FlowCon EVS User manual

INSTALLATION AND OPERATION INSTRUCTION

1D95011 04/2012

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

Denmark Dubai USA Brasil Singapore www.flowcon.com

FlowCon EVS insert

- 1 -

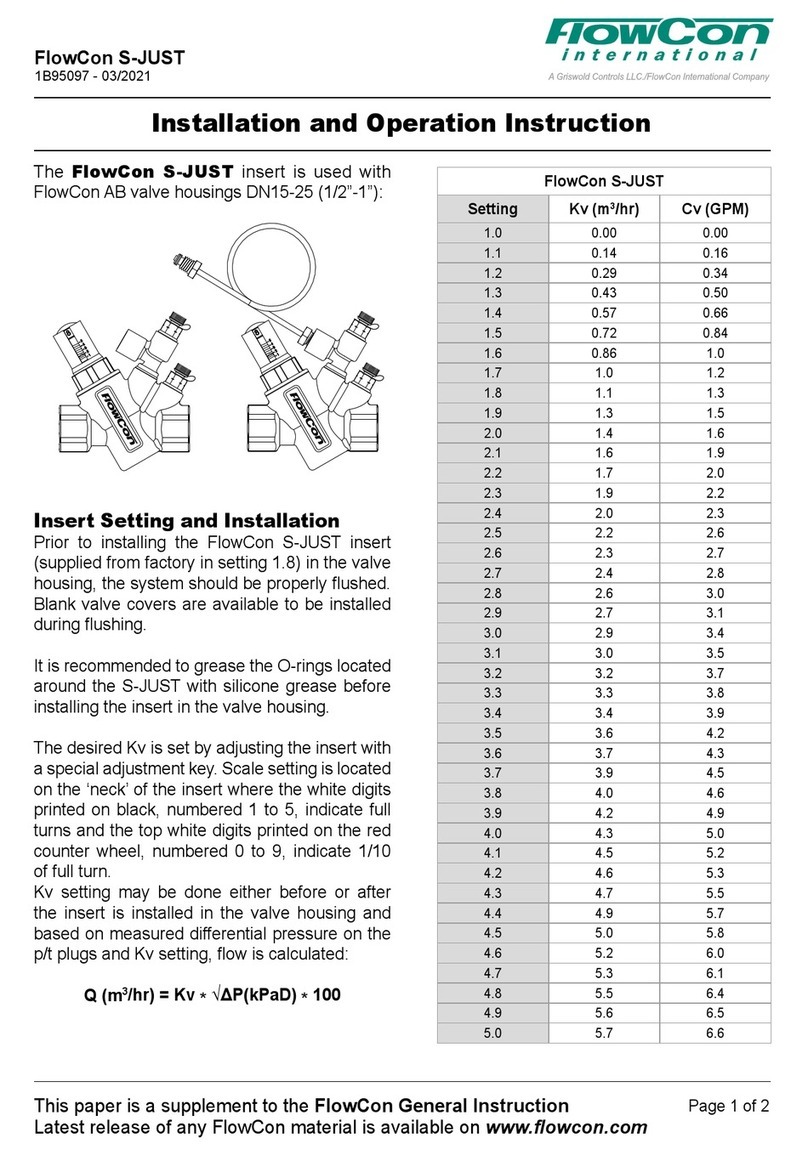

FlowCon EVS insert

DN

15/20

Figure 1

DN

15/20

Figure 2

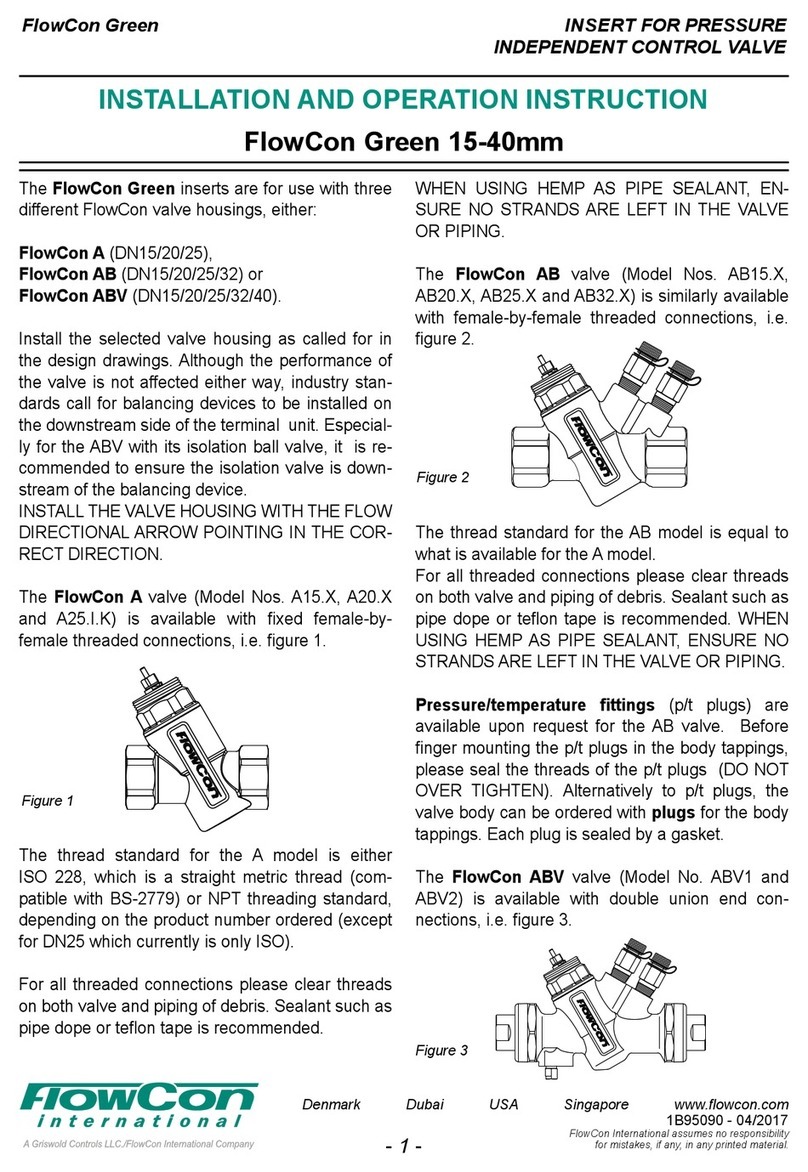

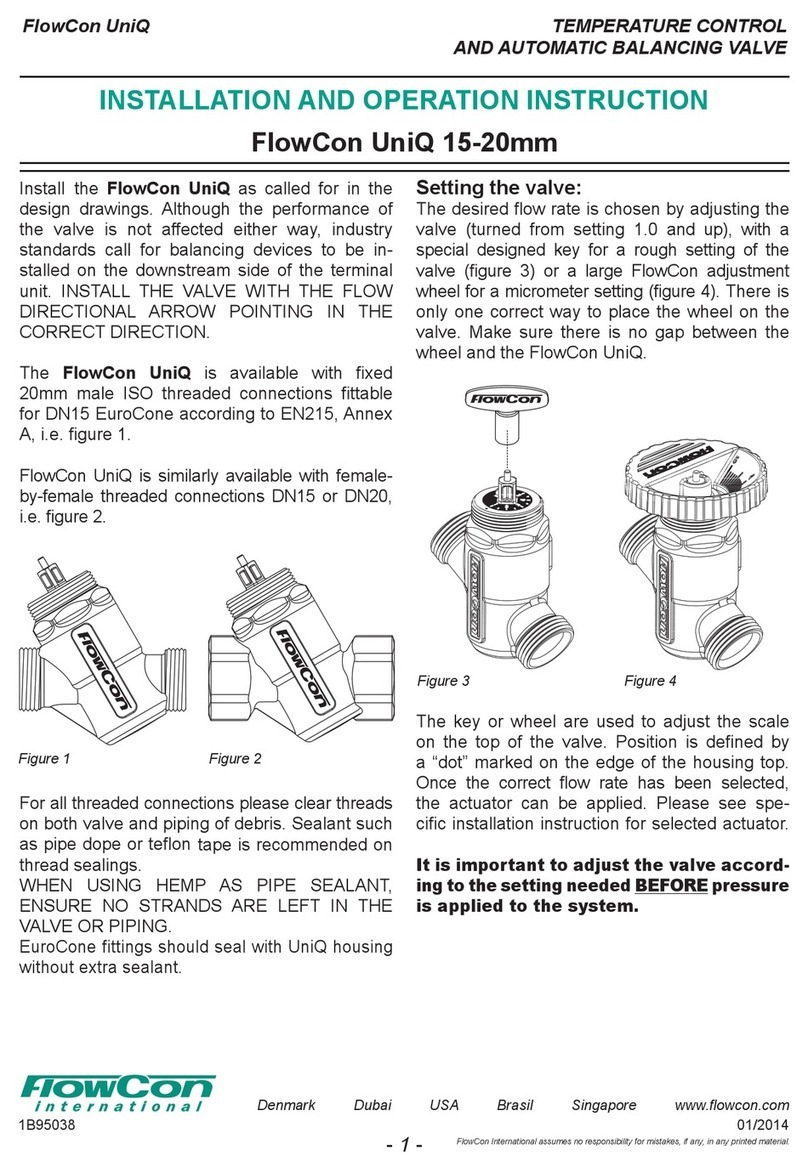

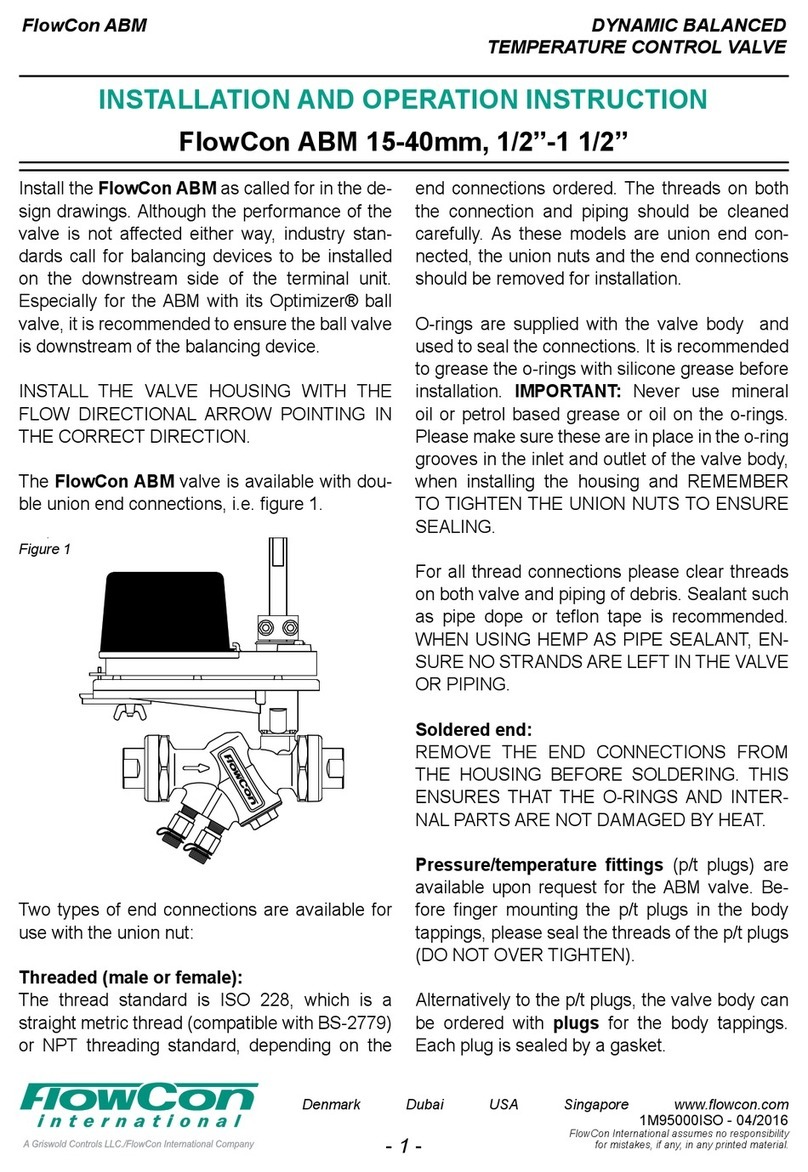

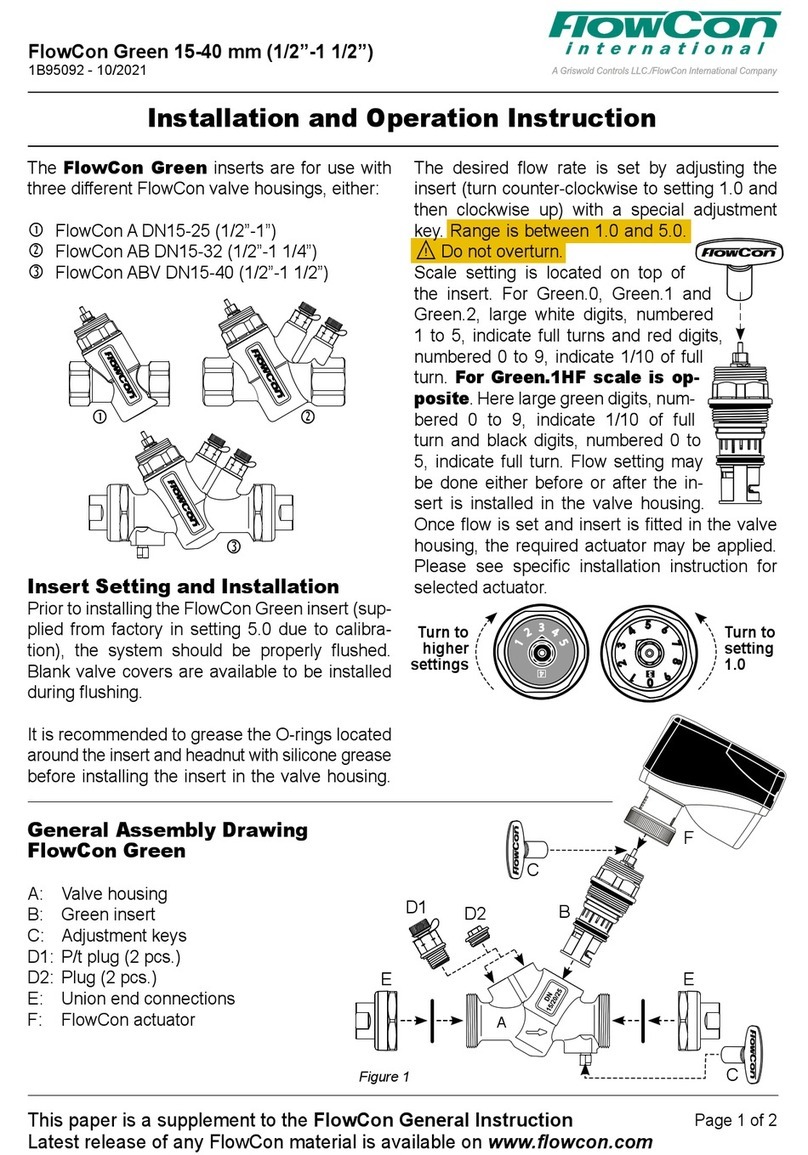

The FlowCon EVS plug-in insert is for use with

three different FlowCon valve housings, either

FlowCon A, FlowCon AB or FlowCon ABV1.

Install the selected valve housing as called for in

the design drawings. Although the performance

of the valve is not affected either way, industry

standards call for balancing devices to be in-

stalled on the downstream side of the terminal

unit. Especially for the ABV1 with its isolation

ball valve, it is recommended to ensure the iso-

lation valve is downstream of the balancing

device. INSTALL THE VALVE HOUSING WITH

THE FLOW DIRECTIONAL ARROW POINTING

IN THE CORRECT DIRECTION.

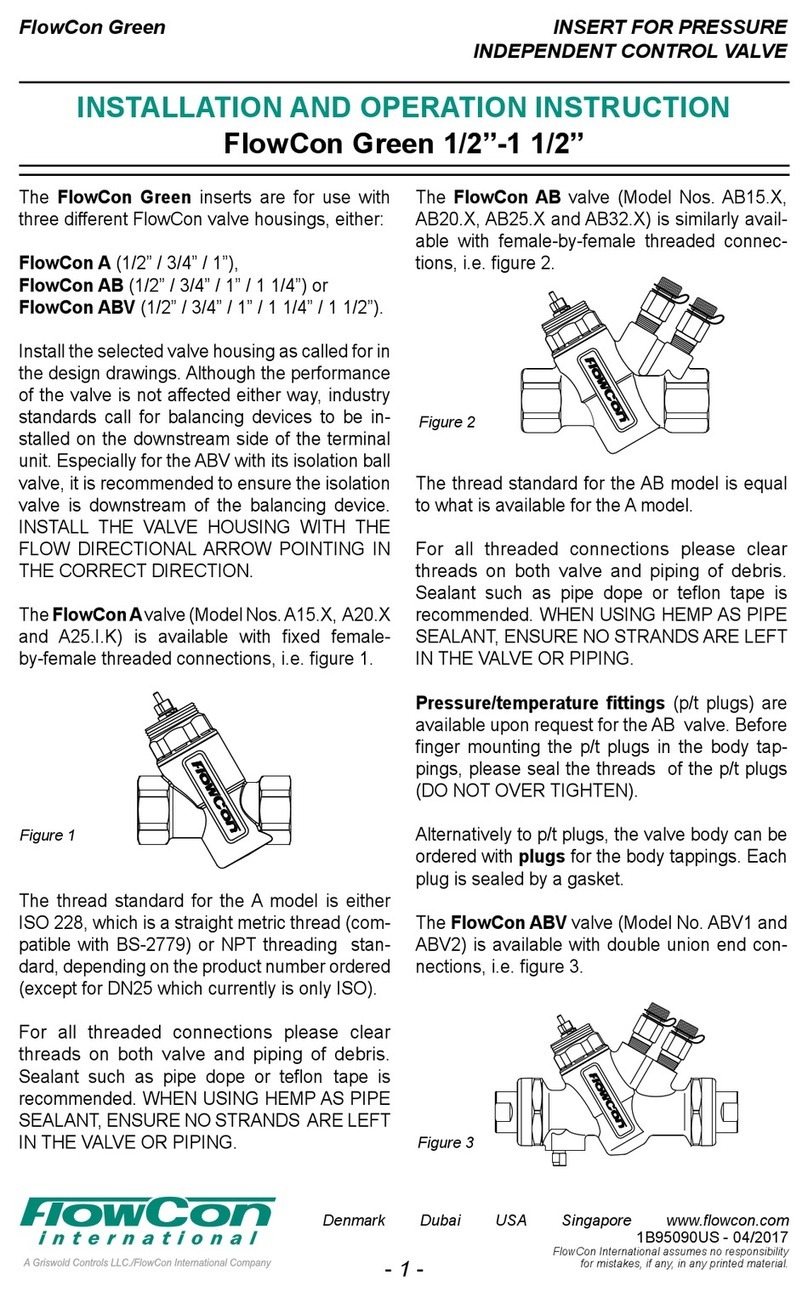

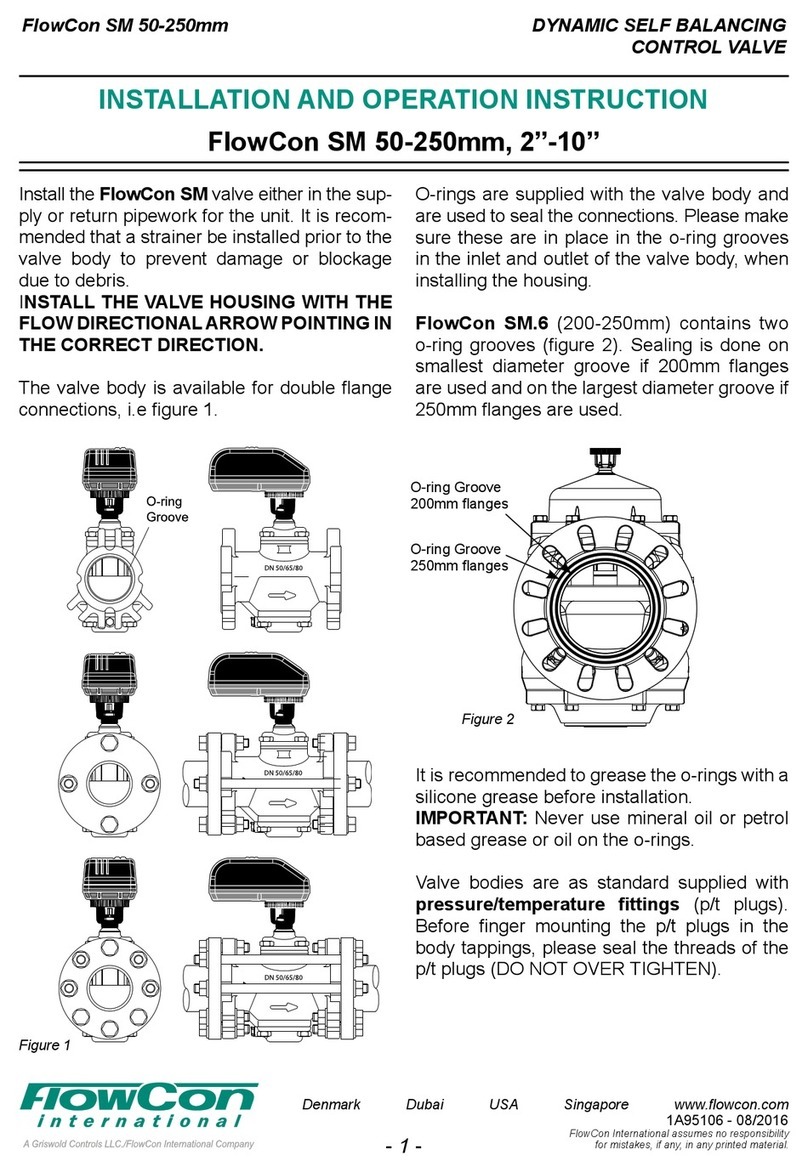

The FlowCon A valve (Model Nos. A15.X,

A20.X and A25.I.K) is available with fixed female-

by-female threaded connections, i.e. figure 1.

The thread standard for the A model is either

ISO 228, which is a straight metric thread

(compatible with BS-2779) or NPT threading

standard, depending on the product number

ordered.

For all threaded connections pls. clear threads

on both valve and piping of debris. Sealant such

as pipe dope or teflon tape is recommended.

WHEN USING HEMP AS PIPE SEALANT,

ENSURE NO STRANDS ARE LEFT IN THE

VALVE OR PIPING.

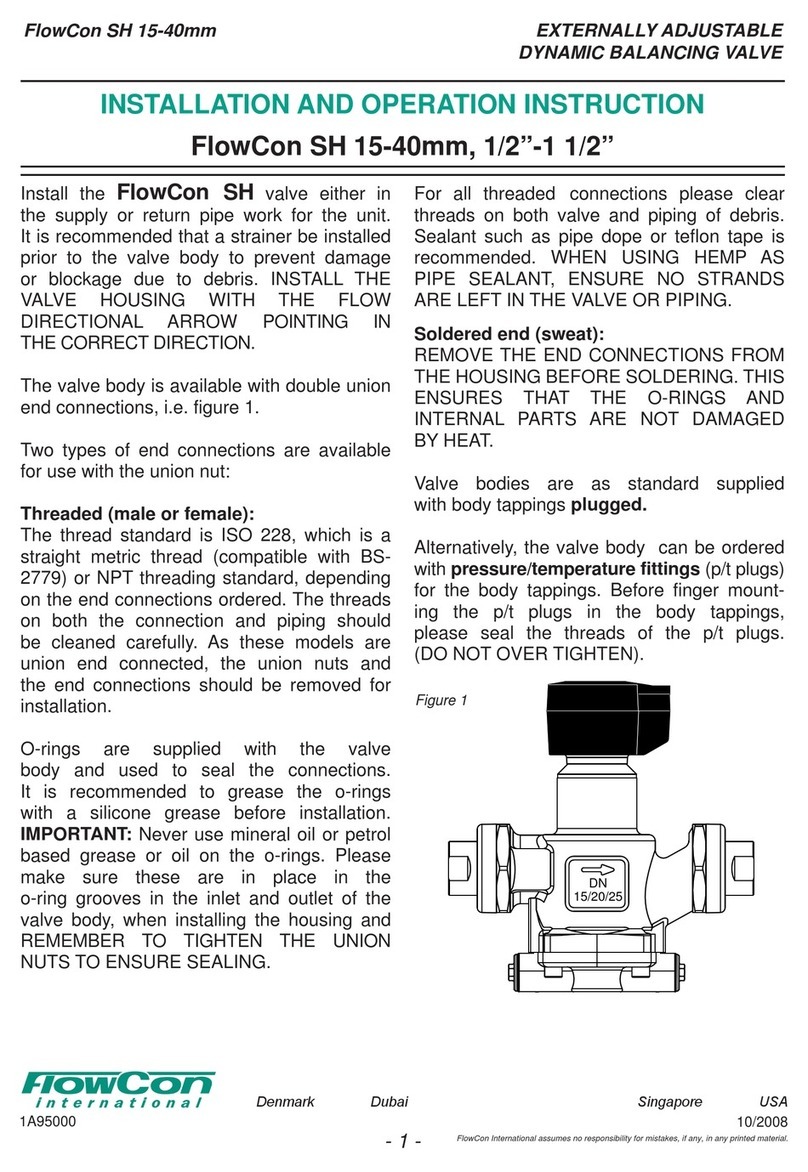

The FlowCon AB valve (Model Nos. AB15.X,

AB20.X and AB25.I.K) is similarly available with

fixed female-by-female threaded connections,

i.e. figure 2.

The thread standard for the AB model is equal

to what is available for the A model.

For all threaded connections pls. clear threads

on both valve and piping of debris. Sealant such

as pipe dope or teflon tape is recommended.

WHEN USING HEMP AS PIPE SEALANT,

ENSURE NO STRANDS ARE LEFT IN THE

VALVE OR PIPING.

Pressure/temperature fittings (p/t plugs) are

available upon request for the AB valve. Before

finger mounting the p/t plugs in the body

tappings, pls. seal the threads of the p/t plugs

(DO NOT OVER TIGHTEN).

Alternatively to p/t plugs, the valve body can be

ordered with plugs for the body tappings. Each

plug is sealed by a gasket.

Denmark Dubai USA Brasil Singapore www.flowcon.com

1D95011 04/2012

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

FlowCon EVS insert

- 2 -

DN

15/20/25

Figure 3

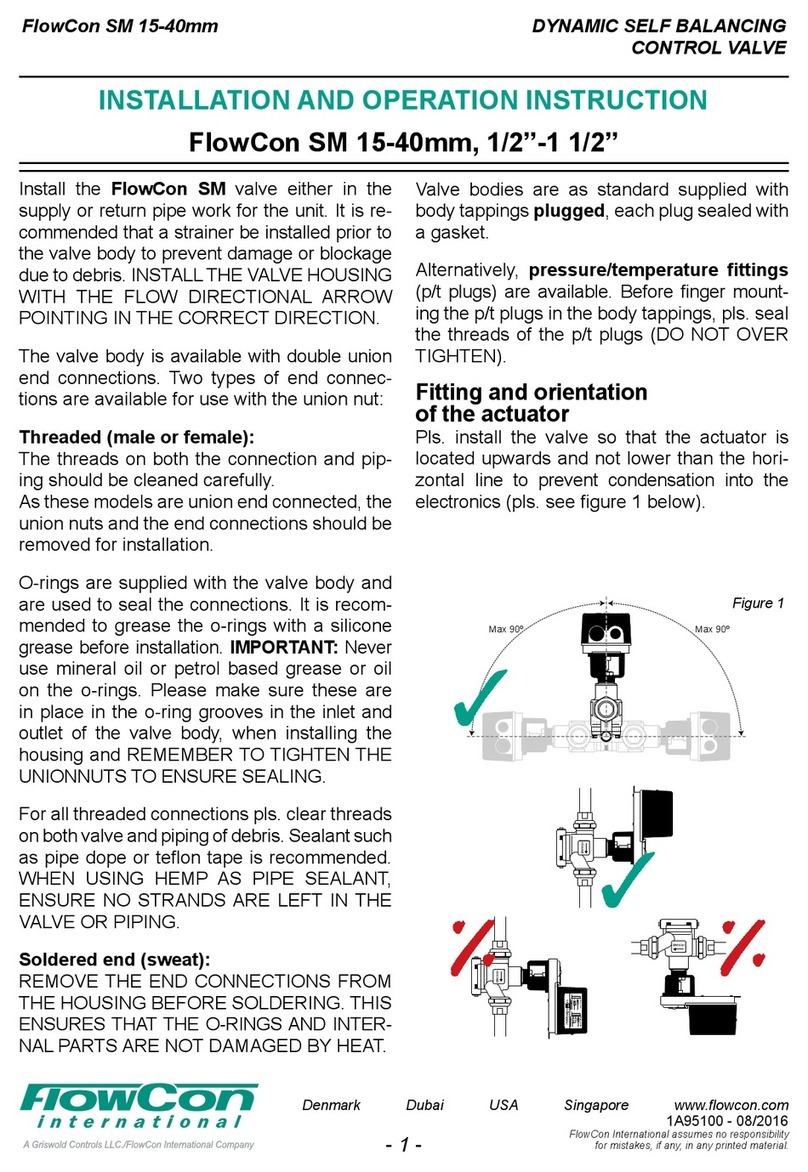

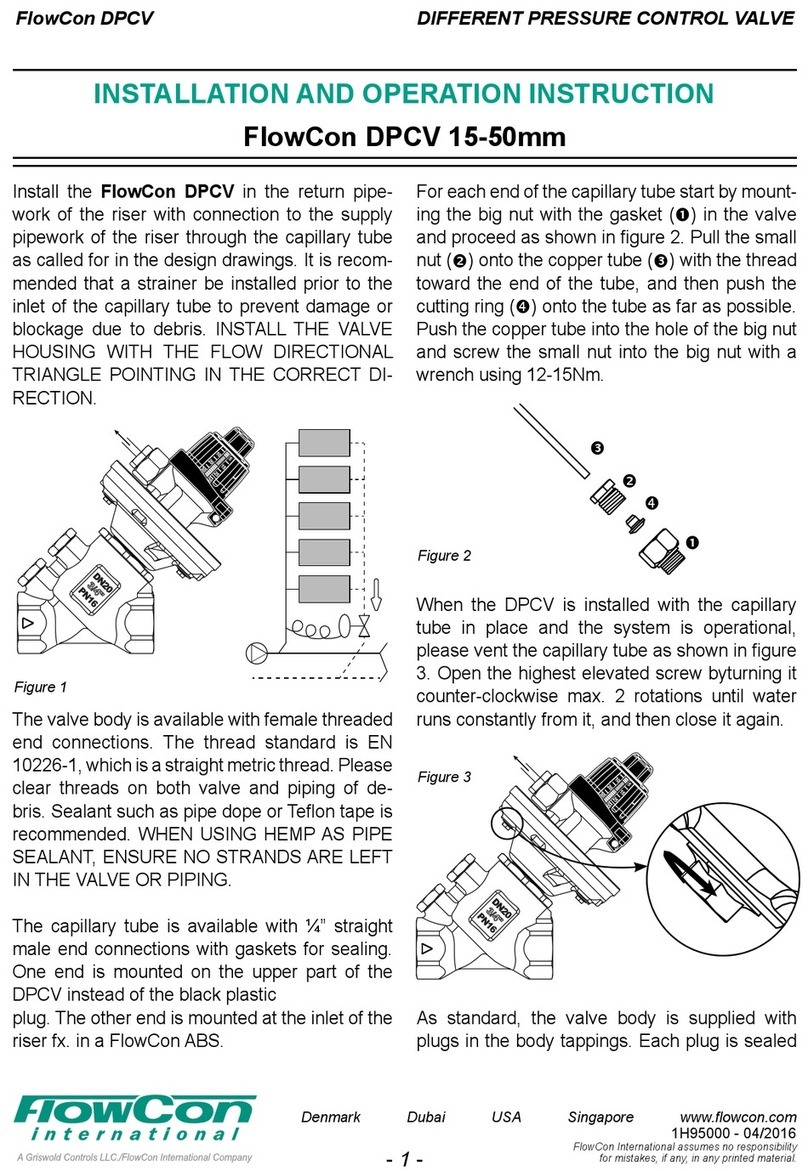

The FlowCon ABV valve (Model No. ABV1)

is available with double union end connections,

i.e. figure 3.

Two types of end connections are available

for use with the union nut:

Threaded (male or female):

The thread standard is ISO 228 which is a

straight metric thread (compatible with BS-2779)

or NPT threading standard, depending on the

end connections ordered. The threads on both

the connection and piping should be cleaned

carefully. As these models are union end con-

nected, the union nuts and the end connections

should be removed for installation.

O-rings are supplied with the valve body and

used to seal the connections. It is recommended

to grease the o-rings with silicone grease before

installation. IMPORTANT: Never use mineral

oil or petrol based grease or oil on the o-rings.

Please make sure these are in place in the

o-ring grooves in the inlet and outlet of the

valve body, when installing the housing and

REMEMBER TO TIGHTEN THE UNION NUTS

TO ENSURE SEALING.

For all threaded connections pls. clear threads

on both valve and piping of debris. Sealant such

as pipe dope or teflon tape is recommended.

WHEN USING HEMP AS PIPE SEALANT,

ENSURE NO STRANDS ARE LEFT IN THE

VALVE OR PIPING.

Soldered end (sweat):

REMOVE THE END CONNECTIONS FROM

THE HOUSING BEFORE SOLDERING. THIS

ENSURES THAT THE O-RINGS AND INTER-

NAL PARTS ARE NOT DAMAGED BY HEAT.

Pressure/temperature fittings (p/t plugs) are

available upon request for the ABV valve. Before

finger mounting the p/t plugs in the body

tappings, pls. seal the threads of the p/t plugs

(DO NOT OVER TIGHTEN).

Alternatively to p/t plugs, the valve body can be

ordered with plugs for the body tappings. Each

plug is sealed by a gasket.

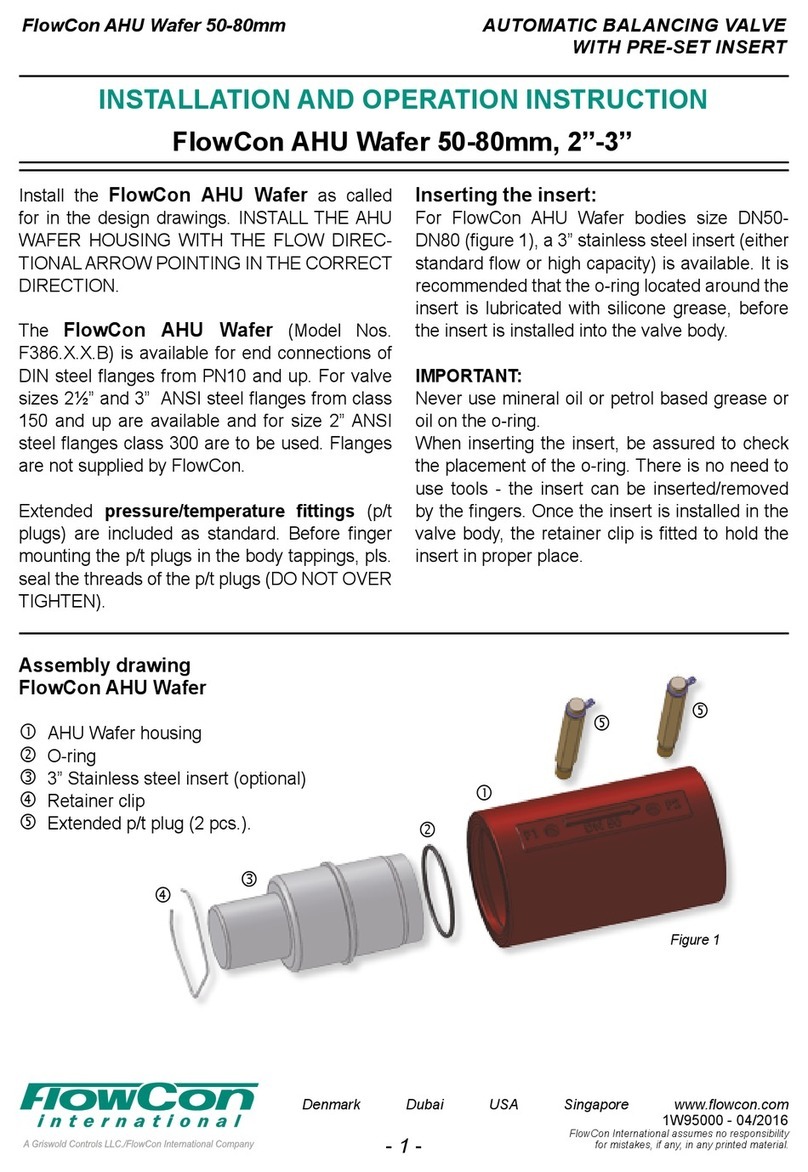

Inserting the cartridge

The factory pre-set stainless steel flow control

cartridge is fitted into the EVS insert from the

bottom and is held in position by the lock ring

screwed onto the EVS insert.

It is recommended that the o-rings located

around the EVS insert, in the bottom and in the

middle, are lubricated with silicone grease, be-

fore the EVS insert is installed into the valve body.

IMPORTANT: Never use mineral oil or petrol

based grease or oil on the o-rings.

NOTE: When applying the flow control car-

tridge, please make sure that the cartridge o-

ring is placed on the inside groove at the top of

the EVS insert BEFORE inserting the cartridge!

Hereafter the cartridge is easily inserted with

a hard push. Once you hear a click sound, it is

properly placed and the cartridge is correctly

fitted. Screw on the lock ring and insert the EVS

insert into the valve body. The cartridge can be

removed by unscrewing the lock ring and pulling

out the cartridge. The cartridge o-ring will also

come out. Insert the new o-ring and afterwards

insert the new cartridge as described above.

1D95011 04/2012

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

Denmark Dubai USA Brasil Singapore www.flowcon.com

FlowCon EVS insert

A: Pin

B: EVS insert

C: Inside groove

D: Cartridge o-ring

E: Stainless steel cartridge

F: Lock ring.

Accuracy ±5%

l/sec l/hr GPM

Type 1 Type 2 Type 4

10-95

kPaD

22-210

kPaD

40-390

kPaD

0.0210 75.7 0.333 F360111

0.0315 114 0.500 F360101

0.0347 125 0.550 F360211

0.0421 151 0.667 F360102

0.0473 170 0.750 F360201 F360411

0.0631 227 1.00 F360103 F360202 F360401

0.0694 250 1.10

0.0841 303 1.33 F360104 F360402

0.0946 341 1.50 F360203

0.105 379 1.67 F360105

0.126 454 2.00 F360106 F360204 F360403

0.147 530 2.33 F360107

0.158 568 2.50 F360205

0.168 606 2.67 F360108 F360404

0.189 681 3.00 F360206

0.210 757 3.33 F360110 F360405

0.221 795 3.50 F360207

0.252 908 4.00 F360112 F360208 F360406

0.294 1060 4.67 F360114 F360407

0.315 1140 5.00 F360116 F360210

0.336 1210 5.33 F360408

0.379 1360 6.00 F360212

0.421 1510 6.67 F360410

0.442 1590 7.00 F360214

0.505 1820 8.00 F360216 F360412

0.589 2120 9.33 F360414

0.631 2270 10.0 F360416

0.757 2730 12.0

0.883 3180 14.0

1.01 3630 16.0

Figure 4

A

B

C

D

E

F

- 3 -

Stainless Steel Cartridges

DN15/20/25, 1/2”-1” (3/4” cartridge)

Denmark Dubai USA Brasil Singapore www.flowcon.com

1D95011 04/2012

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

FlowCon EVS insert

- 4 -

FlowCon EV.0.3, EV.0.4 and EV.0.5

FlowCon EV.0.2

Figure 5

Actuators:

The actuator types FlowCon EV.0.2, EV.0.3,

EV.0.4 and EV.0.5 (i.e. figure 5) are supplied

with a separate green colored adaptor nut. Use

this adaptor nut and screw it finger tight to the

connection thread at top of the EVS insert. Do

not use additional tools. The actuator can now

be fitted to the adaptor nut. A click noise will

indicate that the actuator is fitted into a correct

position.

The visor on the FlowCon EV.0.2 actuator is

used to activate a release mechanism and when

pushed, the actuator can be released and re-

moved from the adaptor nut. By removing the

visor after fitting the actuator, the actuator

becomes tamper proof. Similar for the FlowCon

EV.0.3, EV.0.4 and EV.0.5 actuators, these are

released by pushing the button in the front side

of the actuator and then removing the actuator

from the adaptor nut.

To ensure that the valve is in an open position

during commissioning of the system, all men-

tioned actuators will be delivered in a Normally

Open position and remain in this position until

they are electrically operated first time.

During FIRST TIME POWERING operating

voltage is applied for approximately 6 minutes.

Upside down installation is allowed for all

mentioned actuators along with the standard

horizontal and vertical installation.

1D95011 04/2012

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

Denmark Dubai USA Brasil Singapore www.flowcon.com

FlowCon EVS insert

Blue

EV.0.2 Actuator

Power 24V AC/DC

Ground/common

Red

Input signal 0-10V DC

Black

Blue

Brown

EV.0.3 / EV.0.4 / EV.0.5 Actuator

Power

230V AC

24V AC

120V AC

Ground/common

- 5 -

Wiring diagram:

FlowCon EV.0.2

Calculation of maximum cable length (copper

cable) for 24 V rated voltage

L = K x A / n

A Conductor cross-section in mm²

n Number of actuators

K Constant (269m/mm²)

L Cable length in m

It is recommended the following lines for install-

ing a 24 V system:

Bell wire: Y(R) 0,6/0,8 mm²

Light plastic-sheathed cable: NYM 1,5 mm²

Flat webbed building wire: NYIF 1,5 mm²

FlowCon EV.0.3, EV.0.4 and EV.0.5

A safety isolation transformer according to EN

61558-2-6 must always be used. Transformer

dimensioning results from the making capacity

of the actuators and based on the rule-of-thumb

formula:

P

Transformer = 6W xn

n = number of actuators.

It is recommended the following lines for install-

ing a 120 V / 230 V system:

Light plastic-sheathed cable: NYM 1,5 mm²

Flat webbed building wire: NYIF 1,5 mm²

Denmark Dubai USA Brasil Singapore www.flowcon.com

1D95011 04/2012

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

FlowCon EVS insert

- 6 -

Figure 6

H1

B1

D1

D2

C

A

EE

G

F1

F2

H2

B2

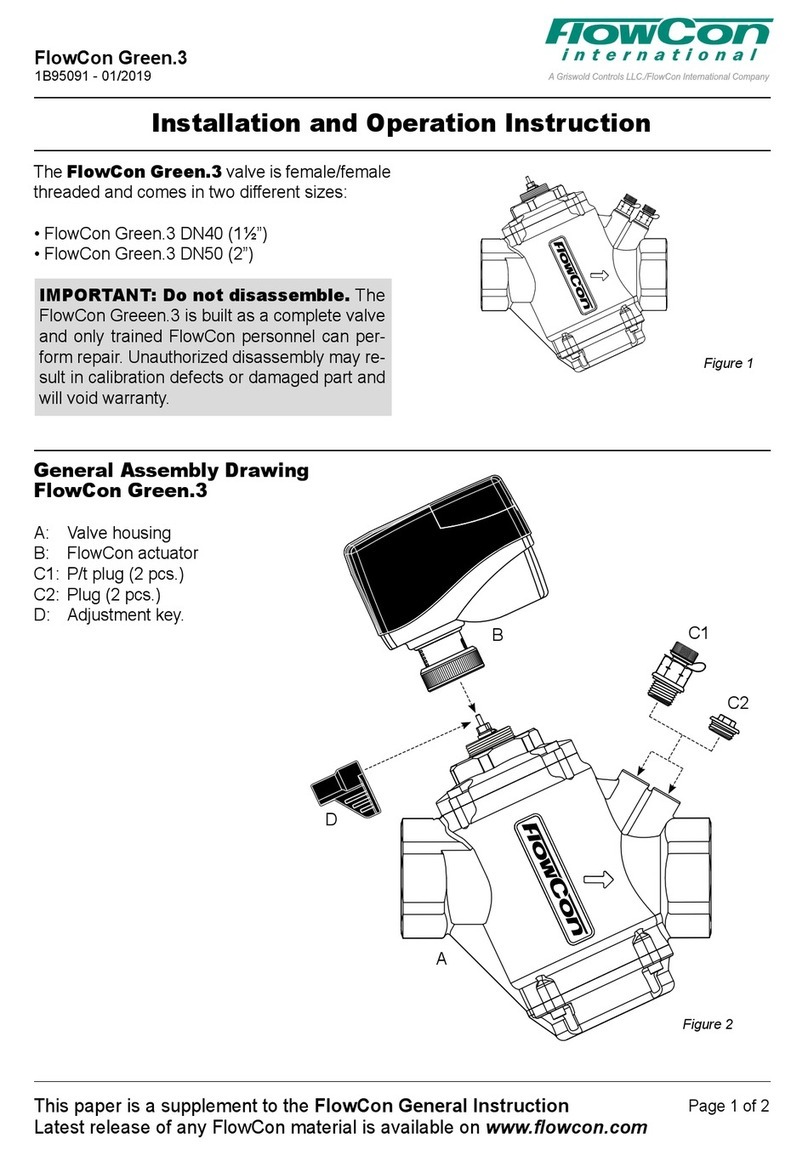

Assembly drawing FlowCon EVS

in ABV1 housing:

A: Valve housing

B1: Stainless steel cartridge

B2: O-ring

C: Adjustment key

D1: P/t plug (2 pcs.)

D2: Plug and gasket (2 of each)

E: Union end connections

F1: Actuator (here EV.0.3 to EV.0.5-type)

F2: Adaptor nut

G: Pushbutton

H1: EVS insert

H2: Lock ring to EVS insert.

1D95011 04/2012

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

Denmark Dubai USA Brasil Singapore www.flowcon.com

FlowCon EVS insert

- 7 -

General.

It is recommended flushing the system before

installing the cartridge in the valve body. Suitable

flushing caps are available. Water must always

be suitable treated, clean and free of debris. It is

recommended that a strainer be installed prior to

the valve body to prevent damage or blockage

due to debris. Ensure that the valve is not in the

fully closed position when filling the system with

water.

Warranty obligation.

Failure to abide by all recommendations as per

this installation and operation instruction will void

warranty.

For latest updates please see www.flowcon.com

Denmark Dubai USA Brasil Singapore www.flowcon.com

1D95011 04/2012

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.

DYNAMIC BALANCED

TEMPERATURE CONTROL VALVE

FlowCon EVS insert

- 8 -

Table of contents

Other FlowCon Control Unit manuals

FlowCon

FlowCon Green.3 Series Owner's manual

FlowCon

FlowCon SM.1.1 Owner's manual

FlowCon

FlowCon SM 50-250mm Owner's manual

FlowCon

FlowCon Green Owner's manual

FlowCon

FlowCon UniQ Owner's manual

FlowCon

FlowCon Green.3 DN40 Owner's manual

FlowCon

FlowCon S-JUST Owner's manual

FlowCon

FlowCon DPCV Owner's manual

FlowCon

FlowCon ABM Owner's manual

FlowCon

FlowCon Green Owner's manual