Installation and Operation Instruction

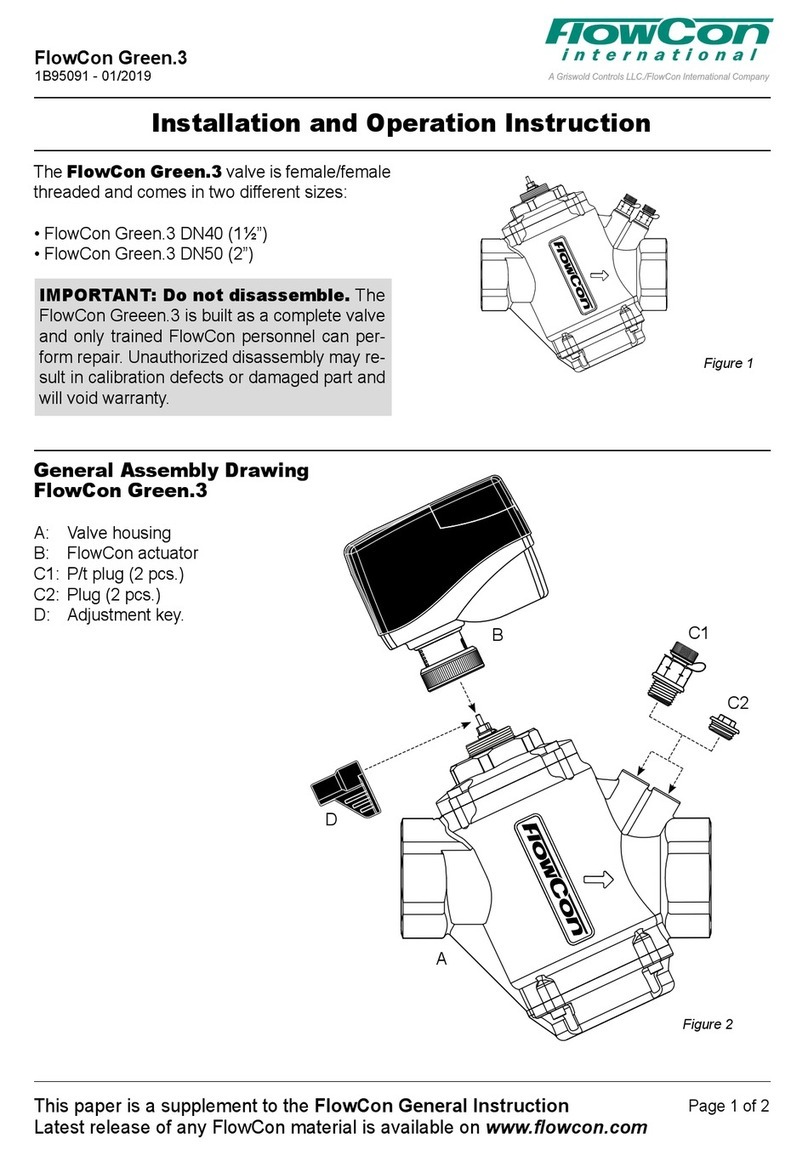

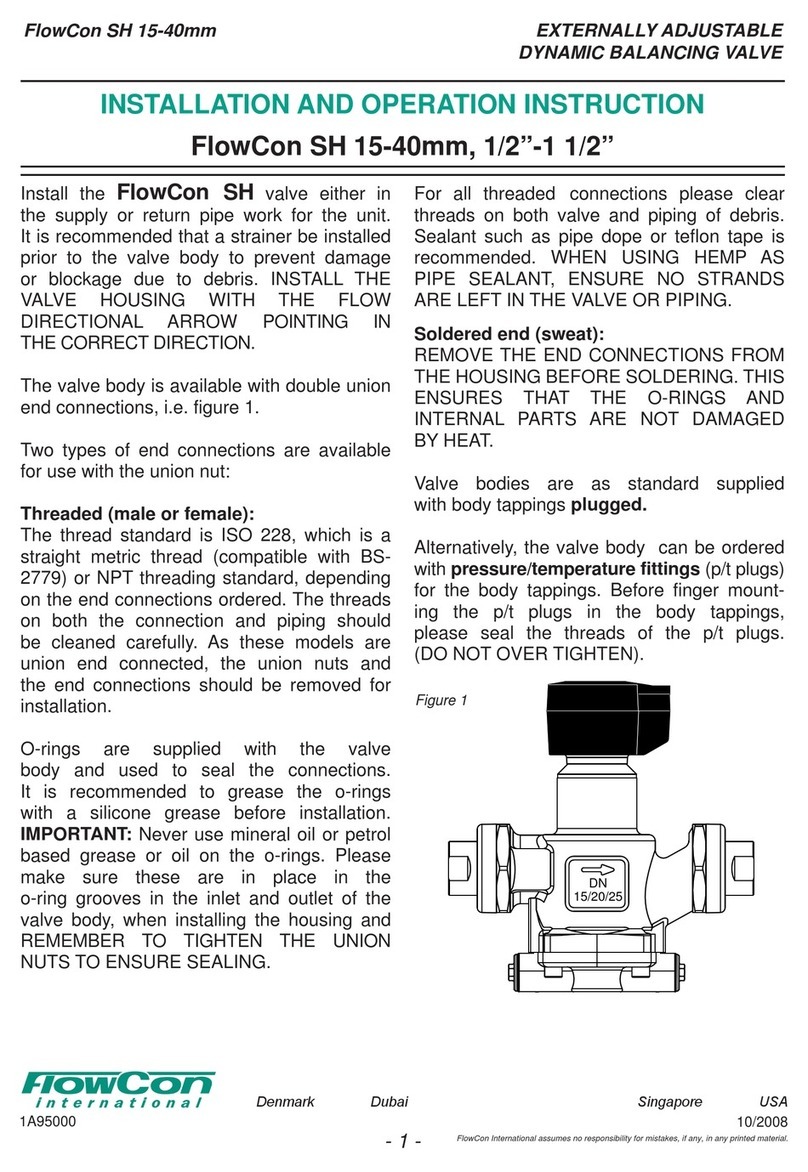

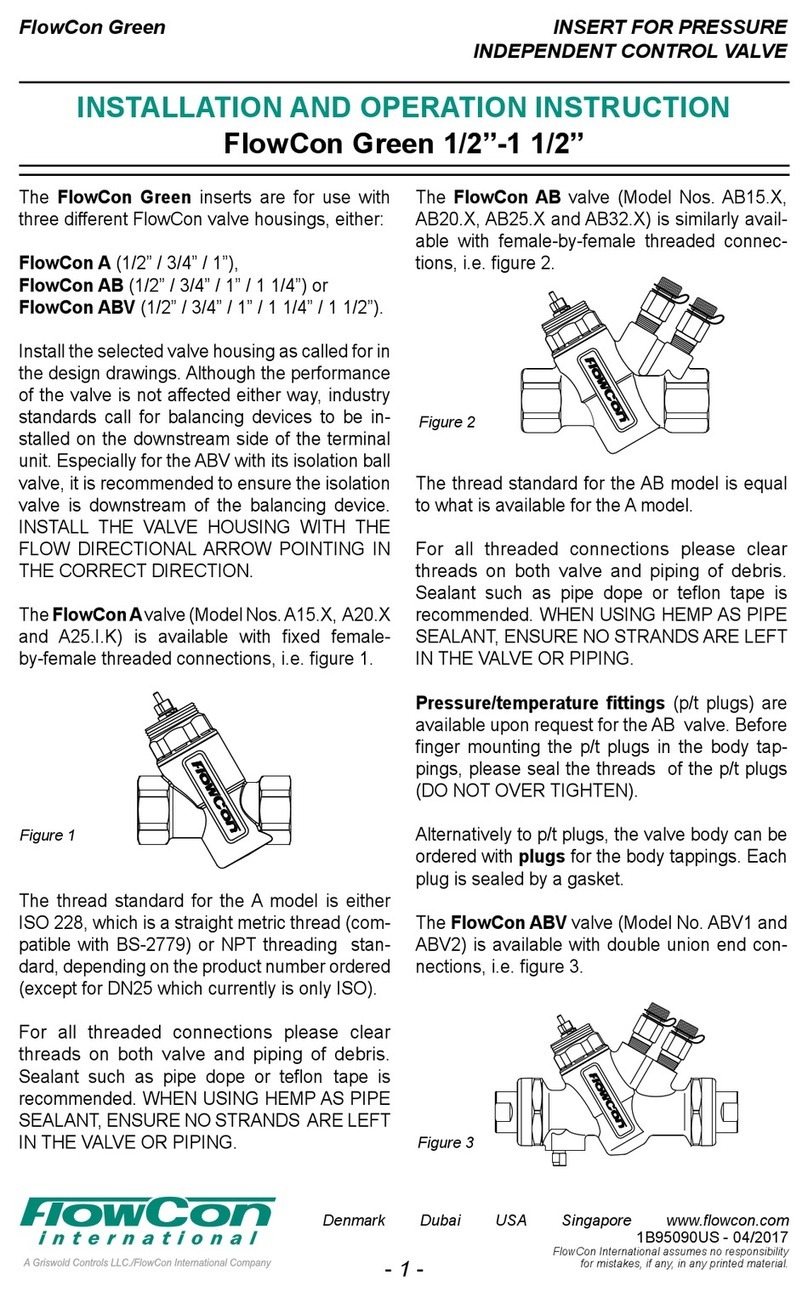

Figure 1

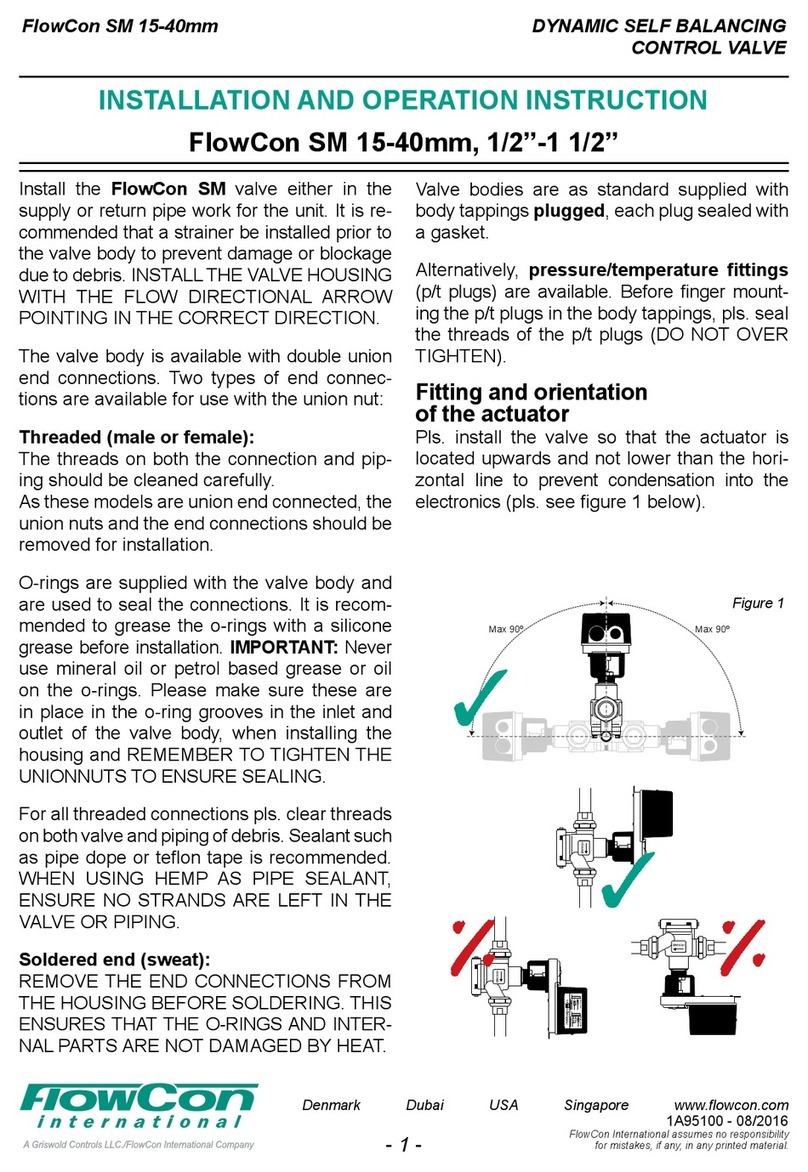

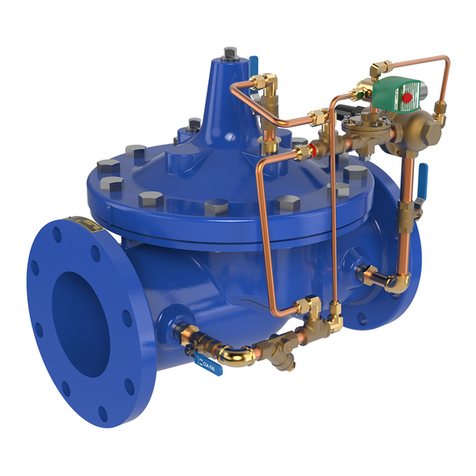

Figure 2

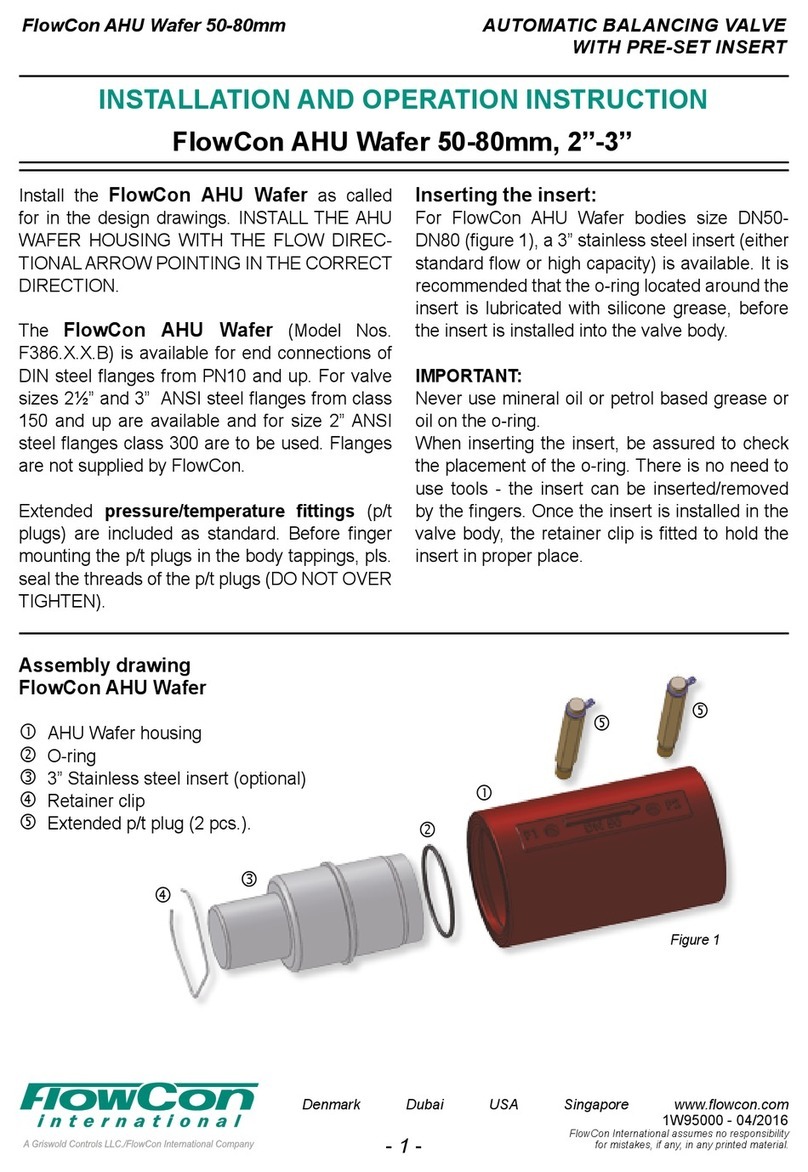

FlowCon PIM™-DP DN65-80 (2 1/2”-3”)

FlowCon PIM™-DP DN100 (4”)

FlowCon PIM™-DP DN125-150 (5”-6”)

The FlowCon PIM™-DP are available in three

different models covering six different sizes:

•FlowCon PIM™-DP DN65-80 (2 1/2”-3”)

•FlowCon PIM™-DP DN100 (4”)

•FlowCon PIM™-DP DN125-150 (5”-6”)

Installation

Prior to installing the FlowCon PIM™-DP (supplied

from factory in fully open position), the system

should be properly flushed.

Capillary tube

Do not damage the capillary tube by compressing

or bending the tube with a bending radius below

20 mm (3/4”). Capillary tube is to be finger

mounted and tightened with 1-3Nm - DO NOT

OVER TIGHTEN.

Air venting

It is important to release all air inside the valve.

Upon doing so open and close the partner valve

fully. It will make the diaphragm to fully extend

and contract and thereby remove all trapped air

inside. PUMP MUST BE OPERATIONAL FOR

THIS PROCEDURE TO BE EFFECTIVE AND

IT MUST BE CARRIED OUT AFTER THE

SYSTEM HAS BEEN VENTED.

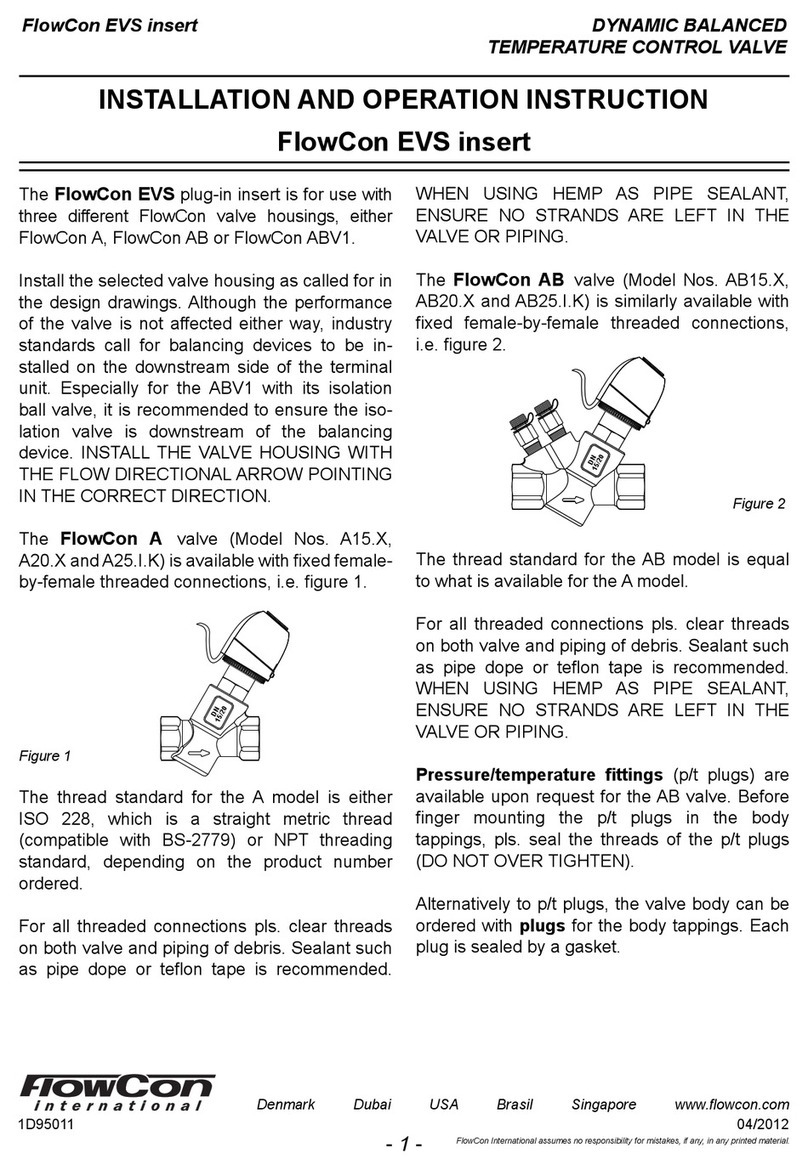

Setting

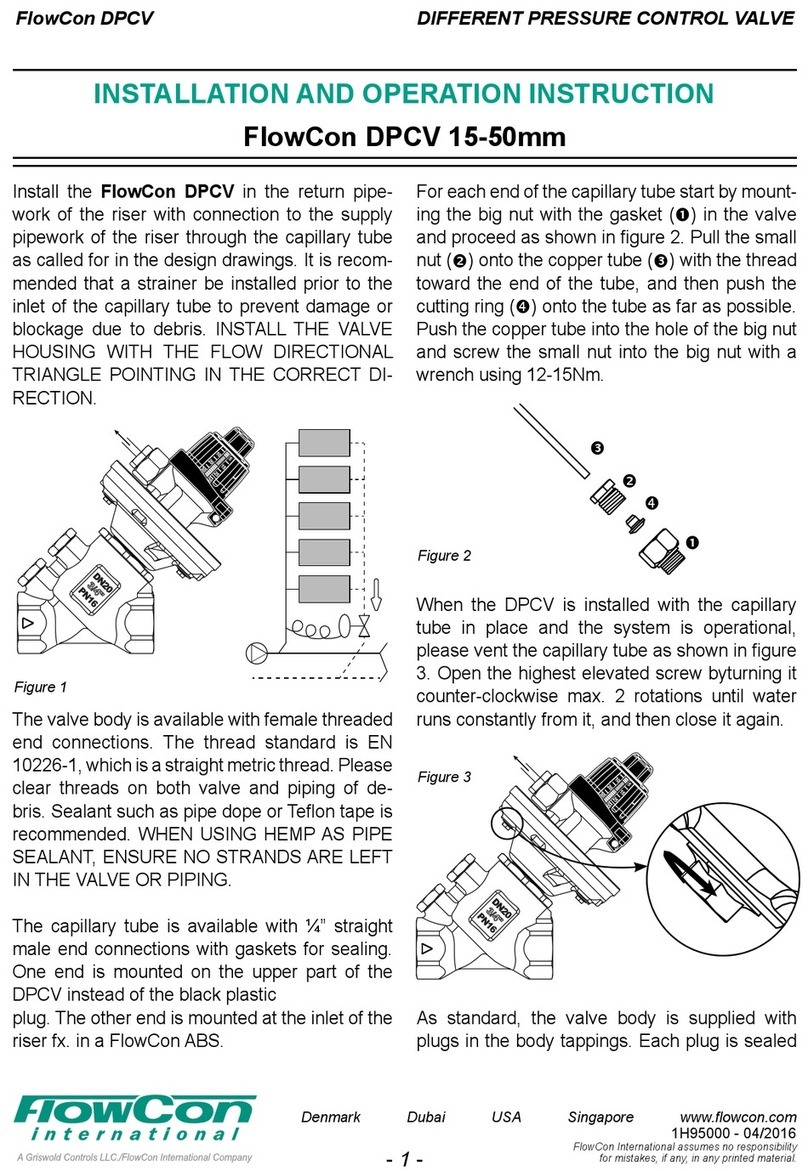

After installation and air venting, the desired

ΔpCircuit is set by adjusting the setting (figure

2) under the cap on top of the valve. Use a 13 mm

(1/2”) Allen key and NOTE: ADJUSTMENT

SHOULD BE DONE SLOWLY, APPROXIMA-

TELY ONE TURN EVERY 10 SEC. Increasing

the ΔpCircuit by turning clockwise and decrease

by turning counter-clockwise. To increase to

maximum ΔpCircuit (170 kPaD / 25 psid) turn the

setting approximately 15 full turns.

FlowCon PIM™-DP 65-150 mm (2 1/2”-6”)

1H95040 - 04/2020

This paper is a supplement to the FlowCon General Instruction

Latest release of any FlowCon material is available on www.owcon.com

Page 1 of 2

FlowCon International assumes no responsibility for mistakes, if any, in any printed material.