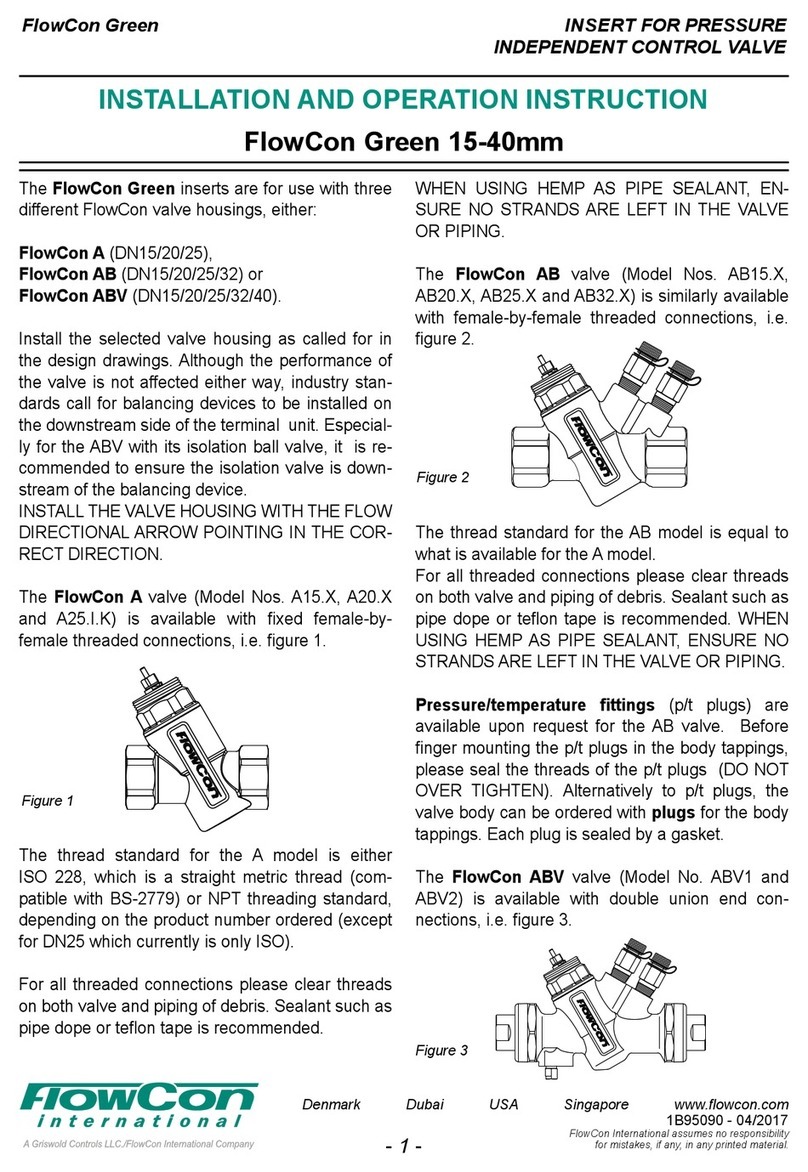

Black

Red

White

Common

24 VAC/VDC

Analog Signal

Analog - No feedback

Black

Red

White

Common

A+

B-

BACnet connection

Black

Red

White

Common

A+

B-

BACnet communication cable

Black

Blue

White

Green

Common

24 VAC/VDC

Control Signal

Feedback

Analog - With feedback

Supply

24 VAC/VDC

Black

Blue

White

Red

Green

Common

24 VAC/VDC

Open if NC, Close if NO

Close if NC, Open if NO

Feedback

Digital - 2 position - With feedback

Supply

24 VAC/VDC

Black

White

Red

Common

Drive CW

Drive CCW

Digital - 3 point floating - No feedback

Supply

24 VAC/VDC

Black

Blue

White

Red

Green

Common

24 VAC/VDC

Open if NC, Close if NO

Close if NC, Open if NO

Feedback

Digital - 3 point floating - With feedback

Black

White

Red

Supply

24 VAC/VDC

Common

Drive CW

Drive CCW

Digital - 2 position - No feedback

Analog

Black

Red

White

Common

24 VAC/VDC

Analog Signal

Analog - No feedback

Black

Red

White

Common

A+

B-

BACnet connection

Black

Red

White

Common

A+

B-

BACnet communication cable

Black

Blue

White

Green

Common

24 VAC/VDC

Control Signal

Feedback

Analog - With feedback

Supply

24 VAC/VDC

Black

Blue

White

Red

Green

Common

24 VAC/VDC

Open if NC, Close if NO

Close if NC, Open if NO

Feedback

Digital - 2 position - With feedback

Supply

24 VAC/VDC

Black

White

Red

Common

Drive CW

Drive CCW

Digital - 3 point floating - No feedback

Supply

24 VAC/VDC

Black

Blue

White

Red

Green

Common

24 VAC/VDC

Open if NC, Close if NO

Close if NC, Open if NO

Feedback

Digital - 3 point floating - With feedback

Black

White

Red

Supply

24 VAC/VDC

Common

Drive CW

Drive CCW

Digital - 2 position - No feedback

Black

Red

White

Common

24 VAC/VDC

Analog Signal

Analog - No feedback

Black

Red

White

Common

A+

B-

BACnet connection

Black

Red

White

Common

A+

B-

BACnet communication cable

Black

Blue

White

Green

Common

24 VAC/VDC

Control Signal

Feedback

Analog - With feedback

Supply

24 VAC/VDC

Black

Blue

White

Red

Green

Common

24 VAC/VDC

Open if NC, Close if NO

Close if NC, Open if NO

Feedback

Digital - 2 position - With feedback

Supply

24 VAC/VDC

Black

White

Red

Common

Drive CW

Drive CCW

Digital - 3 point floating - No feedback

Supply

24 VAC/VDC

Black

Blue

White

Red

Green

Common

24 VAC/VDC

Open if NC, Close if NO

Close if NC, Open if NO

Feedback

Digital - 3 point floating - With feedback

Black

White

Red

Supply

24 VAC/VDC

Common

Drive CW

Drive CCW

Digital - 2 position - No feedback

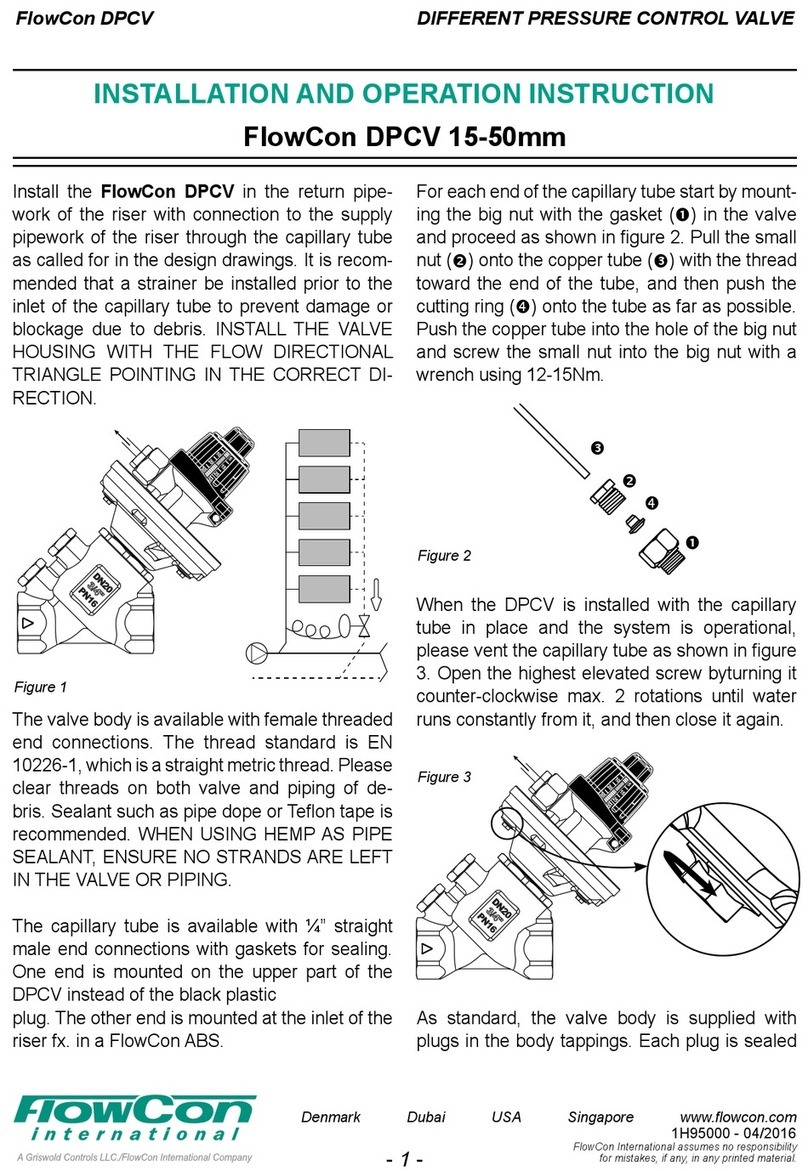

Digital - 3 point oating

If feedback signal is not required, leave green wire detached.

Digital - 2 position

Wiring instructions

Start-Up sequence

When power to the actuator is turned on, the

actuator will automatically calibrate:

• Valve is calibrating to determine closing point.

This calibration can take up to 10 minutes

depending on the valve’s position at start-up.

During calibration lower part of display will

show “CAL”.

•If no control signal is detected, flush is start-

ed if enabled in programming menu (enabled

by default), opening valve to 5/6 of fully open.

Lower part of display will show “FLUSH”

until control signal is detected.

• When control signal is present, actuator will

adjust to current control signal and proceed

with normal operation.

At first start-up please enter programming

menu to adjust actuator settings.

DYNAMIC SELF BALANCING

CONTROL VALVE

FlowCon SM 50-250mm

FlowCon International assumes no responsibility

for mistakes, if any, in any printed material.

Denmark Dubai USA Singapore www.owcon.com

1A95106 - 08/2016

- 4 -

*

*

*

*

*

*

Step Display Description Values

0Password.

*scrolling top:

ENTER PASS WORD

Disabled by default

Password: 3569266.

Only if Enabled (in step 11).

Change one digit at a time, press

and

to move between digits.

At last digit, press

to go to next

step.

1Select language.

*scrolling top:

SELECT LANGUAG

Default: English.

Possibility to choose other languages

later on (not currently an option).

2Select valve model onto which the

actuator is installed.

*scrolling top:

SELECT VALVE MODEL

Default: SM.0.0

Select from the 10 available valve

models.

Options: SM.1.1, SM.2.1...

3Choose unit scale for ow rate.

*scrolling top:

SELECT UNIT SCALE

Default: l/sec.

Options: l/sec or l/hr or GPM.

4Activate Flush mode at start-up.

*scrolling top:

SELECT FLUSH MODE

Default: Enable.

Options: Enable or Disable.

When no control signal (analog) is detected

at start up, ush mode is started (5/6 of fully

opened). It will be dismissed when control

signal is detected.

5Select type of control signal.

*scrolling top:

SELECT CONTROL SIGNAL

Default: 2-10VDC.

Options: 2-10VDC or 4-20mA or digital.

Choose:

• 2-10VDC for VDC

• 4-20mA for mA

• Digital for 2 position or 3 point oating.

Programming Menu

The programming menu is always accesible. To enter the pro-

gramming menu, please simultaneously press

and

for

6 seconds, until bottom line blinks.

Generally, press

to accept value and go to next step and press

button to go to previous step. To change the value, pls. press

or

keys, for quick scroll through values hold down the button.

Press

and

simultaneously for 6 sec. to exit programming

menu. Actuator will automatically return to operation mode if no

action is detected on arrow keys during 1 minute.

All values selected in the programming menu are stored in non-volatile memory.

DYNAMIC SELF BALANCING

CONTROL VALVE

FlowCon SM 50-250mm

FlowCon International assumes no responsibility

for mistakes, if any, in any printed material.

Denmark Dubai USA Singapore www.owcon.com

1A95106 - 08/2016

- 5 -

*

*

*

*

*

*

*

Step Display Description Values

6Select minimum control value.

*scrolling top:

SET MINIMUM LIMIT

Volt default: 2.

Options: from 0-7. Increment: 0.1.

mA default: 4.

Options: from 0-14. Increment: 0.2.

NA if Digital (in step 5).

7Select maximum control value.

*scrolling top:

SET MAXIMUM LIMIT

Volt default: 10.

Options: from 3-10 and at least 3 VDC

greater than the selected minimum

limit. Increment: 0.1.

mA default: 20.

Options: from 6-20 and at least 6 mA

greater than the selected minimum

limit. Increment: 0.2.

NA if Digital (in step 5).

8Select feedback signal.

*scrolling top:

SELECT FEEDBAC SIGNAL

Default: AU; Automatic match of

control signal if analog.

Options: 0-10 VDC, 2-10 VDC or

4-20 mA or AU.

If Digital (in step 5) AU is not an option.

9Set the designed maximum ow.

Accuracy: Greatest of either ±5% of designed

max. ow or ±2% of max. valve ow.

*scrolling top:

SELECT MAXIMUM FLOW

Default: Maximum setting.

Values depend on valve model and

unit scale chosen in step 2 and 3.

Stepping increments as per tech

note.

10 Select direction of rotation.

*scrolling top:

SELECT ROTAT DIRECT

Default: Normally Closed (NC).

Options: Normally Open (NO) or

Normally Closed (NC).

11 Activation of password.

*scrolling top:

ACTIVAT PASS WORD

Default: Disable.

Options: Enable or Disable.

If Enabled password is required

to access alarm and programming

menu.

12 Select direction of rotation when

Failsafe.

*scrolling top:

SELECT FAIL SAFE DIRECT

Default: Closed.

Options: Open or Closed.

Only valid for SM.0.0.0.4 (failsafe

model). Failsafe direction open

means opening to max. ow

chosen in step 9.

Failsafe mode (only SM.0.0.0.4)

If power supply is out of range or lost, failsafe mode will be activated:

1. Approx. 80 sec. delay.

2. Actuator opens/closes valve (according to failsafe direction chosen in programming menu).

3. Actuator shuts off.

If power supply is restored during action 1. or 2., failsafe mode is deactivated.

DYNAMIC SELF BALANCING

CONTROL VALVE

FlowCon SM 50-250mm

FlowCon International assumes no responsibility

for mistakes, if any, in any printed material.

Denmark Dubai USA Singapore www.owcon.com

1A95106 - 08/2016

- 6 -

Information

Current ow rate1.

Indicates current ow rate in

l/sec, l/hr or GPM.

Display Description Values

Indicates unit scale system. l/sec or l/min or GPM.

mA or VDC.

Indicates battery level. Basic version with no battery (SM.0.0.0.3)

Failsafe version with battery (SM.0.0.0.4)

Battery level low, charging needed.

Medium battery level.

Battery charged.

Alarm indicator. Blinking if actuator is still functional (warning).

Fully on if actuator is not working (critical).

CONTROL SIGNAL 2.0 VDC

FEEDBAC SIGNAL 2.0 VDC

VALVE SM. 3.1

pressur range 35-400 kpad

MAXIMUM FLOW RATE 6.580 L/SEC

OPERAT DIRECT NC

FAIL SAFE DIRECT CLOSE

ERROR CODE 01

Information

Control signal Indicates value of control signal. 0-10 VDC or 0-20 mA or Open/Stop/Close

Feedback signal Indicates value of feedback signal. 0-10 VDC or 0-20 mA.

Valve Indicates valve model. SM.1.1, SM.2.1...

Pressure range Indicates pressure range. 32-320 kPaD, 40-320 kPaD.....

Maximum ow rate Indicates selected maximum

designed ow rate.

Depends on valve etc.

l/sec, l/hr or GPM.

Operational direction Indicates direction of rotation. NO or NC.

Failsafe direction Indicates failsafe direction. Open or Closed

Only valid for SM.0.0.0.4

Critical Alarm Indicates alarm error code. 01, 03, 05 (without failsafe) or 06.

Only if critical alarm is present.

In Operation

Note 1: Note that the ow rate displayed on the actuator is a calculated value based upon differential pressure being within control range.

If display shows “NA” instead of current ow rate, it indicates that the ow rate is below minimum dened ow rate according

to tech note, or that valve model has not been chosen in programming menu step 2.

Use

to go to next information line and

to go to the previous.

DYNAMIC SELF BALANCING

CONTROL VALVE

FlowCon SM 50-250mm

FlowCon International assumes no responsibility

for mistakes, if any, in any printed material.

Denmark Dubai USA Singapore www.owcon.com

1A95106 - 08/2016

- 7 -

Alarm Menu

To enter the alarm menu, please simultaneously press

and

for 6 seconds.

You can access the alarm menu only if an alarm is present (i.e when icon ⚠is displayed).

Press

to go to the next alarm display, press

to return to previous step.

Press

and

simultaneously for 6 seconds to exit alarm menu.

Actuator will automatically return to operation mode if no action is detected on arrow keys during

1 minute.

In case of ERRORS or ALARM

If actuator is still functioning (error 02, 04, 05 with failsafe and 07 with failsafe) the ALARM icon ⚠will flash.

Error codes can be found in the alarm menu.

If actuator is not functioning (error 01, 03, 05 without failsafe and 06) the ALARM icon ⚠is turned on.

The error code will be available in the information in the upper part of the display and the alarm menu.

Display Description Action

Alarm.

Enter password. If enabled in programming menu step 11

Disabled by default. Password: 3569266.

Code Icon Description Details

01 Valve/actuator is overtorqued. Operation is stopped. Actuator will retry operation

every 4 minutes. If over torque condition

disappear, error will convert to error code 02.

02 Actuator has reached its torque

limit in the past.

Actuator is functioning.

To reset the alarm simultaneously press

and

for 6 seconds.

03 Critical - over temperature. Critical: Temperature in actuator is at least 70ºC,

motor operation is stopped. If temperature is

decreasing, operation will resume.

04 High temperature. Actuator is still functioning. Temperature in actua-

tor is at least 50ºC as limited according to tech

note. If temperature is decreasing, operation will

resume.

05 No Failsafe: Power supply not in

range.

Operation is stopped. Alarm will automatically

reset when voltage is back in range.

With Failsafe: Power supply not

detected / not in range.

Failsafe is activated. Alarm will automatically

reset when voltage is back in range.

06 Control signal not detected. Operation is stopped. Alarm will automatically

reset when control signal is back in range.

07 Battery error. Battery is not properly connected. Alarm will reset

when battery is properly connected.

Only valid for SM.0.0.0.4.

FULL ON

BLINKING

BLINKING

BLINKING

BLINKING

FULL ON

FULL ON

FULL ON

DYNAMIC SELF BALANCING

CONTROL VALVE

FlowCon SM 50-250mm

FlowCon International assumes no responsibility

for mistakes, if any, in any printed material.

Denmark Dubai USA Singapore www.owcon.com

1A95106 - 08/2016

- 8 -

Auto-stroke - re-calibration

In case the valve does not operate as expect-

ed, start the auto-stroke sequence to re-cali-

brate the closing point of the valve and to

make sure that the actuator is able to open the

valve fully. Press buttons

and

simultane-

ously for 6 seconds to start the auto-stroke.

Auto-stroke sequence

(display shows: “AUTO STROKE CYCLES”):

1.Valve is closed to determine closing point.

2.Valve is opened fully (independent of max.

flow chosen).

3. System returns to normal operation.

If actuator is not able to open valve fully, an

error will be displayed. An auto-stroke cannot

be cancelled.

Manual override

Manual override is used to temporarily set the

position of the valve regardless of the settings

and control signal for the actuator.

1. Turn off power to the actuator.

2. Remove actuator from valve as described.

3. Turn spindle to the relevant position (Clock-

wise to close valve, counter clockwise to

open valve). Be sure not to use more than

10 Nm torque. Please protect actuator from

water while not on valve.

4. Re-mount actuator on valve as described.

5. Turn on power to the actuator when normal

operation is needed.

General

Water must always be suitable treated, clean

and free of debris. It is recommended that a

strainer be installed prior to the valve body to

prevent damage or blockage due to debris.

Ensure that the valve is not in the fully closed

position when filling the system with water.

Further, it is recommended not to exceed

maximum differential pressure control range.

Warranty obligation

Failure to abide by all recommendations as

per this installation and operation instruction

will void warranty.

Do not remove cover from actuator. Opening

cover will void warranty.

When manually operating the valve (actuator

disconnected) do not use more than 10 Nm

torgue. Using more than 10 Nm torgue will

void warranty.

For latest updates please see www.flowcon.com

Table of contents

Other FlowCon Control Unit manuals

FlowCon

FlowCon EVS User manual

FlowCon

FlowCon Green Owner's manual

FlowCon

FlowCon Green.3 DN40 Owner's manual

FlowCon

FlowCon SM.3.0 User manual

FlowCon

FlowCon AHU Wafer Owner's manual

FlowCon

FlowCon PIM-DP User manual

FlowCon

FlowCon S-JUST Owner's manual

FlowCon

FlowCon Green Owner's manual

FlowCon

FlowCon FlowCon Green Series Owner's manual

FlowCon

FlowCon Green.3 Series Owner's manual